A friend and I once went shopping, nothing foreshadowed trouble... We were looking for either a seal for his viburnum, or some other small thing. I suddenly remembered how I recently watched the guys install pneumatic horns, and they sound decent! I wanted the same one for myself, because the standard signal is quiet and inconspicuous anyway. I decided to ask, one elderly man brought me to his stall and showed me a huge selection of beeps. Of these, I liked this one the most.

I couldn’t find any clear instructions, many of the manuals just contain a couple of photos and diagrams, so I decided to write in detail how I did it myself. I hope this post will be useful to someone who doesn’t know much about it and wants to stage it.

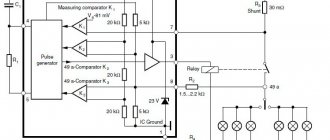

The kit included the pipe itself, a hose and a small compressor. No papers, nothing went through. There was no doubt that it was made in China, but the price was reasonable, and so was the quality (nothing fell apart during assembly and works fine). Having looked at the drive, and surfing the Internet anyway, I came across 2 types of connection - through a relay and from a standard bell. At first I didn’t want to do it through a relay - it was too complicated, but I decided to do it anyway. I bought a holder with a 30A fuse, found 2 meters of copper wire, gathered my courage and started assembling it. I found several relay diagrams, here are some of them:

One of the horn options is a pneumatic signal on a car, which has both its pros and cons. Previously very common, it is much less common on modern machines. However, many car enthusiasts still want to install such a device for themselves. You will learn how to do this and much more about pneumatic signals in the article.

Characteristics of the pneumatic signal

Before moving on to how to make this device with your own hands, you need to understand what a pneumatic signal is. And also, what is its operating principle, what are its functions, design. And of course, the pros and cons of having such a horn on board your car.

Working principle and functions

The operating principle of the device is quite simple. Pressurized air from the compressor moves through the tube. This causes it to vibrate and make sounds of a certain frequency. Due to the certain complexity of the design, the cost of such a device is quite high . If you decide to assemble and install it yourself, you will save some money, but the costs will still be significant.

There are signals with different pipe shapes, as well as signal power, which can reach up to 125 dB (video author - Varan Varan).

Design

This device consists of the compressor itself and a tube. The number of the latter can reach up to three. The increased number of horns allows you to achieve a richer and more powerful sound. However, even with one tube, the pneumatic type signal makes a powerful impression. The design also includes a solenoid valve, a check valve, a pressure switch and a receiver.

Lada Priora Sedan › Logbook › Installation of air horn (very detailed + many photos)

A friend and I once went shopping, nothing foreshadowed trouble... We were looking for either a seal for his viburnum, or some other small thing. I suddenly remembered how I recently watched the guys install pneumatic horns, and they sound decent! I wanted the same one for myself, because the standard signal is quiet and inconspicuous anyway. I decided to ask, one elderly man brought me to his stall and showed me a huge selection of beeps. Of these, I liked this one the most.

I couldn’t find any clear instructions, many of the manuals just contain a couple of photos and diagrams, so I decided to write in detail how I did it myself. I hope this post will be useful to someone who doesn’t know much about it and wants to stage it.

And here, by the way, is a new buzzer.

At first I wanted to connect the contacts using construction adapters, I even sharpened and tried them on.

On the other side of the fuse holder I soldered a homemade power terminal made from shelf fasteners using a grinder and a drill =)

Then he wrapped the whole thing with a bunch of electrical tape and put it in a plastic corrugation.

And proceeded to connect the compressor.

Next to the battery I found a place for the relay

Before attaching the compressor, I put cellophane on it from under the pipe, it was already in the morning, because I had been fiddling around for half the night, so it was only in the morning that I realized that like a compressor it would suck air through the cellophane, then I fixed everything and here is the result:

Here is a video of the sound, although it was not possible to convey all the sound, in real life the buzz is louder.

I soldered everything with a regular soldering iron, used solder with rosin and soldering flux (a very good thing!).

In total, all the fun turned out to be 730 rubles. In my opinion they are worth it!

I hope the article turned out to be quite detailed and informative, it will help someone!)

Source

Similar master classes

Do-it-yourself automatic exhaust The most reliable relay for turn signals Has the battery died? A screwdriver will help! The simplest circuit for automatic water level control Do-it-yourself solid-state relay Washing machine malfunction

Particularly interesting

A 100% quick way to obtain seedlings with roots from Effective rooting of a rose using a plastic bottle 3 fresh ideas for the master and do-it-yourselfer 4 signs of how to identify a sweet watermelon 5 fresh ideas for your workshop A way to learn welding without consuming electrodes Comments (2)

Connecting an audio signal via a relay.

I have a 5-pin relay. (Contact 87A - not used)

Automotive relay 12V. Permissible current 30/40A. Relay 5-pin, 12V, 30-40A with mounting plate. Relay is an electrical device (switch) designed to close and open various sections of electrical circuits for given changes in electrical or non-electrical input quantities.

The electromagnetic relay consists of:

Electromagnet (represents an electric wire wound on a coil with a core of magnetic material). Anchors (a plate made of magnetic material that controls contacts through a pusher). Switches (can be making, breaking, switching).

Making a pneumatic signal with your own hands

You will definitely need to purchase the following items to create a pneumatic signal with your own hands:

- Compressor. Most car enthusiasts in Russia and neighboring countries use products under the Berkut brand. It has several models, the power of the R15 will be enough for you.

- Solenoid valve . With its help, air is discharged from the receiver into the pipes. It can come with them. For convenience, we recommend purchasing these. However, you can buy the valve separately - then pay attention to the voltage and diameter.

- Check valve. It is installed at the outlet of the compressor and should not allow air to flow back from the receiver.

- Pressure switch . Used for this. So that the compressor turns off when the required pressure is reached and turns on again when it drops.

- Receiver. A 4-liter model with a pressure of 12.5 bar is suitable. It should have two holes - one for connecting the compressor and blower, the other for draining condensate.

- Pipes.

Also useful are pneumatic connectors (according to the thread size and the size of the holes of the receiver, compressor and pipe) and fittings.

Non-standard solutions

In some cases, drivers prefer to install a locomotive whistle on their car. It has very significant power and is able to dramatically attract the attention of others. However, its installation requires quite a lot of space in the engine compartment.

The locomotive whistle is the most powerful

The installation of locomotive or steamship signals is not prohibited, but the need for such a whistle is debatable. Its use in city mode may result in a fine. In addition, to use such signals, the car must have good sound insulation.

A locomotive whistle on a car can scare anyone. The video below shows jokes with a locomotive whistle installed on a small runabout.

Instructions for installing an alarm device

Installing this system on your car is carried out in several basic steps.

- First you need to find a place for the compressor. This may not be so simple. Most cars have a space under the bumper where you can place it.

- Remove the compressor from the frame, it is not needed and interferes with installation.

- The pipes can be installed on the radiator cooling system. They and other elements should not interfere with the heat transfer of all elements of the car.

- Now lay the pipes, fittings and valves. To connect the threads of pneumatic tubes, you can use FUM tape.

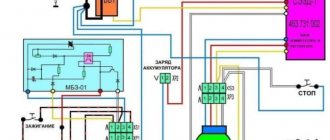

- Take the wires from the standard power button into the interior.

- Now you need to connect the system to the battery. It is best to do this through an additional relay, so that power is supplied only after the car is ignited.

- Lay air lines up to the air signal.

- You can make a connection through a relay, which will close the contacts of the system toggle switch and control it. It will also be activated from the standard button on the steering wheel.

- Before assembling the car body, check how everything works. Place the air intake fittings higher in the engine compartment. Check how the pressure is maintained.

Removing the Frame from the Compressor

Remember that you can always remove the air hose. It is long enough that you can use it to inflate the tires of any wheel. This is an additional advantage of installing such a signal.

Price issue

Universal car horn WEISHINE (135 dB)

Price: from 431.21 rub. (check price and discount) Seller reliability: excellent!

Delivery within Russia: free!

Customer reviews:

Review No. 1: Delivery month to Arch.region. no tracking. The horn arrived simply in a bag and in its original packaging, surprisingly intact. I couldn't get an answer to my question from the seller. The sound is not super loud, but louder than what is installed on Kia from the factory. The tone seems rough (high). I checked the houses, it works, no one was scared. I will install two of these. Thanks to the seller.

The process of installing a pneumatic signal on a car with your own hands

The pneumatic signal will be installed on a KIA Sorento 3.5. In fact, a set of ready-made solutions from . This way a station capable of delivering up to 7.5 a will be used (BERKUT) SA-03)

Let’s say right away that the use of a more productive station and a station with increased pressure is not justified; for a pneumatic signal, a pressure of 5 atmospheres and an air supply of 2.85 liters, which corresponds to the volume of the station’s receiver, is quite enough. In addition, the BERKUT TG59 installation kit is used, which is actually a set of valves and adapters. An audible pneumatic signal from Cicada was also used during installation. One of the main problems is choosing a place to install the pneumatic compressor, because free space on the car is extremely limited; to understand this, just look into the engine compartment of most modern cars. As a result, the optimal installation option for the compressor turned out to be the space under the bumper.

But first, in order to compactly install the compressor, it must be removed from the frame. In this case, the compressor and receiver can be installed locally.

So, after disassembling the compressor for its further installation, we select only all the essentials that are necessary for the functional operation of our pneumatic signal. The frame on which everything was installed earlier will not be useful to us for installation.

We try on the components of the pneumatic signal. Everything will be pre-installed on the power elements of the “TV”. Here it is necessary to pay attention to the fact that the mounted elements do not interfere with the heat transfer of the radiators of the air conditioner and cooling system.

The air pneumatic signal “pipes” were installed “against the background” of the cooling radiator.

Next, service, control and regulatory equipment is installed. This is how pipelines are laid, fittings and valves are installed. When installing pneumatic pipelines, it is necessary to use FUM tape to connect the threads. This is despite the fact that the threads are, in most cases, conical, and therefore self-sealing. Control wires are routed from the standard system activation button, which will go into the cabin.

What types of horns are there?

Today, every car owner can choose a signal for his vehicle to suit his taste. But before you go to the store, it is important to understand what is their difference from each other, what advantages and disadvantages are inherent in a particular type.

Car horns are divided into three main types:

- Electromagnetic

- Pneumatic

- Electronic.

The types of sound signals differ in both structure and sound. The main characteristic of a car horn is its noise level.

Advantages and disadvantages of a pneumatic signal

We have already listed the advantages of pneumatic signals, but it is not difficult for us to repeat them. A very loud sound level will allow you to become “noticeable” among other motorists on the road, which can prevent an accident. In addition to the pneumatic signal, you also get a standard compressor on the body of your car, which is also not bad at all. The disadvantages of a pneumatic signal include the high cost of the equipment, as well as the complexity of its connection. In addition, working with pneumatics requires high tightness of the connections, otherwise the compressor will be turned on from time to time to pump into the receiver. Such inclusions can significantly drain your battery, especially during long-term parking. In this case, it is better to connect power to the system through a relay that turns on when power appears in the ignition system circuit. In any case, the tightness of such a system will be lost much earlier than the functionality of the standard signal, which will lead to the need to replace the sealing elements and valves in it. That is, we can say about more expensive maintenance. In any case, weighing all the pros and cons and making a choice based on what is a priority for you is only your prerogative.

Tuning VAZ 2109

- signals from the Volga with a “mass” on the body

- relay type 90.3747 with mounting flange

- relay socket

- female terminals wide

- heat-shrinkable tube (HERE)

- stranded wire with a cross section of 2.5 mm. sq.

- blade fuse block

- 20 A fuse

- metal corner

Spare parts for modification

First of all, remove the ground terminal from the battery.

To access the standard signal of the VAZ 2109, remove the radiator grille, unscrew the standard signal along with its fastening bar. The signal ground wire is attached nearby, we dismantle it too.

At home, we will first prepare the mounting of signals from the Volga based on a steel angle purchased at any building materials store. We will attach the signals to the standard place where the original signal is attached. We mark the corner at the installation location, saw it off, and drill holes for attaching signals from the Volga. It is also advisable to paint the corner to protect it from corrosion. Next, we attach the signals to the corner. The signal fastening bolt is also a “ground”, so it is necessary to ensure its electrical contact with the angle, for example, by securing the Volgov signals through a castle washer.

We fasten the corner with the signals to the bolt securing the standard Samara signal through a castle washer to ensure contact of the corner with the ground. It is possible that the bolts securing the Volgov signals on the corner will touch the radiator; in this case, we put washers, thereby moving the corner with the signals away from the radiator. Do not forget about the need to preserve the corner with the car body (“ground”). That's it, the mechanical part is over, let's move on to the electrical part.

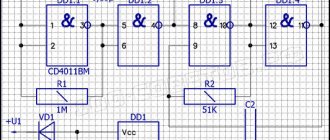

Signals from the Volga to the VAZ 2109 are connected according to the following scheme:

Electrical diagram for connecting Volgov signals to Lada Samara

We crimp the ends of the wires with appropriate terminals. We hide all connections in a heat-shrinkable tube.

The relay can be mounted on the back of the radiator frame, next to the headlight.