Do-it-yourself metal engraving at home - instructions and video

It makes no sense to talk about applying inscriptions on metal using special paints or varnishes.

By the way, this is also one of the methods of engraving on metals. But how long will such drawings, symbols, and icons last on the sample? They will be washed off quite quickly with any of the solvents, although due to banal abrasion their service life will be short. There are more efficient metal engraving technologies, which we will talk about. But are they all suitable for independent performance, and even at home? When you just read about them, everything is clear and easy. But practical implementation is another matter.

Laser engraving

This method is considered the most effective, as it allows you to apply a pattern (drawing) of any complexity to metal, “writing” the finest lines and smallest icons on it.

But taking into account the fact that engraving samples using this method will require expensive equipment, it is acceptable only for those who have decided to make this craft their business, that is, to put production on stream. It is unlikely that anyone will want to shell out a tidy sum just to put memorable inscriptions on a couple of teaspoons or on the blade of a hunting knife. The services of professionals in any workshop will cost less.

Mechanical engraving

The accessories are much simpler here - you only have to purchase a set of required cutters and the engraver itself. A drill is often used for these purposes (anyone who has ever visited a dentist knows what this is). Another option is to apply images using incisors.

The quality of the inscriptions will be high, but only if you have not just knowledge in this area, but also extensive practical experience. This work requires a “sharp eye” and a steady hand. How many of us can boast of our skills? It turns out that quite a lot of time will pass from what was conceived to actually executed, which is necessary to acquire skills. Who is happy with this prospect? In addition, you also need to be able to sharpen cutters (stiches) correctly if the work is carried out with their help.

Let's consider the technique of electro/chemical etching for the purpose of applying inscriptions. It belongs to the simplest category, and anyone who has chromed metal parts at home will get the gist of it right away.

Lettering on metal is a great way to make a unique gift or mark a valuable item. There are not many ways to make a clear and indelible inscription or design. One of them is electrochemical engraving...

There are several ways to apply inscriptions or drawings to metal:

- paint applied by hand or stencil . The easiest way available to everyone. The main disadvantage is that even after complete drying, the paint can be easily removed with a solvent or mechanically. Therefore, only a temporary inscription can be applied with paint.

- mechanical engraving . Engraving requires an engraver and a suitable cutter. The main disadvantage is that working as an engraver requires sufficient skill and a steady hand. It is difficult for a beginner to draw a clear, even line even according to the markings. You can take it to an engraver’s workshop, it’s not very expensive. But they are unlikely to bother with anything more complicated than standard inscriptions, and it’s much more pleasant to do it yourself

- laser engraving . Allows you to apply any drawings and inscriptions with the smallest details and halftones. Requires expensive equipment, only available in the workshop

- electrochemical engraving . The method is relatively simple and fast. When working from a template, you don’t even need artistic skills

Electrochemical engraving – what will you need?

Electrochemical engraving of metal using a stencil is done using laser-iron technology, which is well known to radio amateurs. You can also make a stencil by hand if your artistic skills allow it.

To engrave metal you will need simple and affordable materials and equipment:

- DC source 5-15 volts, capable of providing a current of at least 0.5 amperes (electronic power supply, cell phone charger, car battery or power tool)

- wires (it’s convenient if they come with clamps)

- iron

- packing or stationery tape

- thin glossy paper or backing from self-adhesive film

- plasticine of any color

- cotton pads or cotton gauze swabs

- saline solution (2 teaspoons of table salt per glass of water)

- clear nail polish

Electrochemical engraving - description of the process

As an example, consider applying a personal mark to a knife blade. In principle, inscriptions and drawings can be applied to any more or less smooth, preferably polished, metal objects. It’s okay if the surface is slightly convex or concave. Objects with an embossed or otherwise textured surface are completely unsuitable for electrochemical stencil engraving.

The inscription or drawing that needs to be applied to the metal is prepared in any graphics or text editor that allows you to print the result. Please note that the final result needs to be mirrored in order to get the correct image later.

The image is printed on a laser printer. An inkjet printer is completely unsuitable for the laser-iron method.

Thin glossy paper (paper from various cosmetics catalogs works well) can simply be inserted into the printer; the typographic designs and text on the sheet do not matter. You can also immediately print on the glossy side of the backing from the self-adhesive film. In the printer settings, you need to cancel the toner saving mode (if it is enabled) and set the maximum brightness (“blackness”) of the image.

Unfortunately, I was only able to get a small piece of the film backing that the printer couldn't grab. Therefore, I had to attach this piece to a regular sheet of office paper with scraps of the same film.

My printer successfully chewed this sandwich and even printed everything successfully, but I don’t recommend repeating the experiment. It felt like a little more and the film would have melted and remained inside the printer.

After printing, the inscription is carefully cut out. In this case, under no circumstances should you touch the drawing with your fingers; it is better to wear cotton gloves.

The metal surface of the object (knife) is thoroughly cleaned of dirt and degreased with alcohol or acetone. After this, the work area should also not be touched with fingers .

The stencil is applied to the desired location. If there is any doubt that you can keep it from moving on a hot knife, prepare tweezers or something similar.

Now the stencil along with the knife is well heated with an iron. The temperature and heating time strongly depend on the properties of the specific toner and the object on which the inscription is applied, so you will have to select it experimentally. You can start with maximum temperature and 1-2 minutes.

If the surface is not completely flat, then after heating with an iron, you can walk with a cotton pad or a cotton-gauze swab, pressing the stencil onto the metal surface over the entire area. During the entire process, do not move the stencil along the knife!

After cooling, the paper can be removed. The backing from the self-adhesive film comes off without any problems, but you just need to soak the glossy paper for a few minutes in warm water.

Now you need to evaluate the quality of the resulting drawing. If some places did not transfer to metal, then the heating temperature or pressure was insufficient. Too high a temperature will cause the fine lines of the toner to blur and become less clear. In case of major defects, the pattern is washed off with acetone and the operation is repeated.

Small flaws can be corrected - the missing parts can be filled in with nail polish, and blurred lines can be corrected with a scalpel or razor. It is also advisable to cover large areas of the design covered with toner with nail polish - pores in the toner that are invisible to the eye can ruin the entire effect. There is no need to rush here; the finished engraving cannot be corrected.

If you have artistic abilities, you can do without toner altogether. To do this, the entire surface of the metal is coated with varnish and an inscription or design is applied, removing the varnish in the right places with a suitable tool.

If everything is in order, then you can start etching . To do this, you should arrange a small side of plasticine around the drawing. To be safe, I covered the adjacent areas of the knife blade with tape so as not to accidentally damage it.

A saline solution is poured into the resulting pool. The positive terminal of the current source is connected to the knife, and the negative terminal is simply lowered into the solution so as not to touch the surface of the knife.

Carefully! If the wire touches a metal surface, a short circuit will occur! If the current source is powerful (battery), strong sparking, splashing of the solution, heating and ignition of the wires are possible.

To prevent a short circuit, it is better to wrap the negative wire with cotton wool, thoroughly soaking it in a saline solution.

The engraving time depends on the power of the current source. If the solution turns black and foams, then everything is in order. After 20-30 seconds, you need to drain the solution and evaluate the result. If necessary, a fresh saline solution is poured into the bath and the process continues. Etching for too long will cause the drawing to lose clarity, and closely spaced lines may merge.

If the result is satisfactory, then the tape and plasticine are removed, and the toner is removed with acetone. The result of the work is visible in the photograph. It all took about an hour.

When applying the stencil, I cheated a little and did not varnish the design, for which I paid - in some places the solution penetrated under the toner and etched areas that should not have been etched.

We recommend reading

- How to choose a knife for modeling?

- How to make a custom connector?

- Simple DIY key holder

- What rod diameter should I choose for an external metric thread?

- What hole diameter should I drill for metric threads?

- How to use a blowtorch?

- Engraver with EVERISE attachment set

- Hot glue gun - home handyman's assistant

- How to choose a drill?

- How to drill correctly?..

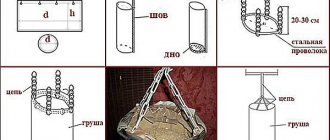

Engraving method 1

- Glass container (according to the size of the workpiece being processed). Naturally, not a bottle with a narrow neck, but a jar, glass or bath. Constant voltage source (up to 15 V). It should provide a current of 0.5 A, at a minimum. The best option is a battery charger for a personal car. This is exactly what the author used. Although some craftsmen use battery chargers for household tools (screwdrivers, etc.) and even cell phones for these purposes. A couple of wires for connection and clamps (for example, alligator clips). Any metal workpiece (the same spoon) that will play the role of a second electrode. Saline solution. The concentration is determined by eye, so the general recommendation is as follows: per glass of water – 2 teaspoons. Varnish. You will need it to paint the segment of metal on which you plan to engrave. Most articles devoted to the electro/chemical method contain tips on using the nail composition. The author, in order not to “injure” his wife with such extravagance, used the so-called tsapon-varnish, which is well known to radio amateurs and electrical installers. It costs a penny, is not in short supply, and can be easily removed with a solvent.

Glass engraving

Photo 4. For home engraving you will need regular salt, nail polish, nail polish cleaner and a glass of water.

Do-it-yourself engraving on the glass surface is done chemically and mechanically. The mechanical method involves the use of a nozzle that is driven by an electric motor. Procedure:

- Using a dark marker, the drawing is transferred to the glass.

- A damp sponge is applied to the image on the glass. This must be done carefully so as not to smudge the drawing.

- When working, you must use safety glasses.

- After completing the drawing, it is washed and examined for gaps. If necessary, missed places are processed again.

Engraving technology

Electrolyte is being prepared

Water is poured into the container, salt is added in the required amount (depending on the volume) and thoroughly mixed until completely dissolved. The quality of the engraving largely depends on this.

A part (product, sample) is being prepared for applying something

The dimensions of the inscription or design are known, so it is not difficult to determine the area of metal varnish coverage. After the layer “sets” a little, the required contour is drawn. What - a needle, a thin awl, a toothpick, a sharpened match and the like - is up to you, dear reader. Whatever it is more convenient to do the work with your own hands, do it. The task is to “expose” the base metal along the lines of the pattern to ensure its direct contact with the electrolyte.

You can do it differently. Wait until the varnish is completely dry, and only then “scratch” the lines. But these are already details, and it’s easy to decide on your own what’s best.

Next, the electrodes are placed in the solution

One is designated - any metal blank. It is connected by a wire to the “–” of the current source. The second is the sample on which the engraving is applied (to its “+”). The technology is similar to chrome plating of metal.

Supply voltage

The time of the technological operation is determined visually. If the etching depth suits the master, then you can turn off the charger. Typically, engraving using this method requires no more than 5 minutes.

All that remains is to remove the metal product from the bath, remove the varnish, rinse the sample well under running water and wipe dry. That's it, the engraving is done!

The drawing and inscription can also be made convex.

To do this, you need to apply varnish to previously drawn (felt-tip pen, pencil) lines (stripes). And all the rest, “uncoated” metal will be etched.

Laser engraving

This technology, due to its advantages, has become most widespread. A drawing, inscription or ornament is formed due to the impact of focused laser radiation. The metal particles evaporate and are removed from the treatment site by the auxiliary gas. The main advantages of laser engraving are high accuracy and productivity. When used on an industrial scale, there is currently no alternative to this technology.

Advantages of laser engraving:

- high degree of image detail;

- fine processing;

- durability: the design lasts as long as the workpiece itself;

- absence of mechanical stress and deformation, which is due to the local impact of a narrow beam;

- the possibility of automation, which allows you to fulfill large-circulation orders;

- versatility: laser can engrave not only metal, but also a whole range of other materials.

Features of the method

Preparing a drawing (lettering)

Everything you need can be easily found on the Internet and copied. For those who know computer graphics, this is not a problem at all. The main thing is to have a printer at hand for printing.

- You will have to do a mirror image conversion. For this technology, only a laser printer can be used. Any other type of device is not suitable. You will need not ordinary paper, but thin glossy paper. As an option - self-adhesive film. In this case, you need to refill so that the print falls on the substrate. You can also attach it to standard (office) paper with pieces of this film. The printer “brightness” mode is set to maximum.

After printing, the image is carefully cut out.

Attention! Work should be carried out with gloves to prevent contact of fingers with the pattern.

Metal preparation

It is cleaned of foreign fractions and degreased.

Fixing the stencil on metal

To prevent it from slipping in the future, it is advisable to secure it (at the edges) with adhesive tape.

Heat treatment

It involves ironing the stencil with an iron. The difficulty is that both the heating time and temperature will have to be selected experimentally. The general recommendation is no more than 2 minutes at maximum heating of the iron.

Cooling

After the metal temperature drops to room temperature, the stencil is removed.

Next is metal etching. One variant of this technology is described above.

It only remains to add that there are quite a lot of DIY engraving techniques - both with the help of solutions and without them. After all, the conversation was about metals, without indicating which ones specifically - steel, brass or something else. The above methods are some of the most common and accessible for DIY implementation. Typically, they are used for engraving steel products. Anyone who wants to master literally all technologies practiced at home will easily find the relevant information.

Good luck with your DIY engraving!

Currently reading:

Engraving with a drill

The principle of do-it-yourself engraving can be seen in the dentist's office. The special tip is held in the hand in the same way as a regular pen when writing. The pattern can be applied to any object: a ring, a mirror, a motorcycle, a sign, etc. You can engrave a portrait or any other image. We must not forget that the color of engraving on glass, ceramics, stone, porcelain is always white. But it can be carefully coated with silver, gold and any other waterproof paint. The effect can exceed all expectations. Drawings and patterns can be applied to wood coated with a layer of paint, to plastic, silver, plastic. Manual work requires patience and certain skills that develop over time. The skill is honed over the years.

Metallization of printed circuit board holes at home - step-by-step instructions

yes, perhaps I drilled 2 through holes in the workpiece for the scissors

Of course, this is possible, but it’s not difficult to determine the time; check the workpiece from time to time, and stop etching when the desired depth is reached.

In the second picture with a description of mechanical engraving, the engraving was made not with a drill with cutters, but with a stichel, this must be learned, learned and learned again. And with a drill you can only scribble, although most basement “Jewelers” do just that. A little advice for beginners: there is no need to etch at great depth; it will create uneven edges and your varnish may not hold up in places; as a result, you will end up with an uneven pattern and a bunch of small dots where you don’t need them. If you need to make exactly 0.2 mm deep or more, it is better to use milling (if possible). If you decide to start with a drill, then immediately throw away the entire set of burs that came with it: 1 - they are all crooked, the runout will not allow you to draw lines normally, 2 - they are all thick, there can be no talk of any small inscription. Therefore, you have a direct route to the jewelry store for carbide burs, they cost around 50 - 100 rubles. per piece you need to take the smallest 2 spherical pieces and a pair of a slightly larger 1.mm size.

Maybe not to jewelry stores. Carbide burs of excellent diameters are also available in dental stores. It's cheaper there.

Source

How engraving developed in Russia

A whole street of new houses was built, and each settler was given a considerable salary, as well as a workplace at the factory. A little later, just a couple of years later, their first students began to appear, the Germans began to pass on their knowledge and secrets of engraving. Including gilding through fire. The students were quite literate and already had some specific skills.

Modern factory logo.

And literally in a matter of months they adopted all the techniques of German craftsmanship. And they started working on their own. One of the students, Ivan Bushuev, decided to try his own methods of engraving; the technique was changed almost radically.

And over time, they began to call it Zlatoust. Ivan Nikolaevich can be considered the progenitor of the Russian school of engraving. Already in 1823, the Germans themselves asked to be fired from the factory, recognizing that new developments were much better than what they could do.

These are Russian men, literally in 5 years, the students surpassed their teachers.

There were difficult times for the plant, but it never stopped its activities. In the 19th century, numerous awards received at world exhibitions are proof of this.

Today, hand engraving is gradually fading away as a craft, but there are still followers of this art.

The essence of the method

The technology is to protect areas that should remain intact from exposure to the chemical. The protective coating can be applied in different ways - we will describe them in detail below. After this, the acid must act. An iron part is immersed in an electrolyte solution and subjected to a reaction. The longer it is, the thicker the layer will be removed from the surface. An interesting result is shown by multilayer etching, when immersion is carried out in several stages.

Old School Engraving Techniques

Handmade by a master.

Today, hand engraving on a good blade, made using ancient methods, is very rare. Such a knife can be considered a bladed weapon that has artistic value.

Even the state did not stand aside, and an amendment to the law “On Weapons” was adopted. The very principle of engraving violates the integrity of the product, there is no escape from this.

To do this, most products are hardened after work by the craftsman. But this even becomes a plus; gold and silver inclusions take on a magnificent appearance. Quite often, coating with printing ink is practiced, which gives the engraving a richness of shades and shadows. Let's try to look at the three main methods of the old school of masters:

- Coinage (plate engraving). It has a rather rare application today; casting has come to replace it. It can be called rough-shaped modeling, done using hammer cutters. After casting a rough shape, the master gets to work and the result is the ideal figure originally conceived.

Chasing work. - Planar. In the production of edged weapons, this technique is not very common. It is more used to decorate sheaths. The technique is that two or more planes are created to achieve the correct shadow impression. In this case, the image will seem to stick out from the overall picture or, conversely, that it is deepened.

An example of flat engraving.

Most often, hunting knives were not depicted with animals or birds of prey, but, on the contrary, the theme was of plant origin, which had its own sacred meaning. For example, the oak tree symbolized power, the lotus symbolized immortality, and the palm tree symbolized peace and victory. - Reztsovaya. This technique was originally used to decorate firearms. But knifemakers gradually adopted this technique. It so happened that the main products of such engraving were edged weapons. In the old days, craftsmen used a basic cutter called bulino, of Italian origin. Now, of course, there are many auxiliary tools, but the principle of action remains the same.

Chisel engraving, master at work.

The main principle of image transmission is cutting into steel, at different angles and with different forces. And many craftsmen prefer to work with a needle; it can convey any texture, any theme.If you go a little deeper, there are three types of technicians. Linear, dotted and mixed, each master chooses the most suitable option for himself, but in reality, for a complete picture, they use all types at the same time.

The materials on which engravings are made can be completely different. Typically, for all these types of art, craftsmen use a “diamond-shaped” cutter, a steel needle, and a spitztichel with a cross-section similar to a triangle with rounded edges. Well, of course, they use various dyes, pencils, magnifying glasses and many other auxiliary little things.

Methods used

Despite the fact that the essence of the technique is the same - it is the removal of the top metal layer by exposure to an aggressive substance in pre-prepared, ideal conditions for this, the technology can be divided by type. The classification will be based not on how to etch a design on metal, but on what etching solution to prepare. Depending on the material, there are different methods:

Chemical. It is also called liquid because liquids are used - acids. Despite the fact that the result is quite fast and of high quality, and there is no need to purchase specific or expensive equipment, not everyone uses this method, since during etching, caustic fumes are formed that are harmful to health. It is very important to adhere to safety precautions and ensure protection of the upper respiratory tract.

Engraving in production

Metal engraving in production is not much different from the procedure carried out at home. Initially, the working surface is cleaned and degreased. After this, it is tinted with a solution of sulfuric acid. Next, the contour is outlined with a metal needle. The engraver does the bulk of the work. When the main work is completed, the surface is covered with colorless varnish.

Engraving on metal is done in various ways. A variety of equipment and tools are used for this. There is no need to buy expensive equipment to decorate a metal surface.

How to etch a design on metal at home using the galvanic method

Let's consider this process as the most popular, giving an excellent result, and also not very expensive and accessible at home.

The first pleasant difference from the chemical method is that there are no harmful fumes. The electrolyte solution depends primarily on the etched material: The chemical elements used

Ammonia, ferrous sulfate

Copper alloys (pure copper, bronze, brass)

In order to apply a pattern to metal with your own hands, you will need to prepare the following materials and equipment:

A non-conducting capacitance that matches or slightly exceeds the dimensions of the workpiece.

5 volt electricity source.

Cathode - it must be made of the same steel as the workpiece.

Wire hangers on which the metal element will need to be suspended.

There are two conductor rods that exceed the size of the bathtub.

Now we present the algorithm of actions:

We connect the first rod to a source of electricity (negative charge), attach the cathode.

The second, respectively, to the positive terminal, and it will also serve as a support on which the product (anode) will be suspended.

Then voltage is applied. When it turns on, electrolytic transfer occurs. However, only from those surfaces that were not covered with any protective coating.

Do-it-yourself engraving on leather

You can apply a beautiful ornate inscription to a diary, passport cover or belt in a special workshop or do it yourself. However, for beginners, making a complex pattern will be extremely difficult; the skin engraving technique requires precise movements and a huge amount of patience. Therefore, before starting complex multifaceted work, it is worth paying attention to training. This way you can master the skill of operating special tools—knives of different sizes and different degrees of sharpening.

You can combine skillful engraving on leather with stamping and embossing - it looks very impressive and looks organic. However, it is worth considering that all these techniques are only suitable for working with genuine leather—the substitute has a more fragile and delicate structure.

Artistic metal etching at home

The technique used to decorate metal products can be any of the ones presented above.

It is usually popular for applying patterns on bladed weapons, firearms, kitchen utensils, steel parts of cars and any other steel objects. Most often, hunting scenes, abstractions, and animal silhouettes are used as stencils. Sometimes the etching process is combined with a number of other methods of decorating metal surfaces, for example, bluing. Then the drawing receives an additional yellowish tint. Let's watch a video about etching metal at home:

Typically used for these purposes:

A hot needle is taken for the pasted surface. It scratches the contours of the image or engraving. This way the material is cut through. Take tweezers, use them to carefully lift and remove sections of adhesive tape from those fragments where etching is supposed to be done. And other parts remain protected. To then remove the adhesive layer, you can use a regular solvent. Do not forget about mandatory degreasing before starting the process.

Incisive engraving

Photo 5. Master's kit is a set of tools and materials that is always at hand for a professional engraver.

There is a type of hand engraving, which is usually called incisor engraving. It is performed using special cutters - gravers (photo No. 5). There can be different numbers of gravers. Some allow you to make the finest lines, others allow you to make several parallel cuts at the same time. Experienced engravers use this tool. Stichels need to be able to be sharpened correctly and brought to working condition. Beginner engravers may not be able to do this. Do-it-yourself engraving, especially on metal, is an ancient art. Cold steel, and then firearms, decorated in this way are considered especially valuable and of high quality. Absolutely anyone can try engraving on small objects like cutlery and knives at home.

Surface preparation before applying a design to metal for etching

Why clean and degrease? In order to speed up the entire procedure, as well as for an improved result, removal occurs in an even, uniform layer. The first step is to remove any contaminants - these are both mechanical (ordinary dirt) and chemical (oil, for example) elements. For this purpose, you can use a soap solution, classic dishwashing detergent, or powder. Next, let the parts dry under normal climatic conditions. It is better not to rub with those rags that can leave lint, but to soak it, for example, with paper napkins.

The next step is to remove the greasy, oily layer; a degreaser or regular gasoline, solvent, acetone, or alcohol can help with this.

You can use not only chemical cleaning methods, but also mechanical ones - combining them. To do this, you can use polishing and grinding. If polishing compounds and sponges are not available to the master, and only sandpaper is available, then it is important to sand strictly in one direction so that the marks are parallel and not chaotic. This will improve the overall appearance of the finished product.

Drawing a pattern on metal for etching: how to make a pattern

The general principle is the same: you need to protect one part from the corrosive effects of the etching composition. You can only act using different materials. Below we give examples of such substances.

Nail polish

The availability of this method is very high - the cosmetic product can be purchased at any relevant store. But users note that there are several negative aspects:

Since the liquid is quite viscous, it cannot be applied to very small parts or thin strokes.

Not every person without experience will be able to draw a pattern with a brush without a stencil. Must have some drawing skills as well as a steady hand.

If a mistake was made, it is quite difficult to carefully erase the wrong area of varnish; it will smudge.

Etching a design on stainless steel with a primer or bitumen

The method is quite painstaking. First, the entire surface to be treated is covered with liquid material. After it dries, take a pen or felt-tip pen, pencil, and transfer the pattern with it. Then you need to take a needle, thin wire or other pointed metal element. With its help, you need to scratch all the details of the design that are not etched. At the same time, pay attention to ensure that there are no chips. Primers of types GF 021, XB 062, as well as the most common bitumen varnish are suitable for application. Typically, the technique is used when it is necessary to apply thin lines, as well as images that are highly complex.

Modern Engraving Techniques

I hope it has become clear to the reader that the old engraving methods can be found very rarely today. We can say that they practically do not do it. Today you can find methods and methods that are more technically advanced and affordable.

Modern solutions make it possible to apply almost any available design to a blade in a short period of time. It is even possible to print a color image. Let's look at modern engraving methods.

Laser engraving and laser sublimation

This method is available almost everywhere; even in a small town you can give a knife away for half an hour and get it back with the necessary inscription or image. Equipment for this engraving method does not cost a lot of money and takes up little space.

The general principle of operation is as follows: a light beam evaporates part of the metal, so that this trace becomes visually noticeable. The equipment can be simple and limited in scope, or it can be more powerful and multifunctional.

Ordinary souvenir shops use CO2 laser engravers; they do not have a strong beam, which is enough to work on wood, plastic or leather. The CO2 label means that the printing is produced by carbon dioxide molecules.

There is equipment to work with the hardest and most durable grades of steel. All these lasers are very good, but they cannot produce a color image. For color laser engraving, you will need the laser sublimation method.

This method involves applying a special printed transfer, which will evaporate using a laser. As a result, the drawing remains on the surface forever. The technology is very interesting and practical.

Laser engraving.

Mechanical engraving

Modern metal engraving is reminiscent of old methods. But this is done with the help of special machines. The cutter is guided along a given course by software.

For hard materials, a diamond tip is used.

For simpler tasks, special attachments for the milling cutter are used. Using this method, you can form relief surfaces and make carved artistic miniatures on the blade. There is a cutter that is controlled by a human hand.

This mechanism is called a pantograph. This method is very common and although it is manual work, it is completely different from the traditional chisel technique. This engraving is possible on any steel and surface. But the cost of such engraving is higher than that of laser engraving.

Mechanical engraving.

Sandblasting engraving

Products processed in this way externally resemble knives made using the old flat engraving technique. Using sandblasting, you can achieve a three-dimensional pattern, since the metal in this case is cut deeper.

A pre-cut stencil is placed on the surface, and then an abrasive device sprays abrasives precisely and in a targeted manner. The object is processed with powder with different particle fractions and under different pressures. By changing these indicators, you can achieve different depths and relief.

Sandblasting.

Artistic electrochemical etching

Using electrolyte liquid and the use of an electrode, you can remove unnecessary metal particles from the surface of the blade. Etching has been around for a long time. Damascus steel has even been counterfeited using this method.

Special patterns were made using the so-called camouflage technique. Part of the blade was varnished, and the remaining area was etched, and thus stains similar to Damascus steel appeared.

There was a way to create a pattern using ultraviolet light. Then the craftsmen learned to use not varnish, but a special film. This method made the work cleaner and is still used today. In addition to the film, the master needs an electrolyte and a constant power source to work.

Under the influence of current, the electrodes tear out metal particles from the surface; such a pattern can be made of any depth. This method is also called galvanic. The method is quite safe for human health and practical in terms of quality.

Electrochemical etching.

Pickling of non-ferrous metals

There are several different metal alloys and individual substances on the periodic table, so numerous are the mordants used. Their effectiveness is often determined by the atomic weight of the element.

The most commonly used non-ferrous metals are copper, brass and bronze. Such acids as hydrochloric, phosphoric and nitric react equally well with them. Chromium compounds in the composition help accelerate the reaction.

One of the few elements that reacts not to an acidic, but to an alkaline environment is aluminum and, accordingly, aluminum alloys. In addition to it, you can call molybdenum. For them, mix caustic soda and add hydrogen peroxide.

It is very difficult to process titanium; it must be prepared in two baths - first with an alkaline solution, and then with strong acids, such as sulfuric and nitric in high concentrations. Thus, oxides are first removed, and then galvanization is carried out.

If you need to etch rarer metals, such as nickel or tungsten, you should mix hydrogen peroxide with HCOOH.

Creation of printed circuit boards

A thin sheet of textolite is used as a blank, which is coated on both sides with a layer of copper. The specialist’s task is to make conductive paths in exact accordance with the drawing. This is quite delicate work. You need to attach some protective material to the lines (usually varnish), and remove the remaining copper foil using tweezers. The following materials are used for etching:

Composition of sulfuric acid, hydrogen peroxide and water.

Copper sulfate with sodium chloride.

This is the case if the liquid method is used. After this, all chemical residues must be thoroughly removed. The electrolytic option is also suitable.

How does the process work for other materials?

Glass is often decorated this way, for example, kitchen utensils, windows, mirrors. The only substance that easily and fairly safely dissolves glass is hydrofluoric acid. Wax and rosin are suitable as a protective coating. Otherwise, all the steps are the same - surface preparation, protecting areas, applying liquid chemicals, removing residues.

Subjects of images and inscriptions

Engraving allows you to make the blade individual and unique. Any ordinary-looking knife can be turned into a work of art with the help of engraving. This is what people are guided by when ordering engraving for themselves or as a gift.

Manufacturers must place marks on the product.

There are exclusive engraving options that are addressed to a person of a certain profession, a hero of the day, or someone who engages in an extraordinary hobby.

An image of the head of a wolf, bear or leopard is perfect for a hunting blade. Hunting weapons are often decorated with floral designs. If a person serves in certain types of troops, he will be pleased to receive a product with the symbols of his service as a gift.

This is very important for FSB, OMON and customs officers. A blade with the image of the organization's coat of arms will be a wonderful gift. You can put a significant date or the name of the hero of the day on the knife. Abstract drawings also look very original.

Examples of sketches for etching.