It is no secret that in the workshop of every home craftsman there are tools that could rightfully retire to a “well-deserved rest.” The owner does not raise his hand to throw out of his life a tool that, on the one hand, is already outdated, but on the other hand, can still solve this or that problem. Or it can serve as the basis for the “homemade” product needed by the master.

So an old Soviet-era hand drill can serve as an attachment for a screwdriver, a key for opening and closing bolts, a device for stripping cable insulation and other devices. You can come up with many different tools, everything is limited only by your imagination.

And what owner would deny himself the pleasure of decorating his home or workshop with a vintage drill?

Cool ideas and lifehacks for using a screwdriver at home

In addition to the listed mechanisms, a screwdriver can also be used to implement other ideas on the farm.

This hand-held power tool will help you automate the opening of an entrance gate, make a winch for a car, or make scissors for cutting metal. If you attach an attachment for cutting tin to it, you can turn an ordinary rubber boat into a motor boat, and modernize the process of drilling holes for ice fishing. In addition, everyone knows that a screwdriver is used as a drive for a mixer, meat grinder or juicer. After reading the article, the reader gained knowledge about the unconventional use of a screwdriver. Now he can use this hand tool to create carpentry equipment, improve children's vehicles and other useful things in the home.

Screwdriver attachment

With a little thought, you can make an attachment for a screwdriver.

Such a simple nozzle in its design can be created without unnecessary complications.

The good idea is that there is no need to spend money on additional parts. Everything you need is already in the drill design. All you need is a lathe, an angle grinder, a welding machine and, of course, a screwdriver, which we will now attach to:

- Remove the two covers from the drill body. Unscrew the thrust part.

- We knock out the cotter pin from the small gear and remove it from the shaft on which the drill chuck is mounted.

- Using a sharpening machine, we bore the conical tip of the shaft to 10 mm.

- We insert the shaft back into the drill body, put on the gear and cotter it.

- On the right side, use a grinder to cut off the threaded shaft.

- We screw the rubber handle (improved version) into the body on the right.

- Cut off the threaded part of the large gear shaft.

- The head must be welded to the large gear shaft.

- Screw the two covers back to the body and lubricate the gears with special graphite lubricant.

- The nozzle is ready to use!

The DIY mechanism allows you to screw in and unscrew bolts and nuts in hard-to-reach places. Increases torque by 6-7 times. Since the attachment is longer than a simple screwdriver, the tool can be used around the house, for assembling furniture, or for car repairs, if the nut connection cannot be reached in any other way.

Bottom line

The complexity of the design is adjusted according to the tasks to be performed. It can be made so strong and precise that it will allow even soft metals to be processed. In any case, we are guided by the principle of expediency.

If the limit of complexity of the workpieces is cylindrical door handles, you can simplify the machine to an ordinary clamp that presses the drill body to the table.

A block as a support platform, and a chisel instead of a cutter.

The hand drill is a tool that was very popular before the advent of power tools. Every self-respecting master had at least one such drill in his arsenal, which was simply an indispensable assistant. But such a tool has a significant drawback - the need to use physical force. Today, such tools have been replaced by more rational ones - electric drills and cordless screwdrivers. New tools have appeared, but what to do with old hand drills? If you have a USSR-era hand drill lying around in your garage, do not rush to dispose of it. You can make some useful things out of this tool. This material will explore several ideas.

The hand drill was created to drill holes in various types of materials: wood, plastic and metal. The operating principle is based on a pair of gears of different diameters, which allows you to increase the rotation speed, thereby making the tool quite suitable for drilling. It is thanks to the gear mechanism that the tool has become widespread and is used even today.

Interest in the use of a hand drill has decreased since the invention of electric drills, but they still resort to using this tool in extreme cases when there is no electricity and it is necessary to urgently drill a hole. Let's not delve into the details of this tool, but rather find out what can be made from an old hand drill?

Option 1

If you are wondering what can be done from an old hand drill, then you are on the right track. Don’t rush to throw it away, as it can be used to make an excellent attachment for a screwdriver. The finished product will allow you to unscrew and tighten various types of fasteners in hard-to-reach places using a screwdriver. Let's look at how to make such a device in more detail.

Carpentry workshop equipment

A few more interesting suggestions on how to make equipment for home carpentry using a regular screwdriver.

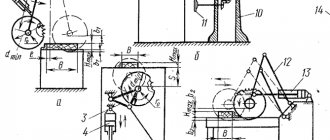

Wood lathe

When making wood products, it is difficult to do without a lathe. You can build it yourself. A flat wooden workbench is ideal for the bed. A screwdriver can be used as a headstock and rotation drive. You need to place the tool in a wooden bed made from a block in the shape of a screwdriver and secure it with a clamp. The block can be secured with a clamp, and if the machine is constantly used, screwed with self-tapping screws. A tooth mandrel must be inserted into the chuck. The tailstock is made of two bars with an adjusting screw, which is sharpened to a cone. It is installed opposite the fixed screwdriver so that the axis of the tool coincides with the axis of the tailstock adjusting screw. The back support structure is secured with a clamp. If you plan to process large parts, then the fastening should be more reliable. The tool rest can also be made from a block, securing it to the workbench with a clamp. A primitive lathe for the home workshop is ready.

Bench Drilling Machine

Another equally important piece of equipment is a drill. It can also be made from a screwdriver. To do this you will need a used screwdriver. From it you need to take a motor with a gearbox and a cartridge. Now you need to make two clamps from textolite, which will perform the function of fixing the drilling head of the machine. To achieve maximum alignment of all holes on the clamps, it is better to process them together, in one installation. Then you will be able to avoid distortions.

Bushings with internal threads are used as limiting posts. They must be the same size, corresponding to the distance between the clamps. After this, another clamp is made from textolite and two bosses from caprolon. They are drilled off-center, resulting in two eccentric bushings. The clamp is installed on the rod and the backlash is selected using eccentrics. After this, install a wooden lever on a spring so that the drilling head returns to its original position. To supply power, you must use a transformer with a power of more than 150 watts and an output voltage similar to the screwdriver you are using. After this, you need to install a diode bridge and a capacitor, and install the drilling head on the frame.

Manual router from a screwdriver: step-by-step instructions

It can be converted into a hand router. To do this, you do not need to purchase expensive materials. Everything you need can be found in the workshop or garage, practically under your feet. To make a manual router from a screwdriver, you will need pieces of thick plywood or chipboard, a clamp for attaching the tool, fasteners in the form of bolts and self-tapping screws, plumbing tools and a feather drill for wood. In the latter case, you can use a drill bit.

Assembling a homemade router is quite easy. To do this you need:

- From pieces of the selected material, cut out a base, a vertical stand on which a screwdriver will be attached using a clamp, a stop and a gusset to impart rigidity to the structure. The dimensions of the parts are chosen arbitrarily, in relation to the dimensions of the power tool.

- Using a pen drill, drill a Ø 40 mm hole in the base for free access of the cutting tool to the processing area.

- Make a clamp according to the diameter of the hand tool.

- Using a clamp, secure the screwdriver to a vertical stand so that its chuck is a few millimeters from the base.

- Install the stiffener.

- Secure the screwdriver with the stop on the vertical stand.

- Install the cutter into the tool chuck.

The screwdriver cutter is ready for use. Such a machine cannot become a full-fledged replacement for a manual milling cutter due to its low power and low spindle speed, but it will solve the problem of milling small parts in a home workshop.

Circular Saw

In addition, for your carpentry workshop you can make a circular saw from a screwdriver. To do this, you need to make a working surface using a sheet of chipboard or thick plywood. You need to make a cut in the tabletop to allow the circular saw to exit. The screwdriver must be securely fastened to the underside of the work surface using metal or wooden clamps. In the same way it is necessary to mount the shaft

It is important that the saw blade extends above the working surface of the table by no more than a third of its diameter

Assembly technology with a wooden frame

Using a clamp and clamps, the drill is rigidly attached to the base. This unit automatically receives the name of the headstock of a mini-lathe from a drill.

By rigidly connecting two wooden blocks to each other on the opposite side of the drill chuck, we get a unit called the tailstock. One end of the adjusting bolt should look like a cone.

The support can be made from a wooden block and thick plywood. Using two clamps you can attach the tool rest to the base of the mini machine.

The assembled design of the machine ensures that all working units are located strictly on the same axis. The most accurate centering along the axis of rotation of the workpiece from the drill chuck to the tailstock adjusting bolt must be ensured.

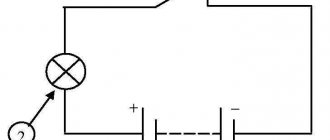

Method No. 1 – Second life for an old tape recorder

As you understand, the first version of a homemade mini drill will be made from a CD recorder forgotten by time. All you need from the former bestseller is a motor that will rotate the chuck with the tool. Since the device is powered by 6 Volts, you will additionally have to find an appropriate power supply or several batteries. You can use a USB adapter, but in this case the power will be slightly reduced. In addition, you need to buy a collet yourself (sold in any radio store or on the market, on the Internet on AliExpress, the price is low) and find a suitable housing for homemade work, although this is not necessary, you can hold the tool directly by the motor.

So, in order to make a mini drill from a motor yourself at home, you must follow these steps:

Solder two flexible wires to the contacts of the device, as shown in the photo.

Install a drill of a suitable size into the collet.

3. Place the finished nozzle on the motor shaft and secure the cartridge with screws

Please note that the collet hole must ideally fit the shaft diameter, which is usually 1.5 or 2.3 mm. Otherwise, it will be difficult for you to remove vibration when operating a homemade small drill. If the hole in the collet chuck turns out to be larger than the motor shaft, then you can try wrapping several layers of tape, thick paper, polyethylene or other material

This will compensate for the gap and reduce vibrations

If the hole in the collet chuck turns out to be larger than the motor shaft, then you can try wrapping several layers of tape, thick paper, polyethylene or other material. This will compensate for the gap and reduce vibration.

Carefully tighten all 4 bolts on the nozzle, then connect the wires to the power source and test the finished homemade product. For ease of use, it is advisable to add a button or switch to the power supply.

That's all the technology for assembling a device with your own hands. As you can see, making a microdrill from a motor is not at all difficult, even for a novice electrician. The only drawback of this device is the low strength of the thin drill. If you drill holes that are not at right angles, it will break immediately, so be careful and buy a few drills in reserve for practice.

A very important point that you should know about is that to make the drill spin in the other direction, just swap the wires! You can watch an interesting video instruction on how to make a simple drill below:

A simple drill made from improvised means

Preparing for work

The readiness of the drill for operation is determined by the following conditions:

- the device is connected to an outlet (for drills powered by an electrical network);

- the battery is charged and installed in the compartment (for cordless tools);

- a drill is installed in the chuck.

Attention! To make the hole smooth, the cutting edge of the drill must be sharpened. Take a new drill or sharpen an old one using a whetstone.

You can press the start button to check the power. If the chuck rotates quickly, then electric current is supplied to the motor and the tool is ready for use. If the cordless drill chuck rotates slowly, the battery is discharged and needs to be charged.

Making a screwdriver attachment from a hand drill

Few people know what can be done from an old drill, so don't be in a rush to recycle or sell this invaluable tool. From it you can make a device for a screwdriver, which is designed for screwing and unscrewing various fasteners. These can be not only long self-tapping screws, but also bolts and nuts. The secret of this device is that you can make a very useful thing out of an old drill, which will allow you to get to hard-to-reach places and then unscrew the fasteners.

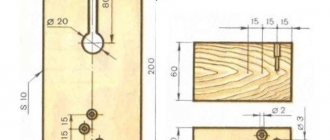

The principle of making an attachment or device for a screwdriver from a hand drill is to perform the following manipulations:

- First, we free the tool from unnecessary parts. To do this, remove the chuck from the tool, as well as the handle.

- The thrust heel is also dismantled, which will not be needed in the new device.

- The shaft on which the cartridge was located has a fairly large diameter. It will not be possible to install a shaft of this diameter into a screwdriver chuck, so let’s start grinding it down

- It is recommended to grind the shaft to reduce its diameter on a lathe. The use of an emery wheel or grinder for such purposes is not recommended, since the grinding will be uneven

- To grind a shaft on a lathe, it will first need to be removed from the tool. It's not difficult to do this. In the mechanism, near the bevel gear, which is mounted on the shaft, there is a hole with a cotter pin. This cotter pin must be knocked out, thereby disconnecting the gear from the shaft

- After grinding the shaft down to 8-10 mm on a lathe, it should be installed in place, not forgetting to pin it. The shaft is made of hardened steel, so before grinding it, it is recommended to do heat treatment (heat it with a blowtorch)

- The shaft is driven by a ball bearing, which can be lubricated to extend its life.

- The first part of the work is completed. The shaft that was ground off will be used as a transmission device on the new device. The working element on the device will be the shaft on which the handle is attached

- The second shaft has a specific hexagonal shape, which should also be machined so that socket heads or other attachments can be put on it. The simplest option is to make a square shape from the hexagonal shape of the end protrusion for securing the heads

- This can be done using a grinder and a cutting wheel. In this case, only heads for screwing and unscrewing bolted connections can be installed on such a shaft

- If you plan to use the device for other purposes, then threads can be cut on the shaft by first making it cylindrical and grinding it to the required size

- A drill chuck must be screwed onto the cut thread, into which you can install various attachments - bits, mixers, drills, cutters, etc.

- Please also note that to install the chuck on the secondary shaft of the device, you will also need to cut an internal thread for control fastening of the collet chuck

- To complete the manufacture of the device from an old hand drill, it is necessary to cut off the remaining part on which the thrust foot was attached

- After this, the homemade device is ready for use. All that remains is to fix it in the screwdriver chuck and test it

The advantage of such a device is that it increases the torque. The screwdriver drives a small diameter gear, which transmits force to the larger gear. A small gear is attached to the large gear, and the force is transmitted to the second large gear, on which the secondary shaft is located, thereby reducing the rotation speed, which means increasing the torque. As a result, the device allows you to unscrew and tear off stuck and rusted bolted connections. However, do not forget that the main role is played by the screwdriver, which must have the necessary power reserve, otherwise its engine may suffer.

Review of the most popular attachments for working on wood and metal

Wood is one of the most commonly processed materials for engraving, along with glass, metal, and stone. Dremels are often used for carving wood, drilling miniature holes in it, applying images to the surface of a given material, sanding, and creating small grooves or tongues. Therefore, popular types of attachments for woodworking are:

- wood cutters;

- drill;

- cutting circles;

- polishing, grinding wheels and cylinders;

- spherical and cone-shaped burs;

- diamond and carbide bits of various shapes;

- felt balls.

There are also specific types of wood cutters, but they are used very rarely even by specialists. It is recommended to purchase consumables for processing wood of different species using a straight grinder as a set. Thus, everything that may be needed when performing work manipulations will be collected immediately in one case.

Read also: Manufacturing of plastic products

How to do it yourself?

Finally, it remains to talk about making a simple hand drill on your own. The described method involves using an old umbrella, a dowel and a drill as components of the tool being created, as well as the simplest equipment - a hammer and a hacksaw. Practice shows that this problem can be solved in a few minutes by following the algorithm below:

- take an umbrella and saw off a fragment of the required length from its rod (along with the handle);

- bend the workpiece in two places at an angle as close as possible to a straight line;

- select a dowel of a suitable diameter and drive it into the tube to the maximum possible depth, and then securely fix the drill in it.

If the master needs a thinner cutting tool, he will need another dowel, which must be driven into the already installed one. Upon completion of this action, all that remains is to take a drill of a smaller diameter and secure it in the manner described above.

To summarize, we can state that hand drills deservedly enjoy their popularity. It makes sense to use them for anyone who values reliable and unpretentious tools that can ensure high quality of work performed.

You can see an overview of a hand drill and how it works in the following video.

Making a machine for winding coils from a drill

What else can be made from an old hand drill that has been gathering dust in the garage for more than 10 years? Of course, you can make a simple device that will allow you to wind coils. You can wind not only threads and ropes, but also wire, for example, when rewinding electric motors.

The design of such a machine is very simple, and to manufacture it you will need to use the following devices:

- Vice - a fixed handle or tool stop located in a horizontal position is attached to them

- A block of wood of the appropriate size, which is located near the cartridge. This block acts as a stop, holding the tool in a horizontal position

- A reel or other devices are attached to the tool chuck, onto which material is wound - wire, rope, threads, etc.

A photo of such a device is shown in the photo below. If you attach a sharpening wheel to the chuck, the tool can be used as a hand sharpener.

Device for tightening and unscrewing long screws

To unscrew or screw a long self-tapping screw into wood, you will need to put in a lot of effort. If you've tried doing this with a screwdriver or electric drill, you know that it's quite difficult to do. The self-tapping screw will “go” into the wood to a certain depth, but it is almost impossible to tighten it completely with electric tools. It is also extremely difficult to do this manually, so you should call an old hand drill for help.

The tool for screwing or unscrewing long screws does not need to be modified. You just need to clamp a bit in the collet chuck of the device of the appropriate size and get to work. The efficiency of using hand tools when screwing long self-tapping screws is an order of magnitude higher compared to low-power screwdrivers and high-speed electric drills.

Wind generator

Using a screwdriver engine, you can design a small wind generator for a summer house or personal plot, and be independent of the power supply. It will also help during a power outage.

It will take a little time to create a wind generator. The rotor part is removed from the screwdriver. The motor shaft is attached with a bracket to a plastic plate. We attach the flywheel to the end gear with bolts and attach four blades made from PVC pipe to it. You can use a tea can for the body, carefully sealing the cracks with sealant. The wind generator is ready to provide electricity that costs you nothing.

pros

There are a sufficient number of advantages that fully justify the use of the described tools.

- Simplicity of design. Due to the absence of a large number of components, mechanical drills are easily repaired and do not require particularly careful maintenance. This allows you to significantly reduce the amount of time and money required to ensure the functionality of the tool used. The solution to this problem is not difficult: it involves timely application of lubricants and replacement of parts that have exhausted their working life.

- Reliability and durability. Experience shows that it is very difficult to break a hand drill even with regular and very intensive use. This is due to the high quality of the materials used in the manufacture of such instruments (especially those produced during the Soviet era). Many mechanical drills produced several decades ago still serve successfully, having repeatedly justified their original cost.

- Autonomy. The described tools do not require electrical power, and therefore they can be used anywhere. This advantage of hand drills is especially important for those who have to work far from the usual benefits of civilization.

- Reasonable price. Today, a new hand drill can be purchased for 600-1000 rubles, while a used mechanical “assistant” will cost even less (about half). In addition to the technical condition, the cost of the instrument is influenced by its dimensions, equipment, body material and the reputation of the manufacturer.

Most often, craftsmen give preference to drills produced in two-handed versions, using them to create small holes and grooves

Accurate performance of such work requires precise adjustment of the drilling depth and extremely careful rotation, for which the described tool is most suitable

Minuses

One of the main disadvantages of hand drills is their massiveness, due to the specifics of the parts used.

Provided that the latter are made of cast iron, the weight of the tool can reach 3 kg, creating certain difficulties for the performer during work and transportation. Another disadvantage of such drills is their large dimensions: as a rule, craftsmen do not consider it critical, however, some craftsmen refuse hand tools for this very reason. This circumstance leads to the fact that many performers prefer power tools. In addition, hand drills are significantly inferior to the latter in terms of productivity, and therefore are practically not used when performing large volumes of work.

Budget option - we make a machine from a drill for 300 rubles

This is an unusual method, and you will need to spend about 300 rubles. This way you will get a device that drills at any angle, from 45 to 90 degrees.

So, let's look at the features of such a device:

- Tilt angle. In order to tilt the device to the required drilling angle, it will be enough to unscrew the two green levers on top and set the required degree on the scale.

- Drilling limitation. If you tighten the limit knobs to the desired height, you can limit the depth to which the drill can go.

- Fixation. The device can be fixed in absolutely any position on a vertical plane. For example, this is very convenient if you change drills so that the drill does not fall down.

- Fixing on the table surface. If you can fix the base of the device with four self-tapping screws, for example, to a table, be sure to use this opportunity. This function will be very convenient if you need to drill many similar parts.

- Sole. At the bottom there is a recess with a width of 6 cm to make it more convenient to install the device. The top of the sole has a 45 degree chamfer on both sides and may require drilling a hole into the edge of the square shaped timber.

This device is simple and convenient to use. This will greatly help make work in the workshop easier, and at the same time it costs mere pennies.

Electric car or children's catamaran

To create an electric car for children you need:

- make a frame (frame) from a metal profile or PVC pipes. They need to be assembled together so that you get a small car or a tricycle;

- as an axle for the wheels, you can use a metal pipe or rod, on which you need to attach a large sprocket;

- on the frame under the seat, make fastenings for a screwdriver with a battery and a shaft with a small gear;

- put the chain on the sprockets;

In order for a car to brake, you need to make a gas pedal or handle. The first part can be constructed from a rod with springs, to one end of which a pedal will be attached, and to the second a metal part that will press on the button. This design requires welding skills and a lot of time.

Car made from a screwdriver

To make the job easier, the throttle handle can be made from a set of bicycle rim brakes. To do this, you will need to take a part of a bicycle fork that has mounts for the brakes or make an analogue of them yourself from a metal rod of the required diameter.

A children's catamaran is made according to a similar principle, but its assembly requires PVC pipes. Since the movement of the gears is provided by the motor from the screwdriver or the tool itself, additional protection should be provided for it from water ingress. If the structure is made from a broken screwdriver, then the gas button can be removed with separate wires through pipes, and only its motor can be used as a motor.

An example of a catamaran design made from pipes for children

Important! The motor of a drill or screwdriver is not designed for heavy loads, so this electric vehicle is designed only for light passengers. Also, from prolonged use in this mode, the screwdriver can quickly break.

Armchair

The famous armchair, which was found in most Soviet apartments, is again at the peak of popularity today. Owners are captivated by its convenience, simple design and frame quality.

The owner of this specimen used foam rubber 8 cm thick for the back and 10 cm thick for the seat, also adding two layers of synthetic padding. Upholstery fabric with the effect of furniture screed in lemon color was purchased at the store. Rounded shapes were created by bending the foam overlapping the edge of the back and seat, as well as by stretching it tightly.

To paint the frame, inexpensive matte white enamel “PF-115”, tinted with black, was used. Painting was done with a velor roller in three thin layers.

After drying, it is recommended not to touch the chair for about two weeks - this way the composition will polymerize completely and will be stable in use.

Drilling machine, why is it needed?

Drilling through thin material is not a problem. All you have to do is pick up the drill, a few seconds, and the job is done. But what to do if you need a precisely calibrated hole in a thick beam? A hand tool will not work; there is a high risk of damaging the workpiece. The result will be a shift in the center of the hole, a change in geometry, and torn edges. A drilling machine will help you avoid such shortcomings and create a hole with the specified parameters.

Thanks to the reliable fixation of the workpiece and the centering of the tool, drilling accuracy is ensured, which cannot be achieved when working with a drill. Precision is a must when making furniture in a home workshop. To create a homemade furniture additive machine, you will have to slightly modify an already finished tool. Manufacturing does not require much effort or time.

Don’t forget about the versatility of this machine: by changing drills, you can work with any material, from soft wood to metal, easily drilling through sheet steel. Instead of a drill, you can use a milling cutter, then the device will replace a low-power milling machine. Among other things, a drilling machine will significantly facilitate the work of the master. It is easier to work with a stationary device; there is no need to hold a heavy tool suspended.

Practical examples of a homemade lathe, taking into account the recommendations outlined above

Let's start with the simplest option, which can be made in one weekend with virtually no financial costs (you already have a drill, its cost is not taken into account).

A set of blanks in the illustration: the tool itself, several wooden blanks, fasteners.

The most crucial moment is the alignment of the drill shaft with the support tip of the improvised tailstock. Therefore, we take measurements with an accuracy of up to a millimeter.

Since the machine will not be very large, we place it on a bed made of thick plywood. The holder for the drill neck is also cut out of plywood, and the clamping clamp is not necessary. A fixing screw will be sufficient. We place the nodes on the bed:

A spindle is not required: thin workpieces can be clamped in a standard drill chuck, and for larger parts an improvised washer can be made.

On such a machine you can easily process wooden blanks, as well as blanks made of composite materials: textolite, etc.

Using similar materials (only thick textolite is better than durable multi-layer plywood), you can make a machine that is more complex in terms of settings.

The drill itself is fixed not only in the neck area, but is also supported by an additional bracket. This will avoid vibrations, especially with high loads or unsymmetrical workpieces.

Taking into account the possibility of precise adjustment of components to a specific drill, it is possible to perform the fastening as gentle as possible for the tool itself. For example, ventilation openings should not be covered.

The support for the incisors (even if they are held in the hands) is movable. And both horizontally and vertically. During processing, the blank becomes thinner, and the supporting surface can be moved closer to the part.

The tailstock is not vertically adjustable, this is logical. And horizontally, rough adjustments are made (the support is moved), and fine adjustments are made using a screw.

The main principle of any such design is that you do not permanently lose the power tool itself. That is, the drill can be dismantled at any time and used for its intended purpose.

Cool ideas and lifehacks for using a screwdriver at home

In addition to the listed mechanisms, a screwdriver can also be used to implement other ideas on the farm. This hand-held power tool will help you automate the opening of an entrance gate, make a winch for a car, or make scissors for cutting metal. If you attach an attachment for cutting tin to it, you can turn an ordinary rubber boat into a motor boat, and modernize the process of drilling holes for ice fishing. In addition, everyone knows that a screwdriver is used as a drive for a mixer, meat grinder or juicer.

After reading the article, the reader gained knowledge about the unconventional use of a screwdriver. Now he can use this hand tool to create carpentry equipment, improve children's vehicles and other useful things in the home.

New life for the sofa

You can repair not only small wooden objects, but also large items. This book sofa from 1974 was once reupholstered, but has worn out again. His mechanism broke and the bolts were bent. During the remodeling, the owner of the sofa saved not only the budget, but also the space: this model is very compact and takes up little space.

There is no foam rubber inside - only springs and a harsh canvas on a cotton backing, so the design is odorless. The frame is in satisfactory condition. The owner bought new hinges, a piece of furniture fabric and new bolts.

Thanks to the perseverance and patience of the craftswoman, the mechanism of the sofa was updated, and the soft part was reupholstered with new material. All that remains is to add a couple of decorative pillows.

Making a garden shredder

A garden shredder for grass and thin twigs (less than 1 cm thick) can be made on the basis of a corded drill-driver.

Create an aggregate like this:

- choose a suitable container, for example, zinc boiler;

- a hole is drilled in the center of the bottom for the shaft on which a knife or several blades will be fixed;

- make a wooden or metal frame to install the container or place it on the edge of the table;

- a drill-driver is attached to the frame or bottom of the boiler, which is equipped with knives;

- install an on/off button;

- make a slot in the side of the container - cut out a rectangle 10 by 20 cm in front of the bottom;

- A sleeve is made from tin for disposing of crushed plants;

- attach it to the container;

- check the functionality of the unit.

Knives are easiest to make from hacksaw blades. They need to be installed with the point down. In this case, you can make several versions of blades for different grasses. If you make an attachment in the form of knives for a drill-driver, then you can simply chop the grass in a bucket or other suitable container.