Somehow I had a need for tar: voles started running around in the garden, the Colorado potato beetle was infested, and the wooden shed needed to be tarred. The pharmacies only sold small tubes of tar; they definitely wouldn’t have been enough for me. Remembering how to make birch tar at home, I went to the forest, collected birch bark and tried it the next day. There was a lot of tar, I had enough for everything and still had some left.

Source womond.com

What is it used for?

When figuring out how to make birch tar with your own hands, you should start with why it is needed in the first place.

Tar is a liquid obtained by dry distillation of wood. Birch tar is boiled in special retort pots made of birch bark. The composition is thick, oily, but non-sticky, has a black color with a greenish or bluish tint, as well as a specific odor. The latter is especially noticeable at high tar concentrations.

It is worth noting that if the tar is sticky, then it contains another resin, for example, pine. Birch tar does not stick.

Birch tar is used in various fields:

- In the garden: it protects against the Colorado potato beetle, mosquito, mole cricket, ants, aphids, flies, rodents, hares, mice and other insects and pests. It is noteworthy that the tar does not kill them, but only drives them away;

- For impregnation of wooden products and lubrication of parts;

- As a wheel lubricant;

- Like glue;

- To protect leather products: in Rus', boots and harnesses were lubricated with tar so that the latter would not rot, dry out or tan at low temperatures;

- As a raw material for subsequent processing;

- Tar is a natural antiseptic that disinfects humans well;

Source otnogi.ru

- When choosing how to prepare tar at home, it is worth remembering that it is also used in medicine. Use the product only externally, in pure form or as part of preparations. In folk medicine, tar can be used internally, but it is better not to do this: tar contains carcinogens. The latter cannot be removed, since the beneficial properties are also lost;

- In veterinary medicine, the remedy is used for lichen; it is used to treat the hooves of cattle.

What does birch tar treat?

Due to its unique chemical composition, the product has a huge number of medicinal properties. However, for the most part it is used for external use as an anti-inflammatory, regenerating and antipruritic agent.

What else does tar help with when used externally or internally? The list is quite extensive:

- psoriasis;

- haemorrhoids;

- mastopathy and mastitis;

- cancer;

- opisthorchiasis;

- prostatitis;

- cutaneous mycosis;

- seborrheic dermatitis;

- helminthic infestation;

- nail fungus;

- scabies;

- vitiligo;

- papilloma;

- uterine fibroids, cervical erosion and a number of other gynecological diseases.

Birch tar effectively destroys pathogenic microorganisms, soothes irritations, eliminates swelling, bruises and compactions. It is not for nothing that the familiar Vishnevsky ointment contains birch tar.

Preparing to produce tar at home

You can easily buy tar at a pharmacy or make it yourself. The second option is preferable, since the result is a pure natural product. The production of tar is called tar smoking or tar smoking. This is an old production: in Rus' they have been doing this since the 12th century.

In industry, the production of the substance is a simple process: birch bark is placed in closed devices where air does not enter. heated to +250-300 degrees, after which the birch bark begins to decompose into water, gases and tar.

Birch bark itself is mined in different ways:

- They use leftovers from a wood processing plant. When peeling blanks, the birch bark is removed and given away. This is an inexpensive and profitable method.

- The top cork layer is removed from the growing tree. The bast layer is no longer suitable. This is a labor-intensive and expensive process.

Source rusunion.com

Making tar at home begins with removing birch bark using the second method. Anyone can use it. It is important to remove bark correctly for tar:

- It is necessary to use a special cutter knife with a limiter. This device allows you to remove only the necessary top layer, which will grow back in a few years without damaging the tree.

- You can make preparations until the fall, but most often it is done in the spring, when the juices begin to flow. At this time, the birch bark is easily separated. Most often this time falls at the end of May and lasts up to 40 days.

- Birch bark is removed from trees 50-70 years old at a distance of 3-4 meters from the roots. The diameter of the trunk must be at least 12 cm.

- It is not advisable to cut down trees. In industry, birch bark is usually removed from trees that will be cut down in a few years.

To obtain 0.5 kg of tar you will need 2-2.5 kg of birch bark. It is necessary to make an incision at the top and bottom, then pull off a strip of bark.

The raw material for this production is the outer layer of birch bark: white, flexible birch bark, otherwise called rock. It differs sharply in physical and chemical properties from the bast layer - greenery, and even more so from the trunk part of the tree. According to V.I. Sharkov, the composition of birch bark is characterized by the following data (Table 14).

| Table 14 Composition of birch bark in% Birch punishment | Ash | Aqueous extract | Alcohol extract | Me - current - strength | Volatile acids | Cellulose | Hexo - zany | Uranic acids | Pen- That- Zany | Suberin | Lignin |

| Birch bark | 0,52 | 4,49 | 24,78 | 2,59 | 1,1 | 3.85 | — | 2,2 | 4,8 | 34,4 | — |

| Oak . | 2,42 | 21,80 | 13,1 | 3,2 | 0,77 | 19,3 | 5,1 | 7,35 | 12,5 | 0 | 24 |

Birch bark is prepared in various ways, which greatly affects the yield and quality of the final product - birch bark tar. The best raw material, “sap” birch bark, is harvested during the sap flow season: practically in April and May. To determine the beginning of the harvest, a small triangle is cut on the birch bark with a knife. If the corners of the triangle move away from the bast and begin to curl, then the time has come for collection, otherwise you should wait a few more days.

Birch bark without bast is removed from growing trees. A suitable forest stand is considered to be birch forests aged 40-60 years with a diameter at chest height of at least 10-12 cm.

A special “mower” - a knife equipped with a depth limiter - makes an incision along the trunk to a height of up to 4

m.

Birch bark

in the form of a hollow

cylinder is easily separated from the bast. If the knife, having cut through the gap - laziness, does not touch the cambial layer, this operation is almost painless tree.

In place of the removed birch bark, a new, thin brownish “barma” grows, unsuitable for reuse, but providing life to the tree. The production rate of raw birch bark is 100-150 kg

per working day, in some cases, with high-quality stands and well-organized work, up to 400

kg.

The average yield is 1.5

tons

per 1

hectare

of pure birch forest (from 400 to 2500

kg).

Birch layers are dried in bundles or heaps and then pressed using primitive installations - “bagasses”.

1

m3

of raw material (

Oy

= 20%) of unpressed birch bark weighs 90-100

kg,

pressed 140-150

kg.

Deadwood birch bark is collected from littered or burnt forests (fallow birch bark). Birch bark is preserved because it is very resistant to fungi and bacteria compared to the stem and bast.

This type of raw material is secondary. Close to it in quality is birch bark, removed from ridges at plywood factories.

The worst raw material for tar smoking is birch bark, removed from firewood. They remove it with a special curved two-handed knife - a stapler. Debarking in this way 1 cl. m

3 birch firewood requires up to 8 hours to remove more or less clean birch bark, and about 2 hours to remove the bark as a whole (birch bark and bast).

Exit from 1st cell.

m3 of firewood: pure birch bark 8-15

kg,

birch bark with bast up to 40

kg.

On average, the yield of birch bark from sanding is about 14

kg.

Almost regardless of further technology, sap birch bark produces 27-30% by weight of grade I tar = 0.925-0.950, deadwood 25% grade II d20 = 0.950-0.970, wood-burning (from sanding) 13-20% grade III D 20 =

0,980—0,990.

The technology for processing birch bark consists of its thermal decomposition without air access in devices heated by bare fire in metal cauldrons - rectangular retorts.

The cauldrons are made riveted or welded from three-millimeter iron with a geometric capacity of 0.68 m3,

into which 0.5–0.55

m

3 (75–80

kg)

of birch bark is placed. The cauldrons are lined in a simple stove device, heated by a grate firebox. The vapor-gas mixture is cooled in a tubular refrigerator. There is a small collection tank for collecting condensate, and a wooden settling tank for settling. The pressed birch bark in bags is placed vertically in the cauldron through the loading door. The door is sealed. In the first period, until drops of distillate appear, the process is carried out intensively, then until the end - moderately, as the raw tar is released.

The tar is left to stand from tar water for 2-3 days if the raw material is of good quality. After settling, the tar water is drained, and the finished commercial tar is poured into containers: preferably into aspen barrels enameled with animal glue. When processing wood birch bark, settling slows down significantly (7-10 days) and sedimentary birch resin falls out.

The turnover of the cauldron is about a day, of which the process itself takes about 80% of the time. Thus, in one cauldron you can process about 2.5 tons

cart - stuffy dry birch bark. It should be noted that usually tar installations consist not of one cauldron, but several (4-8-16), lined in one masonry.

The consumption of fuel wood can be taken as 5 cl. m3

for 1

t

of birch bark.

| III |

The resulting tar must meet the requirements (OST 2098) given in table. 15.

Table 15

Requirements for tar

Variety

Indicators

Specific gravity……………………………………..

The acidity of the aqueous extract (in terms of acetic acid) in % is not higher

Acidity coefficient….

Saponification number……..

The essential number is not higher than………………………

No more than % of substances insoluble in petroleum ether. . . .

| 0,925-0 ,950 0,5 15-25 36-60 45 |

| 0 ,950-0,970 1,0 Up to 35 up to 85 53 8 3 |

Content of tar water in % no more than

There are also simple methods for determining the quality of birch bark tar. Among them, we will mention two that allow us to detect an admixture of wood pyrogenic resin, which is quite common in practical conditions.

1st method. Shake a small amount of tar (20-10 g) in a glass of clean water. In the presence of tree resin, the water turns brown and tar sticks to the walls. With pure tar, the water is almost not colored and is easily separated.

2nd method. A drop of tar is placed on porous paper (filter paper, unglued newspaper). Pure tar

The percentage of resin acids in pine resin immediately after it leaves the tree is as follows: D

— pimarovaya 10, / — pima — rova 30; a - sapinic 55, (3 - sapinic 5%. The structure of all resin acids is based on the phenanthrene ring. The structural formulas of the main resin acids of oleoresin are given below.

| CH3 coon |

| CH3 coon |

| Denstropimarovaya nyslota Levopymarobaya nyslota. Tmelting2F? °C T melting >50 "C SOON OS - sapic acid, |

The structural formula of abietic acid is presented in two versions. t

Sich GOUN

| LbaegpinaVaya naslotp. |

| In addition, neoabietic acid, CH3 COOH |

| /CH3 |

CH3

Neoadium/lino3pn acid

As well as products of hydrogenation and disproportionation of abietic acid:

| CH-. soon |

| S n 1 |

| Tetrahydroabiesic acid |

| CH3 coon |

| Migrobietic acid |

CH -1 COOH

| CH3 |

| DehydroabietinoVar Nislota |

| CH3 |

When abietic acid is dehydrogenated with sulfur or selenium, the hydrocarbon retene (1-methyl-7-isopropylphenane - tren) is obtained.

| Sn z I WITH |

Solved

As can be seen, oleoresin resin acids differ from each other mainly in the placement of double bonds. In addition, they have different melting and boiling points and differ from each other by unequal optical activity.

Physico-chemical parameters of rosin according to GOST 797 - 55 are given in table. 17.

Rosin as a technical product is an amorphous, hard, brittle substance, with a characteristic conchoidal fracture and glassy sheen.

Table 17

| Physico-chemical properties of rosin Rosin variety | |||

| Property | Higher | First | Second |

| The color is not darker than the color of the standards…………………………… | Svetly | Yellow or orange | Dark |

| Moisture content in % no more than…………………………… | 0,3 | 0,4 | 0,5 |

| Ash content in % no more than……………………………. | 0,05 | 0,05 | 0,07 |

| The content of mechanical impurities in % is not | 0,05 | 0,10 | 0,10 |

| Softening temperature in °C is not lower. . | 69 | 65 | 52 |

| Acid number is not less than………………………………….. | 168 | 166 | 150 |

| The content of unsaponifiable substances in % is not more than….. | 6,5 | 7,5 | 10 |

Good quality rosin is light yellow or almost colorless. The lower grades of rosin are highly colored, barely translucent, with black-brown and ruby-red hues. The color of rosin is determined by comparing (in transmitted light) a sample of rosin in the form of a cube with an edge size of 22 mm

with a cube of the same size on a standard scale that contains four standards.

Standard scale for determining the color value of rosin

Reference Reference color

Light…………………………………………………………… Pale yellow

Yellow…………………………………………………. Yellow

Orange……………………………………………. Orange

Dark…………………………………………………. Ruby red

Rosin dissolves well in the cold in methyl and ethyl alcohols, ether, chloroform, acetone, carbon disulfide, carbon tetrachloride, trichlorethylene, acetic acid, benzene, toluene, xylene, aniline, essential and fatty oils, and partially in gasoline and kerosene petroleum products.

Rosin is insoluble in cold water, but partially emulsified in hot water.

When stored in air, rosin absorbs oxygen. Ground rosin oxidizes very quickly. If it is in barrels, then the absorption of oxygen is very weak. Rosin dust mixed with air forms an explosive mixture. Rosin is not a chemically homogeneous substance. Therefore, its physicochemical characteristics are of a group nature.

The specific gravity of rosin ranges from 1.070 to 1.085. Heat capacity - 0.54 kcal/kg ■ deg.

When burning, 1

kg

of rosin releases 9074 - 9171

calories

of heat.

Rosin burns with an even, smoky flame. Its thermal conductivity is 0.11 cal1m-hour

°C.

Heat of fusion 15.8 kcalkg.

The heat of evaporation of rosin, depending on the residual pressure during vacuum distillation, is:

Residual pressure in mm

RT. st 2 4 b 10 15 20 30

Latent heat of evaporation (kcal1kg)

40,4 40,7 41,1 42 42,8 44 46

The coefficient of volumetric expansion of molten rosin, according to Kollerov’s calculated data, is 0.00055. From here, the dependence of the specific gravity of liquid rosin on temperature is determined

<*, = </„-( 1 -0,000550-

The viscosity of rosin depends on temperature. In addition, the viscosity value is affected by the composition of rosin, the degree of isomerization and oxidation of resin acids. In table 18 shows the viscosity of different types of rosin in degrees Engler.

For cable rosins, electrical conductivity is of greater importance. Insulation resistance (in ohm/cm)

at a temperature of 110° it should be at least 200-1010. Since cable rosin is obtained by polymerization with sulfuric acid, its sulfur content is determined according to Eschka. As a percentage of the weight of rosin, sulfur should be no more than 0.015 (Time

| Table 18 Temperature, °C | Viscosity of rosin, °E | ||||||

| Zhivichnaya | Extraction room No. 6 (.Vakhtam") | Abietic resin No. 7 (Tikhvinsky) | |||||

| Tikhvinskaya No. 1 | Gorkov-skaya 2 | No. 3 from China | No. 4 from China | Kyiv No. 5 | |||

| 110 | 119,0 | 79,7 | 82,2 | 10«,1 | 101,0 | — | — |

| 120 | — | 38,8 | 33,5 | 26,3 | 45,2 | — | |

| 130 | 23,0 | 11,2 | 14,0 | 12,0 | — | 25,4 | — |

| 140 | — | — | 7,2 | 6,5 | 4,4 | 12,4 | — |

| 150 | 4,5 | 1,7 | 3,1 | 2,8 | 3,0 | 6,6 | — |

| 160 | — | — | 2,4 | 2,0 | 2,2 | — | 77,6 |

| 170 | — | 1,6 | 1,7 | — | — | 2,4 | 17,0 |

| 180 | 1,8 | — | 1,5 | 1,5 | — | b7 | — |

| 190 | 1,4 | 1,5 | — | 1,4 | -— | 1,5 | — |

| 200 | — | — | 1,4 | 1,3 | 1,4 | 1)4 | 3,1 |

| 210 | 1,3 | 1,2 | 1,3 | 1,2 | — | — | — |

| ‘220 | — | — | 1,1 | 1,1 | — | — | — |

| 225 | — | — | — | — | — | 1,3 | — |

New technical specifications for cable rosin VTU 779-57).

When heated for a long time to 250-300° and above without access to air, rosin decomposes to form a number of liquid products called rosin oil.

An important technical property of rosin is its interaction with alkalis according to the equation

C19 H, e COOH + NaOH = C1E H2E COONa + H2 O.

The resulting salt, sodium resinate, is soluble in water and is called rosin soap. Calcium rosin soap is insoluble in water.

The acid number shows the amount of acid in rosin. It is expressed in milligrams of KOH used to neutralize 1 g of rosin. If rosin consisted entirely of resin acids of the formula C2oH3o02, then the maximum acid number would be 185.4. In practice, the acid number of rosin ranges from 140 to 180.

Saponification coefficient is the number of milligrams of KOH used to neutralize all acids, both free and bound, contained in 1 g of rosin. The acid number is determined by titrating an alcohol solution of rosin with alkali in the cold, and the saponification coefficient is determined by boiling an alcohol solution of rosin with an excess of alkali. The saponification coefficient of rosin ranges from 150 to 200.

Rosin forms esters with both monohydric and polyhydric alcohols. Most often, glycerin ether of rosin is obtained by treating molten rosin with glycerin at high temperatures (280-300°). The reaction proceeds according to the following scheme:

CH2OH NOOCH29C(9 CH2OOCH29C, g

SNON +■ NOOSNgdS, d

—»- SNOOSN 2g Cig + 3H20

CH2OH NOOCH 29 C ig CHOOSNgdC^

To give rosin stable properties, it is hydrogenated. Hydrogen is added via double bonds (see structural formulas of rosin acids, pp. 184-185). In addition to resin acids, which are the main component of both resin and rosin, they contain in small quantities:

1) water-soluble bitter substances that can easily oxidize in air, giving dark-colored products that give rosin a dark color;

2) neutral hydrocarbons with the composition C20H30 (diterpenes), with a boiling point of 270-360°C;

3) resenes - high-molecular inert substances of a hydrocarbon nature, very resistant to chemical reagents, insoluble in alkalis, but soluble in organic solvents.

The liquid part of oleoresin - turpentine (TuH^) is a natural essential oil. Depending on the growing conditions of the plantings, as well as on the methods of production, the composition of gum turpentines can be far from the same. In table 19 shows the composition of turpentine from common pine resin.

| Table Vj Composition of turpentine from Scots pine resin Turpentine components | Content of turpentine components in % according to data | |||

| Arbuzova (1929) | Christening- Skogo (1931) | Pigulev-sky (1950) | Bardyshsva (1951) | |

| A-Pinen………………………………… | 81 | 68-70 | 76,5 | 62,68 |

| (5-Pinene………………………………. | — | — | — | 6,36 |

| A3-Karen……………………………. | 14,3 | 14,9 | 13,67 | 28,82 |

| /-Terpene………………………………. | — | — | 6,87 | |

| Camphene…………………………….. | — | 5,0 | — | — |

| Limonene with dipentene…………….. | — | — | — | 3,73 |

| Higher fractions (phellandrene, sesc - viterpenes, etc.)………………………. | 4,7 | 15,1 — 17,1 | 1,20 | 5,41 |

Novena according to research by various authors, and in table. 20 - composition of turpentine from the resin of many coniferous trees.

| Table 20 Composition of turpentine from softwood resin Breeds | Content of components in%: | ||||||||

| A - Pnnen | Kam - hairdryer | Pinen | World - prices | D'-ka-ren | Limonene | [Z-fel lun - drsn | Boron-nil-acetate | Remainder | |

| Common spruce. . | 40,0 | 40,0 | 33,0 | 10,0 | 10 | 10,1) | — | — | 7,0 |

| Siberian cedar. . . | 69,0 | — | 7,0 | 2,0 | 17 | 2,0 | — | — | 3,0 |

| Siberian fir. . . | 25,0 | 19,0 | 8,0 | 2,0 | 8 | Eat | 18 | 15 | 5,0 |

| Daurian larch. | 50,0 | — | 25,0 | 15,0 | 15 | — | — | — | — |

| Crimean pine. . . | 83,7 | 4,0 | 2,5 | 0,7 | — | 1,4 | — | — | 4,6 |

| Austrian pine. . | 86,4 | 2,4 | 1,9 | 1,6 | — | 4,4 | — | — | 3,3 |

The main component of turpentine is a-pinene. This is one of the widespread terpenes in the plant world; a-pinene boils at a temperature of 155-156°. It occurs in dextrorotatory and levorotatory forms; specific gravity 0.8518. Relatively easily subject to isomerization and oxidation, a-pinene is the starting material for the synthesis of camphor. D3-Karen boils at a temperature of 172-172.5°. Rotates the plane of polarization to the right [a]d +1b°. Both dextrorotatory and levorotatory D3-carene were found in osmolal turpentines.

D3-Karene is easily oxidized by atmospheric oxygen. Specific gravity - 0.8616.

The structural formulas of the main terpenes included in the composition of gum turpentines are as follows:

| AC - piney L 2 - paren D - pinene |

The qualitative composition of the hydrocarbon part of turpentines obtained from the resin of spruce, Siberian cedar and Daurian larch is almost the same and is similar to the composition of turpentine from Scots pine. The composition of gum turpentines includes in small quantities terpene alcohols of the general formula C10H17OH (terpineols, fenchyl alcohol, etc.). Physico-chemical parameters of turpentine oil according to GOST 1571 - 54 are given below:

Color, expressed by the number of milliliters of potassium dichromate solution, not more than....

Specific gravity <1st within……………….

Refractive index n'{° within. .

Initial boiling point in °C not less than.

Distillation volume at temperatures up to 170° in % not less than

Residue from evaporation in % but not more than by weight

Acid number no more than……………………

Turpentine mixes easily with most organic solvents, as well as fatty oils and salts of fatty and resin acids. When stored in light, especially in glass bottles, turpentine oil oxidizes, releasing a sticky, resinous sediment.

Turpentine oxidation products: verbena ketone (CiuH40); alcohol verbenol (CuH^O).

When exposed to sunlight, turpentine produces the alcohol sobrerol (CioHisO). The specific gravity of gum turpentine is usually taken to be 0.86. As the temperature increases, it decreases noticeably:

Temperature in “C……………………… 40 60 80 100

Specific gravity of gum turpentine. . 0.84 0.83 0.81 0.789

The latent heat of vaporization of turpentine is

68—70 kcalkg.

Viscosity at 20° is 1.49

spz,

and at 100° -

Only 0.35. Specific heat capacity 0.45–0.47 kcal/kg ■ deg

And the thermal conductivity of turpentine is 0.117

kcal/m • hour.”

Related posts:

- LED strips for home use

- Omsk news

- Online converter

- Why do we need monitor reviews?

- Events that everyone is talking about on the Internet

Manufacturing process

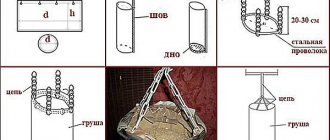

First of all, you need to prepare the containers. You will need two dishes:

- Small for collecting finished tar;

- More for birch bark. The container should have a tight-fitting lid and a small hole in the bottom through which the tar will flow out.

The larger container must be connected to the smaller one so that there are no gaps or holes between them. Air should not pass inside the large container.

Source blogspot.com

Next you need to make a fire. When figuring out how to get birch tar at home, don’t forget about safety. You need to make a fire in an open area away from fire-hazardous buildings. They dig a hole in the ground, place a small dish inside, a large one above it, and cover them with firewood. Shredded birch bark is placed inside the latter and closed with a lid. To prevent air from getting inside, the lid is pressed down with a brick or the joint is covered with clay. The lid can also be covered with firewood so that the heat comes from everywhere.

Now all that remains is to light the fire and wait. The process will begin when the temperature inside rises to +650 degrees. Tar will begin to separate and flow into the pan below. When finished, you need to let it cool, then pour it into a storage container and you can use it. A dark glass bottle with a tight-fitting cap is suitable for storage.

It will take several hours to obtain birch tar: at a temperature of +600-650 degrees it will take 1.5-2 hours. Burnt birch bark can be used as birch coals.

You can see clearly how the tar production process occurs in the video

Birch tar: application in veterinary medicine

In veterinary medicine, tar-based shampoos, emulsions and oils are mainly used. These remedies quickly eliminate itching and help get rid of lichen, seborrhea, mites, lice, nits, fleas and other parasitic insects.

Birch tar has an unpleasant odor only during use, but on animal fur it reveals the aroma of wood and bark. To avoid harm to your pet, strictly follow the instructions and follow the veterinarian's recommendations.

How to get it?

Now you know enough about what tar is like and how to use it correctly. This means we can tell you how tar is made.

As an example, let’s consider the simplest option, which does not require special knowledge, skills, rare raw materials and expensive equipment. At the same time, the output can be obtained from environmentally friendly and maximally safe raw materials.

So, how to get birch tar?

First you will need birch bark or birch bark. It is quite easy to collect it in almost any deciduous forest. True, this should be done carefully - it is better to remove a little bark from a dozen birches than to strip one - in this case the tree will be doomed to death.

It is advisable to remove the bark in long strips that are not too wide (about 3-5 centimeters). When you have enough, you can proceed to the next step. To do this, you will need several cans of canned food - you almost always have them on a hike. Yes, and along the picturesque banks of rivers and lakes, alas, you can almost always pick up in sufficient quantities.

You will need three cans: two high and one low, wide. This is the most convenient way to work. To start, take a wide one. Bend the bottom a little - just press with your palm or a stone - and then make several small holes in it with a knife.

Then place the birch bark as tightly as possible in one of the free jars. Dig a small hole, preferably in wet sand or soil. Place a flat jar in it so that the concave side with holes faces down into the buried jar. Now carefully bury them so that only one plane with holes remains on the surface. Place the jar with the birch bark open side down on it. Fix it (you can also dig it in slightly) and build a small fire on top. Due to the lack of air, the birch bark will not ignite, but will simply heat up, releasing valuable tar. It will flow down and end up in an empty jar buried at the very bottom.

As you can see, the mechanism is quite simple and can be used in any conditions.

Harm of tar

Any tar poses a certain danger. Even pure birch applied to the skin of the face can lead to various problems. But those extracted using complex chemical methods are much more dangerous. For example, tar extracted from oil poses a danger even during normal storage. It is enough to inhale the vapors emanating from it to get serious poisoning.

Therefore, it should be handled with the utmost care. As mentioned above, when applied to the face, natural wood tar must be diluted with any cream. Then it lasts a very long time, acquires a pleasant smell and will not cause skin problems. Well, most people are not familiar with complex chemical analogues. Anyone who encounters it at work already knows perfectly well the rules for safe handling.

Myth three. Adenoma is a precancerous condition.

An adenoma, which is a benign hyperplasia (tumor) of the prostate gland, has nothing in common with cancer. These are two different diseases. Another thing is that their symptoms are largely similar. First of all, this is a violation of urination, which is expressed in frequent urges that occur with monotonous consistency at night. The final period of the disease is sad: the bladder is so blocked by the tumor that it stops emptying completely. Therefore, if you feel that your bladder is not emptying completely, if you urinate intermittently for several minutes, if the pressure of your stream is weak, there cannot be two opinions. Hurry to the doctor! Otherwise, you risk developing a complication that is fraught with acute urinary retention and the urgent installation of a special cystostomy drainage tube, which you will have to walk with for several weeks, or even months, to relieve the burden on the bladder and kidneys. who also suffer. The formation of cameos in the bladder, pyelonephritis, and renal failure are frequent companions of advanced forms of adenoma. It’s even worse to miss prostate cancer - the incidence of which has recently taken first place among cancer diseases in the male population. In order to exclude a dangerous diagnosis, in addition to ultrasound and digital examination of the prostate gland, it is necessary to take an analysis for the level of specific prostate antigen (PSA) in the blood - the main marker of malignant prostate disease.

The benefits of pine tar for survivalists.

1. A pleasant smell that can be used to create some comfort and improve morale. If you manage to organize a sauna, you can dilute it with water and pour it on hot stones for aroma.

2. Wood paint when mixed with linseed oil.

3. Anti-dandruff component in shampoo, component for soap.

4. Impregnation of wood and rigging

© SURVIVE.RU

0 0 votes

Article rating

Post Views: 5,289

Indications for use

Birch tar products are used by patients to combat:

- with ticks, lice, worms;

- arterial hypertension;

- atherosclerosis;

- metabolic disorders;

- gastrointestinal ulcers, intoxications;

- constipation, cramps, tuberculosis;

- colds, stomatitis;

- bronchial asthma, otitis, mastitis;

- infections, consequences of chemotherapy and the use of certain medications.

The compositions are intended to prevent the development of malignant and benign neoplasms. External medicines made from birch tar help in therapy:

- bruises, dermatitis, psoriasis;

- acne, acne, eczema;

- fungus of the skin, nail plates;

- burns of thermal, chemical origin;

- scabies, diathesis, bedsores, trophic ulcers;

- seborrhea, calluses, splinters;

- focal baldness.

The success of treatment depends on the susceptibility of the patient’s body and the absence of allergic reactions to the components of the substance.

Birch tar is an invaluable aid in the garden

Thanks to a wide list of useful properties, tar will provide effective assistance in protecting plants from pests and diseases. At the same time, it does not accumulate in plant tissues and does not threaten human health.

Tar repels pests with its sharp, specific odor, acting as a repellent. The smell will also repel small animals. The healing, antibacterial and anti-putrefactive properties of tar will help plants cope with pathogens.

Compared to conventional commercially available pesticides, tar has undeniable advantages:

- natural origin and complete safety for human health;

- helps cope with a wide range of garden pests, not only insects, but also mammals;

- there is no addictive effect in insects;

- no special equipment is required for use in the garden;

- animal rights activists can rest assured: tar does not kill pests, but only misleads them with its smell and scares them away; so the forest thieves, the hares, are in no danger;

- the protective effect can last from 3-4 weeks and throughout the entire growing season.

Birch tar is a reliable protection against fungal diseases, a good antimicrobial agent with an antiseptic effect.

For use in the garden and vegetable garden, tar can be purchased at a garden center or store or pharmacy chain.

What garden pests can tar be used against?

A good effect can be achieved by using tar against pests living in the soil: mole crickets, voles, mole rats, moles. Because they have a good sense of smell, and the smell from the soil does not disappear for a long time. As a rule, one treatment per season is sufficient.

To repel flying insects, various butterflies, sawflies, Colorado potato beetles, flies, moths, several treatments will have to be carried out. Spraying the beds under plantings approximately every 25-30 days. The same treatments will also be effective against ground rodents and hares.

Tar is not particularly effective against ants, click beetles, weevils and bronze beetles. Therefore, other drugs will have to be used against them.

By the way! Tar cannot be used in tank mixtures with biological products and chemical pesticides. But when used in combination with natural extracts and extracts, the effect is mutually enhanced.

Tar against Colorado potato beetles

As you know, the voracious larvae of the Colorado potato beetle can greatly harm nightshades: potatoes, tomatoes, eggplants. To curb the appetite of pests, the plantings are sprayed with a tar solution.

To prepare it, grate ¼ bar of laundry soap. Pour 2 liters of water and boil until the soap shavings dissolve, cool. Tar does not dissolve well in water, it is lighter than it and spreads over the water, forming a film. Therefore, two teaspoons of tar are added to the soap solution and mixed well until a homogeneous emulsion is formed.

After this, stirring, add water to bring the volume to five liters.

Spray the plantings before and during flowering so that a wet film forms on the leaves. The soil is also cultivated between rows and under bushes.

The same solution can be used to treat plants and beds against mole crickets.

Find out what methods can be used to combat mole crickets here.

How to drive away moles, mole rats, hamsters

The fight against burrowing mammals should begin in early spring. And there are several ways to do this:

- prepare an oil-tar mixture (1 part of any vegetable oil to 3 parts of tar), soak rags in the mixture, place it in all discovered holes and passages, cover with earth;

- You can dig pieces of rags soaked in the mixture into the beds at the rate of 1 per 2-3 square meters; after 4-5 weeks the rags can be renewed.

Protecting the bark of trees and shrubs from rodents, hares and voles

To prevent rodents from getting into the bark of trees and shrubs, mulch the tree trunks with sawdust in the fall. Which are soaked generously with tar solution prepared according to the above recipe.

For the same purpose, you can add tar to the whitewash mixture when whitewashing trees in the autumn. At the rate of 3 tablespoons of tar per bucket of mixture.

Tar in the fight against onion fly

To discourage the onion fly from eating onions or garlic, treat the planting material. To do this, prepare an emulsion: a teaspoon of tar per liter of water. Pour this solution over the onions or garlic cloves. Leave for about half an hour and plant. And after germination, spray the bed with a soap-tar solution.

Don’t be afraid, by the time you clean, the smell of tar will completely disappear.

Tar against sawflies

You can find various sawflies in the garden. These sessile-bellied hymenoptera harm not only berry bushes: gooseberries, all types of currants. But also fruit pome and stone fruit trees: apple, plum, cherry... As well as vegetable and ornamental crops.

But all these pests do not like the tar smell. Therefore, we are preparing an unkind reception for them with refreshments:

- Grate ½ part of a bar of laundry soap, approximately 100 g, on a coarse grater, add 2 liters of hot water, heat until the soap shavings are completely dissolved;

- pour a glass of sifted wood ash with three liters of hot water, stir, let it brew for 2-3 hours;

- add 2 tablespoons of tar to the cooled soap solution, stir thoroughly;

- combine the ash infusion and tar-soap solution, the treat is ready;

- spray plants 3-4 times during the season, because sawflies can produce up to 4 generations per season.

If currant and gooseberry bushes are treated with this solution before flowering, it will also help against the gooseberry moth.

By the way, spraying the fruit and trunk circles under them immediately after flowering will repel the codling moth. Hang the remaining solution in small containers in the crown of trees. Quite effective and completely safe for health.

Birch tar against click beetle larvae

The larvae of the click beetle, more often called wireworms, cause great damage to root and tuber crops. They gnaw passages in them, making them unsuitable for food. To scare it away from potatoes, soak the tubers in tar emulsion (a tablespoon of tar per 10 liters of water) before planting. Spray the planting holes with the same emulsion.

Let's scare away the cabbage butterfly

All gardeners are familiar with the white butterfly (cabbage butterfly) - a large insect with a wingspan of up to 5-6 cm. It can develop 2-3 generations per season. Females are very fertile, laying up to 250-300 eggs. From which voracious caterpillar larvae hatch. It is they who cause enormous damage in the garden, devouring the leaves of cabbage, rutabaga, turnips, horseradish...

But it can also be dealt with. As you know, the cabbage plant finds the plants it needs by smell. If you place pegs with rags soaked in a tar-oil mixture on the beds, this will confuse her. You can spread sawdust moistened with a tar solution between the rows.

Types of tar

Depending on the raw materials used in the extraction of the substance, its properties seriously change. In general, classic tar is extracted from birch bark, less often from pine bark. These raw materials have served for many centuries to extract valuable substances used in various areas of human life.

Relatively recently, many methods for the industrial extraction of tar from peat, oil and even coal have been developed. True, despite their external similarity, their properties are very different, as is their composition. Some can be used as medicines, while others are downright poisonous and extremely dangerous to human health.

How to prepare tar yourself?

If your farm needs large volumes of tar, and you are not afraid to work with your hands, you can prepare birch tar yourself.

To get started, stock up on birch bark and two metal containers.

Make a small hole in the bottom of the larger one (in our case it’s an old boiler with a lid).

Fill it tightly with dry birch bark and small wood chips, and close the lid as tightly as possible.

Place a smaller container in a hole dug in the ground. The resulting tar will collect in it. Place a large container on a shallow one with the hole facing down (the tar will drain from there). Cover the top container with firewood and set it on fire. You can see the process in more detail in the video below. After 4 hours, tar will collect in the lower container. From 10 kg of birch bark it will yield about 3 kg.

To protect against mosquitoes

In taiga villages, their own method of protection against midges and mosquitoes has been practiced for centuries.

The local population does not need chemical means of protection. They already have the most universal and effective thing - simple birch tar. Tar is mixed with oil and applied to exposed skin. However, this product can only be washed off later in a bathhouse. The solution is to dilute birch tar in alcohol in a proportion of two-thirds tar and one-third alcohol. An alcohol solution of tar works no worse than an oil solution. It is enough to lubricate the edges of the hood and sleeves with it. There is another way - to set fire to a tar cone soaked in a spirit solution. Thick smoke with a peculiar smell will create a barrier that will protect you from insects. To treat pets (dogs, cats, cows, rabbits), you can use tar water (tar diluted in water). After this, ticks and fleas will bypass them ten times.