Looking at the photo of a pendant made by yourself, you can see that its beauty is not inferior to jewelry purchased in a store. Jewelry attracts attention with its originality and ability to emphasize the individuality of the master.

This product can be made for your own use or as a gift. And it’s worth considering several schemes that novice needlewomen can easily use.

DIY lifehack 1: Polisher tube

Along our tube we make a longitudinal cut on one of its sides.

After the longitudinal slot, leave four centimeters untouched, cut it off and carefully remove burrs from the resulting workpiece. As a result, we get this:

We tear off the tape from the sandpaper sheet, insert its edge into the slot so that when twisted to the left, the sandpaper is directed upward.

Twist the sandpaper around the tube and secure its edges with masking tape.

We install one of the ends of the resulting homemade tool into the cam of the drill.

Using the resulting product, you can quickly process the edges of parts.

They can also process any holes. For convenience, the free end of the manufactured device can be placed in the hole of a large washer.

Coin pendant

Making this bat craft requires masculine strength. You will need a ten-ruble coin, which must be treated with abrasive paper. The hole for the ring is drilled with a small diameter drill.

The central part of the coin is removed with a hammer using a bearing. The image is applied to the central part of the coin, fixed in a vice, using needle files, a special jigsaw and a diamond bur.

After applying the image, the central part is installed with a hammer in its original place. The chain ring is threaded through the previously drilled hole and the pendant is ready for display.

DIY lifehack 2: Twister tube

This time we make a very small longitudinal slot, no more than 1 cm.

Having cut off the tube and removed the burrs from it, insert its uncut end into the drill, and place the tip of the wire into the cut.

By turning the drill on at low speed, we get a very neat spring.

To provide the resulting product with the necessary functionality, its outer turns should be carefully bent. This is how it turns into a full-fledged spring, which can be used for its intended purpose.

Working techniques

- Various weaving techniques help create a wide variety of products. Among the variety of methods for working with wire, several basic techniques can be distinguished:

- Decorative weaving with the addition of beads and bugles. You can create various interesting crafts from beads and wire. Unlike fishing line, which can break, the wire base holds its shape well and bends well in any desired direction.

- The technique of twisting in the form of a spiral and other curls allows you to make unique products. The emergence of this twisting technique gave impetus to jewelry delights. They began to weave expensive jewelry and luxury items from silver and gold wire.

- Ganutel involves mixing wire with silk threads to create a variety of flower crafts using pearls, beads, rhinestones or precious stones.

- The filigree technique makes it possible to produce openwork interior items and decorations.

Experienced craftsmen can sometimes use several techniques in their work to make one product. They specifically use this solution. The important thing here is not to overload the result in the end.

DIY lifehack 3: Curler tube

This time the tube will be useful without longitudinal cuts. Using pliers, just flatten it at some distance from the edge.

We insert the long end of the tube into the cam of the drill, and into the short flattened end - the ends of the wire stripped of insulation, which must be twisted when performing electrical wiring.

We turn on the drill at low speed and end up with tightly twisted ends.

Each life hack that we have listed above is very easy to implement. However, the homemade product obtained with its help will be very useful for you when performing a fairly large number of operations. And in addition to this, the metal tube, which we had lying around idle and which we really wanted to throw away, found a completely worthy use for itself.

Homemade products from a washing machine engine:

1. How to connect a motor from an old washing machine through a capacitor or without it 2. Homemade emery from a washing machine engine 3. Homemade generator from a washing machine engine 4. Connecting and adjusting the speed of a commutator motor from an automatic washing machine 5. Potter's wheel from a washing machine machines 6. Lathe from an automatic washing machine 7. Wood splitter with an engine from a washing machine 8. Homemade concrete mixer

30 ideas for homemade pipes (bright photo selection)

PVC and aluminum pipes can be used not only for their intended purpose. They can be used to make furniture, garage shelving, closets or rooms, decorative items and even jewelry. See a selection of things made from PVC and aluminum pipes, choose what your home is missing, and try to make it yourself.

Algorithm of actions

It is not easy to assemble a moonshine still from a milk can; it is advisable to have certain skills in assembling such devices.

But even if your knowledge can hardly be called deep, you can get to work counting on success. Operating principle or how to make a moonshine still:

- The first step is to make two holes in the lid of the can. It is worth measuring the diameter in advance, and then drilling or cutting. We insert a fitting into one of the holes (this is the part of the pipeline that is used to connect to the system). A thermometer will be mounted in the second hole. If a sensor is not needed to measure temperatures, then there is no need to drill a hole.

- The next step in the work can be considered sealing the holes. To prevent alcohol vapors from escaping, you should carefully treat all holes. The question of how this can be done remains open. For sealing, you can use rubber gaskets or nuts. But rubber can give alcohol a specific aroma and this is worth taking into account. Some people advise using plastic: it will melt when heated and will seal the holes on its own. But it is best to give preference to the nuts and coat all the necessary places with dough. You can use epoxy. But flour with water is still safer than any chemical elements that can get into the drink in small quantities. The ends of the coil outlet should also be coated with the dough.

- We fix the tube on the coil (it is desirable that the coil - this is a wire twisted into a spiral - be made of copper). To do this, you should select a silicone tube of a suitable diameter so that it matches the diameter of the coil and fitting. Then we fix the structure. For this purpose, we use a cuff or soft wire.

- The last step is to pass the coil through the refrigerator, the hole is sealed using dough. To prevent the release of alcohol vapor, it is worth using gaskets, rubber bands or fittings, in general, everything that is used in plumbing. A hole in the bottom of the container is drilled in advance, then a coil is passed through it. The spiral is fixed on both sides with nuts and gaskets.

In principle, the device is ready, but it will still take a long time to polish and bring it to perfection. The device will need to be checked, that is, tested. This will help identify shortcomings and modify the moonshine still if necessary.

There is one more nuance: in order for the device to start working and produce high-quality alcohol, it must be equipped with a heating element. Tens are often used for this.

The structure of the apparatus, which was described above, allows you to heat the flask on the stove, but you can also equip the device with additional heating elements - this will help regulate the boiling temperature of the solution. You can disconnect one heating element or connect a second one.

But if you want to make a device that will dispense high-quality alcohol, it is worth equipping it with a steamer.

A steamer is a device that allows you to rid moonshine of harmful impurities. Fusel oils affect the quality of the drink: they change the taste of moonshine and give it an unpleasant odor. In addition, these substances can have an effect on the human body and cause intoxication.

The dry steam tank works like a sump: all the fusel settles in it. This happens for the reason that the boiling point of fusel oils is much lower than the boiling point of water or alcohol.

To make a steamer, you need to take a glass jar; it must have a tin lid with a thread. Two holes are made in the lid; they are made using a soldering iron or drill. The sump is equipped with tubes, and one of them should be 5–10 cm shorter than the other. Having cut the holes, you should take care of their tightness.

Copper as a material for making pipes

Copper is the optimal material that ensures the performance of systems at high pressures and temperatures. Therefore, copper pipe is used not only for the installation of hot water supply pipes or heating system lines, but also for other purposes.

For comparison, you can take polypropylene pipes and copper ones. The former are able to withstand temperatures only up to + 95ºС at pressures of no more than 25 ATI. The latter are capable of operating at T=250ºС and pressures up to 300 MPa.

Copper is the main material from which the French, British, Australians, and Swedes prefer to install water supply and heating systems. High mechanical strength, ease of machining - these properties have made seamless copper pipes popular in the construction of various types of communications.

Modern production of such products involves applying a protective polymer layer to the surface of the pipes, which eliminates the appearance of stray currents in magnetic field zones.

What not to do?

Therefore, use common sense and follow the rule - “do no harm.”

Here's what you definitely shouldn't do:

- Aluminum and copper should not be scrubbed harshly (such as with steel wool) as they are soft metals and may leave visible abraded parts.

- Metal scrapers and brushes should not be used when cleaning external stainless steel parts, as they leave unsightly scratches on the polished surface.

- The use of chemical solvents and other aggressive chemicals is strictly prohibited. After all, all this may not be washed off with water properly and will end up in the final product.

And most importantly, you should not leave the device unwashed, because all the “dirt” that has accumulated in it will end up in the moonshine and can irreparably damage it. Distilling is a business that requires cleanliness and even sterility.

Nuances of installing copper lines

Plumbers, who have a set of tools and experience working with copper, perform a number of actions during the installation of copper pipelines:

- cleaning, calibrating, cutting;

- giving the desired shape;

- crimping, soldering, connection.

Each owner of an apartment or private house can perform the same actions with their own hands.

The main thing is to learn the nuances of technology and the secrets of producing such work. Each action requires an appropriate tool.

As a rule, a mechanic's tool kit includes:

- copper pipe cutter or hacksaw;

- files, sandpaper, rags;

- locksmith wrenches;

- gas key No. 1;

- manual calibrator, pipe bender;

- gas burner, flux, solder, fum tape.

The start of installation work is always preceded by activities aimed at calculating and drawing up a layout of the water supply or heating system.

Based on their diagram, the required number of copper pipes, their length, diameter, and the number of additional installation parts are calculated.

Do-it-yourself spinner from a tube: step-by-step preparation instructions

Since ancient times, spinners made from tubes and rods of different diameters have been used to vertically lure pike perch in both winter and summer.

These spoons are distinguished by their efficiency, accessibility, and most importantly, their catchability. We will try to tell you how this is done.

To make round spinners, both tubes made of different metals and solid rods are used. The shape of tubular spinners is also varied.

For an example of making different types of spinners, let's take an aluminum rod and a copper tube.

What are spinners?

Spinner is the most catchy and easy to use bait. Oscillators have different sizes, shapes, and colors. Each option also has its own vibration frequency.

The spoon is the oldest bait with which you can catch predatory fish. Experienced fishermen observed how crucian carp or perch behave in the water. Oscillating spoons convey these movements of fish in the water.

It is necessary to add game elements to fishing - create movements that attract prey. Recreate the fluttering sounds of a wounded fish or one that is very frightened and is trying to swim away from a dangerous area as quickly as possible.

Lately, fishermen have been buying “wobblers” and forgetting about the main thing - our ancestors used to fish with spoons and did it successfully. They have been used for centuries. Unfortunately, this type of bait is undeservedly fading into the background.

But oscillators are still often used and they could not be replaced by modern purchased devices.

Oscillating spinners from a spoon

“Spoons” or oscillating spoons are a special type of metal bait made of a curved metal plate to which a hook is attached. The store sells a great variety of them, in various shapes and colors. However, we are not looking for easy ways, and today we will find out whether it is possible to make such a spinner yourself, what is needed for this, and how much time it will take.

After reading fishing forums and talking with professionals in this matter, we identified the easiest way to make a spoon at home - from an ordinary metal spoon.

The main thing here is to decide for yourself what size you need. Some people use the dining room, others the dessert room. The dining room is for hunting large trophies, the dessert room is for relatively small predators.

What do you need:

- Metal spoon;

- Balgarka or file;

- Metal drill;

- Winding rings.

- We prepare all the tools and ask my wife for a metal spoon.

- Use a grinder or a file to cut off the handle from the scoop.

- Drill two holes at the top and bottom. One for attaching a leash or fishing line. The second is for attaching the hook. Insert the winding rings.

- If desired, we sand the resulting lure or paint it in any color you like.

A stainless steel corrugated water pipe with a corrugated texture is very suitable for an oscillating spoon, but as you understand, it is not the only thing that can be used.

An ordinary tin can of green peas or sweet corn, which is so often used by anglers when fishing on a feeder, is also suitable for such a spoon.

- It is necessary to cut the blank we need from the pipe.

- Fill the concave part with molten lead or tin.

- Then drill holes for the winding rings, to which the tee and the main line will cling.

Advantages of tubular spinners

There are several types of spinners that can be made from a tube at home. A tube spinner is easy to make and has great advantages:

- With the help of tubes, you can produce an effective, productive and interesting game that reproduces the movements of fish.

- These tackles are compact, but have enough weight, which is enough for long casting.

- Low manufacturing cost.

- Relatively easy to assemble.

- Readily available materials.

- It can be used multiple times.

- There is no fear of losing it, since you can quickly make a new copy.

- Suitable for vertical luster.

But, despite the undeniable advantages, tubes also have a number of disadvantages:

- You must be able to handle it correctly, because if used ineptly, predatory fish will not be interested in the bait.

- If fishing is carried out among a large amount of algae, then the tackle will often cling to it.

Preparing a homemade spoon from a tube and fishing technique

In all likelihood, the psychology of a fisherman is structured in such a way that it will never be possible to fully achieve perfection in fishing. Always and under any conditions, there are reasons that provide reasoned food for improving fishing techniques, equipment and bait.

The spinner is constantly on the lookout, trying to have a universal, catchy bait, or better yet several copies of it, in his fishing arsenal and constantly help him achieve a significant result when fishing.

But even with today’s huge offer of all kinds of baits from manufacturers in the field of fishing accessories, it is not always possible to get such a lifesaver.

In this regard, the ability to independently make a fishing tool that can satisfy the needs of a spinning player plays an important role. In our article we will talk about making a spinner for pike perch, the material of which will be a blank from a tube.

In particular, we will talk about the various modifications of the spinner that can be made from the type of metal profile and tools required to complete the work.

We will discuss the technology of making homemade products and give recommendations for its use in the practice of pike perch hunting.

A tube spinner for pike perch can be made in several effective versions for both winter and summer fishing with spinning rods and for plumb trolling. The most common type of tubular spinner for pike perch is a modification of the cut spinner.

The cut modification itself can be hollow or filled with a filler that creates noise or serves purely for loading purposes.

The type of direct bait is used less frequently, but in some conditions, especially high predator activity, such options are preferred due to the increased fishing speed.

Types of tubular spinners

- Hollow baits are the easiest to make. Used for deep fishing or in strong water currents. The “tube” has low lateral maneuverability, and therefore it is possible to quickly navigate through the bottom layers.

- Tubes made with a sealed end are not used so often.

This type has increased resistance at the end, and therefore, when wiring, the displacement reaches 30 or even 40 centimeters. But there is also an advantage of this bait - a passive predator may be interested in the prowling game, as well as the specific sound that the hollow part of the bait makes. - The loaded spoons are half or a third filled with material.

Lead makes a good filler. This type of bait is rarely used. It is customary to take this tackle only when you need to cast over a long distance during strong winds. The device has just enough weight for a long throw. - Another common modification is the noise type.

To make it, the ends are sealed and a lead pellet is placed inside. When wiring is carried out, the tackle will make rattling sounds that will interest the predator. Such tube spinners, for example, work well for pike perch, as well as for pike or perch.

Spoon tube: types, materials, technological process

Spoons, spinners, balancers, edible rubber - the market offers fishermen a huge number of artificial baits of different shapes, sizes, and prices. Although more recently, the catch depended solely on the observation and ingenuity of the fisherman.

A tube spoon is a catchy bait that can be made at home if you have the material and tools.

In addition to being effective in catching freshwater predators - pike perch, pike, perch, this homemade artificial bait will cost the fisherman disproportionately less than, for example, silicone twisters, wobblers and similar imports.

The ease of manufacturing tubular spinners allows you to “stamp” several dozen baits in a short period of time, which will give an advantage when catching a predator in snags, where such a thing as a hook with the subsequent loss of a homemade product is not uncommon. We’ll figure out what and how to make a spinner tube from, and also answer a number of questions related to this topic.

The invaluable fishing experience of their ancestors in making baits gave their contemporaries the opportunity to make the following types of tubular spinners at home:

- Hollow homemade products. Thanks to its slight lateral maneuverability, which makes it possible to make fast retrieves, a tubular spoon of this type is used when catching freshwater predators at depth (in the bottom layers) or in strong currents.

Photo 1. Hollow spinner tube.

Photo 2. Whole-bodied spoon.

Materials and tools for making a tube spoon

A self-made spinner tube for pike perch or any other freshwater predator will require the following materials:

- aluminum or copper tubes;

- lead rods or solder;

- abrasive material (fine sandpaper for final polishing);

- swivels, winding rings, tees, stabilizer fins.

The necessary tools will require a hacksaw for metal, a small vice, but always with soft pads on the lips so as not to damage the surface of the body of the future bait, a drill with a set of drills, and a file. In addition to these tools, you cannot do without a portable melting set for casting lead loads.

Photo 3. Elements of the spinner.

The question about the size of tubular spinners does not have a clear answer. It all depends directly on the fishing conditions. In particular, the season on which the behavior of freshwater predators depends, the depth of the horizon, the strength of the current, and whether fishing is carried out from the ice, shore or watercraft.

The topography of the bottom of the reservoir is also taken into account. For example, a hollow aluminum tube lure for pike perch in winter will be 50 mm in length. External diameter – from 7 to 10 mm. Unloaded, but equipped with swivels, guide rings, and a tee, it will weigh about 7 grams.

A similar bait, but made of a copper tube, twice as heavy - 14 grams. An oblique cut on both sides of the bait - the so-called angle of attack, can also have different meanings.

As a rule, at one end of the bait it varies between 30° and 60°, on the opposite side this value remains around 20°.

The undeniable advantage of a pike spinner-tube for pike, pike-perch, and perch is its ease of manufacture when compared with the technological process for “spinning spoons” or “spinners.” The algorithm of actions will be as follows:

- We take an aluminum billet with a wall thickness of 0.8 mm and an outer diameter of 7 to 10 mm.

- Using a hacksaw, we cut off a small piece from the workpiece, having previously secured it in a vice. In our case, the length of the sawn piece of tube is 50 mm.

- Using the same hacksaw or grinder, whoever has it, we process the edges of the future bait on both sides. In particular, we make a cut angle of 60° on one edge, and a bevel of 20° on the other.

- We clean the cut areas with a file or sandpaper so as not to leave sharp edges, burrs, etc.

- At the edges of the body of the bait, use a drill to make holes on both sides with a diameter of 1 - 1.5 mm. And we sand the future lure-tube first with coarse sandpaper, and then with sandpaper until it shines.

Photo 4. Tube prepared for fitting.

So, the tubular spoon - bait for pike perch, pike perch, and pike perch is ready for use. Loaded tubular spoons are made according to the same scheme. But in addition, we pour molten lead on one or both sides of the bait.

When sealing both sides, you can put a pellet in the cavity for a sound effect. As soon as the surfaces to be treated have cooled, they must also be sanded. Next, we carry out the installation of the suspensions described above.

As mentioned above, a composite spoon made from tubes requires more scrupulous work during its manufacturing process. A fisherman from behind the “bump” would say that such a bait would never be made without a milling machine and special equipment. A naive foreigner, Russian ingenuity and perseverance works wonders! So, the step-by-step instructions look like this:

Methods for connecting copper pipes

In practice, one of two methods is used to assemble copper pipelines - by soldering or mechanical crimping.

Secrets of soldering with a gas torch

When choosing a soldering method for installing the system, you must consider the following: all connections made in this way are permanent. Soldering provides a high percentage of density guarantee, but imposes some restrictions on maintenance. It is often impossible to upgrade a system without adding complexity.

Interior

Anyone who dreams of creating the furnishings of their home so that it becomes vibrant, varied, and uniquely designed can make unusual decorative items from wire themselves. The material can very easily be given any desired shape.

Wire is used to make various decorative items that are suitable for different styles.

Without experience, you can make an unusual wall decoration yourself. You need to have thick wire and a pattern diagram. The result will be an original photo frame, interesting figures of animals or birds.

Hanging wire figurines of anchor starfish and fish will look harmonious in the bathroom.

A non-standard look at weaving will help you create many different unique and practical things.

Tools for mounting elements

It is not always possible to cut a pipe without damaging the wall structure. The wall thickness of copper pipes up to a diameter of 28 mm is only 1 mm. Even the use of a disc pipe cutter for copper pipes does not fully guarantee an even cut. If wall disturbances are observed, a calibrator is used. This tool is used to calibrate (align) the pipe and socket.

Pipe cutters are available in manual, electric, pneumatic, and hydraulic types. Structurally, the pipe cutter is a mechanical clamp, where two rollers act as supporting elements. One of the rollers has a cutting edge.

The cutting process is carried out by sequentially pressing and rotating the pipe cutter around the pipe axis. The smoother and more often the pressing is performed, the better the quality of the pipe cut.

Installation work is often accompanied by bending of copper pipes. A high-quality, even bend of any radius helps create a tool called a pipe bender. There are two types of copper pipe benders - spring and mechanical.

The first tool has a simple but effective design. Designed for bending small diameter pipes. The second type includes several design varieties.

A spring pipe bender is made in the form of a long casing that fits onto a copper pipe. One end of such a casing is slightly widened for greater ease of use. The copper pipe placed in such a springy shell is bent by hand without the risk of jamming at the bend.

Disadvantages - the bending radius has to be checked by eye; for a specific pipe diameter you need your own spring pipe bender.

Mechanical pipe benders (lever, segment, crossbow, hydraulic) allow you to bend pipes of different diameters (from 10 to 125 mm). Copper pipes of large diameters are usually bent using a segment bender or a hydraulic pipe bender. The bending angle when working with such devices can be 180°.

Types of alambics

There are several types of copper moonshine stills. According to the production method they are divided into:

- Riveted. They look impressive, but are less reliable in operation, since even a master of his craft finds it difficult to achieve a tight structure.

- Soldered ones look original, and at the same time they are more reliable in the robot. Some manufacturers use silver flux when soldering. This is a contribution to additional purification of the distillate.

The purpose of the alambic type depends on the shape:

- Classic. A distillation cube in the shape of a ball slightly cut off from the bottom. Above it is a domed (onion-shaped) helmet, rigidly connected to a tube - a “swan neck”. The design is completed by a coil with a cooler. The still with the helmet and the swan neck with the coil are connected telescopically (wedge-shaped) and no additional gaskets are used. Tightness is achieved by adjusting each element. In addition, when heated, the copper elements “enclose” each other more tightly and steam leaks become impossible. But sometimes the connection between the coil and the tube is threaded.

- With a column. This type of alambik has previously and today been used more often than others in the perfume industry. But also for the home distiller, this is a godsend, allowing you to get a strong distillate, moreover, additionally flavored, depending on what you put in the removable basket between the still and the column. The column is a wide copper pipe between the helmet and the cube. In it, alcohol vapors are cooled, flowing down with impurities and water, and ethylene rises into the tube and goes into the refrigerator. At the same time, cleansing (flavoring, if you have such a goal), and strengthening.

- Charente (cognac). Has an additional intermediate tank with a helmet between the cube and the cooler. The vapor first enters this tank, where it is cleaned of sulfur and fusel, and then passes into the distillate in the refrigerator. Such alambiks are used in the French province of Cognac to distill world-famous drinks.

- Whiskey. A distinctive feature is the elongated conical helmet. Due to this, there is a better selection of impurities from the steam.

- Portuguese - with an enlarged helmet chamber, usually not bulbous, but in the shape of an inverted pear. This design helps strengthen the resulting distillate.

- Alkitar or Arabic alambik. Looks a little like the classic one. Here all the component parts stand on top of each other. The design is crowned by a refrigerator that looks like a copper basin connected to a helmet. It is beautiful and comfortable in its own way. Excellent for obtaining essential oils, but moonshine can also be distilled.

- In a water bath. In addition to the classic alambik, the design contains another copper container into which the cube is placed, mash is poured into it, and water is poured between the walls. The best design for distilling thick mash.

- With distillation column. With its help, purified alcohol with a strength of up to 90° is obtained. But at the same time, a significant part of the aroma is lost, for which, in fact, grain and fruit mashes are made.

There are several other varieties of copper devices, but this depends on the imagination of the manufacturer.

Attention. The description of the types does not mean at all that you will not get cognac alcohol using a whiskey still and vice versa. It’s just that one or another alambik gives the best results on grain or grape raw materials

It’s just that one or another alambik gives the best results using grain or grape raw materials.

See the video below for a description of the operating principle of different types of alambics:

Characteristics of copper water supply

The durability of copper water pipes is to some extent due to the fact that the chlorine contained in the water, in reaction with copper, contributes to the formation of a thin oxide film on the inner surface. This film additionally protects the pipe wall from the negative influence of the pumped medium.

Copper is also considered the optimal material according to the results of sanitary and bacteriological studies. This metal has a bacteriological effect, for example, against the staphylococcus virus.

Copper has a high thermal conductivity coefficient. This point forces us to take measures aimed at isolating pipes from the external environment.

An uninsulated cold water supply system in the summer can create a serious problem with the collection and disposal of condensate. Uninsulated hot water pipes experience significant heat loss. When installing copper pipe networks with your own hands, you should take these points into account.

Decorations

Making jewelry is a very interesting activity, but very labor-intensive. The craftsman must have significant experience and show maximum concentration in the process of making jewelry. First attempts do not always end in success.

When creating jewelry, beads are most often used. The beads are placed on a wire to create a bracelet with a unique design.

Craftsmen use copper to create unusual ethnic jewelry, in which stones or beads are inserted into the frame.

You can create any type of jewelry: earrings, bracelets, pendants, rings and brooches. A variety of weaving techniques, adding bright stones and other decorative elements allows you to create almost any decoration for all occasions.

Conclusions and useful video on the topic

You can learn how to install a copper water supply from the following video:

Quality, reliability, durability – plumbing and heating systems endowed with these properties often delight apartment and house owners if copper is used for installation work.

Indeed, when there is confidence that there are no leaks and are not expected in the future, that there are no gusts even in severe winter, this means that a system of copper pipes is installed in the house.

Do you have anything to add or have questions about the technology for installing copper pipes? Please leave comments and participate in discussions about the post. The contact form is located in the lower block.

Clay pendant

One of the most popular materials for making beautiful handmade pendants is polymer clay.

To work you will need:

- Polymer clay of two sharply different colors.

- Metal tape (wire).

- Parts of different sizes are cylindrical in shape.

- Plastic rolling pin.

- Transparent acrylic varnish.

- Pin.

- Ceramic, glass or plastic board as a working surface.

- Protective gloves (optional).

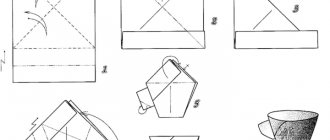

Stages of work

- Bend the metal strip (wire) at the end to give it a spiral shape.

- Bend the other end of the ribbon using cylindrical pieces to give it a zigzag shape.

- The tape should be aligned so that, when placed on a flat surface, it is in the same plane.

- The clay must be kneaded, both pieces of different colors must be rolled out into sheets and folded.

- The blank is then rolled into a spiral so that the lighter color becomes dominant.

- The resulting part is bent several times and rolled out to a cylindrical state.

- The resulting cylinder is rolled out into a sheet.

- The wire element is carefully pressed into a flat clay sheet.

- Excess material is removed.

- A ball is molded from a piece of dark clay and fixed with a pin on the top of the main workpiece.

- Polymer clay is baked at the temperature indicated on its original packaging. After cooling, the workpiece is coated with a layer of varnish.