Cutting round holes in plywood

Often, when repairing or installing various wooden products, it is necessary to drill a perfectly round hole.

In this article we will try to highlight all the ways in which such a hole can be cut. Options with the use of special tools, as well as without them, will be considered. How to cut plywood

A hacksaw with a very narrow blade, a jigsaw, a drill saw and a round file are among the hand tools that can be used to cut curves.

It is the narrow blade that provides maneuverability to the hacksaw, but for the same reason it is extremely difficult to operate. You must have a steady hand and an attentive eye to prevent deviations from the markings. However, do not try to work quickly. On the contrary, it is better to advance in small spurts. This will help you hold the saw handle more confidently and guide it exactly along the given line.

It is better to cut out small round or oval holes and “narrow” curves using special tools - a drill saw and a round file, which can also be used to clean out curves.

However, the most suitable tool for cutting rounded parts and holes is an electric hacksaw. Its advantage is not only that it saves energy and time. The included set of interchangeable blades with different teeth allows you to choose a blade for sawing almost any type of workpiece, be it wood, plywood or chipboard. In other words, an electric hacksaw can rightfully be called a universal tool.

Round corners of furniture

You can even get injured by hitting a sharp corner of the table. Therefore, we recommend cutting corners where possible. For homemade furniture, they need to be rounded from the very beginning.

Cutting circles and curved lines is no more difficult than making an absolutely straight cut on a workpiece, but under one condition: you have the right tool in your hands and you are good at it.

Mark missing parts

It may happen that the holes that you drilled to insert a narrow blade with a hand or electric hacksaw will end up in useful areas. To avoid such mistakes, you should mark all missing parts of the workpiece with shading.

What is suitable for the template

You can make a circle on a workpiece not only with a compass. Any object of a similar shape is suitable for this purpose. This could be a pan, plate, cup or bowl. However, when starting work related to the repair of furniture or some piece of furniture, calculate in advance the need for parts with rounded contours or with round holes. It may be enough to make only minor changes to the design.

How to cut a circle from chipboard or a review of a circular saw with variable diameter Buttress (Ballerinka)

The other day I came across this folding shelving unit made of chipboard. So for it it was necessary to make about 15 nickels from the same chipboard with a diameter of 80 mm. And since I didn’t really want to cut such a number of pancakes with a manual jigsaw, and besides, there was no narrow file for a small radius. Then at the nearest tool shop I bought this circular saw, Buttress, popularly known as a “ballerina.” Judging by its appearance, it immediately became clear that this Chinese drill was practically disposable, and there was no need to look at it, because its cost of 300 rubles and change speaks for itself. But since there was no ordinary wood bit of a suitable diameter in the store, I grabbed this “miracle” in the hope that I would somehow cut 15 round timbers with it, and then I could throw this ballerina into a long box.

Instead of a compass

A school compass can also be useful in a home workshop, but its range of action is small. What if you need to draw a circle of large diameter?

An easy way is to do this with string, a nail and a pencil. The nail is carefully driven into the workpiece, the rope is secured to it at one end, and a pin is secured to the other end. The length of the rope determines the radius of the circle being drawn. The only condition is that the rope must be taut along the entire path of the pencil. Then the distance from the center (nail) to the circle in all sections of the marking will be the same.

Strip of cardboard or slats

An equally simple, but more reliable way is to use a strip of cardboard or, even better, a wooden plank instead of a rope. Drill two holes in this bar (strip) - one, smaller, for a nail, the other, larger, for a pencil. The distance between their tips should correspond to the radius of the desired circle. All that remains is to install the nail in the right place and rotate the bar around its axis.

Two sharpened nails and a wooden strip or a strip of thick cardboard can replace a compass.

Ballerina device

The design of this tool is simple; in the most common version, it is a bracket with a drill fixed along its axis of rotation. This center drill not only marks the center of the future large hole, but also provides support for stable rotation of the entire device. On two opposing arms of the bracket there are two carriages with cutters fixed in them. The bracket rod is specially marked, which allows you to install carriages with cutters with fairly high accuracy. Having spread the lateral incisors to the required distance, they are fixed on the bracket with clamping screws, after which work begins. It would be a good idea to check the spread of the cutting edges using a caliper.

In addition to this, there are several more modifications, in which there are one, two or even three incisors. They differ in the different design of the bracket - it can be a disk along which cutters move in special slots to adjust the diameter. Also, in the axis on which the ballerina rotates on wood, a hole is drilled, straight or at an angle, and a cutter is inserted through it, fixed with a locking screw. This also makes it possible to adjust the diameter of the resulting circle, and one cutter does a good job, especially if it is made of good steel and used correctly.

The shank of the central axis can be round or have a special shape for fixation in the SDS chuck. Quite often, knives of various shapes are used, capable of removing straight or rounded chamfers where necessary.

Read also: Resanta sai 220pn circuit diagram and malfunctions

How to draw ellipses

An ellipse is a rather complex shape, but to draw it on paper, you only need two thumbtacks, a piece of string and a sharpened pencil.

Attach two buttons to the surface of the workpiece at some distance from each other. Take a piece of rope, tie both ends into a knot and hook the rope onto the button heads. Now, with a pencil, draw a line that the stretched rope allows you to describe. You can change the shape of the ellipse at your discretion.

The distance between the two focal points of the ellipse is indicated by buttons. If you guide a pencil within the boundaries assigned to it by a rope, then the outline of an ellipse will appear on the paper.

The ellipse shape can be larger or smaller, thicker or narrower, depending on the distance between the buttons and the length of the rope.

How to make a wooden garden path with your own hands, photos and videos

There are many possibilities for organizing garden paths. Many of these methods are very simple, and these ideas can be implemented on your own, without hiring professionals and even spending a very modest amount on materials.

The second most popular material for garden paths after stone is wood in all its shapes and colors. Wood is inferior to stone in terms of reliability, but it creates a feeling of warmth and does not require serious expenditure - both monetary and time.

Even in a garden decorated in a modern style, a wooden garden path looks very impressive. We have found wonderful instructions for you on how to make a garden path from wood cuts with your own hands.

You will need:

- several tree trunks of different diameters

- saw

- varnish for waterproofing wood and protecting against mechanical damage

Templates

Shot glasses, cups, plates, pots or baking dishes - in any household there are many round-shaped objects that can be used to mark a circle. If you are making something and decide to give your product a rounded shape, then first look to see if there is a suitable template among the household utensils. To be sure, select a few items and take them to the workshop. There you can immediately try them on the workpiece and determine what is most suitable. With some practice, you will be able to make rounded lines from several round objects with different radii. Arcs of a circle can be drawn sequentially, or bridges-transitions can be made between individual arcs.

Preliminary drawing

Before attempting to trace a curve on a piece of paper, design it on a large piece of paper or piece of corrugated cardboard. Only after the result is satisfactory in all respects can you cut out a template from paper and make markings on it on the workpiece.

You can draw circles and fragments of a circle using a cup or plate by simply tracing them with a pencil.

Shape cutting technologies

Jigsaw

As we noted above, a jigsaw will come in handy if we are looking for how to cut a word out of plywood or make other parts of complex shapes:

- We transfer pre-printed drawings or templates onto the workpiece using carbon paper.

Figured carving with a jigsaw: photo of the finished product

- If the structure has through sections, we make starting holes with a thin drill.

- Insert a file or jigsaw blade into the hole. Secure the free end of the file with a fastening screw or clamp.

- We make a cut along the intended line, pressing the workpiece to the workbench. The saw moves either automatically (for electric jigsaws) or manually.

After all the arc elements have been sawn, we remove unnecessary areas and process the finished part with a file or sandpaper.

Finished hole

Fraser

A furniture router is great for cutting out thick plywood. Of course, you can’t make a complex shape with it, but cutting an arc or circle is easy:

- We fix the standard ruler included in the router in the center of the circle using a self-tapping screw.

- If the length of the ruler is not enough, you can assemble a simple bracket from a metal profile or wooden planks.

- By rotating the cutter along a fixed radius, we select a groove along the circumference, resulting in an almost perfect hole.

Bracket for router: with it you can cut a disc of almost any diameter

Note! When calculating the diameter of the circle, you should take into account the dimensions of the working cutter. The instructions for the device will tell you the exact numbers.

In this way, you can cut not only circles, but also individual arcs - for example, in order to make grooves for furniture brackets.

Using improvised means

For shaped elements, it is advisable to have special devices, but any craftsman may need to make a round hole in a slab of laminated veneer. Below we will tell you how to cut a circle from plywood when you have nothing at hand. Well, almost nothing:

- To cut plywood, use a wooden strip with two nails.

- One nail is driven through the strip into the workpiece, exactly in the center of the hole being made.

- We drive the second nail into the bar so that the point protrudes on the wrong side by at least 5-10 mm. The distance from the first nail should be equal to the radius of the hole being made.

- Rotating the bar, use the tip to draw a groove on the plywood, deepening it with each turn.

- Instead of a stick, you can use a strong cord. The operating principle remains unchanged.

Diagram of "threading" using nails. The sharper the nail used, the faster the hole will be made. It should be noted that although the price of such a device is low, it is worth using it only when other methods are not available: the edges still turn out to be far from ideal.

Inserting a sink according to a template

The sink is one of the most important elements of kitchen equipment. If you decide to cut your sink into your kitchen worktop yourself, the first thing you need to do is prepare an exact template.

First, transfer the outer outline of the shell onto a thick sheet of paper. Next, measure the width of its sides, which will rest on the tabletop. Usually this is 2-3 cm. Now step back from the outline drawn on the paper, inward by the width of the side and draw a parallel line. This will be the cutting line.

When applying markings, make sure that the position of the template itself on the plate is correct. Of course, if all the corners of the sink are symmetrical, then nothing bad will happen if, according to the markings, it appears to be in a mirror image. But if the sink has the shape of a trapezoid and the roundings at the front corners differ from the roundings at the back, then under no circumstances confuse the front and back parts.

Use a similar pattern to make templates and cut holes for wall lights or loudspeakers mounted on wood panels.

The line drawn around the sink is auxiliary. The second, drawn parallel closer to the center, is the sawing line.

Cutting an even circle in plywood without special tools

Hello everyone, dear friends. This is rather my last article here, I think it will be interesting to many. I encountered the following problem: I needed to make an even circle in the plywood under the speakers, but there were no tools for this, this device was invented. The device is very simple, anyone can make it, and it is very easy to use.

For this “device” we need:

- a board 20-30 cm, thickness 2-3 cm - two self-tapping screws - a screwdriver - and something in which the hole will be made

You screw one screw into the middle of the board or a little closer to the edge, as convenient

Next, measure the required diameter, measure it on the board and mark it, screw in the second screw

This is roughly what it should look like

Now we screw the central screw through into the plywood, and slightly unscrew the second one so that its “sting” sticks out slightly from the board.

And we begin to rotate the board, thereby cutting through the board or whatever you call it

Each time, as soon as the board becomes easy to move, we screw the screw in a little inside, and thereby cut further and further into the circle

Here is the final result, the hole has already been cut, everything is perfectly smooth, if desired, you can sand it to give a smoother surface

That's all, we cut an even circle without any costs or special tools.

Source: www.freeseller.ru

Electric hacksaw

If you need to cut a round-shaped part and saw a round hole in the workpiece, then an electric hacksaw is the most suitable tool. With its help, you will save effort and time, since such a saw has great advantages over a manual one. Thus, the blade of the electric hacksaw is narrower, which provides increased maneuverability. Further, it has replaceable blades with different teeth, which allows you to process workpieces of any type, that is, wood, plywood, chipboard (it is no coincidence that the tool is also called a jigsaw).

To cut a section inside the workpiece, a hole is first drilled for a hand saw. But if you have an electric hacksaw, then this is not necessary. The tool is brought to the workpiece with a slight tilt forward and turned on in this position. The saw will cut the hole itself. Just don’t put too much pressure on the body - this can lead to breakage of the saw blade.

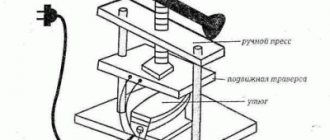

Lead in a circle

This device, simple in design, makes cutting out round holes or arcs much easier. It is enough to mark the center of the circle on the workpiece, fasten the device along the mark and connect the rod coming from it with an electric hacksaw. The divisions on the rod help set the saw blade at the required distance from the center of the circle. As a result, without preliminary marking, you can cut a circle or saw an arc with a radius of 5 to 20 cm.

The device (more precisely, its “sole”) is attached to the surface of the workpiece with screws. They should be well tightened. If the fastening is not rigid and starts to wobble, then an even circle will not work.

Suitable for lefties too

Left-handers can also use the device, since the guide rod is attached to the movable unit both on the left and on the right. So cut at your own discretion - clockwise or counterclockwise.

Using such a device, you can cut a round hole with a diameter of 10 to 40 cm in the workpiece without preliminary marking.

Advantages and selection criteria

The advantages of a ballerina are as follows:

- obtaining neat holes with a diameter of up to 300 mm;

- simple and reliable design;

- low price, which, if it is necessary to make only a few holes (in everyday life, for example), turns out to be decisive;

- Possibility of adjusting the diameter.

Many people argue that where woodworking is used, crowns or circular saws could be used. However, the crowns have a fixed diameter without the possibility of adjustment and a rather high price. Therefore, they are more often used in such work where it is necessary to cut a large number of identical holes (for fastening standard lamps, sockets, etc.). If you need to work with several holes of different diameters, a ballerina is more suitable.

This device should be selected carefully, using criteria that are important for any instrument. This is the quality of workmanship, the accuracy of sharpening knives, the reliability of fixing structural elements and other subtleties known to anyone who has at least occasionally encountered cutting equipment. Despite this, many choose a ballerina based only on such criteria as cost. These people should be even more careful, since a cheap tool may not have the proper characteristics and can be quite dangerous. You should always remember that rotation occurs at high speed and an insecurely fixed cutter can hit a person or simply fly to the side with an unpredictable result.

However, for everyday use, with small volumes of work or the need to drill several holes of different diameters, the ballerina for wood shows its good side and, thanks to its low cost, pays for itself quite quickly. It is not always justified to use other types of tools for such tasks.

Jigsaw

When cutting holes or curves in small workpieces, sometimes you can’t do without a jigsaw. Replaceable blades with teeth of different shapes and locations allow you to work with wood of different densities. However, it should be taken into account that the depth of the cut is limited by the arc of the jigsaw, that is, the saw blade will not be able to move further than 30 cm from the edge of the workpiece.

Very thin, narrow saw blades can be easily damaged if the jigsaw is used incorrectly. The saw must be operated with careful, methodical movements. The main thing is to prevent the canvas from skewing. Otherwise, small and light workpieces will begin to move with the saw, which may ultimately lead to the blade bursting.

The thinnest jigsaw blade will “master” the narrowest curve, but only in small workpieces, since the advancement of the blade is limited by the arc of the jigsaw.

Drilling blind holes in chipboard for hinges

Cup drills are used to drill blind holes. Chipboard is no exception. It is worth paying special attention to thin chipboards with a thickness of 16 mm. To cut a hole for a hinge with a diameter of 35 mm and a depth of 8-10 mm, the drill has an unacceptable depth. The drill bit will go right through the slabs and create an unwanted hole in the door face. To overcome this unpleasant situation, we do the following.

We start drilling with a 35 mm drill and make a hole of small depth. We obtain the remaining depth with a cup drill of a smaller diameter, moving it along the surface of our hole. Not much work, actually, because... The hinge cup is not strictly round in shape.

By the way, during operation the scattering of “fragments” is quite decent. To limit the range and reduce the time for subsequent cleaning, you can use a simple technique. A protective casing is made from a cake or pizza lid (it’s the latter in the photo below) (sounds pretentious). During operation, all sawdust is inside and nearby.

We remove the cardboard and sawdust all nearby. All that remains is to remove it with a brush/vacuum cleaner in one pass.

Maria , Access date: 2015-02-18 18:10:07

Please tell me what to do if the drill “leads”? The hole is ellipsoidal. Material - beech (everything is better on chipboard). The drill has a side blade. I’m already thinking about buying a machine for a drill or looking for someone to make it to order (((

Roman , Access date: 2011-08-01 19:14:59

It’s been a long time since I read somewhere this technique for drilling for hinges. Take two Forstner drills. One of them has the central spine completely cut off. Start drilling with a normal drill, finish with a sawed one - and the hole will be perfectly blind.

boris-yarovoj , Access date: 2011-03-24 17:51:23

About the letters A, B, C on the strikers. This is how they used to designate more accurately (I'm afraid to confuse the order of the letters) overhead, semi-overlay and inset hinges - Chinese manufacturers. It’s as if it was made especially for Chinese storekeepers (and for ours too). But the furniture maker doesn’t need to get hung up on this - look at what the loop actually is along the bend of its “neck” - i.e. what you hold in your hands and what you use, but these letters seem to be a thing of the past.

boris-yarovoj , Access date: 2011-03-24 17:42:37

There is no need to use two “Fostner drills” of different diameters. I choose one hole - 35 mm. It’s just that when you buy such a drill specifically for hinge cups - in chipboard 16mm - then you need to blunt the centering tip of the drill by the amount you need, so that it is just a little in front of the lateral incisors. In principle, you don’t even need to sharpen it after that - you just need to punch each future hole a little. Of course, you will need to develop the habit of holding the drill as perpendicular to the surface as possible. Before each drilling on a plane, I make a mark with a thick awl. This is also useful for drilling soot with an ordinary 8mm drill - a plane - for a confirmat (euro screw). More about the Fostner drill (you can’t put a stop on it): we develop a 6th feeling in ourselves - “first, we drill under the loop not all the way to the bitter end,” blow out the chips, try on the loop and, if there is a lack of depth, drill through with little effort (or better yet, again try on a hinge if you have doubts about your 6th sense). And probably it’s not even worth mentioning that there should be a flat surface of the workbench under the part, otherwise you can tear everything out without a drill, but simply with effort.

Drill saw

Neither a hand saw nor an electric hacksaw will help if you need to cut a small hole in the workpiece - less than 10 cm in diameter. A jigsaw may also be useless if the workpiece is large. In this case, the most suitable tool is a drill saw. With its tip it bites into the wood like a drill and thus makes a “starting” hole for further cutting. Externally, the saw is similar to a round file with the difference that its shaft is surrounded by a spiral around the cutting edge.

Drill saws are available with interchangeable attachments of various diameters, designed for processing both soft and hard wood, as well as a variety of materials made from it.

The working body of a drill saw is a metal rod with a cutting tip, like a gimlet, and a cutting edge that goes around the rod in a spiral.

This is what the narrowest of hand saws looks like. Thanks to the fastening unit, the blades in the hacksaw can be changed depending on the nature of the material being processed.

Drill attachment

One of the most popular and convenient options for cutting a hole is a special attachment for a drill. It is made in the form of a crown comb and has a rounded shape. With this attachment, cutting holes occurs quickly, and they turn out quite smooth.

drill bit for holes

Nozzles come in different diameters, which allows you to cut a hole of the required diameter. If you have already prepared a hole, we can advise you to try your hand at options trading.

Drill

You can also cut a large hole using a drill. To do this, it is necessary to pre-mark the outline of the hole to be drilled. Next, use a small drill to drill through holes along the contour prepared in advance. Next, using a jigsaw or a very sharp knife, we cut off the holes, thereby connecting the holes. After which you can smooth the circle using sandpaper of various grain sizes.

Chisel

You can also cut the required hole using a chisel. It is enough to remove the wood layer by layer along the contour. This option is the least suitable for interior decoration. The hole must be smooth, which cannot be achieved by using improvised and unsuitable materials for the job. The best option would be to use a drill bit. The hole is even and has smooth edges.

Thus, to summarize, it becomes clear that you need to choose a tool for cutting a hole based on your goals. If you need a high-quality cut, then you cannot do without a special tool.

Criteria for choosing a quality option

Below we will look at the main types of devices for cutting holes in wood, but for now we will outline the criteria that any option must meet, regardless of its modification:

| Reliable manufacturing material | Of course, it is unlikely that you can determine this criterion by eye, so it is best to ask the seller for a quality certificate for the product. Unreliable counterfeit versions from China most often do not have any documents. |

| High quality performance | Examine the product carefully: the surface must be smooth without flaws or defects, the cutting part must be carefully sharpened. If you purchase a long wood drill, check whether it is level; this can be done by eye or by rolling it over a flat surface - any irregularities will be immediately visible on it. |

| Good packaging | Low-quality fakes are most often packaged haphazardly, moreover, there are mistakes in the words. No well-known brand will allow itself unsightly packaging, remember this. |

| Price | Price is also an indicator of quality; as a rule, the most budget options do not last long, especially when it comes to large-sized drills and fixtures. After all, they are subjected to very high loads during operation. |

Advice! To be guaranteed to purchase a quality product, be it an electric jigsaw for wood or a circular saw, you need to contact official representatives of a particular brand or buy products from well-known stores that care about their reputation and do not sell cheap fakes.

Cheap core drill sets are so unreliable that they may only last for a single use

Read also: Do-it-yourself workbench for carpentry work