People who at least sometimes do repair and installation work know that a clamp may be needed at the most unexpected moment. This is the first device that comes to mind when you need to quickly fix a pipe leak. Indeed, applying a clamp is a temporary measure, but sometimes necessary. It is possible that, due to circumstances, it cannot be purchased right now; besides, even a simple wire clamp will do to solve the problem. Therefore, you need to do it yourself.

Pipe leak

Band metal clamps

Most often, this type of fastener comes standard at the factory. This is due to reliable fixation and ease of installation. In order for the CV joint clamp to be used for a long time, the following conditions must be met:

- when making the tape, the manufacturer used high-quality steel;

- installation on the boot was carried out using a device for tightening CV joint band clamps;

- To install fasteners, you must have skills in using the tool.

To tighten the CV joint clamps, you can use improvised means, but the quality in this case will depend only on the experience of the craftsman. The only tool you need is pliers. Sequence for tightening the clamp:

- The clamp fits onto the boot;

- The tip is grabbed with pliers;

- Pull with a little force and make sure that the clamp tightens the boot without distortion;

- Create maximum force and bend upward;

- Bend the antennae;

- Fasten the end of the ribbon.

Upon completion of installation on the constant velocity joint, it is necessary to check the uniform fit of the clamp and the absence of distortions.

How to make a pipe clamp with your own hands

At the first signs of depressurization of the pipeline, it is necessary to quickly find the damaged area and eliminate the identified defect. When performing emergency emergency work, you can use homemade clamps to stop the flow in the pipeline for a while.

Ready-made clamps for fastening pipes, made in the factory from stainless steel or fire-resistant plastic, are used when performing installation work on the installation of heating, sewerage, water supply, and gas supply systems.

These fasteners allow you to reliably fix the position of pipes running along horizontal and vertical surfaces (ceilings, walls), as well as those installed on special racks.

In this video, an experienced craftsman shows how to make a wire clamp:

How to repair a fistula in a pipe

How to repair a fistula in a pipe. Sometimes a situation occurs that a fistula appears in an iron pipe of a water supply or heating riser. This is especially common in hot water risers. The first signs that a pipe will soon burst is when a red growth appears on it, but it may not appear.

In scientific terms it is called pitting corrosion, but in simple terms it is “Pipe” to a pipe. Fistulas appear on the pipe, either due to wear or due to stray currents.

In principle, when you get a fistula, you won’t care why it appeared, you will have a question: how to fix it quickly? I'll try to describe a couple of options on how to do this.

How to seal a fistula in a pipe with a clamp

In general, if you see that your pipe is not of the first freshness, then it is advisable to purchase a couple of clamps in advance for the diameter of the water supply riser, and cut rubber for them. Because most often this happens at night, and by the time the emergency crew or mechanic arrives, it can be heavily flooded. There are a couple more nuances regarding the size of the fistula.

If the fistula is the diameter of a needle, then you can install a clamp without shutting off the water, but if it is larger, then when installing the clamp, you risk getting burned; if the fistula is in a pipe with hot water, it is better to turn off the water at the riser. If the fistula is small, you can try to seal it with a regular car clamp, as in the photo.

You do this: take a piece of rubber and cut out a thin ribbon, the width of the ribbon should be equal to the width of the clamp, maybe 3-4 millimeters more, but not less, now measure the length of the rubber band. We wrap it around the pipe and cut off the excess. Then cut off another 1 cm. Next, open the clamp, put it on the pipe, and grab it a little.

We insert the rubber gasket that you cut out under it and carefully bring it to the place where the fistula has formed. Cover it and tighten it with a screwdriver or a wrench, depending on what kind of tightening device the clamp has.

I have had such cases in practice that in an apartment there is a fistula with the diameter of the “eye of a needle”, it whistles very loudly, but there is not a lot of water, the tenant, the grandmother “God’s dandelion” is screaming like crazy, but I can’t turn off the water, since it is from won’t let me out of the apartment, and I didn’t have the clamp with me, what I do, after looking and determining that the pipe is in excellent condition, I break off a piece of a match, and insert the tip into the fistula, and there was no fistula, but this is so that the grandmother calmed down. Then, of course, I installed the clamp. I often closed such fistulas in the basement this way, but there were also punctures, you insert a match, and the fistula becomes 2 times larger, so I do not advise you to use this method. Well, this is a digression, let's consider another option.

How to quickly fix a leak?

A leaking water pipe can cause flooding of your home and damage to your property and that of your neighbors. You need to act quickly in such a situation:

- If possible, turn off the water supply to the system (area being repaired).

- Clear the repair area. Move the furniture aside and put down dry rags.

- Prepare tools: pliers, screwdriver, flexible wire or clamps, thin rubber.

- Cut out the desired piece of rubber sheet. It should cover the leak site with a margin of 2–3 cm in each direction.

- Press the pad firmly onto the fistula (crack). If it is too thin, wrap it in 2-3 layers.

- Holding the overlay with your hand, place the wire on top. Tighten it by making tight turns with pliers.

- Cut off the excess wire, leaving 5mm ends.

- Bend them so they don't protrude.

Pipes leak especially often in houses with old plumbing. In bathrooms and toilets where humidity levels are high, metal is at high risk of corrosion. Salts and various impurities in the water contribute. To prevent leaks, anti-corrosion paints and primers are used. Some of them can be applied directly to the rust.

If water comes out of the fistula under pressure, find something to plug the hole with. The easiest way is to block the flow with a chopper. Sharpen the end of the piece of wood to fit into the hole. Lightly tap the chop with a hammer.

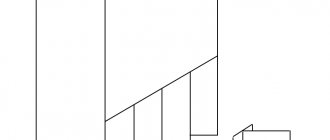

The procedure for making a homemade pipe clamp

To work you will need:

- A strip of galvanized steel or iron, no more than a millimeter thick

- Three-millimeter rubber flap

- Bolts M6, M8 or M10 – your choice, which ones are available. 2-3 pieces are enough.

In addition to materials, you will need tools:

- metal scissors (jigsaw, grinder)

- hammer

- spanners

- calipers

- pliers/vise

- drill, drill bits (M7, M9, or M10, M12)

The first thing to do is measure the diameter of the pipe using a caliper. But if the pipe is large in diameter, then it will be more convenient to measure with a ruler with a corner.

Then you need to cut a metal strip with a width of 4 to 8 cm. The selected width depends on the thickness of the pipe and the size of the damage. You will have to tinker a little with the length of the strip, calculating it according to the rules: the diameter of the pipe obtained during the measurement is multiplied by the number Pi - 3.14, then 3-4 cm is added to it, after which the piece can be cut off. This reserve of centimeters (“ears”) is needed so that the bandage can be fastened in this place using bolts and nuts.

In the “ears” you will need to drill two holes for the bolts, taking into account the size of the latter, however, the holes may be slightly larger to make them easier to screw. If the pipe has a large width, then it is better if there are not two, but three holes. Then the ears are bent at a right angle using pliers, you can just use your hands if the tin is thin.

The next step is to try it on - bending the tin strip around the pipe. And the finished “ears” are brought together until their opposite holes coincide. If the strip does not fit tightly, tap it lightly with a hammer. When the clamp takes the desired shape, it is lifted and a rubber gasket, cut in advance, is inserted under it.

Procedure for replacing the outer CV joint boot

The procedure for replacing the outer CV joint boot, which has a unified design, is identical for most cars with front-wheel drive. The work is carried out on an overpass or inspection pit.

Required Tools

Minimum set of tools required to perform repairs:

- mechanical or hydraulic jack;

- wheel stops and auxiliary stands for holding the body;

- a metal brush to clean the surface from dried dirt;

- hammer and chisel;

- rags for wiping;

- set of wrenches and sockets;

- torque wrench;

- flathead screwdriver and pliers;

- a spatula for applying lubricant to the cavity of the cover.

Progress

Sequence of actions when replacing the external boot:

- Place the car in the pit, apply the handbrake and place chocks under the rear wheels.

- Loosen the nuts or bolts securing the wheel rim to the hub, and then jack up the body.

- Install safety stops under the threshold (if they are missing, it is allowed to use a spare wheel with a board).

- Dismantle the wheel, and then remove the clamps of the central nut (a cotter pin or a bevel of the nut bent into the grooves is used to hold it in place).

- Unscrew the nut; to complete the procedure, you will need the help of a second person to press the brake pedal.

- Remove the brake pads and caliper, which is moved to the side (removing the hose is not required). The caliper is bolted to the steering knuckle, the size and location of the heads depends on the car model.

- Pull off the brake disc. If the part is stuck to the hub, then you need to use a hammer. The blows are applied through a wooden spacer that prevents damage to the disc surface.

- Remove the bolts connecting the hub and the shock absorber housing. Before disassembling, it is necessary to remove the layer of dirt with a brush and wipe the surface with a rag.

- Pull the hub towards you, moving the shaft splines out of the hole.

- Remove the old cover using a knife or screwdriver. At the same time, the old clamps are removed; reusing the fasteners is not recommended.

- Carefully remove old grease with traces of water or dirt from the hinge surface. Grease is removed with a wooden spatula and clean rags or rags.

- Remove the outer hinge together with the housing. To complete the task, you will need the help of a partner, who does not allow you to disconnect the shaft joint near the gearbox housing. The hinge is removed from the axle using a chisel and hammer (the design uses an internal retaining ring that is compressed upon impact).

- Wipe the shaft and CV joint from any remaining lubricant; you can disassemble the unit and wash the parts with gasoline.

- Assemble the assembly and apply a layer of lubricant to the parts; the substance is tightly packed into all cavities and grooves.

- Place a new boot on the shaft; a portion of lubricant is first added to the cavity of the boot.

- Connect the hinge and the axle shaft, first aligning the seating teeth.

- Place the clamps in their original places, and then install the removed parts. When tightening threads, use the tightening recommended by the manufacturer.

Option without removal

The procedure for removing and installing the cover without separating the shaft and the hinge involves the use of a special device that stretches the rubber boot. The method is used in cases where it is impossible to separate parts without destroying the metal elements (due to corrosion or design features).

Possible problems

A common problem is the joint sticking to the shaft. If the hub is secured with a bolt, then to separate the parts it is necessary to screw the bolt into the hole until it stops. After the part rests against the end of the axle, you should make another 2-3 turns with a wrench, which will allow you to remove the hinge. If fastening is carried out with a nut, you will need to completely remove the axle shaft and then clamp the drive in a vice. Tightly fixing the part will allow you to knock down the hinge with a chisel, but if the contact cannot be separated, you will have to cut the inner ring of the CV joint with a grinder.

DIY clamp - a simple and effective solution to the problem

A clamp is a useful and sometimes irreplaceable thing in the household. With its help, it is always possible to ensure a tight connection of hoses, pipes, pipelines, both flexible and rigid. In technology, there are a great many types of clamps for various purposes. The thrifty owner will always have them in his tools for all occasions.

However, there are situations when there is no suitable device at hand, and the problem needs to be solved urgently. For example, a fistula has formed in the heating or plumbing system, and water threateningly rushes to the floor. To make matters worse, while driving a car, a pipe in the interior heating system or in the engine cooling system fell off. There is no mounting clamp among the tools.

What to do in such cases? Is it possible to make a clamp with your own hands? What is needed for this?

Seal onto a pipe - it's easy

Often in our homes, metal pipes rust and leak. Such areas require repair or replacement. However, our home craftsmen solve the problem quickly and efficiently with the help of clamps, which “decorate” the interiors of our apartments for many years.

How to quickly make a pipe clamp with your own hands? What will you need for this?

Tools needed for manufacturing:

- hammer, pliers, drill;

- drills with a diameter of 6 or 8 mm;

- metal scissors or grinder;

- caliper, ruler;

- spanners.

In addition, you will need the following materials:

- metal strip up to a millimeter thick (for example, stainless steel, galvanized sheet);

- a strip of rubber 3 mm thick;

- bolts, 6-8 mm nuts, washers for them.

How to make a pipe clamp

Making clamps requires certain skills. Experienced plumbers advise carrying out work in the following sequence:

- depending on the damage, a strip of metal of the required width is cut out;

- the circumference of the pipe is determined;

- the length of the workpiece is determined (4-5 cm must be added to the circumference);

- holes are drilled from one and the other edge of the strip at the same distance;

- using pliers or a vice, bend the fastener ears at right angles to the strip;

- a rubber strip is cut along the width of the device and along a length slightly less than the circumference of the pipe.

It is necessary to take into account that the small clamp is tightened with one bolt. It is advisable to tighten fasteners up to 6 cm with two bolts. Products wider than 6 cm must be secured with three bolts.

Installation

The device you made yourself should be carefully bent and adjusted around the circumference of the pipe so that the holes in its ears coincide coaxially.

Bending of clamps can be done on a piece of pipe of equal diameter with the pipe being repaired. Then, when installed in place, the clamp is slightly unbent and, with little effort, is installed on the surface to be repaired.

Previously prepared rubber is put on the leak site under the fasteners.

True, you need to remember that a home-made device is a means designed to temporarily eliminate the sealing problem. You should not delay repairing or replacing corroding pipes, as the corrosion process will continue underneath it, and over time the problem will “come out” again.

Making a wire clamp

Very often, home craftsmen need to seal rubber pipes or pipes tightly and securely. This can be while working in the garden, at the dacha or in the garage. In such cases, make a wire clamp with your own hands.

To make it, you need to have pliers and a screwdriver on hand, preferably a Phillips-head screwdriver. It is best to use a special wire - knitting wire (it is soft and quite strong).

Fold the wire in half and throw it over the hose, thereby determining how much it will be needed for fastening, taking into account 40-50 mm for twists. Then cut the desired piece and fold it in half again. At the bend, use a screwdriver to make an eyelet and turn it half a turn. Pull the ends of the wire apart and wrap them around the tube.

Using pliers, you need to twist the ends clockwise a few turns. Finally, tighten the wire clamp with your own hands using a screwdriver. In this case, you need to ensure that the tightening force is sufficient for sealing and does not lead to wire rupture.

With some skill and practice, making and installing clamps is not difficult. Homemade wire devices can serve without problems for a very long time. Replacing them with store-bought ones is a matter of the owner’s aesthetic taste.

Now you know how to make a clamp with your own hands. We hope that for every owner, home problems with repairing pipes, pipes and hoses will become an easy and unburdensome practice.

Your gratitude for my article is to click on any button below. Thank you!

Insertion into the main water supply

When connecting the water supply of a private house to the central water supply system, a mortise pipe clamp is used, which allows work to be carried out under pressure in a short time using specialized professional equipment.

A clamp for tapping into a pipe without pressure is installed by a simple mechanic using a milling cutter and a pair of wrenches. This does not involve the use of a welding machine. In any case, this work is carried out by employees of services servicing the main water supply in a populated area, provided that the client has all the permits.

Stages of installing a mortise pipe clamp in a main pipeline. Clamps for inserting into pipes simplify work on connecting the facility to central water supply systems

Now you know how to make and install a clamp on a water pipe. If the pipeline is damaged, you will be able to fix the problem yourself, at least for a while before professional plumbers arrive.

- Author: MarinaPrint

The proper functioning of heating and water supply systems is one of the primary tasks that every home owner must ensure.

In the case of laying new communication lines and high-quality work, this issue may not worry for a long time. However, time is inexorable, and sooner or later, under the influence of external factors or the influence of water, the pipes will begin to leak. In this regard, let's find out how to install a clamp on a pipe. The technology for carrying out the mentioned work will be discussed further.

What types of clamps are there?

Let us consider on the website remstroisovet.ru the main types of clamps that are most widely used today:

Worm-worm clamps are widely used for connecting pipes and hoses; they are quickly put on, tightened with a regular screwdriver, and also easily removed. The worm clamp can be used several times and can provide a reliable and durable connection.

Pipe clamps - the main purpose of pipe clamps is to fix plastic and metal pipes to the wall and ceiling. Pipe clamps can have different diameters and be used for certain loads. This type of clamps also includes U-shaped and sprinkler clamps.

Ventilation clamps - mainly used for fastening air ducts and various other elements of the ventilation system. These types of clamps are made from two strips of thin steel that are connected to each other using bolts and nuts. Ventilation clamps have several varieties, with U-shaped and U-shaped profiles.

Repair clamps are designed for reliable sealing of pipelines, without any welding. These clamps are made of steel and have a rubber seal inside that quickly closes the fistula. A repair clamp, or as it is also called a “crimp” clamp, should be selected based not only on the diameter of the pipe being repaired, but also taking into account the pressure in it.

Plastic clamps - they are called differently, for example, ties, “shmorgalki”, etc. As a rule, these types of clamps are made of high-quality nylon. The clamp itself looks like a narrow strip, with notches on one side, and a lock at the very end. By tightening the plastic tie, you can quickly fix the insulation to the pipe or secure the wire to it.

AISI 316 steel

It would seem that 304 steel is quite enough to fully carry out all types of work.

But what to do if the installation is carried out in a chlorine environment, at facilities with phosphoric acid? Or where seawater, pitting and crevice corrosion are constantly present. Under these conditions, it is already necessary to choose steel No. 316. This is an improved version of 304 steel with a higher content of nickel and molybdenum. For its anti-corrosion properties it is also called ship steel.

316 steel and polymer coating make it possible to use SKS and SKS-P ties at facilities with special requirements for the reliability and durability of structures. They are ideal for areas with a maritime climate, on ships, floating platforms, offshore structures, as well as in underground communications and tunnels. They must be used at such critical facilities as nuclear power plants, thermal power plants, and subways.

These couplers SKS (316) and SKS-P (316) are available in three sizes:

standard, 4.6mm wide

reinforced – 7.9mm

for working with extreme loads – 12mm

The length of the ties is in a wide range - from 125mm to 1 meter. Tables of technical characteristics for ties made of 316 steel SKS Fortisflex:

SKV ties (316)

Thanks to the wave-shaped damper on these couplers, the intensity of mechanical vibrations is reduced. Simply put, VCRs are vibration-proof and will not weaken under operating conditions that involve constant shaking and vibration.

This is an ideal solution for fastening cables, hoses or pipes to vibration machines, test benches, etc. This tie is like a spring, which guarantees constant tension of the fastener throughout its service life. In addition, SCR (316) compensates for thermal expansion during constant heating-cooling cycles.

Its operating temperature is from minus 80 to + 538 degrees Celsius.

SKV (316) also has an automatic self-locking ball-type lock, which blocks the reverse movement of the belt itself.

Technical parameters and characteristics of steel ties SKV 316 fortisflex:

Screed SKL (316)

SKL – ladder-type steel cable tie. It has a rigid clutch and a multilock lock.

The holes in the tie blade engage the metal teeth of the lock. This eliminates backlash and ensures high strength of fastening structures.

SKL 316 have two main sizes:

reinforced version 7mm wide

ties for extreme loads 12mm wide

Their length starts from 150mm and ends with a maximum size of 6 meters. SCLs are also produced with an additional polymer coating. They are marked SKL-P (316).

The round hole at the end of the tie is necessary to enhance the tightening using a special tightening hook.

Technical data and characteristics of SKL and SKL-P 316 (dimensions, girth diameter, tightening force):

Screed SKB-P (316)

SKP-B stands for yoke-type cable tie.

During installation, the tie strip is bent into the yoke lock mechanism. The result is a reliable clamp. Side clips in the form of ears provide additional fixation of the tape in the lock.

This tie is reusable and can easily be used several times on different fasteners. The polymer coating protects the product from galvanic corrosion between heterogeneous materials.

Technical characteristics and size table SKB-P:

Varieties

Clamps are presented on the construction market in a wide range. Models are produced in a wide variety of standard sizes and are divided according to such characteristics as the method of fixation, the presence of a seal, shape, material of manufacture and purpose.

Based on the material used, products are divided into plastic and steel. Moreover, steel elements can be made either with or without galvanization. Compared to plastic models, steel clamps are considered more in demand and popular. This is due to the low cost of the products, good tensile strength of the metal and high strength. The disadvantage of metal clamps is the low resistance of non-galvanized models to corrosion processes. Therefore, in cases where the installation of clamps is planned in extremely humid rooms, you should choose models made of stainless steel or clamps coated with zinc.

Plastic options are characterized by increased elasticity, high resistance to vibration and the ability to create movable fixation. Models can be used for fastening pipelines with a diameter of no more than 10 cm.

Depending on the tasks assigned to them, clamps are divided into spiral, power, wire, worm, pipe and mortise options.

A spiral clamp is a fairly common device and is intended for rigid fixation of pipes in the system.

The power one has the shape of a tape with holes for bolts and is indispensable when working on lines with increased operating pressure, at pumping stations, pneumatic and hydraulic systems.

Wire clamps are presented in the form of one or several steel rings equipped with tightening fasteners. The model is designed for corrugated pipes and is indispensable for fixing them during strong movements.

The worm model is a steel strip with a track, equipped with teeth and screws for tightening. The model is used in the construction of heating systems, as well as as a fixing mechanism for pipelines exposed to severe vibrations.

Pipe clamps are presented in the form of rings with brackets and are installed to secure the pipeline in cases where it is necessary to reduce the internal stress in the system during repairs.

The spring clamp has a fairly narrow specialization and is used on pipes subject to linear expansion.

A mortise, or saddle, clamp with a branch is a more complex mechanism and is designed for installation in places where the pipeline branches. Its main difference from traditional models is the presence of a coupling equipped with threaded pipes, which allows you to insert the clamp into the system and quickly connect an additional branch. The tightness of such a connection is ensured by a gasket located inside the clamp and made of profiled rubber.

Pivot models, also known as hinge locks, are used to install scaffolding and are used when attaching diagonal type braces. Thanks to the rotary clamps, all elements can be fixed at any angle, which gives additional strength to the structure and ensures its stability.

According to the type of fixation, all clamps are divided into two types:

- The first include models that form a rigid type of fastening, in which the pipe becomes completely motionless. The crimping brackets of such products are securely tightened with bolts, and the clamp itself is firmly attached to the wall. This type of fastening is used in areas where the pipeline bends and in the presence of branches.

- The second type includes models with movable fastenings, used for fixing heating and hot water pipes. The specificity of the fastening does not create obstacles to the elongation and compression of the pipeline and ensures its longitudinal mobility. As a result, an optimal line voltage is created, significantly extending the life of the networks.

Structurally, clamps are available in several types:

- a split ring, formed in the form of a circle and having one fastening mechanism, fixed with a bolt;

- a ring consisting of two semicircular plates and having fastening ears on both sides;

- a tape folded into a ring and having several positions for fixation;

- A U-shaped model, often made of plastic, equipped with a locking latch and capable of being attached in a rigid and movable manner at the same time.

Repair coupling for 300

Repair pipe clamp 300 is used for repairs on large diameter pipelines. This device copes excellently with problems such as:

- Formation of cracks running longitudinally (with a possible deviation of 5 degrees).

- The appearance of a dimensional fistula on a steel and cast iron main.

Using repair tools for 300, you can connect steel and cast iron lines with polyethylene ones. The 300 part allows you to eliminate the leak without cutting off the entire system.

These couplings use gaskets made of certified food grade rubber. And the use of random materials on devices is completely excluded. Therefore, such products are characterized by a high level of environmental friendliness.

The 300 device is a reliable and high-quality device because it is made from high-quality raw materials. To all these advantages should be added its affordable cost.

How to make a pipe clamp with your own hands

At the first signs of depressurization of the pipeline, it is necessary to quickly find the damaged area and eliminate the identified defect. When performing emergency emergency work, you can use homemade clamps to stop the flow in the pipeline for a while.

Ready-made clamps for fastening pipes, made in the factory from stainless steel or fire-resistant plastic, are used when performing installation work on the installation of heating, sewerage, water supply, and gas supply systems.

These fasteners allow you to reliably fix the position of pipes running along horizontal and vertical surfaces (ceilings, walls), as well as those installed on special racks.

In this video, an experienced craftsman shows how to make a wire clamp:

How to repair a fistula in a pipe

How to repair a fistula in a pipe. Sometimes a situation occurs that a fistula appears in an iron pipe of a water supply or heating riser. This is especially common in hot water risers. The first signs that a pipe will soon burst is when a red growth appears on it, but it may not appear.

In scientific terms it is called pitting corrosion, but in simple terms it is “Pipe” to a pipe. Fistulas appear on the pipe, either due to wear or due to stray currents.

In principle, when you get a fistula, you won’t care why it appeared, you will have a question: how to fix it quickly? I'll try to describe a couple of options on how to do this.

How to seal a fistula in a pipe with a clamp

In general, if you see that your pipe is not of the first freshness, then it is advisable to purchase a couple of clamps in advance for the diameter of the water supply riser, and cut rubber for them. Because most often this happens at night, and by the time the emergency crew or mechanic arrives, it can be heavily flooded. There are a couple more nuances regarding the size of the fistula.

If the fistula is the diameter of a needle, then you can install a clamp without shutting off the water, but if it is larger, then when installing the clamp, you risk getting burned; if the fistula is in a pipe with hot water, it is better to turn off the water at the riser. If the fistula is small, you can try to seal it with a regular car clamp, as in the photo.

You do this: take a piece of rubber and cut out a thin ribbon, the width of the ribbon should be equal to the width of the clamp, maybe 3-4 millimeters more, but not less, now measure the length of the rubber band. We wrap it around the pipe and cut off the excess. Then cut off another 1 cm. Next, open the clamp, put it on the pipe, and grab it a little.

I have had such cases in practice that in an apartment there is a fistula with the diameter of the “eye of a needle”, it whistles very loudly, but there is not a lot of water, the tenant, the grandmother “God’s dandelion” is screaming like crazy, but I can’t turn off the water, since it is from won’t let me out of the apartment, and I didn’t have the clamp with me, what I do, after looking and determining that the pipe is in excellent condition, I break off a piece of a match, and insert the tip into the fistula, and there was no fistula, but this is so that the grandmother calmed down. Then, of course, I installed the clamp. I often closed such fistulas in the basement this way, but there were also punctures, you insert a match, and the fistula becomes 2 times larger, so I do not advise you to use this method. Well, this is a digression, let's consider another option.

Summarize

It is safe to say that clamps, regardless of their purpose, are truly irreplaceable. If desired, a plumbing fastener can be turned into a repair product and save the neighbors below from flooding. In addition, the home handyman will be spared the costs associated with repairing the lower apartment. If it is necessary to replace sewerage or water supply lines, there is no alternative to fastening clamps. In addition, the price of such plumbing products is low, and you can buy them at any hardware store, which makes them accessible to all segments of the population.

We hope that the information presented in today's article was useful to our dear reader. While reading, you might have some questions on the topic. Feel free to ask them in the discussions below. The editors of Seti.guru will be happy to answer them as soon as possible. If you have experience using various clamps professionally or for DIY repairs, please share it with other readers. This will be useful for beginning home craftsmen. Write, ask, communicate. And finally, we bring to your attention a short but quite informative video on today's topic.

Making a clamp from scrap materials

Find a strip of galvanized sheet metal, the thickness of which does not exceed one millimeter, and a piece of three-millimeter rubber. Look in your supplies for a couple of bolts (M6, M8 or M10), as well as matching nuts and washers. Tools that will be useful:

- hammer; calipers; wrenches; vice or pliers; metal scissors, which can be replaced if available with a jigsaw or grinder equipped with appropriate cutting elements; drill and bits (M7, M9 or M10, M12).

Use a caliper to determine the pipe diameter. If the pipe diameter is large, then take the necessary measurements using an angle and a ruler.

Next, cut out the tin frame of the clamp in the form of a strip, the width of which should be 4-8 cm, and the length will have to be calculated. To do this, determine the circumference of the pipe by multiplying its diameter by 3.14 (the number Pi, familiar to everyone from a school geometry course). 3-4 cm are added to the result obtained, from which “ears” are subsequently made with drilled holes for fastening bolts.

The size of the holes in the “ears” depends on the diameter of the bolts, and if the washers are wide, then you can add an extra 2-3 mm to simplify the installation of the clamp in the future. If the width of the bandage exceeds 6 cm, then it is recommended to drill holes not for two bolts, but for three.

Mark with a marker a line along which to bend the “ears” at a right angle to the tin strip. This operation can be done manually if the strip is thin. Thicker material is worked with a vice or pliers.

Next, the tin is bent around the pipe on which it is planned to put the clamp, and they try to connect the ears so that the holes drilled in them coincide. If the tin does not bend well, then tap the strip with a hammer. A pre-cut rubber gasket, cut to fit the width of the bandage, is inserted into the clamp.

Main technical characteristics of repair devices

Crimping repair clamps for pipes consist of the following parts:

- Bandage. This is a crimp element (stainless steel or galvanized), which has a thickness of one or two millimeters. Carbon steel (one and a half to three millimeters thick) is also used to manufacture this structural element. And often cast iron parts are used for this task.

- Cuff. It serves as a sealant on crimping devices. It is made from cellular rubber 6429 - from 8 to 13 SHAFT.

- Fastening elements of crimping mechanisms are made of stainless steel or galvanized.

Acceptable standards for the operating pressure that crimping devices can tolerate are from 6 to 10 atm. The working medium for them is water, air, or any inert gas.

The temperature standard for crimping devices is from -20 to +600C. And their diameters range from 1.5 to 120 cm.

Modern wire clamp - design and operation

First of all, I would like to clearly define the concepts: what can actually be called clamps. So, this is a ring-shaped device, usually made of light metal alloys. It has a tightening mechanism in the form of a special nut, mainly with a worm thread, and also, depending on the models, a metric thread is used on the nut. In our case, the base of the device has a wire base, but is made of a fairly strong metal that does not deform when pulled together.

In the modern version, the tightening element is precisely a nut with a metric thread, when tightened, the mechanism tightly fits the surface, while firmly clamping it onto the working base. The scope of application of clamps is quite wide, but the range of action is designed to create a hermetic connection of hoses, rubber pipes with solid bases, and pipes. Using a clamp, you can tightly connect the water pipeline with a rubber hose and not be afraid that there may be a leak somewhere.

Even the corrugated exhaust pipe is attached to the chimney using a clamp and does not allow combustion products to enter the room.

Initially, such a device was created not for domestic needs, but for the automotive industry. Clamps are an important element in the engine of almost any car. Ask why? The fact is that the engine of the machine during operation, due to vibration, is in a moving state, and various connections, fuel and oil supply are different pipes. It is the rubber pipes that have free movement and vibrate evenly along with the engine, while fulfilling their duties of supplying fuel. Well, they are attached to a metal base with clamps; they are able to provide a reliable, sealed, and most importantly, durable connection of important engine components.

Types of clamps

Modern clamps for fastening pipelines are available in various modifications. They are classified by:

- purpose;

- type of material;

- type of fixation;

- form;

- the presence of a gasket.

Purpose

Depending on which pipelines the clamps are used for, they may have different structural properties. Main types:

- Spiral clamp. Can be rotated clockwise or counterclockwise. Used to connect reinforced parts of water supply systems.

- Power clamp. It looks like a tape with a tension component. Designed for connecting round and rectangular pipelines, rigid and flexible hoses, and reinforced hoses. The clamp is used for mounting systems operating under pressure - pumps, hydraulic pneumatic actuators.

- Reinforced fasteners. It is a lock connected to a tape. The clamp is used to fix hoses with reinforcement or thick walls, operated under pressure.

- Wire fastening. It looks like one or several thin steel rings with a mechanism for tightening them. Used to secure hoses, corrugated and spiral pipes with thin walls that are subject to vibration.

- Worm clamp. The design includes a metal strip with a toothed track and a screw (bolt) for tightening. Used for fixing hoses and pipes in places with high vibration, including water pipes and heating systems.

- Pipe clamp. They are a ring or bracket with fasteners. They are used to openly secure pipes in a specific area in order to reduce stress from the internal part of the system and fix the position of the pipeline.

- Spring clamp. Designed for fixing pipes providing hot water supply, that is, structures susceptible to thermal expansion.

Material

In addition to metal, plastic and nylon can be used to make clamps. The functionality and durability of plastic products is lower, but the price is more affordable. Nylon fasteners are durable and lightweight. They do not corrode and are used for installation of air pipelines.

As for metal clamps for fastening pipes, they can be made of stainless or galvanized steel. Stainless steel has a longer service life as it effectively resists corrosion. For large diameter pipes and pressure structures, only metal fasteners are suitable.

Fixation type

The clamp can fix the pipeline motionless (rigid) or movably. With a rigid connection, the element is not able to move from the fixation point. The brackets are firmly bolted together and attached to the wall (floor, ceiling). This fixation is used in places of bends, branches of sewerage and cold water supply systems. Fasteners are used that can withstand maximum loads and ensure static pipes.

Floating (movable) fixation is used for heating and hot water pipelines that are susceptible to high temperatures. Their feature is the periodic expansion/constriction of elements. Floating clamps do not interfere with this process, allowing for slight longitudinal movement of the pipes. In this case, transverse deviation from the axis is impossible.

Form

There are three main structural forms of fastening clamps:

- A split ring that opens on one side and has a movable connection on the other. After installation, the fastener is secured with a bolt.

- Two half rings of the same size. They are connected to each other with bolts or studs.

- The bracket is shaped like the letter U. It can be rubberized inside or completely metal.

Pad

Steel clamps may have a microporous rubber gasket inside. The advantages of such products:

- “damping” vibrations when liquid passes through a pipe;

- reduction of noise level during pipeline operation;

- increasing the tightness of joints.

Clamps with gaskets provide reliable and durable fixation. Their disadvantage is their higher price.

Installation process

As for the process of installing a clamp, for example, on a heating pipe, everything is quite simple. For maximum efficiency, it is best to carry out actions in stages: First, it is necessary to shut off the flow of water (in this case, acting as a coolant) into the pipe. Next, the installation site of the clamp must be cleaned and leveled for maximum sealing in the future.

For these purposes, sandpaper is suitable, with which you need to remove the top layer of paint. Thus, not only will the surface be leveled, but the location of the damage will become more clearly visible. After this, a clamp is installed. To do this, the fastener is untwisted on one side, and the half rings are moved slightly in different directions so that the element can be put on the pipe. In this case, the rubber seal should be positioned so that the place where the leak occurs is located in the middle of the rubber part. Next, the fastening elements of the clamp are inserted into the ear holes, and the element is tightened using keys.

If all stages of work were carried out correctly, the leak will be eliminated. This will be most clearly noticeable if the water was not shut off. In addition, it should be added that for additional sealing of the joint, the inner surface of the rubber seal of the clamp can be treated with silicone sealant, which, after polymerization, will give almost complete confidence in the tightness of the joint.