Sanding wood is a mandatory procedure prior to finishing. To perform the work, special machines are used that operate on different principles and grind the material in different directions. However, the price of such devices is quite high. For a home craftsman, it is not always advisable to purchase equipment that will be used occasionally. It is better to make a wood grinding machine with your own hands, which will cost much less and will allow you to get a completely effective device.

Types of grinding machines

Wood sanding machines are divided into the following types:

- design features;

- the nature of the tasks being solved;

- processing accuracy;

- permissible geometric dimensions of processed parts;

- power of installed engines;

- manufacturer ratings;

- cost with a set of attached equipment.

Modern manufacturers present three types of design of such machines: disk, belt, cylinder. Each of these species has its own highly specific subspecies. For example, belt sanding machines are available in the following versions:

- narrow-belt (allow grinding of wooden structures with complex geometric shapes);

- units equipped with a fixed table (capable of processing only wooden workpieces with flat rectangular surfaces);

- machines equipped with a freely moving table (they are used for grinding large-sized wooden structures - doors, panels, door slopes).

Belt Sanding Machine

The nature of the tasks to be solved determines the classes of this equipment. The main classes (sometimes called models) are:

- belt grinding machines;

- vibrating tools such as delta grinders;

- disc-type grinding machines (orbital and eccentric);

- specialized angle grinders;

- combined type grinding systems.

Despite such a variety of ready-made factory tools, home craftsmen prefer to develop and assemble a wood grinding machine with their own hands to carry out simple grinding operations.

Installation

The engine is securely mounted on a statically installed base. The rotating axis is threaded through a pre-prepared hole in the housing wall. The grinding drum is installed in the upper part and rests on bearings in cages that are fixed on the side walls of the structure.

Pulleys are attached to the axis of the drum and engine. The drive belt is being tensioned. Wiring and switches are connected. Clamping bolts are screwed into the sides of the housing, and adjustment bolts are screwed into the lower part.

To give the structure a complete and attractive look, you can treat the surfaces with paint. Naturally, it is necessary to undertake such work before assembling and installing the unit. To increase safety during operation of the device, the design can be supplemented with a protective casing placed above the drum.

Principle of operation

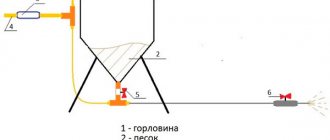

The operation of a belt-type grinding machine is based on the principle of counter-movement of an abrasive belt located on two rotating drums and the processed wooden part. Both drums are located at a certain distance from the desktop surface. To ensure the required grinding quality, the following parameters must be correctly taken into account:

- size (number) of abrasive applied to the tape;

- the tension force of the belt on the rotating drums;

- the speed of its movement;

- the force of pressure on a moving wooden part.

Working with a belt sander

Incorrect selection of these parameters significantly degrades the quality of grinding. For example, if the pressure on the workpiece is insufficient or the rotation speed of the drive drum is too high, some places on the workpiece will remain unprocessed, that is, they will not be polished. On the contrary, if there is excessive pressure from the belt on the surface and insufficient speed of the belt, burns and changes in the color of the wood are possible. Therefore, when assembling a grinding machine with your own hands, it is necessary to provide for the possibility of adjusting these parameters.

Advantages and disadvantages

The advantages of grinding machines include:

- Quality and speed of processing.

- High performance.

- The ability to obtain the surface of the desired roughness.

- The ability to process not only the wood itself, but also pre-grind the finishing layer.

The disadvantages are:

- Release of a large amount of dust, requiring the organization of a dust removal system.

- Large quantities of consumables (abrasive) of several sizes.

- Difficult to manufacture and maintain (this especially applies to belt installations).

Considering the existing shortcomings, before starting assembly, you need to decide how necessary the machine is. If it will be used only occasionally, it is not practical to spend time on manufacturing - you can get by with hand tools.

Application areas of the machine

Each of the manufactured machines performs a predetermined list of technological operations.

The drum-type system produces high-quality sanding of flat wood pieces. Processing of chipboard, OSB or MDF, including those covered with veneer, is allowed.

Application of Drum Sanding Machine

Processing of large, long, non-standard wooden wood products (for example, molded structures) is carried out using profile grinding equipment. Finished workpieces are fed to the grinding unit via a conveyor chain.

To grind the surface of wooden products that have a complex geometric shape (decorative frames, artistic products), belt sanding machines equipped with a freely moving table are used.

DIY grinding machine

The desire to make wooden structures yourself is always faced with the need to equip your workshop with sawing and grinding machines. Modern manufacturers produce them in a wide range. Such machines have good performance and high reliability. The most important and quite significant drawback is their high cost.

Therefore, many craftsmen try to assemble a grinding machine from existing components. The most experienced ones try not to limit themselves to a machine capable of performing only one function; they immediately try to assemble a universal machine capable of performing several functions: cutting wooden blanks, grinding followed by polishing, removing old coatings and preparing surfaces for renovation.

Homemade grinding machine

This is possible because the basis of any home-made machine is a frame on which are mounted: an engine, drive and driven drums, a set of additional equipment (saws, cutters, grinding wheels, and so on).

What is necessary?

So, before you start making a belt sander from an angle grinder, you need to prepare all the component materials and tools. For this you will need:

- the grinder itself, which is the basis of the future device;

- bolts and nuts;

- Sheet steel;

- springs;

- square tubes.

Among the tools you will need:

- a vice on which most of the operations in the manufacture of the grinder will be carried out;

- drill;

- hammer;

- welding;

- set of wrenches;

- roulette.

Calculation of grinding machine power

Before you begin assembling the machine, you must calculate its power. To correctly make such an assessment, it is necessary to determine the following parameters:

- power consumed by the electric motor;

- rotation speed of the selected engine;

- the area of contact of the entire surface of the part with the moving abrasive belt;

- grinding ratio;

- coefficient of friction between the back side of the belt used and the surface of the drums.

Based on data on these parameters, the power of the future unit can be determined.

Grinder and sharpener: a brief comparison

A belt grinder and a sharpener are analog devices, as they perform almost the same functions. But there are also differences in the quality of processing and design. The grinder has several advantages that a regular sharpening machine cannot boast of. This:

- precise processing geometry;

- simple replacement of abrasive tape;

- versatility of use.

Please note that due to the presence of a shaft and rollers, the tape becomes perfectly level. This makes it possible to more accurately position the workpiece for processing. As a result of cleaning parts, defects, nicks and burrs do not appear (this often happens when processing metal parts with a grinding wheel).

The grinder belt is made from strong sandpaper. For belt grinders, many belt options are sold with different abrasiveness. Having a whole set of them on the farm, you can perform work of varying complexity.

How to make a belt sander

The basis of the machine is a powerful frame that can withstand the weight of all equipment and perform the function of damping the resulting vibration. The frame of the bed is best fastened by welding. A plate is attached to the top. Chipboard with a thickness of at least 22 mm is chosen as such a plate.

An electric motor is mounted on the frame. The engine power must be no lower than the calculated one. The number of revolutions must be at least 1500 rpm. A gearbox is attached to the anchor to transmit rotation to the drive drum. The required diameter directly depends on the engine speed. It determines the speed of the belt at the moment of friction against the surface of the part.

The following relationships can be given as an example. When the belt speed is 20 m/sec, the diameter should be 20 cm. To prevent the slipping effect, rubber covers are placed on the drums. It is more expedient to make the platform for installing the drums at a slight slope. This will create smooth contact of the tape with the surface being treated while moving.

If you plan to process parts made of different types of wood, it is advisable to provide the possibility of changing the rotation speed of the drum. The above technique shows that it is quite easy to assemble a grinding machine with your own hands.

What to make the bed out of

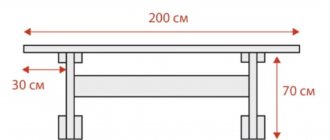

The frame to which all other elements of the machine are attached is a powerful bed. It must have a large margin of safety and have good weight and size characteristics. It is made from sheet steel more than 5 mm thick.

The most acceptable dimensions of a homemade frame are considered to be the following dimensions: 500x180x20 millimeters. For a bed of this size, the optimal dimensions of the working platform are 180x160x10 millimeters.

For the convenience of further work, it is necessary to mark the work site. Three holes are made for its fastening. Then it is secured to the frame with three bolts.

Selecting and installing a motor for the machine

Calculations and operating experience of this type of units show that the engine must have a power of at least 2.5 kW. The shaft rotation speed must be 1500 rpm or more. The speed of movement of the abrasive belt largely depends on the engine rotation speed. This seriously affects the quality of processing. In turn, the speed of the belt affects the diameter of the drums.

Motor for grinding machine

As a finished device, you can use the motor that is installed on washing machines. You can also select an engine from other household units, for example, a powerful pump or other device suitable in terms of power and speed.

Master and slave drums

The drive drum is firmly fixed to the electric motor pulley. The driven drum is fixed on a separate axis. To ensure its free rotation, bearings are attached between the shaft and the drum.

DIY sanding belt

Abrasive belts for such machines have a fabric base. Calico or a fabric of similar density is used as a base. Abrasive chips are applied to the surface of the material on one side using special glue. Depending on the grain size of this crumb, it is divided into large, medium, small and zero.

In principle, such a tape can be made independently. Select the required fabric and apply abrasive powder of the required fraction to it. By applying glue to the surface of the material and sprinkling it with this powder, you can obtain a sanding belt of the required size. However, it should be recognized that modern industry produces such a wide range of such consumables that it is better to use the factory one.

Grinder “from Chapai” - a brief overview

Grinders from Andrey Chapai have already become a household name. Hundreds and thousands of samples of grinding machines “from Chapay” have settled in the workshops of craftsmen in Russia and neighboring countries. The peculiarity of GCs (grinders from Chapai) is that they are universal and are created based on the needs of the customer: for sharpening knives or processing wood, with or without a certain type of engine. There are both mobile versions for home processing of products, and professional models.

Grinder “from Chapaya” is a universal machine for processing complex-shaped products made of metal, plastic and wood

You can buy a product, as they say, “turnkey”, or you can choose a modest set of tools and equipment.

At the moment, the most popular models of MGs are: GC-10, GC-12, GC-16 (professional series), as well as new mobile versions of the grinder 610 series GC610-63 and GC610 -71" - manufactured with zinc coating

General points characteristic of all machines:

- All mating surfaces of the grinder are polished. This helps to eliminate distortions during the running of the belt.

- Grinders come without painting or coating. The surfaces of the MS (short for grinder from Chapai) work for sliding. To prevent corrosion of the product, it is enough to periodically wipe it with a special oil or silicone spray.

- Unique pressure pad design.

I would like to dwell on the last point in more detail. The master came up with a unique design for this platform with the same size of 165x50 mm, there are 2 rotation positions for the base and two stop positions for the frame.

Options for rotating the pressure table and attaching it to the stop

Additionally, the set of tools and equipment includes a wheel for installation instead of the drive roller. It is recommended to be used when working on metal, when large amounts of paint or rust have to be removed.

Turning wheel with polyurethane coating, it is very convenient when adjusting and grinding concave slopes of products

Let's take a closer look at one of the professional models. The GC-16 is made on a reinforced rotary frame with 2 racks made of 12 mm thick sheet, which provides the necessary rigidity and allows you to quickly move the grinder to a vertical or horizontal position.

Grinder “from Chapai” – GCH -16. Appearance:

The design uses an enlarged sanding belt - 1600−1800×50 mm. And a fairly powerful engine - 2.2 kW. The machine has higher productivity and is ideal for continuous work in large industrial production. The price of such a product currently varies from 55,000 to 60,000 rubles.

Sanding machine from a hand sander

Very often, to carry out simple grinding operations, homemade wood grinding machines are made using ready-made grinding machines.

A mounting system for a grinding machine is being manufactured. It is mounted on a pre-prepared frame. Grinding wheels intended for processing wooden workpieces are attached to its shaft. Instead of such a machine, you can use an ordinary electric drill. This design allows sanding of simple wooden parts of limited size.

Setting up and checking the grinder in action

After completing the assembly of the entire structure, we begin to tension the tape. When rotating, it can move along the rollers to the left or right. To eliminate this phenomenon, we rotate the driven roller around its axis by both nuts until the tape stops moving to one or the other edge. Thus, we will find a position when all interacting elements are in place. Now we can safely turn on our homemade product and process the metal object. We make sure that the processing proceeds normally, without jerks or impacts, and we are quite satisfied with the result.