DIY moped from a chainsaw

Moped from a chainsaw - made by a craftsman with his own hands: photo and description.

In the last article we already looked at the step-by-step production of a moped from a Druzhba chainsaw, this time we’ll take a look at another homemade product - this is a mini moped from a Stihl-MS180 chainsaw. So, to build a homemade product you needed the following materials:

- Chainsaw.

- Square pipe.

- Wheels from a walk-behind tractor.

- Handlebar, fork, chain and sprocket from a bicycle.

The mini bike assembly process is shown in the photo. Trying on all the details.

Making a frame from a profile pipe.

Finalization of the leading star.

Video testing a homemade moped.

Mini bike after painting.

The result is such a simple and compact mini moped, all that remains is to install the fuel tank, a protective cover for the chain and make the brakes. The moped can easily carry an adult weighing 90 kg and accelerates to a speed of 30 km/h.

Scooter tuning - intake pipe tuning

| The gasoline-air mixture prepared by the carburetor then flows into the crankcase through the inlet pipe. This part is sometimes mistakenly called a manifold, which is incorrect, since this pipe does not collect anything, but only directs the mixture into the crankcase. It is important that the flow area of this part is no less than the size of the carburetor, otherwise there is no point in installing a carburetor! The flow area of the standard pipes on most scooters is such that you can easily use a 17.5 mm carburetor instead of the standard one. The same cannot be said about 19 mm carburetors! What can we say about such scooters, subjected to grief tuning with the help of 21 or even more carburetors without replacing the intake pipe!? Through tears, we call these “scooters named after the 19th carb”... An anecdote comes to mind: Stirlitz gave the dog gasoline and let him go. The dog ran 5 meters and fell. “The gasoline has run out,” thought Stirlitz. |

DIY scooter with gasoline engine (33cc/4T)

Hello to those who like to make things, I propose for consideration a project for making a homemade scooter. The author used a motor from a gasoline trimmer as an engine for the scooter. An interesting fact is that this engine is four-stroke and needs to be powered with pure gasoline without oil.

The only problem with such engines is high speeds; to solve this problem, the author used a reduction gearbox from an electric motor. The homemade product accelerates to 40 km, and the motor used here is not the most powerful, only 33 cc. If the project interests you, I suggest you familiarize yourself with it in more detail!

Materials and tools used by the author:

List of materials:

— engine from a 4T/33cc petrol trimmer; — chain transmission; — gear motor; — brake system for a bicycle; — throttle handle; — bicycle stand; - small wheels from a children's bicycle; - old bicycle for spare parts; — profile pipes; - round pipes; - sheet iron.

Homemade manufacturing process:

Step one. Gearbox installation

The shaft speed of the selected engine is too high, and the torque is weak, since the engine used is not very powerful. To solve this problem, we need a reduction gearbox, which will allow us to obtain high torque and reduce speed. The author found the required gearbox in an electric motor, we disassemble it and remake the gearbox. The drive gear here is made directly on the engine armature, so we cut off a piece of the axle and now it needs to be installed on the shaft of the gasoline engine.

The motor shaft has a splined hole into which the trimmer shaft is inserted. We need to make the diameter of the rod cut from the anchor smaller; for this, the author clamps it in a drill and, thanks to the grinder, sets the desired diameter of the shaft. Well, then we drill a hole in the trimmer shaft, cut a thread for the screw, and make a groove in the installed shaft. As a result, we will not have to damage the engine from the trimmer.

Manufacturing

Making a snowmobile from a scooter with your own hands is not that difficult. No special adjustments to the original design are required. In this case, it will be possible to easily replace tracks with wheels and back when the weather changes. It is recommended to take tracks and driven sprockets from Buran snowmobiles. Additionally, a pair of wheels from a children's scooter and a pair of medium-sized wheels from any cart (with the addition of roller bearings) are used.

The drive wheel must be replaced with a propeller of a much smaller diameter. This is due to the need to adjust the gear ratio.

The fact is that scooters by default allow travel at a speed of 40 to 60 km/h, and on first-class roads. When driving in snowy areas, the load on the engine increases. Excessive speed is also a source of risk.

Next, focusing on the main wheel disk, cut out the brake drum and splines for the drive shaft. A small-diameter disk is secured by first punching a hole in the drum with a drill. Making homemade hooks helps prevent the caterpillar from slipping off the wheel and sliding during movement. They are obtained using PVC water pipes. Such hooks have to be inserted into the holes of the caterpillar.

Then they take flat roofing iron and prepare a bandage of a suitable diameter. Hooks are fixed on such a bandage using furniture bolts. Fasteners must be placed at a constant distance. The pitch is determined by the placement of the holes. A soft star is made on the basis of a simple wheel.

The frame is obtained using a metal angle and square pipes. The dimensions of the frame and its parts must be selected independently. At the same time, they take into account what kind of scooter the snowmobile is based on and what kind of caterpillar is used.

If there are no plastic skis from children's scooters, you can make an exact wooden analogue by hand. The ski is attached to the front fork using a special rack.

Usually there are 2 levels of freedom of movement. No matter where the scooter leans when moving, 100% of the ski plane remains exactly on the snow. It is worth taking care of installing a wide support platform for the feet and a small decorative shield under the front fork. Recommendation: For long trips in winter, you will definitely need a windshield. Typical scooter body kits will have to be redesigned because they do not tolerate extreme cold well and are susceptible to snow accumulation in the “pockets.”

Additionally, a casing is installed to protect the caterpillar. It is formed from polycarbonate, plexiglass or other synthetic materials. The side part of the casing is cut out carefully. The workpiece is transferred to a large sheet, which turns out to be the wall of the matrix. We fix the plastic corners with hot glue around the perimeter at equal intervals.

After cutting a strip of flexible plastic of small thickness that exactly matches the width of the casing, assembly of the matrix begins.

Then the fiberglass fabric is cut into the required fragments. All joints are coated with plasticine. You need to keep the matrix for about 24 hours.

Next, you should consider making a snowmobile from a Chinese scooter with a 50cc engine.

In this case:

the frame is made of steel profile 50x50;

the drive is taken from the expanded wheel;

the caterpillar cart is formed from a profile and corners taken from a school desk;

Silent blocks from Zhiguli are used as hinges;

slimes are made from a thick water pipe (plastic);

To obtain skis, extenders for snowmobiles are used.

There is no particular point in installing engines of 150 cc or larger. They are really needed only by people going on long tourist trips or engaged in hunting and fishing professionally. This is what a drawing of a homemade tracked snowmobile frame looks like. The width in the frontal plane is 0.7 m, and at the rear - 0.4 m. The height reaches 0.5 m, and the total length is 1.25 m.

The following drawings can be taken as a starting point:

distance between wheel axles – 1.27 m;

width in the rear plane - 0.74 m.

How to make a moped with your own hands

In modern life, people make various devices from scrap materials. Everything has become much easier thanks to the advent of the Internet, where there are many diagrams and step-by-step instructions. In such a situation, even the implementation of a complex mechanism does not cause any particular difficulties, since everything is described in separate stages. In this case, we also have to consider one of the schemes for assembling a moped from scrap elements with our own hands, and in addition, some options that can be made later from an ordinary moped.

Recommendations

It is worth considering that ready-made foreign samples most often have to be modified and modified. The thing is that they are not designed for deep snow. One of the most affordable engine “donors” are the powerful Ural and Druzhba gasoline saws. You can also use a Stihl saw as a base, which is slightly more advanced than previous samples. In addition, it is easier to find spare parts for newer engines.

It is useful to remember that a snowmobile with a chainsaw engine cannot carry large loads. In most cases, such structures are designed for one seat. But they are great for children. For driving at night, it is recommended to use headlights. They will also help out in bad weather.

Particular attention should be paid to the gearbox. In many ways, the reliability of the vehicle as a whole depends on it. The sprockets are secured to the track shaft with a nut.

You just need to make a suitable thread. They work in a similar way with the shaft and its sprockets.

Inexperienced and inexperienced people should equip their snowmobile with any simple handlebar. Even a standard road bike handlebar will do. But the simplicity of the control scheme will result in the complexity of manually adjusting the speed. The use of handlebars removed from mopeds or scooters helps to make riding easier. To avoid mistakes, it is recommended to draw up sketches and diagrams in advance, indicating dimensions and profiles.

The tip for transmitting mechanical force on the right must be longer than the same tip on the left. It is necessary to carefully consider the connection of any motor to the steering wheel. It is errors at this stage of work that often cause unpredictable behavior of the snowmobile - and they are very difficult to detect. A braking system is practically unnecessary for homemade snowmobiles. The only exceptions are children's models and items designed for travel to hard-to-reach places.

To learn how to make a snowmobile from a scooter with your own hands, see below.

Source

Plan and drawing of a moped

In order to make a hole yourself with your own hands, you have to prepare first, and in addition find the appropriate manufacturing scheme, which can be done in the following order:

- First of all, you can prepare everything you need yourself, but certain skills are required.

- If necessary, you can find a suitable scheme freely available on the Internet on thematic websites and forums.

- A person can seek help from a specialist who can develop an appropriate drawing.

- Additionally, there is the opportunity to select a suitable option from the available elements.

Scooter tuning - crankshaft tuning

| Once you have decided on the cylinder, the next question is whether to change the crankshaft. The answer to this largely depends on the class of cylinder that you have chosen for yourself. When using Midrace and Hi-End class cylinders, replacing the crankshaft is mandatory! Installing cylinders of the indicated classes in combination with a standard crankshaft is a gross violation and an indicator of the unprofessionalism of the people involved in installing parts on the scooter. In all the variety of tuning crankshafts, it is necessary to distinguish two groups. The first one is simply reinforced . They replicate the corresponding standard crankshafts in all respects, but have greater strength (and therefore a longer service life), as well as improved heat removal from the piston pin. Reinforced crankshafts are great for use with Sport class piston when there is a need to replace the standard one. The second group is racing crankshafts (the abbreviation HPC is often used - high primary compression). Such crankshafts significantly affect engine performance, as they provide an increase in the compression ratio in the engine crankcase. This significantly improves the efficiency of cylinder scavenging at high speeds, providing an increase in power. At the “lower” ranges, the efficiency of purging, on the contrary, suffers, but for forced engines this is not significant. Racing crankshafts are indispensable when it comes to tuning based on Racing class piston engines. When replacing the crankshaft, it is recommended to replace the main bearings with oil seals. |

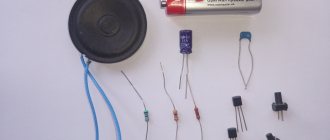

Necessary tools, parts and materials

In order to make such a device yourself, you have to prepare for the process in the proper order. In practice, free space is prepared, and in addition the following elements:

- car tool set;

- You will definitely need a ready-made frame (you can take it from a bicycle);

- here you have to find a full-fledged fuel system;

- requires a small internal combustion engine;

- of course, all fasteners will be required;

- it is also necessary to prepare the wheels for the frame and the drive chain;

- a set of sprockets for transmitting torque to the wheel;

- gas and brake cables, as well as corresponding levers and wires.

Subsequently, after preparing everything necessary, it is also necessary to select a paint coating to protect the device from corrosion and rust.

Scooter tuning - carburetor tuning

| You can get more complete output from a larger-volume piston by appropriately improving the operation of the power system. First of all, we are talking about the carburetor. Scooters come standard with carburetors from a variety of manufacturers, but they all have a common feature by which they can be classified - the size of the diffuser. On standard 50cc engines there are carburetors with diffusers from 12 to 17.5mm. Tuning carburetors are also diverse: there are cases of installing even 28mm carburetors on 70cc tuning engines, but all this is already in the realm of experimentation. Carburetors with a diffuser diameter of more than 17.5 mm (19, 21, 24, etc.) are impractical to operate and require regular attention and reconfiguration. Of course, all this is not important if you are going to make a street rocket out of a scooter, sacrificing convenience and reliability. A standard and proven recommendation for 70cc cylinders is to install a 17.5 carburetor, if one is not included in the standard equipment (for example, on the latest Piaggio HiPer2 engines). |

Assembling a moped

The assembly procedure itself consists of a simple step-by-step algorithm. This involves following the relevant instructions, which consist of a number of steps:

- the frame is first cleared of all present elements;

- here it is necessary to prepare a platform for the motor;

- subsequently the gas and brake cables are separated;

- fuel supply and brake switches are also installed;

- subsequently the internal combustion engine is installed;

- the next step is to install drive sprockets and wheels;

- Next we have to install the fuel supply system;

- at the very end, additional auxiliary elements are hung;

- The starter and drive mechanism are installed.

Upon completion of this procedure, all that remains is to check the assembled unit for functionality.

Painting

After the device is assembled, you can begin to coat certain structural elements with paint and varnish. It should be noted in advance that the frame itself is painted immediately before the start of full assembly, otherwise the paint may damage the existing elements. In practice, any part is first cleaned of old paint, after which the existing corrosion and rust are removed. Subsequently, the bare metal must be degreased and subsequently applied with primer. The primer is coated in several layers and dried thoroughly, after which several layers of paint are sprayed and sanding and polishing are performed. It is recommended that all removable parts be painted in the same order as the frame of the device itself.

Homemade mopeds

In modern life, such a device can act not only as a means of comfortable movement, but also as an auxiliary element for certain devices, namely:

- Quite often, such devices are converted into special equipment for subsequent cultivation of the land.

- It is envisaged to use such a unit as a surface transport when combined with a boat.

- If necessary, such a structure can be converted from a two-wheeled vehicle into an ATV.

- There is also the possibility of using parts of a former moped to equip a small conveyor.

We adjust valves (4t engines).

As mentioned earlier, the engine must be serviced before boosting. Work that will help improve dynamics includes adjusting the valves. The procedure is suitable for tuning Chinese 4t scooters and other 4-stroke engines. For small-capacity equipment, it is recommended to carry out such adjustments at least once every 3, and preferably once every 2 thousand km. It is also necessary to carry out adjustments after manipulations with the CPG.

Before you begin, you need to make sure that the engine has completely cooled down and that you have a set of keys (8,9) and feelers of 0.05 for the intake valve and 0.07 mm for the exhaust valve at hand. You can get to the adjusting nuts by first removing the valve cover. When access to the valves opens, the piston is installed at top dead center. Next, a feeler gauge is installed in the intake valve gap and, depending on the current position, an adjustment is made.

To increase or decrease the clearance, you need to loosen the lock nut (while holding the adjusting bolt), turn the adjustment bolt and, while holding it, tighten the lock nut back. Thus, we achieve a gap when the probe passes into it with little effort. After adjustment, make a full revolution of the crankshaft and make sure that the adjustment is accurate.

Homemade mopeds

Photos of homemade mopeds for those who love to ride and those who are already shy.

For those who don’t know, it comes from the name of the D-6 engine.

If a person assembled something like this himself, even if it was based on diagrams, and someone helped, then he is already a serious person. A small motor is like a puppy dog that was given to you and you raised it.

Such people, as a rule, generally handle things with care and dignity.

Nowadays tablets are held in high esteem among children.

The first photo finally looks like a style, I could drive it myself if I tweaked it a little.

When I was a child (early 90s), a man in a neighboring house bought a new motorbike. About 50 people gathered for the launch. I left, it was never launched. Since then I have no trust in these shaitan machines.

Now the man in the neighboring house will buy a cayenne, no one will come to look.

Why look at him? A man is like a man

I haven’t seen such devices in real life for a long time, although in some of the photos the engine is in a dangerous place, you can end up without skin on your leg)) but of course it’s cool.

They drive through garages. We went for a drive and went home.

Only three have normal brakes. The rest brake against a pole or fence.

They write that the rear brake is not enough. It also needs to be installed on the front wheel.

Since childhood I dreamed of a hole. To push, to rattle and smoke.

Ehh, in the last photo there is a cross with a sawed-off upper frame beam. Great bike, reliable.

Costs from 6 to 10 thousand. This beast is called Velomotor F50 (or F80, with an increased volume of up to 80 cm3).

But almost all of them have engine from the rig. oh and the shaitan apparatus.

Velomobile with engine.

Scooter tuning - CPG tuning

| The variety of tuning cylinders offered is quite large, including standard 50cc and more powerful 70cc. Standard 50 cc tuning cylinders provide an increase in scooter power due to the improved design of the cylinder itself, and 70 cc cylinders also due to a 40% increase in volume. In this case, the scooter becomes much faster than stock. But comparing cylinders of the same displacement, it is clear that they all produce different results. This is due to the fact that different cylinders are designed for different operating speed ranges of the engine. Hence the differing effective power. Tuning cylinders for scooters are usually classified into Sport, Midrace (Racing) and Hi-End. The lifespan of the scooter's Sport cylinders is approximately equal to the lifespan of the standard ones, since these cylinders are adapted to the same engine speed. In addition, these Sport class cylinders are usually no more expensive than similar standard parts Different racing tuning piston class Racing 70cc differ from each other. These are such manufacturers of CPGs as Top Due Plus, Polini Corsa, Malossi MHR Replica, Hebo Manston Replica. For example, cylinders from Hebo and Malossi have high quality, wear resistance and power. These are aluminum CPGs with a very durable chrome-nickasil coating. Cast iron racing scooter cylinders from Top Performances and Polini are generally just as good. An aluminum cylinder undoubtedly has the best heat transfer. But if it is damaged, you will have to change both the piston with rings and the cylinder (this can happen from, for example, a lack of oil in the mixture, or when it is depleted). However, cast iron piston engines in such emergency situations can only get by by replacing the piston, and the surface of the cylinder should be polished. Racing cylinders have much higher compression and compression ratios (up to 14:1), as well as engine speed. All this requires mandatory strengthening of the crankshaft; it should be replaced with a tuned one from a racing kit. |