Heat guns are one of the most powerful tools for heating a room. They are an analogue of traditional heaters, but with significantly greater power and a convection system that blows out a powerful heat flow. On average, a gas heating gun with a capacity of 10 – 15 kW capable of 20 minutes in a room with an area of 150 m2 raise the temperature by 5 – 10 ℃. Traditional electric heaters simply do not have such power, since only industrial electrical networks can withstand such a load.

Scope of application and principle of operation

The operating principle of such a unit can be compared to the operation of a fan, however, the heat gun releases warm air into the room rather than cold.

The air operating inside the housing is heated by heating elements or burners operating on various types of fuel.

The name “gun” is due to both the external resemblance of the device to an artillery gun and the powerful jet of heated air that the unit “shoots”

Heat guns of various modifications find a wide range of applications.

They are successfully used:

- in industry for heating large production and storage facilities;

- in agriculture to maintain comfortable air temperature in greenhouses, greenhouses, greenhouses;

- in construction for quick drying of plastered, painted or otherwise finished rooms;

- in everyday life for heating and drying utility rooms and garages;

- for heating residential buildings in emergency circumstances (for example, accidents on heating routes).

There are other ways to use such devices, for example, gas units are widely used when installing suspended ceilings.

Types of heat guns

There are several types of classification of thermal heaters.

They are most often distinguished:

- on the design of the heating element - heating method;

- by type of fuel used as a heat source.

In addition, devices can also be divided according to purpose of use into industrial and household.

Classification by heating method

Although all heat guns are used to increase the temperature in a room, depending on the design of the model, the process can be carried out differently.

Devices with direct (direct) heating

In such devices, a powerful fan takes air from the environment. Due to direct contact with the heating element, the air mass acquires a high temperature, after which it is “thrown out” into the room through a special hole.

The diagram shows a schematic design of modern heat guns with open and indirect heating, with the designation of the main structural elements (+)

Such units are relatively low cost and have solid efficiency, but they lack environmental friendliness. All combustion products formed are released into the atmosphere, which can be not only unpleasant, but also dangerous for people in the room.

To prevent this from happening, the rooms where such devices are used must be regularly ventilated or, which is much better, forced ventilation must be organized in them.

Heat guns with indirect heating

Such devices have a more complex design, which includes a heat exchanger where heat is separated from harmful combustion products. The latter are sent to a special pipe connected to the chimney, through which the exhaust is discharged from the room to the street.

In devices with indirect heating, a ring heat exchanger serves as a heating element. The presence of a chimney complicates the movement of such units, so they are most often used as stationary heat sources (+)

Although such devices are more expensive, and their efficiency is somewhat lower than that of devices with an open burner, they are still in great demand due to their environmental friendliness and safety in use.

The specific heat gun model should be selected taking into account the planned use. Options with direct heating are suitable for heating large uninhabited spaces (basements, warehouses).

If the device is intended to be used in rooms where people are present, for example, production workshops, it is better to choose models with indirect heating.

Division by fuel type

Taking into account the fuel on which the devices operate, the following types of heat guns can be distinguished:

- Electrical . Such units are environmentally friendly, they do not burn oxygen and do not emit harmful substances into the air, so they can be safely used for heating living rooms. The only downside is the rather high price of electricity.

- Multi-fuel – diesel guns or units undergoing testing. Such devices operate on waste motor and hydraulic oils that cannot be purified or used for other purposes. These devices are very economical, but they are not recommended for installation in crowded rooms, as well as in spaces where it is not easy to establish ventilation.

- Mermen . The main structural elements of such devices are a heater, a fan and a container of water. The space is heated using a powerful stream of steam. Such units are often used in agriculture, for example, to maintain comfortable air temperatures in greenhouses or greenhouses; they can also be used in residential areas.

- Infrared . Complex devices in which heat is released using infrared radiation. Such structures are excellent for heating open spaces: they can be installed on restaurant terraces, festive areas, and recreation areas.

- Gas . These models, which we will talk about in more detail below, have become widespread due to the optimal combination of quality and price.

You can often find heat guns divided into industrial and household models. The former are distinguished by high power, dimensions and high price, while the latter are small in size, lower heat emissions and affordable.

Principle of operation

“Gas guns” are based on the most common burner (burner), which heats the air by burning oxygen to form carbon dioxide and fumes. This entire mixture is blown out of the combustion chamber using a powerful fan driven from the electrical network.

The principle of operation of the simplest gas gun

Unlike diesel guns, gas guns produce a minimal amount of harmful substances and carbon monoxide during fuel combustion, so they require lower forced ventilation performance. But at the same time, their heating speed and power are identical. And, by the way, the design of gas guns is simpler than that of diesel ones, so they break down extremely rarely (only if operating rules are violated), and manufacturers provide a guarantee of, on average, 3–6 years for such devices.

Closed and open guns

Conventionally, all gas guns are classified into open and closed:

- Open (direct heating). They have a simpler design, the burner is open, all combusted gases enter the room. For normal operation, they require high-quality ventilation of the heated room.

Open burner gun. A more common option, but it can only be used in rooms where there is normal supply ventilation. Otherwise, carbon dioxide and carbon monoxide accumulate, and it is extremely dangerous for a person to be in such a room.

- Closed (indirect heating). The burner is closed, and there is also an outlet for removing waste gas. Such guns are less powerful and efficient and require a mandatory connection to the chimney, but are absolutely safe (and can be used powerfully even in small living spaces). Either air heating elements or radiators (ring heaters) are used as a heating element.

Closed type heat gun. In this case, it is installed outdoors, and warm air is supplied through a special air duct

As a rule, open ones are used in non-residential premises (garage, shed, warehouse), closed ones - in residential ones or in those where there are problems with ventilation.

Classification by connection type

Gas guns according to the type of connection and the fuel used are divided into:

- Methane . These are connected directly to the household gas distribution network. It is also possible to supply methane from cylinders, but these are not refilled at all gas stations (the process itself is long and requires the use of special equipment).

- Propane . They operate on a propane-butane mixture and are connected to cylinders. These are more common, since propane is quite cheap, filling it into a cylinder takes a minimum of time.

Connects to the household gas distribution network. But at the same time, its power is quite low, since in such gas sources the final pressure is low

Prices for the MASTER BLP 17M gas gun range

Gas gun MASTER BLP 17M

Characteristic features of the devices

Gas guns are used both in industry and in everyday life, for example, when heating private houses or garages. Such devices are less mobile than electric ones, but more economical and have quite high power. The figure can reach up to 150 kW.

Natural gas is used as fuel, but liquefied gas can also be used. Such devices require an electrical connection. Electricity powers the fan, thermostat, and other necessary elements.

To operate a thermal gun, different gas modifications are used:

- Liquefied butane, propane.

- Gas supplied through pipelines.

High-power modifications are connected directly to the gas pipeline through special hoses. This allows the device to operate continuously. Typically, such units are made stationary, since their movement is quite difficult.

There are also several types of gas modification in a heat gun

Compact devices run on bottled gas. Some models provide a connection to a large cylinder via a hose, while others have a special compartment with gas. Also, most models have additional elements that ensure safety during operation of the device: case protection, flame level control, automatic shutdown system.

Required materials and tools

It is important to understand that homemade production of gas heat guns should only be carried out with proper qualifications and extensive experience in working with gas and tools. If you take on work unprepared, it can lead to irreversible consequences.

To make a gas gun you will need the following tool:

- Metal pipe. Fuel will be supplied through it to the main system.

- Bulgarian. It is better to use 125, as it is more convenient to work with.

- Sheet steel.

- Electric drill and metal drills.

- Steel tube with a diameter of 8 mm. It will be used to make a heat exchanger.

- Thick reinforcement for the stand on which the gun will be located.

- Fan power – from 12 W.

You can use a welding machine to speed up the process. You can also buy paint that is resistant to high temperatures in advance.

When creating this gun, do not forget about safety precautions

Construction of a heater from a pipe

This homemade design is also called a thermal gas gun. It produces significantly more heat than previous heaters and absorbs more energy resources. Also, such structures are often equipped with chimneys, which makes them bulky and difficult to carry.

The diagram will familiarize you with the principle of operation and design features of a gas heat gun. The heat flow generated by the device is distributed using a fan

To assemble the heater yourself, you need to collect the following material:

- three meter pipes of various diameters (two 8 cm and one 18 cm);

- steel plates with which the fastening will be carried out;

- Metal sheet;

- gas burner with piezo ignition;

- axial fan.

You will also need a variety of tools: drill, welding machine, tape measure, level, grinder, metal scissors. Pipes can be replaced with cylinders or fire extinguishers of suitable diameters. A grinder will be needed to cut the bottom and top, as well as shorten the workpieces.

Working in intensive mode to heat a room of 15 square meters, a forty-liter cylinder is enough for about a week. While working, the gun dries the air, so you need to humidify it

In a pipe with a diameter of 18 cm, two holes of different diameters are drilled: 1 cm and 8 cm. They need to be drilled opposite each other.

A 30 cm section is cut from a pipe with a diameter of 8 cm, which will represent the combustion chamber. Fasteners are welded to this pipe and a hole with a diameter of 1 cm is drilled in it. Then this pipe is inserted into the first pipe.

You need to cut a plug from a sheet of metal. It will close the gap between the heater body and the combustion chamber. A combustion chamber is welded to the body, and a pipe for exhausting hot air is welded to a hole with a diameter of 8 cm. After this, the plug is welded. After making sure that the gas burner is tightly attached to the combustion chamber, you can insert the hose through the centimeter holes.

A fan is installed at the back of the device, and a smoke exhaust is installed at the top. In order for the heater to stand stably on the surface, the legs should be welded. A gas heat gun efficiently heats rooms and uses gas economically. However, when using it, you should adhere to safety precautions.

Making a heat gun - instructions

Next, we’ll look at several popular models of heat guns and DIY methods.

Gas heat gun

A gas heat gun is an effective and economical way to heat large areas.

There are 2 main types: stationary, connected to a gas pipeline, and mobile, for which cylinders are used. Mobile options are used by builders when working in winter; they are used in greenhouses and garages. According to the heating method, they are distinguished:

- Direct heating devices, when the gas from the burner directly enters the fan, and then into the room. The efficiency of such a heat gun is about 100%, although it is not the healthiest.

- Indirect heating devices. Here the gas is heated by a special heat exchanger, and the combustion products go into the chimney, just like in a gas boiler. The efficiency of such a heat gun is lower, but it can be used in residential premises without fear.

To create a simple heat gun of the first type with your own hands you will need:

- An old gas or welding cylinder or thick-walled pipe.

- Fan.

- Gas nozzle with divider.

The bottom of the cylinder is cut off.

A burner and ignition device are installed inside.

A fan is attached to the outlet.

Gas hose and electrical cable are supplied.

The supports are welded or screwed on so that the heat gun does not lie on the floor.

After testing, the device is ready for use.

Electric heat gun

The design of an electric gun is not very different from a gas gun, only heating elements are installed instead of a burner.

Basic assembly aspects:

- The length of the pipe for the housing is taken from the calculation of the length of the heaters and the distance of at least 20 cm between them and the fan.

- The wiring of heating elements and fans must be autonomous, with mandatory grounding.

- A thermostat is required to increase/decrease heating.

- Ideally, protection against overheating is needed.

When assembling and operating an electric heat gun, it is important to follow safety rules when working with electric current.

Heat gun on diesel fuel and diesel fuel

This is the most dangerous type of heat gun, so assembly requires increased care and attention.

The housing will require a sealed tank, which will be divided into a heat exchanger and a combustion chamber. The ideal option would be an old wood-burning boiler or stove.

Using a pipe, burning diesel fuel enters the chamber from the burner and passes through the heat exchanger. Combustion products are removed into the hood.

The fan forces cold air into the housing, creating a flow of heated air from the nozzle.

Wood fired heat gun

A wood-burning heat gun is similar to a diesel heat gun, but is somewhat safer and smells significantly less. In the combustion chamber, instead of a pipe and a burner, a door for firewood, an ash pan and grate bars are installed. A wood-burning gun is heated similarly to a wood-burning boiler, the only difference is the presence of a fan.

Homemade device design

A do-it-yourself gas gun is quite simple. Its basis is a gas burner equipped with a small canister. A hole is cut out in the center of the burner, to which a gas supply tube is attached. This structure is placed in an extension, on one side of which there is a damper, and on the other there are holes for the exit of CO2.

Read also: how to make a gas gun with your own hands.

As an extension cord, you can use a piece of metal pipe with a diameter of 80 mm. To remove CO2, make a vent from an empty gas cylinder and connect it to the chimney. The gun body can also be made from a gas cylinder.

The basis of any heat gun is a burner with a cylinder

The burner jet is drilled out to 2 mm. Metal plates are attached to the extension cord at the top and bottom to increase the heat transfer area. The extension cord together with the burner is placed in a housing, in the upper part of which a hole is cut. A pipe is welded to the hole to allow hot air to escape. There is a fan on the back of the case. The gun works like this:

- a lighter is placed in the hole;

- open the gas, light it;

- remove the lighter;

- connect the fan to the network;

- combustion products are discharged first into the ash pit, then into the chimney;

- Warm air enters the room through the pipe.

The gas flow is controlled using a regulator. To ensure that the operation of the heat gun does not cause problems, it is worth following fire safety precautions:

- warm up the garage as quickly as possible, then turn off the device;

- install the gun compactly;

- select materials for heating elements that do not burn oxygen and do not emit harmful substances;

- prevent explosion and spontaneous combustion of the product;

- equip the installation with a thermostat.

Gas heat exchanger #19 not directly heated:

Rules for using a heat gun in the garage

When heating a garage using homemade heaters, especially with an open flame, it is important to follow fire safety measures:

- It is imperative to install a reliable ventilation system in the garage, preferably forced;

- the open flame of the heat exchanger must be covered with a heat-reflecting protective screen;

- containers with fuel should be located as far as possible from the operating heater;

- do not leave a working device in the garage overnight - this is dangerous;

- the distance from the car’s gas tank to the gun should be no less than one and a half meters.

Step-by-step instruction

The first step is to make the body. You can use sheet steel 3-4 mm thick or a regular pipe. The sheet needs to be given the required parameters, and then it needs to be rolled into a pipe. The edges are secured with bolts or a special connecting lock.

After this, the pipe that is used to supply gas is sawn. This is necessary so that later it will be possible to weld the next element to it.

Homemade gas gun:

Now it is necessary to increase the diameter of the hole, which is intended for gas to enter the system. You need to bring it to 5 mm.

Then the heat exchanger . Take a metal pipe with a diameter of 80 mm. The end must be welded to the burner wall and a hole must be drilled. The burner extension passes through this element.

To allow the heated air to escape, a hole must be made in the heat exchanger housing. Then weld a tube with a diameter of 8 cm in that place.

Then a fan is installed to circulate the hot air. It is also necessary to provide for the supply of electricity. You can connect it to the network or battery.

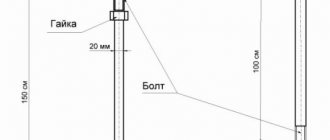

Finally, you need to drill holes to ignite the gas. It is also necessary to provide a structure on which the heat gun will be located. You can use a ready-made stand or weld it from reinforcement.

Heat gun. with your own hands:

Making a drip heater

Most often, craftsmen use old oxygen and propane cylinders with a diameter of 220 and 300 mm, respectively, to assemble droppers. The former are preferable because of their powerful thick walls that can last a long time and not burn out. A pipe made of low-carbon steel (St 3-10) with a wall thickness of 5 mm or more is also suitable.

Select rolled metal for other parts according to the drawing of the furnace with top feed of waste into the combustion zone. The blower fan is a “snail” from a VAZ 2108 cabin heater or its Chinese equivalent, the fuel line is a stainless tube with a diameter of 8-10 mm.

- Make a fire bowl from a piece of pipe or take a ready-made steel container. It must be removed through the inspection hatch, so do not make the tray too large.

- Cut openings in the body for the chimney pipe and cleanout hatch. In the latter, make a frame and install the door (possibly bolted).

- Make an afterburner. Take your time to drill all the holes indicated on the drawing; do the bottom 2 rows first. You will complete the rest while setting up the oven.

- Weld a cover and an air duct with a flange for mounting the fan to the afterburner. Attach the fuel supply device as shown in the photo.

- Assemble the heating unit and connect it to the chimney.

The afterburner in the photo is close-up - side and end views

To regulate the heating power, it is necessary to provide control of the fan speed and a device for dosing the fuel supply (as a rule, an automatic drinker with a jet break is used). According to reviews from craftsmen on a popular forum where heat extraction issues are discussed, fuel consumption in the furnace can be monitored visually. The trend is this: if the oil flows in drops at the break in the stream, then less than 1 liter per hour burns, and when a thin stream flows, more than 1 liter per hour.

Different designs of dropper bowls

After ignition and warming up of the heater, it is necessary to set the optimal operating mode. The procedure is carried out according to the same scheme as with the miracle stove: you need to achieve the most transparent smoke from the chimney by drilling additional holes in the afterburner. The ideal flame color is blue, normal is yellow, and reddish is unsatisfactory. In the latter case, low heat transfer, high consumption and soot formation are observed. For details about the design and assembly of the furnace, see the video:

Trial run

To use the gun you need to perform some procedures.

- We light the lighter by bringing it to the fuel ignition hole.

- Open the valve so that gas begins to flow.

- When the gas lights up, put the lighter back.

- Turn on the fan.

If we briefly consider the manufacturing technology of this kind of heat gun, it looks like this:

- We attach a metal extension disk to the burner;

- we extend the pipe necessary for gas supply to the device;

- we install iron plates necessary to improve heat transfer;

- install the clamp on one side of the extension, after which you need to secure the heat exchanger itself;

- We assemble the entire heating device;

- we make holes in the heat exchanger so that hot air can escape through them;

- We weld a metal ring to the second end of the pipe;

- We install a switch on the heat exchanger that will turn the fan on/off;

- fan assembly itself.

Do not forget that a DIY gas gun also needs a housing. This body, as you know, most closely resembles an ordinary pipe, so we can easily make it ourselves. To do this, take a sheet of steel that is not too thick, cut it to give it the required size, and roll it into a pipe.

In order to connect the edges of the sheet together, you can resort to the connecting lock method. If for one reason or another you cannot do this, then use regular fastening bolts.

Well, so we looked at the features, operating principle and manufacturing technology of such a device as a gas heat gun. This device is very popular due to its efficiency and the ability to heat large areas in record time. You can do it yourself, just have a list of necessary tools, materials, and a little patience.

Required power indicator

The main indicator of a device is its power, since the effective functioning of the device depends on it.

To determine the required heat transfer of the device, it is important to simultaneously take into account a number of indicators:

- The volume of heated space, to calculate which it is enough to multiply its parameters (height, width, length).

- The difference between the temperatures inside and outside the room.

- Heat loss coefficient, the value of which depends on the thermal insulation of the room. The average value of this indicator is 1-2, while an uninsulated building has a coefficient of 3-4, and a well-insulated house has a coefficient of 0.6.

The minimum value of the required power, indicated in kilocalories per hour, can be obtained by multiplying the above values.

To convert a certain number to kilowatts, simply multiply the number by a factor of 0.001163. This value must be kept in mind when choosing a ready-made device in a store.

Safety precautions

This device is a fire hazard, so all safety rules must be followed. Requirements for operating the device:

- A homemade gas gun cannot be left unattended. Factory ones often have an automatic safety system that shuts off the gas supply in emergencies.

- Do not use the devices in places where flammable objects and substances are located.

- Good ventilation of the room must be ensured.

- The open air heating device should be placed only on flat surfaces so that the position is stable.

- Cannot be used outdoors during rainfall.

Before using the device, make sure that the outlet is grounded. The ends of the gun can be covered with a metal mesh to disperse the air flow.

How to make it yourself

Gas guns began to be actively used in our country relatively recently. As already mentioned, this device is excellent for heating various rooms. It is especially popular for heating buildings without gas supply. For example, country houses, country houses, garages, etc.

The gas gun has the following advantages:

- mobility;

- safety in operation;

- small in size;

- high efficiency;

- ease of installation and dismantling;

- good power;

- ability to regulate temperature.

The popularity of a gas gun is significantly influenced by its objective and reasonable cost. Moreover, making it yourself will be much cheaper than buying a ready-made factory product.

Main malfunctions of gas heat guns

Most gas gun malfunctions can be fixed independently, without going to a workshop. Most often the following fail :

- fan;

- piezoelectric element;

- burner;

- security elements.

Typically, owners of these devices encounter the following problems :

- It is impossible to light the gas . This is how the piezoelectric element malfunctions. It should be cleaned, and if this procedure does not help, then replace the part with a new one.

- Gas does not enter the combustion chamber . The cause of this malfunction is a clogged burner. The problem is solved by blowing the burner with a powerful air jet.

- There was a smell of gas . This problem is usually caused by gas leaking from the hoses. Either tightening the fasteners or replacing the hoses is required. The easiest way to identify gas leaks is to use a soap solution.

- Gas consumption has increased - the gearbox needs to be replaced.

- When the burner is burning, warm air does not flow into the room - you should check the serviceability of the fan. If there is power supply and the contact group is in good condition, it needs to be replaced.

Purchasing a gas heat gun equipped with all the necessary safety elements will cost the buyer a substantial amount . Such an acquisition is justified when there is a constant need to heat large areas.

Therefore, many people make heat guns that run on gas fuel on their own. In this case you should remember that such devices should not be left to work unattended under any circumstances.

Additional functions

Additional functions in gas heat guns include:

- Automatic ignition system . It works either from the mains or as a mechanical piezo element. If they are absent, the device is started manually (by bringing a match or any other burning element to the burner nozzle).

- rotation speed adjustment . This functionality allows you to adjust the power of the air flow. For small rooms – less, for large ones – more.

- Adjusting the gas supply . Used to turn on “turbo mode”, when the heating element heats up in literally 10 - 20 seconds. Allows you to start heating the room instantly.

- Availability of additional sensors . These include a gas leak sensor, a gas pressure reduction sensor, a thermostat (responsive to ambient temperature), a position indicator (if the gun accidentally tips over, it blocks the gas supply and the device turns off).

- Thermocouple . Allows the fan to automatically adjust the rotation speed depending on the temperature in the combustion chamber or heating element.

This model has 4 sensors that allow the device to automatically turn on/off to maintain the set temperature in the room

Manufacturers also began to produce automatic gas guns that operate on the principle of conventional electric heaters with a thermostat. That is, they turn on and off automatically, maintaining the room temperature at a given level. However, the response threshold of such devices is high, so you should not count on careful adherence to temperatures down to 0.5 degrees.

Such sensors are responsible for automatically turning off the gun when an emergency occurs. But they fail quite quickly, especially when using low-quality fuel

Video - Gas gun, garage heating (is it worth taking)

Find out how to choose a floor-standing gas heating boiler for a private home in a special article on our portal.

How to choose a gas gun in a store and what to look for

When choosing a gas gun for domestic use, you should first pay attention to the following parameters:

- Power. It is measured in kW; sometimes manufacturers additionally indicate the volume of heated air per 1 hour of operation. In the first case, the formula is followed: 1 kW per 10 m2 – minimum. Secondly, it is necessary to calculate the total volume of the room planned for heating with a gun and divide the resulting figure by 2. This will give the minimum power of the gun, with which the room can be heated within 30 minutes of continuous operation of the heater. For example, the volume of air heated by a gun is 300 m3. Accordingly, it is optimally suited for a room with a volume of 150 m3 (volume and area should not be confused - these are completely different indicators).

- Connection type. This means with a closed or open burner. The first ones are more expensive and they are used for “emergency” heating of residential premises. It is not worth buying them for other purposes. Open ones are the best option for garages, sheds, warehouses and other non-residential premises.

- Presence of automatic arson. In principle, the function is not required. Moreover, piezoelectric elements fail quite quickly, but their presence increases the cost of the gun by almost 10–20%.

- Availability of additional functions. This means adjusting the fan speed, sensor system, thermostats, and so on. All of them help automate the operation of the gun, but manufacturers do not recommend leaving heaters of this type running without supervision. And the presence of those same sensors also increases the final cost of the device. If you need to save money, you can buy a gun without all these sensors.

- Power supply for fan. Available either from 220V or 12V DC. The last option is convenient because the gun can be used as a mobile gun, launching it even in the absence of a household electrical outlet. If such functionality is not needed, then it is better to take it with the simplest 220V motor. Even better - without brushes (such motors are very reliable and durable, but are quite expensive).

The principle of operation of a gas gun

Table 1. Key parameters of gas guns that must be taken into account when purchasing.

| Power | Not less than 1 kW per 10 m 2 of heated room |

| Type of gas the gun operates on | Methane - for connection to the household gas network, propane - for cylinders. There are also “universal” guns, but they are expensive and often break down due to the complex technical design (there are 2 separate valves working at the same time) |

| Auto-arson | It is recommended to take one without automatic ignition - such models are cheaper, their starting is not dangerous |

| Availability of additional sensors | Not necessary. Most of them will not be used by anyone - tested in practice |

| Fan motor power supply | With support for connecting to 12V, buy if the heater will be used as a mobile one. In other cases - only 220V |

| Closed or open burner | Closed - for heating residential premises, open - for everyone else |

An option for using gas guns is for installing suspended ceilings. Under the influence of high temperature, PVC fabric easily stretches, there are no folds or dents left on it

Biemmedue: quality + Italian design

The Italian company, established in 1979, specializes in the production of heaters, generators, dehumidifiers and other heating equipment.

The products, which include both household and industrial models, are distinguished by durability, reliability and excellent quality.

The manufacturer pays attention not only to technical characteristics, but also to design. All lines developed by Biemmedue are distinguished by their compact size, mobility, and aesthetic appearance.

Master: a company with vast experience

An American company that has been producing portable heating systems, including various types of heat guns, for more than half a century. For the manufacture and design of units, only high-quality materials are used, thanks to which the company’s products are distinguished by high technical characteristics.

The diesel heat gun Master BV 110 has excellent characteristics (power 33 kW, 65-liter fuel tank, fuel consumption 2.71 per hour). Within an hour, the unit can heat 460-1000 cubic meters. m of air

Thanks to the innovative technologies used in the production of models, heat guns have many useful additional options, for example, a flame control function or emergency automatic shutdown in case of an unusual situation.

Kroll: innovative technologies

Heating equipment, produced by the well-known German company Kroll , is distinguished by a high level of assembly and the use of high-quality materials, primarily stainless steel. The latest engineering and scientific developments are widely used in the production of products, including diesel heat guns.

Products from other companies (Vitals, Ballu) are also popular. Products manufactured on the production lines of these transnational companies are reliable and have a long service life.

Every year you can see interesting new items in the product range: for example, the latest models of the company’s heat guns are equipped with a heat heating function, thanks to which the devices can operate successfully even at low temperatures.

Review of popular models

Analyzing information on thematic forums, we can identify the following popular gas burners among Russian consumers:

- MASTER BLP 17M . Ideal for heating a garage. Reliable and durable equipment, the reducer is “unpretentious” to the quality of the supplied gas. There is a power regulator from 10 to 16 kW, so it is suitable for garages up to 150 m2. The only negative is manual ignition, although because of this the device almost never breaks down; the manufacturer generally gives a 3-year warranty. The average cost is 9 thousand rubles.

- SPECIAL IGE-15 . Russian-made gun. It is small in size and suitable for use when installing suspended ceilings or for drying walls after painting. Power is 15 kW, but the flow is narrowly targeted. It has 2 heating stages, the kit includes a hose for connecting to the cylinder (with adapters). The average price is 5.2 thousand rubles.

- Caliber TPG-10 . Also made in Russia, power up to 10 kW, suitable for small spaces. The gearbox is collapsible, the manufacturer has provided for its complete replacement with an analogue one. The fan is also serviceable and not pressed into a bearing. But the functionality is minimal. But the cost is only 4 thousand rubles.

- Kroll P 10 . Popular model of foreign production. It works when connected to cylinders, there is a piezo ignition, a safety thermostat and a pressure sensor. The productivity is small - up to 300 m3 per hour, but the flow of heated air is not narrowly targeted, as in other models. The average price is 9.5 thousand rubles.

- Profteplo KG-57 . Industrial type heat gun with a capacity of up to 1400 m3 per hour. Available in two versions - with connection to 220V and 380V. The latter is noisy in operation, but it is not suitable for small spaces. There is flame control, as well as a sensor that turns off the gun when it detects movement in front of it (it can be forcibly turned off). The average price is 11 thousand rubles.

MASTER BLP 17M, one of the best selling models

We recommend our article on the topic - Heating boilers for a private home, where we examined the principle of their operation and how to start the heating system step by step.

In summary, a gas gun is an excellent option for quickly warming up non-residential premises. For residential use this is not the best option, as it requires connection to a chimney. But you can make a cannon yourself; all this will require only 2–3 thousand rubles (for all materials).