by Alexey | Crafts Tips Decor Workshop Furniture Cheap Accessories | Sunday, January 15, 2017

| Follow Make-Self.net on Facebook and be the first to read our articles. |

People who independently renovate their home or assemble furniture may have encountered the problem of choosing fittings, namely handles. I had a similar problem when I decided to install custom doors made of finger-jointed wood.

Installing handles on interior doors

Inserting handles into interior doors with your own hands begins with marking the location of the fittings. In accordance with established standards, a standard door handle is installed at a height of 80-100 cm from the floor (depending on the height of the residents). The work is carried out in the following sequence:

- Mark the installation location on the door leaf, moving at least 6 cm away from the edge.

- Using a ruler, draw a straight line across the end of the door and continue marking from the back of the door.

- Use a drill to prepare a hole ½ the thickness of the door.

- Repeat drilling on the second side of the blade. It is important that there is no deviation of the hole axis horizontally or vertically.

- Use a chisel to knock out a niche for mounting the latching mechanism.

- Insert the latch and check that its edge is in the same plane with the door leaf.

- Place the two parts of the handle on different sides of the door and guide them through the hole. Tighten the structure with bolts.

- Finish the end of the box with a steel plate - prepare a selection for the tongue and frame, try it on and secure the plate with self-tapping screws.

Over time, you may need to do some minor DIY repairs to interior door handles. At times, to prevent the elements from becoming loose, it is enough to tighten the screws with a screwdriver.

DIY turned wood door handle

To produce a turned handle for interior doors, you will need to master the ability to work on a lathe. Creating a similar model requires the introduction of the following tools and materials:

- Machine with three-jaw chuck;

- Oak block;

- Wood cutters;

- Coarse and medium-grain sandpaper;

- Wax mastic.

Sequencing:

- Prepare the workpiece. A square block of wood should not be cut off much on the sides on one side. Thus, the rounded part will be evenly fixed in the machine chuck.

- Insert the workpiece into the jaws and use a semicircular cutter to give it a cylindrical shape along its entire length.

- Level the surface of the block with the end of the cutter, holding it at a slight angle.

- Use the sharp edge of the cutter to shape the upper part of the handle.

- Leave a certain distance from the edge and carve a base, the back of which will be adjacent to the door leaf.

- Trim the base of the handle with a straight cutter and sand the surface with sandpaper. When sanding, it is important not to overdo it and not to press too hard on the paper, otherwise you may burn your fingers on the rotating elements and break the product.

- Cover the handle with wax mastic. The product gets into the pores of the wood, protecting the material from external influences and giving the handle a matte shine.

- Using the tip of the cutter, cut off the handle from another part of the rough timber.

- Insert the handle into the door.

During the production process, some aspects should be taken into account:

- For processing, it is necessary to take material without cracks and knots; otherwise, when rotating, the workpiece may split and cause injury;

- It is recommended to make a pair of handles from one blank, since turned models are small in size;

- Before sanding and impregnating with a protective compound, all minor cracks on the handle must be filled with putty designed for woodworking.

Door handle in Russian folk style

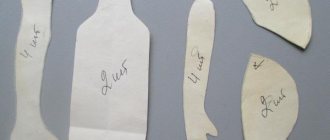

An example of a carved handle will harmoniously fit into an interior designed in a traditional folk style. The handle will perfectly complement an antique-style door. The design of the model includes 6 parts:

- Base;

- Intermediate bars - two pieces;

- Cubes - two pieces;

- Pen.

First you need to prepare each part separately, fit them together and polish them. Production order:

- Preparing the base: apply markings on a board measuring 36*9*2 cm in accordance with the drawing; Cut corners and semicircles with a jigsaw; If there is no tool at hand, the processing can be done with a semicircular file.

- Make intermediate blocks. In planks with dimensions 6*2*2 cm, make a longitudinal hole with a diameter of eight mm. In the future, dowels will be installed in them to assemble all parts into a single structure.

- Prepare cubes with a side of four cm: cut and polish a block with a cross-section of 4*4 cm, about 10 cm long; Saw the block into cubes; In the taken blanks, make two holes with a diameter of eight mm along the horizontal and vertical axis.

- Make a handle from a block fifteen cm long and a cross-section of 3*3 cm. Drill holes at the end sides with a depth of two cm, a diameter of eight mm.

- Perform decorative carvings on wood blanks: Base. Mark the outlines of leaves, squares and crosses on the board. Using the point of a knife, pierce the upper points of the ornament and cut out the tree, first on one side and later on the other, forming grooves of equal width. First, the leaves are cut out, and later the inner crosses. Pen. The carving is made on 4 sides using oblique lines with the same slope. The depth of the groove is about 3-5 mm. Cubes and blocks are decorated with diamonds and winding lines.

- Assembly is carried out using dowels “planted” on PVA glue. At the same time, it is necessary to cover the surface of the holes and the dowels themselves with an adhesive composition.

- Install the handle on the interior doors yourself using self-tapping screws.

Mounting according to view

There are several options for attaching the handle to the knife blade. The most popular are the mounted and overhead handles. Each of them is designed for specific knives.

Horseback

Mounted fastening technology provides for a narrow knife shank. The handle will be made in one piece. This mechanism provides resistance to damage. The design will be lightweight compared to riveted technology. This predetermines when used in long and voluminous work. If the manufacturer has chosen the mounting technology, epoxy resin and wood sawdust will be needed for excellent adhesion. The work is carried out according to the following scheme:

- Selected types of wood are treated with an antiseptic;

- A blank with suitable proportions is made from the block. The cutting angle is taken into account in order to achieve a beautiful cut;

- Marking is carried out and a hole of suitable diameter is drilled;

- You should dilute the epoxy, combine it with sawdust, and pour it into the hole;

- At the same time, you should insert the blade, which was previously wrapped with tape to protect it from dirt;

- Place the semi-finished product in a vice or press and wait until it dries completely (a day or two).

You can make such a handle with grooves for your fingers. To do this, make a recess under the index finger. You can practice performing the correct form on plasticine, only after that you can move on to wood. After this, you should use a cutter, rasp and sandpaper to sand the workpiece. Soak the product in heated drying oil and dry it in the sun. After this, treat the handle again with a zero polish. Complete the production with a coating of rosin, turpentine and wax, melted in a water bath, which should be used to polish the handle.

Invoice

Such a handle provides for the presence of a wide shank, which is necessary to determine the contour of the created handle. It is assembled from two wooden blocks, united by metal rivets. This method of fastening does not affect the dimensions of the product in any way, thanks to this it is possible to balance a wide or elongated blade. The overhead fastening option is popular among the manufacture of kitchen knives. Main stages of work:

- The prepared wood is treated with an antiseptic and placed in a vice, where it is evenly divided into two symmetrical parts;

- The surface of the shank is carefully cleaned and polished to avoid gaps;

- Future fastenings are marked to connect the two parts;

- It is necessary to prepare a rod of copper or brass and drill holes in the markings in accordance with the diameter of the rod;

- Make rivets; their length should be greater than the thickness of the finished handle.

Before doing the work, you can practice rough assembly of parts. After assembly is completed, the handle should be processed using a cutter and sandpaper. The halves must be attached symmetrically. You also need to saturate the wooden halves on the side adjacent to the shank with epoxy glue or resin, and add toner to give the desired shade to the product. Next, you need to wrap the knife blade with tape and connect the workpiece, cut off the pieces of rod and protruding rivets. Place the finished knife in a vice again, after wrapping the handle in oiled rubber. Allow the finished product to dry (a day or two).

Soak the handle in heated drying oil and dry in the sun. After this, treat it with zero. Polish the product with a mixture of rosin, turpentine, and wax, melted in a water bath. Instead of this product, you can use ship varnish.

Manufacturing methods

There are two popular ways of making products from wooden material:

- turning;

- thread.

Turned products

Such parts are made on a lathe; the product cannot be manufactured without special tools. “Balls” and “mushrooms” are made using a similar method. The manufacturing process consists of several stages.

"Mushrooms"

You will need a blank - a wooden board (block) with a section of the required size, which is selected in accordance with the parameters of the product. Leftovers from making the door frame will do. The board must be dry, intact, without cracks or other defects.

Note! The integrity of the blank board is important both for the aesthetics of the finished door handle and as a safety requirement, because such a blank can break at any time during rotation and injure your hand.

"Mushrooms" from a lathe

Manufacturing stages:

- An octagon is made from a blank board; a plane is used for this. It’s faster to work with an electric planer, but if you don’t have one, then a regular manual one will do.

- Next, the hewn workpiece is clamped on a lathe and a cylinder is formed using a chisel.

- Next, markings are applied to it for the future part. The product is formed using a semicircular or beveled cutter.

If you need to make handles for several canvases, then take a block of such length that it is enough for 3-4 copies, then saw them. The surface finishing is done manually using fine sandpaper.

Assortment of turned wooden handles

Carvings

This model is easier to manufacture and does not require special equipment such as a lathe. Tools and materials you will need:

- Board.

- The branch is of a non-standard shape and of such a size that it is convenient to grip the door handle.

- Saw, jigsaw.

- Milling cutter and attachments are optional.

- Drill or screwdriver.

- Sandpaper or sander.

- Clamp.

- Epoxy adhesive.

- Varnish.

- Nog.

Handle blank

Additional accessories

Such devices most often include a trench and a sharpener, as well as secret holes in the back of the knife and pockets on the sheath.

Trenchik

A special loop for attaching the sheath to a belt. When making a trench coat, various materials are used: rope, cord, strip of leather. Making a sheath with your own hands allows you to make a trench coat from any available material.

The trench coat can be glued, sewn, attached with a screw from the inside of the sheath, the main thing is to make a loop with a margin for any belt width. The length must be selected individually.

Sharpener

A small, fine-grained block of stone used for sharpening a knife. The sharpener is attached to the sheath and is necessary when using the blade for a long time.

Pockets

Making a knife and a sheath with your own hands allows you to fully equip it to your taste. But it is worth carefully considering the necessity, and most importantly, the practicality of this or that pocket.

When making handles for knives, some craftsmen leave a cavity in the back, into which small objects can also be placed.

Mounting according to view

There are several options for attaching the handle to the knife blade. The most popular are the mounted and overhead handles. Each of them is designed for specific knives.

Horseback

Mounted fastening technology provides for a narrow knife shank. The handle will be made in one piece. This mechanism provides resistance to damage. The design will be lightweight compared to riveted technology. This predetermines when used in long and voluminous work. If the manufacturer has chosen the mounting technology, epoxy resin and wood sawdust will be needed for excellent adhesion. The work is carried out according to the following scheme:

- Selected types of wood are treated with an antiseptic;

- A blank with suitable proportions is made from the block. The cutting angle is taken into account in order to achieve a beautiful cut;

- Marking is carried out and a hole of suitable diameter is drilled;

- You should dilute the epoxy, combine it with sawdust, and pour it into the hole;

- At the same time, you should insert the blade, which was previously wrapped with tape to protect it from dirt;

- Place the semi-finished product in a vice or press and wait until it dries completely (a day or two).

You can make such a handle with grooves for your fingers. To do this, make a recess under the index finger. You can practice performing the correct form on plasticine, only after that you can move on to wood. After this, you should use a cutter, rasp and sandpaper to sand the workpiece. Soak the product in heated drying oil and dry it in the sun. After this, treat the handle again with a zero polish. Complete the production with a coating of rosin, turpentine and wax, melted in a water bath, which should be used to polish the handle.

DIY Wooden Crosses (1 Dz) - Craft Kits - 12 Pieces - Walmart.com

"," tooltipToggleOffText ":" Toggle the switch to get

FREE Next Day Delivery!

"," tooltipDuration ":" 5 "," tempUnavailableMessage ":" Be back soon! "," TempUnavailableTooltipText ":"

We are working hard to get things up and running again.

- Temporarily suspended due to high demand.

- Keep checking availability.

"," hightlightTwoDayDelivery ":" false ", " locationAlwaysElposed ":" false ", " implicitOptin ":" false ", " highlightTwoDayDelivery ":" false ", " isTwoDayDeliveryTextEnabled ":" true ", " useTestingApi " ", " ndCookieExpirationTime " :" 30 "}," typeahead ": {" debounceTime ":" 100 "," isHighlightTypeahead ":" true ", " shouldApplyBiggerFontSizeAndCursorWithPadding ":" true "," isBackgroundGreyoutEnabled} ":" false " locationApi ": {" locationUrl " :" https://www.walmart.com/account/api/location "," hubStorePages ":" home, search, browse "," enableHubStore ":" false "}," "oneApp" : {"drop2": " true", "hfdrop2": "true", "heartingCacheDuration": "60000", "hearting": "false"}, "feedback": {"showFeedbackSuccessSnackbar": "true", "feedbackSnackbarDuration" ":" 3000 "} "," webWorker ": {" enableGetAll ":" false "," getAllTtl ":"

Manufacturing and installation

The sequence of creating a door handle:

Clean the cut of the tree from the bark, sand it and apply contours to the workpiece - this will be the base of the future handle.

- Use a jigsaw to “go” along the contour and give the tree a suitable shape.

- To add texture to the workpiece, you can use a milling cutter to make indentations in the marked areas of the wooden cut.

- Sand the side ends of the product and chamfer the edges of the workpiece.

- The handle is made from an unusual knot. Remove the bark from the branch and fit the handle to the base.

- Use a saw to trim the edges so that the ends of the handle are in perfect contact with the prepared workpiece.

- Apply epoxy glue to the handle, press it to the base and clamp the parts with a clamp.

- Drill holes in the bases of the handle at an angle, lubricate the dowels with glue and drive them in, thereby strengthening the structure. Saw off excess pegs.

- Leave the handle to dry for one day.

- Coat the product with varnish, wait until it dries completely and install it on the door.

Rules for repairing major breakdowns

In general terms, repairing door handles comes down to eliminating the causes of their breakdowns. Let's list some of them.

- If the handle breaks and the fastening remains in place, in order to repair the handle you need to remove the remaining part of the handle from the door and replace the locking ring with a new one.

- If the square breaks, it will be difficult to open the door, and, unfortunately, it is impossible to repair such a breakdown. This requires a complete replacement of the device.

- To repair a broken latch, you must completely disassemble the device. The short square is replaced with a longer one, which can be purchased at any specialty store. Next, the structure is installed in place; if everything is done correctly, you can open the door without effort. A durable square will serve you long and well.

- If the handle does not fall into place, it is necessary to disassemble the device and correct or replace the spring.

- If pressing the handle is difficult and squeaking occurs, it is necessary to lubricate the metal parts by dripping oil. This failure is associated with the lock becoming clogged during its operation.

Sequence of work

- Clean the board from bark and sand it. Apply a drawing of the future base for the pen onto the prepared surface.

- Cut the workpiece along the contour, thereby giving it a suitable shape.

- Sand the sides and make a shaped notch along the edges using a router.

- The handle itself consists of an unusually shaped tree branch. Remove the bark from it, if necessary, trim and sand it.

- Trim the branch so that it is in tight contact with the prepared board.

- Connect the branch and the base under it using glue. For permanent fixation, clamp with a clamp.

- Drill holes in the base so that they go to the base. Drive the dowels there, pre-coated with glue. Remove the excess length of the pegs.

- Dry the assembled product overnight.

- Cover with varnish or paint after drying and mount on the door.

Carving "before" and "after"

Conclusion

Making a wooden handle for a bath door or front door is not difficult; you only need desire and a certain set of tools. In this matter, thoroughness and strict adherence to the technology of working with the material are important.

Voted over 252 times, average rating 4.8

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Handles, Fittings Why are brass handles considered the best choice for interior and exterior doors? The functioning of any door is ensured by fittings. Locks …

Handles, Fittings How to find the right solution for determining the height of the door handle from the floor? If previously interior doors were the same type of solutions, ...

Handles, Accessories In what interiors can handles on a rosette be installed on the door? Interior and entrance doors are often equipped with a locking mechanism and…

Handles, Accessories How to disassemble and replace a door handle with your own hands in 10 minutes? Door handles, like any mechanism, are subject to malfunctions and...

Selection of wood species for the production of handles

Devices mounted on entrance doors must be made of strong wood. Some experts recommend using conifers, which, when heated, emit a pleasant smell that is suitable for human health. But hardwoods, which are distinguished by their excellent textured pattern and good mechanical resistance, are no less in demand.

Advice. It is better to make door handles from deciduous trees so that no resin remains on your hands when gripping them.

For making door handles with your own hands, the following are suitable:

- Oak – characterized by strength, resistance to external influences and hardness. Oak products look respectable and generous, and are amazingly suitable for furnishing suburban mansions and apartments.

- Beech is a desirable species, similar in many qualities to oak. The wood has an unusual pinkish color with a uniform texture.

- Poplar - has very pronounced bactericidal qualities, which is why it is often used when decorating a steam room.

- Linden – has an anti-inflammatory and calming effect on the human body.

Wooden knife handle

In this section we will try to describe the main stages of the work. As an example, let’s take a more complex mounted handle for a knife made of two types of wood, the so-called composite or stacked handle. We will begin the description, assuming that the bars are already dried and prepared for work.

Stage one

Metal pommel in the shape of an eagle's head

- The first step is to saw and carefully process the wooden blocks. The main thing is that they fit perfectly against each other. You can choose any angles. At this stage, you should estimate the length of the handle. The bar that will be the outermost one on the side opposite to the blade should be made a little longer. Unless, of course, you are planning a handle with a metal pommel, as, for example, in the photo.

- Then in all the bars you need to drill a hole for the shank. It should fit freely into this hole. During the drilling process, we recommend inserting the shank from time to time. This is necessary in order to maintain the evenness of the drilling. So that later the blade does not “go away” to the side.

- After drilling, the handle needs to be assembled. If your idea involves a bolster, it comes first. This is a metal element that protects the junction of the handle and the blade. They can be smooth, come with various carvings and also serve for decoration. After the bolster, you need to put all the wooden parts on the shank. You can also make metal spacers between them, or you don’t have to. If at this stage you see any inaccuracies, for example, a connection that is not tight enough, then you need to correct this.

Stage two

- If everything is in order, we proceed to gluing. For this you will need epoxy glue. It needs to be poured into the hole of the outermost bar and allowed to stand for a while. While it is standing, wrap the blade with masking tape to prevent it from getting dirty. After this, all parts of the handle must be coated in turn with epoxy and put on the shank. At the end, insert it into the outermost block, into the hole of which glue was first poured. By the way, you can read more about epoxy glue here.

- After this, you need to clamp the handle in a vice. Please note that they will have to be modified a little so as not to spoil the blade. There is no need to clamp too hard so as not to bend or break the future knife. In this form, the workpiece should be left for a couple of days until completely dry. Then the epoxy will completely harden and will not be pressed when pressed, for example, with a fingernail.

Stage three

- Once the epoxy has completely dried, you can begin the hard part. First, level the surface using a file. Then you need to make markings with a pencil.

- If you see that there is a lot of excess around the edges, then the first rough cuts can be made with a saw. This is followed by long and careful processing with a file and sandpaper, and then polishing.

- At the very end, you need to saturate and treat the handle, if you have not already done this before gluing.

DIY wooden door handles: photo ideas

The design of door handles amazes with the variety of colors and designs. The fantasies of woodworking masters are embodied in unusual shapes, beautiful curves and stylistic execution of door accessories.

Lightweight version of a wooden handle for a bath

A homemade door handle will amaze the guests of the bathhouse and will become the pride of the owners of the steam room. Constructing a lightweight model will not be difficult. Let's look at an example of creating a pen with a length of 20 6 cm and a height of 10 cm. To work, you will need a board with dimensions of 26 * 10 * 5 cm, a light pencil and a jigsaw.

Method of action:

- Draw a sketch of a pen on the page. It is no more difficult to show the drawing by cells. In order to draw arcs and curved lines, you can use a pattern or improvised round objects of suitable diameter.

- Transfer the contours onto wood and cut out a blank along them using an electronic jigsaw. To obtain an even cut, it is better to use a metal cutting file.

- If desired, you can smooth the shape of the handle and chamfer it, apply a pattern, carve a sketch, or make decoration with a burner.

- Attach the handle to the door with self-tapping screws.