Electricity is not always supplied uninterruptedly, for example, due to the remote location of power lines from residential buildings. And when the power goes out every now and then, have you probably thought about buying a generator? Of course, a purchased device is not a cheap solution, and the costs are not always justified. A more affordable option is to make a generator yourself. This solution does not require large investments in assembly; it can convert energy not only using expensive gasoline or a diesel engine, but also more affordable ones - gas, steam, etc.

Therefore, it solves the problem of power outages and saves a certain amount in the budget. But how to make a really high-quality generator, what other advantages do homemade products have over purchased devices? We will help you understand all the nuances - in this article we will provide diagrams for assembling an electric generator, the principle of its operation, and the advantages of using a homemade one. We will also consider step-by-step instructions for making a generator at home.

What is an asynchronous motor

An induction motor (IM) is an electrical machine used to convert electrical energy into mechanical energy. This engine got its name due to the fact that the rotational speeds of the moving part of the engine and the magnetic field (MF) do not coincide.

- The basis of the IM is the stator and rotor. The stator is a cylinder made of electrical steel sheets.

- Its core contains special windings that must be shifted 120 degrees from each other.

- A rotor is a rotating part of an electrical machine driven by a drive or drive shaft.

The rotor is made of steel sheets. It can be of two types, phase or short-circuited, and is made in the form of a drum, disk or wheel

The operating principle of the IM is that when voltage is applied from an external source to the stationary stator windings, a mutual induction emf is induced in the rotating part of the motor and induces eddy currents. Due to eddy currents, its own EMF is generated, which forms the rotor MF.

Gasoline modification

There are two designs of a self-made gasoline generator based on an engine from a trimmer and a generator from a car.

To assemble the first generator you will need:

- gasoline engine from a trimmer, preferably 4-stroke;

- working car generator;

- 12 V battery, not necessarily powerful, it will only be used for starting; Without it, the generator will not be able to generate electricity, since the collector will need to be supplied with an initial voltage for the first excitation.

The direct feed device is simple and straightforward. The only difficult stage is preparing the shaft for the drill chuck.

- First, the shaft is cut and sharpened on a machine, and then threaded to fit the chuck.

- Then the cartridge is screwed into which the shaft of the electric generator is clamped.

- Then everything is attached to a wooden stand.

- Now you need to start the gasoline engine and connect the generator to the battery. A voltmeter with a light bulb will check its operation.

The second method of assembling the generator is somewhat similar to the first, only a belt is used for the rotation process. A pulley is attached to the trimmer shaft, and everything is connected with a belt. Next, everything is attached to a wooden base. The trimmer is started and the operation of the device is checked.

As for the advantages of gasoline devices, there are many of them:

- The scope of use of the device is practically unlimited. It is used to supply power to a country house, summer cottage, or during emergency power outages in hospitals, pharmacies and retail outlets.

- The gasoline device is small in size and weight. Its small size ensures mobility: it is convenient to take with you and transport in the trunk.

- Low noise levels distinguish gasoline devices from diesel or gas ones.

- Gasoline generators are economical in terms of fuel consumption; it can be purchased at any gas station.

The disadvantages of this type of generators include:

- The main disadvantage is the high price. Gas and diesel are cheaper. Therefore, frequent use of such a device is not financially profitable.

- It has a low duration of continuous operation, which does not exceed 8 hours. But this time is enough to supply power or carry out work on the site.

Types of asynchronous motors

Induction motors can vary in the number of phases used.

There are single-phase, two-phase and three-phase electric motors.

- Single-phase electric motors have one operating winding and use single-phase current. Such an engine can operate from a standard network and is the most common in its category. The disadvantage of a single-phase motor is the need for an additional winding, which provides additional rotation to start the rotor moving.

- A two-phase asynchronous motor is a little more complicated than a single-phase one; it has a phase-shifting capacitor and two windings that are opposite each other. Two-phase devices operate on alternating current.

- A three-phase IM has three working windings shifted relative to each other by 120 degrees. Stable operation in such an engine is achieved due to the MP being shifted in space. The main advantage of such a motor is its resistance to overloads, but three-phase motors have a complex system for adjusting the shaft rotation speed.

Also, asynchronous motors may differ in the type of rotor installed in them. More common in industry are induction motors with a squirrel-cage rotor (induction motor with a squirrel-cage rotor); among the advantages of such an engine are the following:

- Cheapness;

- Strength;

- High performance;

- Easy to maintain.

Asynchronous motors with a phase-type rotor are less popular, due to a number of disadvantages:

- Need for regular maintenance;

- High copper consumption;

- Complexity of design.

How to choose solar panels?

At first glance, all solar panels are the same: the cells of solar cells are interconnected by busbars, and on the back side there are two wires: plus and minus. But there are a lot of nuances in this matter. Solar panels come from different elements: amorphous, polycrystalline, monocrystalline. I will not advocate for one type of element or another. Let me just say that I myself prefer monocrystalline solar panels. But that's not all. Each solar battery is a four-layer cake: glass, transparent EVA film, solar cell, sealing film. And here every stage is extremely important. Not just any glass is suitable, but with a special texture, which reduces the reflection of light and refracts light incident at an angle so that the elements are illuminated as much as possible, because the amount of energy generated depends on the amount of light. The transparency of the EVA film determines how much energy reaches the element and how much energy the panel generates. If the film turns out to be defective and becomes cloudy over time, then production will drop noticeably.

Next come the elements themselves, and they are distributed by type, depending on quality: Grade A, B, C, D and so on. Of course, it is better to have quality A elements and good soldering, because with poor contact, the element will heat up and fail faster. Well, the finishing film should also be of high quality and provide good sealing. If the panels become depressurized, moisture will quickly enter the elements, corrosion will begin, and the panel will also fail.

How to choose the right solar panel? The main manufacturer for our country is China, although there are also Russian manufacturers on the market. There are a lot of OEM factories that will paste any ordered nameplate and send the panels to the customer. And there are factories that provide a full production cycle and are able to control product quality at all stages of production. How can you find out about such factories and brands? There are a couple of reputable laboratories that conduct independent tests of solar panels and openly publish the results of these tests. Before purchasing, you can enter the name and model of the solar panel and find out how well the solar panel matches the stated characteristics. The first laboratory is the California Energy Commission, and the second European laboratory is TUV. If the panel manufacturer is not on these lists, then you should think about quality. This doesn't mean the panel is bad. It’s just that the brand may be OEM, and the manufacturing plant also produces other panels. In any case, the presence in the lists of these laboratories already indicates that you are not buying solar panels from a fly-by-night manufacturer.

What is an asynchronous generator

An asynchronous generator (AG) is an asynchronous machine operating in generator mode.

The design of an asynchronous generator is very similar to an asynchronous motor, but energy conversion occurs in the opposite direction. AG converts mechanical energy (this can be wind, hydraulic, or others) into electrical energy.

The operating principle of asynchronous generators is that magnetic lines of force formed as a result of rotor rotation cross the stator windings. When a load is connected, the EMF generated in the coils leads to the appearance of current in the circuit. Below are photos of asynchronous generators:

The simplest gas generator

As an example, let’s look at a simple homemade design based on a chainsaw and an electric motor from an old washing machine:

- We attach the electric motor from the washing machine to the chainsaw bar using a specially made stable bracket.

- We put pulleys on the drive shafts of both engines and connect them using a belt drive.

- The button for adjusting the speed of the chainsaw engine, located on the handle, is equipped with an additional device for adjusting the pressing force. A simple bolt secured with a clamp will do the job just fine. To increase the speed, it will be enough to tighten it, and to decrease it, loosen it.

- We connect two capacitors in parallel to the external starting winding of the electric motor, designed for a power of 400-450 Volts.

The video shows a generator with a washing machine engine

This installation, the simplest in design, is capable of delivering a current of 220 V 180 A, which is enough to power a drill, screwdriver, and lighting fixtures.

Almost any craftsman can make such a basic device. Of course, except for cases when a person does not see the difference between an engine and a carburetor, or the words bracket and container sound the same to him. It is completely unacceptable to manufacture electrical appliances for a person who does not know the differences between the concepts of power (watt), current (ampere) and circuit voltage (volt). More complex designs require fundamental knowledge and skills that will help to correctly calculate engine power, ensure safe use of the finished design, and correctly configure all parameters.

On the Internet on forums, craftsmen discuss various homemade designs. For those wishing to join the ranks of the “Samodelkins”, participation in the discussions will bring a lot of benefits - you can get a lot of useful advice on building a new one or repairing an old one. Special videos will help you visually see the manufacturing process. Which muffler to choose, electric starter, is it possible to have an autostart function - all your questions can be answered. Would you like to go further and install a wind generator on your site to save energy? What current is needed at the output - 12 or 16 A? There are enough instructions on any topic, study and apply the best of them in practice.

Those who decide to make a gas generator with their own hands need to correctly assess their capabilities. Unsuccessful attempts can cause damage to household appliances or even become a threat to life.

The video shows another DIY generator, let's take a look

Working with electrical devices places increased safety requirements and does not forgive negligence. Be very careful and careful!

Advantages and disadvantages of asynchronous generators

Among all the advantages of an asynchronous generator, it is worth highlighting:

- Ease of maintenance;

- Low cost;

- Low sensitivity to short circuit (short circuit);

Despite this, asynchronous generators are not very popular, the reason for this is a number of disadvantages:

- Unreliable operation under high load;

- Dependence on electrical network parameters;

- Dependence on the active-inductive nature of the load.

Bright mask

You will need: colored paper, a simple pencil, scissors, eraser, glue.

Master Class

- Draw an owl mask template on plain paper.

- Mark the locations for the eyes and cut the holes.

- Transfer the template onto blue paper, then cut out the mask.

- Make circles for the eyes and decor for the ears from black paper.

- Cut and attach the beak as shown in the image.

- Cut out small and large feathers from colored paper and glue them to the mask.

- Make 2 holes along the edges of the mask and secure the elastic.

The bright paper mask is ready!

Asynchronous generator from an asynchronous motor

If necessary, absolutely any blood pressure can be converted into an AH with your own hands. In order to assemble such a generator, you will need any AD that can be removed from an old washing machine or other equipment, neodymium magnets and epoxy resin.

Instructions on how to make an asynchronous generator:

- First you need to make small holes in the core structure and remove a thin layer of 2 millimeters. The depth of the holes is 5 millimeters.

- Measure the rotor and make metal strips in accordance with the dimensions of the device.

- Purchase and install neodymium magnets. Each pole will require 8 magnets.

- Secure the magnets. It is worth considering that when you bring the magnets to the rotor they will begin to move, so they should be held well until they are finally fixed.

- Take paper or tape and wrap the rotor.

- The end part of the rotor must be sealed with plasticine or other similar material to seal the device.

- Fill the free space between the magnets. This must be done using epoxy resin.

- When the resin has completely hardened, remove the previously used paper or tape.

- Sand the rotor surface.

- Determine the condition of the device, replace the bearings if necessary.

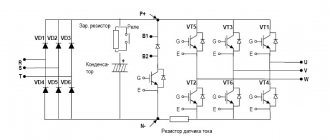

- For the generator, you need to assemble a rectifier and purchase a controller for charging.

If you have completed all of the above steps, then the work can be considered complete. Thus, after spending a little time and money, you get a working generator.

My choice of solar power plant

Before purchasing, it is worth outlining the range of tasks that are set for the solar power plant, so as not to pay for what is unnecessary and not to overpay for what is not used.

Here I will move on to practice, how and what I did myself. To begin with, the goal and the starting points: in the village the electricity is periodically cut off for a period of half an hour to 8 hours. Outages are possible either once a month or for several days in a row. Task: to provide the house with power supply around the clock with some limitation of consumption during the period of shutdown of the external network. At the same time, the main security and life support systems must function, that is: the pumping station, the video surveillance and alarm system, the router, the server and the entire network infrastructure, lighting and computers, and the refrigerator must work. Secondary: TVs, entertainment systems, power tools (lawn mower, trimmer, garden watering pump). You can turn off: the boiler, electric kettle, iron and other heating and high-consuming devices, the operation of which is not immediately important. The kettle can be boiled on a gas stove and ironed later. Typically, you can buy a solar power plant from one place. Solar panel sellers also sell all the related equipment, so I started my search with solar panels as my starting point. One of the reputable brands is TopRay Solar. There are good reviews about them and real operating experience in Russia, in particular in the Krasnodar Territory, where they know a lot about the sun. In the Russian Federation there is an official distributor and dealers by region, on the above-mentioned sites with laboratories for testing solar panels, this brand is present and is not in last place, that is, you can take it. In addition, the company that sells solar panels, TopRay, also produces its own controllers and electronics for road infrastructure: traffic management systems, LED traffic lights, flashing signs, solar controllers, etc. Out of curiosity, I even asked for their production - it’s quite technologically advanced and there are even girls who know which way to approach the soldering iron. Happens!

With my wish list, I turned to them and asked them to put together a couple of configurations for me: more expensive and cheaper for my home. I was asked a number of clarifying questions about reserved power, availability of consumers, maximum and constant power consumption. The latter actually turned out to be unexpected for me: a house in energy saving mode, when only video surveillance systems, security systems, Internet connections and network infrastructure are working, consumes 300-350 W. That is, even if no one uses electricity at home, up to 215 kWh per month is spent on internal needs. This is where you’ll think about conducting an energy audit. And you’ll start unplugging chargers, TVs, and set-top boxes from the sockets, which consume a little bit in standby mode, but still consume a fair amount of power. I won’t agonize over it, I settled on a cheaper system, since often up to half the amount for a power plant can be taken up by the cost of batteries. The list of equipment is as follows:

- Solar battery TopRay Solar 280 W Mono – 9 pcs

- Single-phase Hybrid inverter 5 kW InfiniSolar V-5K-48 – 1 pc.

- AGM battery Parus HML-12-100 – 4 pcs.

Additionally, I was offered to purchase a professional system for attaching solar panels to the roof, but after looking at the photos, I decided to make do with homemade mounts and also save money. But I decided to assemble the system myself and spared no effort and time, and installers work with these systems constantly and guarantee quick and high-quality results. So decide for yourself: it’s much more pleasant and easier to work with factory fasteners, and my solution is simply cheaper.

Where are asynchronous generators used?

Different types of asynchronous generators can be used in domestic conditions when it is necessary to obtain a small amount of electrical energy from mechanical energy.

In addition, AGs are used as the main elements of electric power plants.

For example, they can be used for:

- Power supply for AD, household appliances, lighting, etc. in areas remote from power lines.

- Power supply for low power radios.

- Heating and melting materials with heat.

- Electric welding.

- Obtaining constant voltage in autonomous electrical installations.

Thus, it turns out that by performing a number of simple operations with IM, you can obtain a low-cost generator device for autonomous power generation.

Operation of a hybrid solar power plant

After the launch of the solar power plant, my family and I revised many of our habits. For example, if previously the washing machine or dishwasher started after 11 pm, when the night tariff in the power grid worked, now these energy-consuming jobs are moved to the day, because the washing machine consumes 500-2100 W during operation, the dishwasher consumes 400-2100 W. Why such a spread? Because pumps and motors consume little, but water heaters are extremely power-hungry. Ironing also turned out to be “more profitable” and more enjoyable during the day: the room is much lighter, and the energy of the sun completely covers the consumption of the iron. The screenshot shows a graph of energy production from a solar power plant. The morning peak is clearly visible, when the washing machine was working and consuming a lot of energy - this energy was generated by solar panels.

The first days I went up to the inverter several times to look at the production and consumption screen. Then I installed the utility on my home server, which displays the operating mode of the inverter and all parameters of the power grid in real time. For example, the screenshot shows that the house consumes more than 2 kW of energy (AC output active power item) and all this energy is borrowed from solar panels (PV1 input power item). That is, the inverter, operating in hybrid mode with priority power from the sun, completely covers the energy consumption of the devices from the sun. Isn't this happiness? Every day a new column of energy production appeared in the table and this could not but rejoice. And when the electricity was turned off in the entire village, I found out about it only from the squeak of the inverter, which notified me that it was working in autonomous mode. For the whole house, this meant only one thing: we live as before, while the neighbors fetch water with buckets.

But there are some nuances to having a solar power plant at home:

- I started noticing that birds love solar panels and when they fly over them, they cannot help but be happy about the presence of technological equipment in the village. That is, sometimes solar panels still need to be washed to remove traces and dust. I think that if installed at 45 degrees, all traces would simply be washed away by rain. The output from several bird tracks does not drop at all, but if part of the panel is shaded, the drop in output becomes noticeable. I noticed this when the sun began to set and the shadow from the roof began to cover the panels one after another. That is, it is better to place the panels away from all structures that can shade them. But even in the evening, with diffused light, the panels produced several hundred watts.

- With high power of solar panels and pumping of 700 Watts or more, the inverter turns on the fans more actively and they become audible if the door to the technical room is open. Here you either close the door or mount the inverter on the wall using damping pads. In principle, nothing unexpected: any electronics heats up during operation. You just need to take into account that the inverter should not be hung in a place where it can interfere with the sound of its operation.

- The proprietary application can send alerts by email or SMS if any event occurs: turning on/off an external network, low battery, etc. But the application works on unsecured SMTP port 25, and all modern email services, like gmail.com or mail.ru, work on secure port 465. That is, now, in fact, email notifications do not arrive, but I would like to.

Not to say that these points are somehow upsetting, because one should always strive for perfection, but the existing energy independence is worth it.

Photo of a generator made from an asynchronous motor

Share with friends

Classification of household appliances

Gasoline

Systems driven by wind or flowing water are found only in more or less large power plants. Using them in field (hiking) conditions and even just at home is not so easy. This especially applies to hydrogenerators. As for thermal power plants for private use, they almost always run on gasoline and produce limited power; devices more powerful than 20 kW can rarely be found. They usually use AI-92 gasoline; the use of AI-76 and AI-95 is possible only occasionally, and even then it is not recommended.

We collect the necessary components and tools

This unit consists of the following parts:

- Motor from a brush cutter;

- DC motor – 12-24V;

The tools we will need are:

- Drill or screwdriver + drill bits and Phillips bit for self-tapping screws;

- Circular saw or jigsaw (for lovers of manual labor, a hacksaw is suitable);

- Voltmeter;

- Screwdrivers, pliers, paint knife or scissors;

- Square, tape measure.

Safety Tips and Recommendations

Three-phase voltage of 380 Volt is a great danger of human injury and death. Therefore, safe operation of a homemade product is the most important requirement. To guarantee it, the following conditions must be met:

- Management of a single electrical panel, which includes:

- Measuring instruments: voltmeter (with a maximum of not less than 500 Volts), ammeter and frequency meter.

- Switches for interaction of loads (three keys). One of them turns on the power directly to the consumer, and the other two are responsible for connecting the capacitor elements.

- The protection system is a circuit breaker that trips in the event of a short circuit or power overload. This also includes a protective shutdown device, which should trip if a phase breaks through to the housing.

- Reliable grounding to the earth circuit.

- AVR system. For ease of operation and increased security, we also recommend using automatic reserve entry. It is relevant if you need backup power as a generator. Then it will be able to turn on independently when the current in the stationary network disappears, and also automatically turn off when it appears. ATS is created by installing a changeover switch that uses all three phases.

Video

In this article you will learn how to make a 220 V generator with your own hands using a 2-stroke engine. This generator can be used for various purposes, at home for lighting and connecting small loads, outdoors, for lighting a tent, or find other applications. It is not large in size, and the parts used are not very scarce.

Read also: Device for drilling bolts

Gas tank

As a gas tank, you can use a metal sealed container with a filler neck with a lid and a fitting for supplying fuel to the carburetor. It is best to use the fuel tank from any vehicle. The main thing is its good condition and suitable dimensions.

Plastic containers must not be used:

- Plastic becomes brittle in the cold;

- Some types of plastic are gradually broken down by gasoline;

- Plastics tend to become electrified and accumulate static electricity, which can cause the fuel to ignite.