How to make a grain mill with your own hands

The smell of freshly baked bread evokes pleasant feelings in every person, especially if it is made from healthy whole grain flour, but it is very rare to treat yourself to such a treat. In stores you can find flour of any grind, but its quality sometimes does not correspond to the high cost.

The surest and most logical solution to this problem would be to acquire your own mill, and if, after reading these words, an image of a huge building and massive millstones appeared in your head, we hasten to console you - today you can make a compact machine that will fit in any kitchen.

In this article we will tell you how to build a homemade grain mill with your own hands.

Hand mill

A do-it-yourself mechanical mill is much lighter than its electric counterpart, and its productivity is quite high. It consists of two parts - a millstone and a frame with a handle.

Millstones for the mill

For a productive mill, it is very important to find good millstones. The subsequent grinding and durability of the crusher depend on the quality of the stones. Usually suitable stones can be found in special workshops, or found on the river bank and processed independently. Processing of future millstones is carried out using a grinder with a diamond disk of at least 23 cm in diameter. A powerful drill is needed to make holes in the center of the stones. The optimal diameter of the finished millstones is 22-24 cm, and the height is 10-12 cm. You can make larger millstones, but smaller ones are not advisable. The greater the weight of the stones, the better the grinding quality of the flour.

A hand mill should consist of two millstones and a base. The upper millstone is called the runner, and the lower one is called the nizhnyak. The runner is usually made lighter, since after each cycle of operation it is raised to remove the remaining flour. A hole must be drilled in the runner to reach the center of the grain. It is better to drill with a special drill with a diamond coating, and during the process, cool the drilling site with cold water.

The next step in making a home grain mill is cutting the notches on the millstones. They should have the shape of grooves with a triangular cross-section, about 10 mm wide, at least 2 mm deep and at least 4 mm in the lower part and runner, respectively. In the center of the runner, four large grooves are made, eight millimeters deep and fifteen millimeters wide. It will be easier to understand the location of the notches and holes if you find a finished project or drawings of a burr hand mill.

Required materials and parts

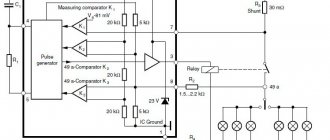

Making a mill with your own hands is not difficult if you have all the materials and tools. Before making a mill, it is recommended to study the diagrams and drawings well. You can find them on the Internet on any thematic forum. The drawings will help you understand the principle of fastening parts, electrical components, cutting elements, and avoid many errors in assembly.

The mill structure includes:

- Motor (a motor from an old washing machine will do),

- Motor support,

- Stanin,

- Receiving bunker,

- Rotor and stator,

- Loading hopper.

Materials you also need to have:

- 20 bolts m6,

- Steel corners,

- Sheet steel with a thickness of at least 6 mm,

- Screeds,

- coupling,

- Sheet steel for the manufacture of the lid, at least 3 mm thick,

- 10 m6 screws,

- A pair of bearings, number 203.

Mill from a washing machine

An interesting flour grinder made from a washing machine. This is a simple and powerful device that works on the principle of a coffee grinder. There are no detailed instructions for making such a mill, since each washing machine has individual parameters. The main thing is to understand the meaning of the device: it is not millstones that are used, but the grain is ground by knives mounted on an axis that rotates at high speed. The device uses 2 electric motors installed oppositely, the knives rotate opposite to each other. The speed of work and the quality of the final product will depend on the sharpness of their sharpening. To make a knife, a steel sheet measuring 200×15 mm with a thickness of 1.5 mm is used. Sharpening is done as the knife rotates; you can experiment with it. After sharpening is completed, a hole is drilled in the place where the knife is attached to the axle. The knife is put on the axle and secured with 2 nuts and washers.

It is necessary to make a container from sheet iron or other material from which the grain will flow into the grinding tank. The container and tank are separated by a manually opened valve.

At the point where the finished flour exits the grain mill, a sieve and a container for collecting flour are installed. To prevent losses when the product comes out, it is recommended to use a sleeve made of rubber or plastic (it can also be made of metal).

To prevent mill failure, it is recommended to clean the millstones every week.

A manual kitchen mill is a modern household design that allows you to easily grind any variety of cereals and grains. To develop a kitchen mill, professional craftsmen use innovative technologies, making work in the kitchen much easier and more enjoyable. Mills are considered the newest devices for working in the kitchen; they are of great value for modern housewives and have already become quite popular in the household appliances market.

Grinding mill

Electric homemade mill

An electric homemade mill can produce flour of both coarse, medium and fine grinding. The fraction size is set in the settings. The advantages of a home grain mill are the ability to process a wide variety of raw materials: rice, buckwheat, wheat, soybeans, rye, corn, oats or millet.

The power of the simplest home device will allow you to grind a bucket of corn to a flour-like state in five minutes, and a similar volume of wheat in just two minutes.

DIY mill: making a homemade mini grain mill for flour with your own hands

A household mini grain mill is a necessary device for producing flour. Making a mill with your own hands will require skills in working with drilling and turning devices. Using this device you can obtain coarse or fine flour and use it for home baking. Read the detailed instructions on how to make a mill with your own hands and try to apply your knowledge in practice.

Characteristics of a homemade mini grain mill

This device was created in Udmurtia by O. Zaitsev and A. Yagovkin and was called “Baby”. Using this handmade mill, you can grind grain, make feed for livestock and poultry on your farm, grind flour from corn, oats, wheat and other grains. A homemade mill is small in size, but at the same time has high productivity: in just 5-6 minutes you can grind a bucket of corn, and wheat and oats - 2 times faster.

Making a stator

Making a stator is a little more difficult because it requires precision. The work is being done in stages. First of all, the workpiece is turned on a lathe, and then a small technological allowance is left. For this purpose, an opening of up to 70 mm is drilled in the center. A circle with a diameter of 105 mm is marked on the workpiece, and the central points of future openings are marked. Subsequently, they will become the working plane for the stator. The markings are applied strictly according to the drawing.

The contours of the holes are marked at the top and bottom, and then blind “windows” are drilled to a depth of approximately 26 mm. On the machine, the allowance left earlier is removed, and the space for the working chamber (105 mm) is bored. The resulting workpiece is turned over and a landing recess is made for inserting bearings. You will also need to make a groove for the sealing parts. The mill can function without this component.

When the stator is ready, you can begin to create threaded holes for the bearing caps, stator, pipe and loading box. The stator, like the rotor, is subjected to thermal treatment using a similar technology.

To ensure smooth operation of the unit, the stator coordinates should be set correctly. In this case, bolts are used. When operating, the rotor should move slowly and easily, without jerking or stopping. Only after checking the functionality of all parts can you begin a trial run of the device. For this purpose, the mill (flour grinding apparatus) is fixed on a stool or table so that it does not fall during vibration.

Manufacturing process

The design of the grain grinder is very simple. Manufacturing also does not require much effort if you buy all the necessary parts. Some craftsmen prefer to make at home not only the device itself, but also the component parts.

In order to assemble a completely home grain mill, you need experience working with a lathe and drilling equipment.

Rotor assembly

The most important element of an electric mill is the rotor. The process of its manufacture is quite labor-intensive, and before starting work you need to remember several important points:

- The shaft of the rotor being manufactured must be of variable cross-section,

- The shaft is made of round steel,

- The work process is divided into several stages.

The first stage includes the preparation of metal blanks. The workpiece must have several identical holes with a radius of 5 cm. The second stage is erasing the outer layer of the workpiece so that the size of the groove decreases to 10.5 cm. With this size, the working teeth of the future rotor open.

Next, the rotor is sent for hardening. Hardening occurs in two stages. The first is in an oven at a temperature of eight hundred degrees, the second is in an oil container. It is not recommended to cool the workpiece with cold water: the metal will become brittle. The next step is vacation: the rotor is heated to four hundred degrees and left at room temperature until it cools completely.

The rotor is attached to the shaft with two bearings, which increases the strength of the mill. A small spacer ring is attached to the shaft between the bearings. They allow the bearings to move along the shaft to create more tension.

Stator assembly

It is very difficult to make a stator at home, so it is recommended to buy a ready-made element. Several threaded holes are made in the stator for the bearing caps and the stator itself, as well as for the branch pipe and the loading box. For greater accuracy of the mill operation, you need to correctly set the coordinates on the stator. This is done using several bolts.

Bed assembly

An important part of the mill is the frame. The base is made of thick steel sheet. The stator is attached to the frame with screws, which at the same time will hold the pipe. If a removable pipe is planned, then it must be attached to the opening in the base corresponding to the diameter of the part. The removable pipe is held in place only by friction.

A pipe is made from a section of pipe with a diameter of about 3 cm. The pipe can have either a round or square cross-section. Next, a loading box is assembled from a sheet of iron. The iron sheet is bent into the desired shape, and the seams are soldered. The finished box is installed on the stator and secured with bolts.