Home→Household Appliances→How to replace a hexagon at home. How to replace a hex wrench. Tools for making a wooden structure

Fastening elements of many designs require the use of products with a certain type of head. A special place among them is occupied by bolts made with a hex key.

Very often such products are found in the furniture industry. Here they are operated using wrenches type DIN 911. You can purchase them on many construction sites, where their main technical characteristics are indicated.

How to unscrew a hexagon: preparation

Whatever the reasons for the situation when the bolt stops unscrewing, the following steps should be taken before plumbing:

- Before unscrewing the hexagon, to reduce the coefficient of friction, it is necessary to open the bolted fasteners with lubricant such as WD-40, kerosene or brake fluid. You can start unscrewing the bolt 30-60 minutes after application.

- A stuck bolt can be gently tapped with a hammer so as not to further disturb the thread.

- If the location of the fastener allows, you can heat it with a gas burner so that the metal becomes more pliable and rust and dirt turn into ash.

Turning: process features

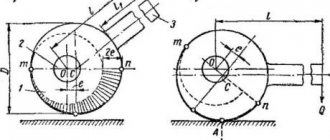

The hexagon is turned from a steel bar on a sharpening machine.

The first main stage of work will be turning a shaft of a certain cross-section from an existing rod. It must correspond to the size of the hexagon that is needed in this particular situation. A caliper will be used for measurements. This is a fairly accurate tool with which you can easily take all the most necessary measurements. So, the workpiece is installed in the lathe. It must be attached on both sides using special holders. By the way, it is worth noting the fact that it is not possible to make a small hexagon using this method. Only a tool of impressive size can be produced at the output.

From the back side, the future hexagon is pressed using the headstock. Now everything is set strictly horizontally, which means you can safely start processing. It can be just rough, or you can bring the instrument to shine. This doesn’t matter, because later you still have to make edges.

So, the machine is started, which means that all that remains is to control all the necessary dimensions. The output should be a rod that has a diameter equal to the size of the hexagon. This is done extremely simply. Most importantly, do not forget to constantly take measurements using a caliper. This is the only way to get a truly correct figure at the end. After the work is completely completed, we can state the fact that the pre-workpiece is ready for further processing. It will be done using a vice and a grinding machine.

Return to contents

All sizes can be measured with a caliper.

So, the turning operations are completed, which means that we can proceed to obtaining the edges. To do this, you should not focus solely on your skill. First you need to make a stencil on paper, which will fully correspond in its geometric parameters to what you want to get at the output. Then it is outlined on the finished shaft. So, all measurements have been made, which means that the part can be safely clamped in a vice. It is completely ready for processing. In a vice it is clamped in a horizontal position.

For grinding, you can use a rough wheel, since you will have to remove several layers of metal.

It is very important to do all the work as competently and accurately as possible. After the work is completed, you can check the edge for compliance with the dimensions. This is also done using a measuring tool. In this case, you can use a regular caliper. If the size does not correspond to the declared values, then it is necessary to adjust it to them. This is done through post-processing.

The hexagon is sanded using sandpaper.

Now you can turn the future hexagon over to the other side and continue sharpening the edges. This will take approximately half an hour. After this, you can check the entire device for compliance with the required geometric parameters. If everything is normal, then the result should be consolidated. For subsequent sanding, you can use regular sandpaper. Be sure to remove all burrs and excess metal. After this is done, you can begin further work. It consists of checking the functionality of the tool. You just need to install the hexagon into the desired bolt and try to unscrew it. If everything was done in strict accordance with the technology, then it should unscrew without any problems.

Of course, the resulting design has several disadvantages. The most important of these may be the incorrect shape of the tool. It turns out strictly straight without any bends. If we talk about a standard hexagon, it is made at an angle of 90 degrees for ease of use. Of course, this drawback will not prevent the necessary bolts from being unscrewed. The resulting tool can be additionally equipped with a handle or simply use pliers to loosen the bolts.

Thus, now you know exactly how to make a hexagon using the tools at hand. As is clear, this process is quite complex, but it is quite possible to carry it out without particularly straining. The main thing is to have all the most necessary tools at your disposal. Of course, you simply cannot do without skills in working with turning tools and a machine. The sanding machine must also be operated correctly. Otherwise, it will be quite difficult to obtain the required tool with the specified quality characteristics. This is where everything comes to its logical conclusion. It is hoped that the resulting tool will serve you for many years.

Is there a pencil near you? Take a look at its cross-section - it is a regular hexagon or, as it is also called, a hexagon. The cross-section of a nut, a field of hexagonal chess, some complex carbon molecules (for example, graphite), a snowflake, a honeycomb and other objects also have this shape. A giant regular hexagon was recently discovered in Doesn't it seem strange that nature so often uses structures of this particular shape for its creations? Let's take a closer look.

A regular hexagon is a polygon with six equal sides and equal angles. From the school course we know that it has the following properties:

- The length of its sides corresponds to the radius of the circumscribed circle. Of all, only the regular hexagon has this property.

- The angles are equal to each other, and each measure is 120°.

- The perimeter of a hexagon can be found using the formula P=6*R, if the radius of the circle described around it is known, or P=4*√(3)*r, if the circle is inscribed in it. R and r are the radii of the circumscribed and inscribed circle.

- The area occupied by a regular hexagon is determined as follows: S=(3*√(3)*R 2)/2. If the radius is unknown, substitute the length of one of the sides - as is known, it corresponds to the length of the radius of the circumscribed circle.

A regular hexagon has one interesting feature, thanks to which it has become so widespread in nature - it is able to fill any surface of a plane without overlaps or gaps. There is even the so-called Pal lemma, according to which a regular hexagon, the side of which is equal to 1/√(3), is a universal cover, that is, it can cover any set with a diameter of one unit.

Now let's look at constructing a regular hexagon. There are several methods, the simplest of which involves using a compass, pencil and ruler. First, we draw an arbitrary circle with a compass, then we make a point in an arbitrary place on this circle. Without changing the angle of the compass, we place the tip at this point, mark the next notch on the circle, and continue this until we get all 6 points. Now all that remains is to connect them together with straight segments, and you will get the desired figure.

In practice, there are cases when you need to draw a large hexagon. For example, on a two-level plasterboard ceiling, around the mounting location of the central chandelier, you need to install six small lamps on the lower level. Compasses of this size will be very, very difficult to find. What to do in this case? How do you even draw a large circle? Very simple. You need to take a strong thread of the required length and tie one of its ends opposite the pencil. Now all that remains is to find an assistant who would press the second end of the thread to the ceiling at the desired point. Of course, in this case, minor errors are possible, but they are unlikely to be noticeable to an outsider at all.

This problem often arises when the hex bolt is torn off and it is not possible to unscrew it with a wrench. The causes of this problem may be the sticking effect, displacement of the parts being fastened, over-tightening when installing hex hardware, as well as the use of inappropriately sized keys.

Whatever the reasons for the situation when the bolt stops unscrewing, the following steps should be taken before plumbing:

- Before unscrewing the hexagon, to reduce the coefficient of friction, it is necessary to open the bolted fasteners with lubricant such as WD-40, kerosene or brake fluid. You can start unscrewing the bolt 30-60 minutes after application.

- A stuck bolt can be gently tapped with a hammer so as not to further disturb the thread.

- If the location of the fastener allows, you can heat it with a gas burner so that the metal becomes more pliable and rust and dirt turn into ash.

How to unscrew a hex or torx bolt

Using an impact screwdriver

It is best to use an impact screwdriver to remove such bolts.

However, she is not always able to crawl up, because the bolt may be in a hard-to-reach place.

Using a grinder and an impact screwdriver

If the edges of the bolt are already torn off, then an impact screwdriver will not be of much help to you.

Therefore, some craftsmen saw through the bolt using a regular screwdriver, and only then, as in the previous method, use an impact screwdriver.

Using a chisel

In some cases, when the edges of the bolt have already been torn off, you can try to unscrew the bolt using a chisel.

By striking in the direction of unscrewing the bolt, there is a small chance that the bolt will give in and come out.

But as practice shows, this method works extremely rarely!

There are other methods, but they are very similar to those described above, so I won’t talk about them, but will move on to a tricky method that I use all the time.

To unscrew a bolt with a broken hexagon, we need a spline cue ball (12-pointed star).

We hammer this cue ball into the bolt.

Then calmly unscrew the bolt.

Thank you for your attention, share the article with your friends, have a good day!

How to replace a hexagon

If the bolt is too tight, it is better to buy a hexagon, as you can tear off the edges and complicate the situation.

There is a hexagon of a different size

If you have a different size hex, you can use it in combination with a flathead screwdriver.

How to make a hexagon with your own hands

It happens that you do not have a hexagon with you or you have lost it. And you urgently need to unscrew, for example, the shock absorber, or the brakes, or the steering wheel. In this case, a hexagon can be made from available materials. For this you will need a nail .

We will place the nail on a hard surface, on which we will make a square head from a round head. To do this, take a hammer and flatten the cap.

Next, use pliers to bend the sharp end of the nail.

This simple hexagon can be made in just 5 minutes.

- Irina on New Balance 574, 999, 996 how to spot a fake

- Maria on How to distinguish the original Givenchy Ange ou Demon perfume from a fake

- Gennady on How to distinguish original Salomon Speedcross 3 sneakers from fake ones

- Alice on LOL Confetti Pop how to spot a fake

- Pavel on How to spot a fake IMCO lighter

Privacy Overview

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category “Analytics”. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category “Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies are used to store the user consent for the cookies in the category “Necessary”. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category “Performance”. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedback, and other third-party features.

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

How to unscrew a broken hex bolt

To unscrew a protruding hex or star bolt, you can use the following methods:

- Using a hacksaw or a grinder, make a neat and clearly vertical cut across the screw head. After these steps, you can unscrew it with a regular flat-head screwdriver.

- Using a Torx star: you need to drive it into the recess for the hex key in the hardware head. The size of the sprocket should be such that its splines do not fit into the hole. Then the hardware is unscrewed with a sharp jerk. It is not recommended to use a Torx with a hole in the center; the sprocket can break off.

- Before unscrewing the hexagon with torn edges, a drill with drills and extractors is used to drill a hole in its center. After this, the extractor is driven into it, then pulled out with pliers along with a hex screw.

- Using a drill with reverse rotation, a thin hole is drilled, then a hammer is inserted into it with left rotation and the fasteners are unscrewed. In this case, the rotation of the drill should be slow and the pressure should be strong.

Unscrewing the internal hexagon

If the edges are knocked down, you can use a needle file, with which you just need to bore the hex hardware corresponding to the size of the existing key. It is also possible to use Torx.

With its help, you can make new splines and reapply hardware. However, it must be taken into account that in the future such a bolt can only be unscrewed with a Torx asterisk.

If you don’t have a hexagon at hand, you can use alternative methods. However, you need to take into account that they are not universal and can damage the structure, which will ultimately lead to its replacement.

Alternative methods are ideal for unscrewing, but they are extremely difficult to tighten the bolt properly. Therefore, you should resort to them only in extreme cases.

Brickwork technology

The next step after the foundation will be brick laying. It is made from both ordinary and facing bricks (in the first case, the appearance will suffer).

If you use bricks of different colors, you can give the gazebo a decorative and sophisticated look.

The bricks are laid on cement mortar using a trowel. The cement mortar consists of:

- 1 part cement M400;

- 3 parts sand;

- water (added as needed).

To give the building a complete look, you can use figured lattices as decoration, as well as decorative architectural elements. If wood products are used, they must be impregnated with an antiseptic to prevent rotting and mold. Products can also be varnished.

As you can see, if you try hard, you can achieve the desired result, and then the gazebo will become a source of pride, and using it will bring a lot of joy and pleasure.

Causes

The occurrence of such problems can be due to various reasons. “Sticking” of the material occurs:

- Due to the fact that the fastened parts were displaced.

- As a result of excessive “tightening” of the bolt during initial installation.

- Due to corrosion of the fastener head and the appearance of rust.

- Due to the use of inappropriate tools (for example, instead of a 13 key, a 14 key is used and a screwdriver is placed under it, which leads to “licking” of the bolt edges.

Wrench sizes

Typically, all of the above types are sold in sets with different sizes and diameters. Let's say the small ring key from the set has a ring of 2−4−6−8−10−13−15, and the hexagon and dodecahedron are only even: 4−6−8−10−12−16 and so on. Wrench, socket and tube tools have the same dimensions as ring wrenches. Depending on the type of set, there may be devices for both larger and smaller nut sizes. The same goes for sliding and gas keys. They have their own numbering, and each of them covers only a certain diameter. The main thing is to be able to choose the right ones for you.

Main characteristics

A hex bolt is a type of fastening tool, characterized by an internal head in the form of several edges. This allows it to be made with the same diameter as the main rod.

Such bolts are used in various fields:

- the furniture sector is used to fasten several parts into one;

- complete set of plumbing mechanisms. The hexagon can often be found on the mixer, which secures the main handle, etc.;

All types of such fasteners also have a peculiar division according to standard sizes. For each of them, a corresponding key is standardized, often having a curved shape in the form of the letter “G”.

Types of wrench tools

Recently, the types of products for working with nuts have begun to expand significantly. This is how improvised means appear for more comfortable use or those that can penetrate hard-to-reach places. The modern market has more than 20 types of tools for unscrewing and tightening nuts. Despite this, the main types are:

Nut - the name speaks for itself - this is the first representative of all types of means for unscrewing and screwing. Actually, it serves to unscrew or tighten the nuts along the threads. Usually it is simply placed on top or brought to the side of the nut. The tool has a comfortable handle and a U-shaped clamp.

Bottom line

If you implement these instructions as carefully as possible, the hexagonal gazebo for your dacha will become a favorite place for relaxing in the fresh air. You can also watch the video in this article, in which you will see the nuances on how to make a hexagonal gazebo with your own hands.

Currently, a hexagon is one of the most indispensable tools in the process of carrying out certain repair work. Many modern bolts are equipped with heads of this particular type, so it is simply not possible to unscrew them with a regular open-end wrench. Not every person has a hexagon at home. If you urgently need it, then the question arises, how to unscrew the bolt if the tool is not available. You can use various improvised means instead of a hexagon, but this is not always convenient. It's better to go a little different way. We will talk further about how to make a hexagon yourself.

Hexagons are used for loosening and tightening bolts when repairing and assembling furniture.

How to unscrew a screw with a screwdriver

Often the situation with bolts and screws confuses the owner, because not everyone knows how to unscrew a bolt if it does not come out .

When there is practically no access, you can make a notch with a chisel or grinder. After this manipulation, unscrewing the bolt with a screwdriver will be quite simple.

Although in some cases this does not give the desired result, then you can take the same screwdriver, placing it at an angle, and lightly tap it. But this must be done so that the bolt begins to rotate.

How to do without a hexagon?

First of all, you can use a screwdriver of a certain size. In this case, you should rest its edges on opposite sides of the groove and try to turn or tighten the bolt. Bolt with a set of nuts. They are screwed onto the thread and placed inside the hexagon.

What can you take instead of a hexagon?

- First of all, you can use a screwdriver of a certain size. .

- Bolt with a set of nuts. .

- As a tool, you can use a triangular file of a specific size or an “asterisk”.

What can replace the small hexagon?

- Grind down the sides of a regular screwdriver so that it fits tightly into the hexagon

- You can make a cut for a flat screwdriver (grinder or file) to unscrew it with a screwdriver.

- A screwdriver wrapped tightly in cloth or rubber will help.

- Select a suitable file with 3 edges

How to unscrew a hexagon socket bolt?

Internal hexagon with torn edges

You can unscrew a bolt with an internal hexagon by boring a hole to the next larger size. Boring is done with a needle file. Another way is to use a Torx star. Use an asterisk to punch out new splines and unscrew the fasteners.

How to unscrew a bolt if there is no hexagon?

- If the size of the bolt is not too small, you can use a chisel or an ordinary hammer: they strike at an angle in the direction of unscrewing the fastener.

- Method using a spanner or gas wrench.

How to unscrew if there is no star screwdriver?

Another option is to use a toothbrush. Melt one end of it with a lighter, then immediately insert it into the recess on the screw head. After waiting a bit for the melted plastic to harden, turn the brush counterclockwise. Of course, this will not help if the screw is tightened too tightly.

What can replace a wrench?

- Pliers

- adjustable wrench

- Files

- Small vise

- Calipers

- Wooden strip and nylon tape

- Hammers

How to replace the Ikeevsky key?

A bent IKEA key (time waster) successfully replaces a T25 Torex inserted into a drill at low speeds

How can I unscrew the star bolt?

If the “star” is internal, then you can make a straight cut using a flat screwdriver; you will need a hacksaw, or an angle grinder with a cutting disc, or a sharp chisel, the same hammer, VD-40, and a screwdriver. In the most extreme case (nothing helps), the bolt can be drilled out; here you need a drill and metal drill bits.

How to replace a hex wrench?

- First of all, you can use a screwdriver of a certain size. .

- Bolt with a set of nuts. .

- As a tool, you can use a triangular file of a specific size or an “asterisk”.

What are the sizes of hexagons?

hexagon sizes (S): from 0.7 (mm) to 36.0 (mm); total key length (L): from 33.0 (mm) to 391.0 (mm); key handle length (l): from 7.0 (mm) to 176.0 (mm).

How to use a hexagon?

- Selecting a hexagon that matches the type and size of the fastener.

- Inserting one side of the hexagon into the internal hole of the part so that it occupies the entire depth. .

- Applying a load to the tool and gradually increasing it until a torque is reached.

How to unscrew a licked hex bolt?

If the hexagon is small, then you can hammer a TORX sprocket of a suitable size into it and unscrew it. If the head is accessible, then you should try to unscrew the screw using pliers, a gas wrench or a hand vice. If you have space, a hammer and chisel almost always helps.

How to determine which direction to unscrew the bolt?

Regular bolts and nuts are unscrewed counterclockwise and tightened clockwise.

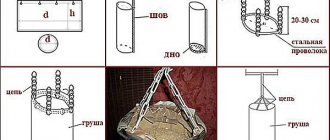

Cutting metal strip

The first thing to do is measure the length of the edge of the hexagon for which you need to make a key.

We multiply this size by six (the number of edges), and we get the length of the metal strip that needs to be cut.

I recommend adding 6 mm to the resulting length (which I didn’t do), then it will be easier for you at the next stage of manufacturing.

The plate should be wider than the height of the bolt for which you are making the key (a couple of millimeters is enough).

Preliminary preparation

First, it is imperative to carefully prepare for the further implementation of the entire complex of events. First you need to prepare all the necessary tools. You also need to select a rod of the highest quality so that it is able to withstand the load that the hexagon takes on during operation.

So, all the most necessary cutters should be at the workplace. Of course, you can’t do this without a lathe. The work ahead is delicate, so you should choose the highest quality cutters. Now it’s time to prepare a stencil that will mark the side face of the hexagon. After all, you will have to make a full-fledged tool from a round shaft. You will need a brush to remove excess iron filings.

These are all the preparatory works that need to be done before further work can be carried out.

Return to contents

Welding hexagonal shape

Now all that remains is to weld the part into one. (In my case I used a 2.5mm welding electrode)

After this, you need to try on the nut again, and if everything fits, you can fill the cuts with welding. (3.2 mm electrode).

We try to put it on the nut again, because the high temperature during welding can deform the metal.

(This time I additionally tried the blank on the hexagonal protrusion on the filter.)

After this, you can clean up all the excess, making the shape of the part smoother.