A vacuum pump is a regular air compressor that uses the suction side.

You can make a 12 volt vacuum pump out of an air compressor if you can connect a hose to its air intake.

This guide will show you how to make a vacuum pump with your own hands. Such a device is useful for vacuumizing food products and increasing their shelf life, or for vacuum packaging things, since a bag with removed air takes up less space than a regular bag with things. You can also do vacuum molding - the production of products from thermoplastic materials in hot form using vacuum.

The vacuum created by such a device is several times higher than what a conventional vacuum cleaner can create (about 0.8 kgf/sq.cm, or 0.08 MPa).

This vacuum is sufficient to use the pump for industrial purposes that require vacuum.

A compressor for inflating car tires in a store costs about 1,300 rubles. You will also have to purchase some spare parts and glue.

You will also need:

- About one meter of PVC tube with an internal diameter of 6 mm.

- Plastic herringbone connector for 6mm ID tubing.

- Epoxy resin (cold welding).

All of these materials are readily available and can be purchased at the store.

Since a 12V pump draws about 4A of current, it will need a fairly powerful DC power supply. A 6 A car charger can be used as a power source.

NOTES.

If you use a cheap air compressor to inflate your tires, like the $700 Harbor Freight one, don't expect too much from it. (A cheap pump will only work for a few minutes, then it will overheat. A good compressor can work continuously for up to an hour). The fact is that the compressor is not designed to work as a vacuum pump. Turn it on for a period of 1/3 to 2/3 of the time specified in the compressor data sheet, then let it cool for 5 minutes.

For example, if the passport for an air compressor indicates a continuous operation time of 15 minutes, then in vacuum pump mode you can run it for 5-10 minutes. with a break of 5 minutes. for cooling. A good pump is one with an aluminum cylinder, a large area of cooling fins, a cooling fan and a powerful motor designed to last for a long time.

Here are some tips on using the pump and its limitations:

For vacuum packaging:

- Do not use the pump to vacuum large volumes of food or items, or to create a vacuum in a container with air leaks.

- Use small containers for vacuuming and fill their volume with products (things) to the maximum in order to pump out a minimum of air from them.

- Turn off the pump from time to time to cool it down.

- If after a long time the pump cannot create a vacuum, then there is a leak somewhere.

For vacuum forming:

- Do not attempt to remove air from a 100 liter tank with this pump.

- To reduce the load on the vacuum pump, use a two-stage air pumping system: first, most of the air is pumped out using a vacuum cleaner, then a vacuum tank with a vacuum pump is put into operation: link.

- Do not start the pump until the vacuum in the system drops to 0.8 kgf/cm2. Typically, a vacuum in the range of 0.6-0.7 kgf/cm2 is sufficient for molding products. Therefore, you should not once again turn on the vacuum pump to increase the vacuum by a couple of tenths of atmospheres, in order to avoid its rapid wear.

The best manufacturers

There are currently a large number of bags for vacuum “preservation” on the domestic market. These are products from both Russian and foreign manufacturers. According to users of such a resource as Yandex Market, the highest quality and most convenient models today are produced by the following companies:

- Ginger cat,

- Paclan,

- Mistress Mila,

- Paterra,

- Elfe.

The table below shows some characteristics of the most popular (according to Yandex Market users) bags for storing things under vacuum. Product prices may vary depending on size and are not shown here.

Table: main parameters of popular models

| Model | What is recommended to store | Protection | Special Features | Material used |

| Elfe | Clothing, household items: pillows, blankets, bed linen, towels | Dust, dirt, unpleasant odors, damage, dampness, mold | Reinforced neck | Polyethylene terephthalate |

| Ginger cat | Any household items and items | Dust, moisture, mold, moths, odors | Reusable | Polyamide, polyethylene |

| Paclan | Any household items and items | Dust, dirt, odors, dampness, mold | Reducing the volume of things up to 70 percent | Polyethylene |

| Paterra | Clothing, bedding, soft toys, etc. | Moisture, dust, moths and odor | Reusable | PET (polyethylene terephthalate), polyethylene |

| Mistress Mila | Pillows, blankets, outerwear, seasonal clothing | Dust, moisture, foreign odors, insects | Long-term and short-term storage of things | Polyethylene terephthalate |

Photo gallery: the best models on Yandex Market

Inexpensive but high quality product

Vacuum bags from domestic class=”aligncenter” width=”600″ height=”600″[/img] Mila’s advantages include high quality and colorful packaging

Paterra is perhaps the most famous brand in the vacuum bag market

Reduces the volume of packed items by up to seventy percent

What is a vacuum?

Yogis were the first to use this exercise. The meaning of the vacuum is to alternately contract and relax the transverse abdominal muscles in combination with a special breathing technique.

4 rules of yoga for a healthy body

These muscles are among the most difficult to reach, so they are difficult to reach with classic crunches. But they are the ones responsible for the tone of the abdomen and the wasp waist.

Vacuum is one of the few exercises that can pump up the transverse abdominal muscles.

Photo: istockphoto.com

Types of vacuum sealers

Depending on the type of purpose, vacuum sealers can be used for household or industrial use. They differ in power, size, and complexity of the device.

Industrial vacuum sealers

Industrial devices for vacuum packaging are divided into several types:

- Chamber. They have a special chamber in which the container is placed. First, air is pumped out of the chamber, then from the container itself. This provides better and more reliable sealing. The device has a built-in special device for gluing film of vacuum products, which seals the edges. There are floor-standing and tabletop equipment options.

- Thermoforming machines. For packaging, a vacuum film is used, which covers a special substrate. This is the most common type of equipment used in large-scale production, as it has very high productivity.

Household vacuum sealers

At home, a tubeless vacuum sealer is most often used. In such a device, bags or film for a vacuum sealer in rolls are processed. The edge of the bag is placed into the device, from which air is removed, and then the material is sealed. Such equipment is not suitable for processing liquids; it is used for household purposes or in small commercial enterprises. The device is compact in size, easy to transport, and does not take up much space.

Well, after a certain number of experiments, we can say that the work on a budget system for vacuuming products has been completed. Buying a ready-made vacuum sealer is a bit expensive. A toad dissuaded me from paying 8-10 rubles for a device that is needed not every day, but only several times a year. So I decided to make it myself. Let me make a reservation right away – the result is not ideal. The whole process requires some skill. Sometimes a package that is not sealed has to be repacked. But it's still cheaper than buying a ready-made packer. ] In fact, you can do without a compressor. I think a hand vacuum pump would be fine.

or a converted bicycle.

?list=PLwU9-q3VyyBBFaLpBT4X1wMYiaFCcpIe3 Perhaps even a regular vacuum cleaner or electric pump for air mattresses will do. And to seal the bags, I used... a bag sealer.

Many large supermarkets have these things. They seal customers' bags in bags so that they don't put anything they don't need in there. I bought such a device before the crisis, second-hand. Got it for pennies. Now of course it will cost more. https:///goods/g270.htm https:///Ksitex-PFS-400-ABS All that remains is to put it all together into a single whole. This is where some difficulties arose. Pumping out the air and immediately sealing the bag is not as easy as it might seem. I connected a hose to the suction pipe of the compressor. I didn’t forget about the filter (I don’t really want grains of rice or other rubbish inside the compressor). I attached the tip of a ballpoint pen to the hose. At first, I did this: I took the bag with the contents and sealed it. Then he cut off the corner of the bag, inserted the tip there and turned on the compressor. The air was sucked out of the bag, after which I sealed the corner. But this method failed. The package wrinkled, it was sealed crookedly and not airtight. And for all the manipulations one pair of hands was not enough. Therefore, instead of a pen tip, I made a special nozzle. It consists of a copper tube flattened at one end, into which a piece of tin folded in half and soldered at the edge is soldered. It turned out to be a very flat tube that did not interfere with the closing of the sealer flaps. To prevent the tip from being squeezed, a thin steel wire was inserted inside.

Now the process looks like this: The package with the contents and the inserted nozzle is inserted into the soldering iron and sealed. The seam is only interrupted at the point where the flat tip enters the bag.

Without removing the bag, I turn on the compressor and pump out the air. Since the edge of the bag is still clamped in the soldering iron, it doesn't wrinkle. As soon as the air has been pumped out (this can be seen by how the bag stops shrinking and you can hear how the compressor began to hum strained), I carefully remove the nozzle and immediately seal the bag again. It turns out airtight and smooth. To be on the safe side, I seal the bag again a little further from the first seam.

(For the demonstration, I used ground beef that had dried out overnight. I don't plan on storing it for long, so I didn't put the silica gel and rusty nails bags inside). The last package had to be repacked later. A few words about packaging bags. Not just any bags are suitable, but specifically those designed for vacuum sealing.

Fortunately, you can buy it now. I buy from a company that sells disposable tableware, garbage bags, shoe covers and other consumables for food establishments. As a last resort, you can buy such packages online. When choosing bags, take those that are denser. If there is no difference for soft foods, then “prickly” foods (long grain rice, oats, buckwheat) can “pierce” the film. It sounds strange, but I have encountered this. The film of the bag is stretched during vacuuming and the solid contents, if handled carelessly (for example, if dropped on a hard surface), may well damage it. And after a while the package will “inflate”. If everything is done correctly, the packaging will preserve the food for a very long time. I’ve had two-kilogram packages of rice and buckwheat for three years now. Flat and hard as a brick. I can’t vouch for the taste, I haven’t opened it yet, but I can’t see any bugs or mold. I apologize for the paucity and quality of photographs. The process takes up all hands, and there is nothing left to hold the camera. ">

Indications for mini-abortion

There are no special indications for a mini-abortion; the leading and sufficient indication is the woman’s desire to terminate the pregnancy. But there are also medical indications for early termination of pregnancy. Vacuum aspiration is indicated:

- during frozen pregnancy;

- with anembryonia;

- if bearing a fetus poses a threat to a woman’s health and life (diabetes mellitus, severe liver and kidney pathologies, malignant tumors, etc.);

- with rubella, influenza and other infections during pregnancy;

- social indications (for rape, being in prison, etc.);

- if necessary, endometrial biopsy;

- if remnants of the fertilized egg are found in the uterus after a pharmacological or surgical abortion;

- when parts of the placenta are retained after childbirth or cesarean section;

- for menstrual irregularities (bleeding);

- with accumulation of blood (hematometra) or serous fluid (serozometra) in the uterine cavity;

- with incomplete spontaneous abortion.

Using a medical syringe

Such a device will certainly come in handy on the farm if you need to pump out liquid or gas in small volumes. The following parts are required for operation:

- plastic tee;

- flexible plastic pipe, its diameter should be identical to the holes of the tee and syringe;

- 2 check valves for aquarium;

- a syringe, the volume of which depends on the power of the device (the larger the syringe, the greater the power).

The plastic pipe is cut into pieces 10 cm in size, and then attached to the tee. The tubes should fit snugly to the spout of the tee. This is necessary so that they do not jump off under pressure during operation of the device.

The syringe tip is then attached to the central tube. The entire structure is presented in the form of a tee, on the sides of which two pieces of hose are fixed, as well as a syringe located at right angles to the retracted ends.

The next step is to install the valves. They are often marked with an indicating arrow. One of them should be placed so that the arrow points away from the tee, and the second - with the arrow pointing towards it. In general, the system will be similar to an entry-exit sign.

The handheld device is ready. It can be used to pump water from one container to another by placing one valve in the liquid and the other in the pumping container. The arrows act as guides. You need to immerse the valve in the water, the pointer of which points to the tee. The system will work when the piston on the syringe begins to move.

Working principle of a vacuum pump

Before assembling the structure, it is necessary to disassemble what parts it consists of and how it works. The principle of operation is not very different from the operation of conventional pumping equipment; when the valves are turned to the opposite side, a vacuum device is obtained. Pump performance is achieved by sealing the system, otherwise the power drops.

You should also monitor the condition of the intake tract, because... During pumping, debris may get in, which clogs the installation channels.

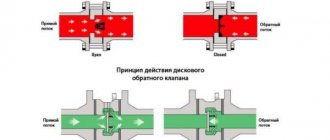

There are basic principles of operation of a vacuum pump:

- A moving element consisting of a piston, membrane, or rotor creates a vacuum in the cylinder through suction mode. At this moment, the exhaust valve is closed, the intake valve is open as much as possible.

- During the reverse stroke, the intake valve moves to a closed state, leaving a low level of pressure in the intake chamber. The gas is released through the exhaust hole, and the cylinder is filled to its minimum level.

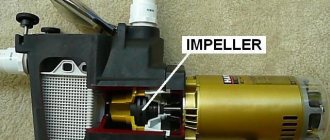

Vacuum pump device

Vacuum pump motor design

This cycle of operation is applied to piston installations; the blade has a rotary arrangement, which moves the suction chamber in a circle, at certain points connecting it to the inlet and outlet openings. The operating principle will help you figure out how to properly make a vacuum pump with your own hands.

The Golden Rule of Three Bandhas

Since we are talking about a yoga exercise, let's go back to the roots. Bandhas are a combination of clamps (or simply locks) at certain levels of the body. They retain energy in its individual parts, control various processes and subject some areas to internal massage.

During the performance of yogic exercises, energy flows accumulate and shift, which allows the physical and mental sides of a person to come into balance.

When training the internal abdominal muscles, you should hold three locks: throat, diaphragm and root. The most common mistake made when performing a vacuum is that many people throw a throat lock, and this can negatively affect intracranial pressure.

Photo: istockphoto.com