folding workbench table

A workbench is needed in every home, even if carpentry or plumbing is not your hobby. Still, from time to time there is a need to fix or do something. The problem is usually where to find space for such a table. The best way out is, of course, to make a folding workbench with your own hands, especially if you need it not all the time, but from time to time .

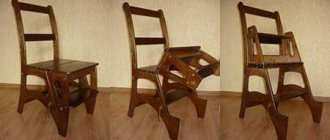

The best option is to attach the folding structure to the wall, it is convenient and reliable. Disadvantage: limited space to work. You can make a completely collapsible workbench so that you can fold it and put it away, and, if necessary, unfold it. Convenient in the sense that you can put it anywhere and transport it is not a problem. But the disadvantage is obvious, such a design should be very light, that is, the list of works on such a table will be quite limited. The article presents different options, choose the one that suits you best.

Why do you need a workbench?

Its design consists of a work table and compartments for various tools and workpieces. The table for it can be made of either wood or metal (depending on the tasks performed on it). Its remaining elements (such as drawers, bedside tables, pendants, etc.) are made from any materials and are arranged at the user’s discretion. The workbench design can even be made collapsible and portable.

According to their purpose they are:

- carpentry;

- metalworking;

- carpentry

For auto mechanics and mechanics, a metal workbench is perfect. His tasks include working with metal and other durable materials. It should have a metal work surface, a vice for securely holding workpieces, a couple of lighting fixtures and a place to store tools. It is advisable to make a table for a metal workbench with the ability to adjust the height, since it is more comfortable to work on it while standing.

A carpentry workbench will be useful for carpenters and wood carvers. With its help you will be great at making different tables and stools, repairing broken furniture or making a variety of decorative crafts. Its design consists of a wooden work surface (large enough to comfortably saw anything), a small vice and drawers for tools. If you like to saw with a jigsaw, then for greater convenience you can make a semicircular cutout in the center of the table. The area underneath should be covered with cardboard to easily and quickly collect scattered shavings.

The carpenter's workbench is not suitable for a balcony because it is too bulky - 1 m wide and 6 m long. It is mainly used for making furniture and processing large parts.

Also, a good workbench should have the following characteristics:

- the working surface is large enough and free;

- the workbench design is stable and motionless;

- enough space to store all the necessary tools;

- There is a place to securely secure the workpiece.

Advantages of folding design

The collapsible table is compact in size. The transformer is made primarily of metal and fiberboard. The metal frame is designed to withstand high loads. Some metalworking and carpentry workbenches have special mounts for mounting various equipment manufactured to increase functionality. Such equipment could be:

Circular plate. A circular saw will be almost indispensable in a home workshop. A similar circular saw is used to divide a workpiece into several parts in the longitudinal or transverse direction.- Grinder machine. To give the surface the required qualities, the surface layer is removed. The roughness can be changed by using a grinding wheel with different abrasive grains.

- An electric jigsaw is used to produce products with different geometric shapes.

- Drilling machine. To produce holes of various diameters, drilling units are used, in the spindle of which a drill or cutter is placed.

When using the design, processing can be carried out with high precision, as in a production workshop. All installed equipment can be removed if not required. The advantages of a folding workbench include:

- Its use allows you to save free space.

- Although the supporting structure can be transformed, it has quite high strength. Some models can withstand about 200 kg.

- Modern countertops are made in such a way that the workpiece can be securely fastened. For this purpose, use the clamps that are included in the kit. If necessary, you can purchase them separately.

In cases where it is necessary to bend and cut thick metal, a folding structure will not be suitable. The moving parts can withstand planing and sawing, as well as cutting and other machining. If the models that are on sale do not fit, then you can make a table according to your own plan.

How to make insulation on a balcony

Insulating a balcony is a significant moment for equipping a workshop on the balcony of a city apartment with your own hands. Without it, you should forget about year-round work and operation of additional premises. And if you decide to insulate a balcony or loggia, then do it like this:

Video instructions for insulating and finishing a loggia

- Eliminate any cracks found on the floor, ceiling, or along the perimeter of the walls.

- Conduct electricity using wiring with a cross-section of 2.5 square meters. mm.

- Insulate your workshop in a convenient way:

- Construct niches by constructing lumber or metal profiles around the perimeter of the balcony room. Fill them with thermal insulation such as mineral wool or polystyrene foam. Lay moisture-resistant material on top of the insulation, and cover the frame with plasterboard. Another option like chipboard or OSB will also work.

- Use polystyrene foam to cover the surfaces of the walls. The benefit of such material lies in the use of a small amount of it, thereby saving the workshop area. This material is glued with glue, and the joints are filled with polyurethane foam.

- Finish the surface of the walls with wooden lining, plastic, tiles, wallpaper or other material.

The ceiling and floor are insulated in a similar way, but for the second option it is often advantageous to use a heated floor system. It is also worth adding that it is important to properly level the floor and, if necessary, install a radiator in the room to heat it in the cold season.

Ceiling cladding - simple solutions

Ceiling decoration is easy to make from inexpensive and accessible materials. These include: finishing polystyrene tiles, plastic and wooden lining, MDF panels. Polystyrene tile products are distinguished by their low cost and remarkable appearance. They look just great on the ceiling. And installing them on the ceiling will take you a minimum of time.

The work flow diagram is as follows:

- Set the center of the ceiling surface. This can be done using two ropes. They must be pulled crosswise from opposite corners of the loggia. The point where they intersect will be the center you need.

- Draw perpendicular axes through the found point (their ends will “rest” against the middle of the wall surfaces). You have received a clear guideline for sticking polystyrene products.

- From the intersection of the axes, begin installing the tiles. The first four products set the layout of all other tiles.

Pro tip: There is no need to apply adhesive to the entire inside of the tile. It is enough to process only its corners and center. Just apply a small drop of glue to these places. Trust me, polystyrene tiles will last forever. Products treated with glue should be pressed against the ceiling for 60–120 seconds. This time is more than enough for excellent adhesion of the overlapping material.

Polystyrene tiles for finishing the ceiling on the balcony

After installing all the tiles, you need to edge them with special skirting boards. They are easily cut into pieces of the required size and glued to the ceiling surface with the adhesive that you used to install polystyrene products. Important! During the installation of the tiles, as well as for 3-4 hours after this procedure, you should keep the windows and doors on the loggia closed. Such a simple precaution will ensure that the fresh finish does not fall off. Drafts are detrimental to glued tiles!

Without much effort, plastic and wooden lining is attached to the ceiling. Such materials are installed on a specially made frame. For plastic lining it can be made of aluminum, for wooden lining - from a metal profile or wood. All facing work in this case is carried out simply. You attach the selected products to the do-it-yourself lathing on the lining with universal self-tapping screws or self-tapping screws. In a day of quiet work, you can easily finish the ceiling of your loggia. And at the same time, the costs of all materials will be minimal.

MDF panels are also quick and easy to install. In essence, they are an analogue of products made from natural wood, but more economical, which is important if you have allocated a modest financial budget for repairs. Most often, MDF panels are mounted on a frame made of aluminum profiles or on a slatted structure. Additional tip.

To finish the ceiling on a loggia or balcony, it is advisable to use moisture-resistant models of MDF panels. Their selection in construction stores is quite large. Therefore, you will not have any problems with selecting facing materials for any interior.

Desk dimensions

To understand what size the workbench should be, take measurements of the balcony. Based on the data obtained, we begin to design technical furniture.

The main size is the width of the table. Usually the workbench is placed on one of the sides of the balcony or loggia. The distance between the front wall of the house and the front fencing of the balcony or loggia will be the width of the table. The height of the table depends on the individual physical characteristics of the owner. The standard height of this type of furniture is 750 mm. The depth of the tabletop can be any convenient for the user.

An opening for the worker’s feet at the table is required. In the absence of one, the workbench will be very inconvenient, especially if a person stays at it for a long time.

Stage 5: installation of light sources

Even a balcony with panoramic glazing and located on the sunny side requires the installation of additional lighting. This will allow you to carry out any work without hindrance and use the workshop in the evening and at night. Similar parameters can be easily achieved by installing at least two artificial light sources.

- The main overhead lighting is calculated according to the area of the room. Standard quadrature allows you to get by with a luminaire with a fluorescent lamp with a power of 63 W. When using LED lamps, preference should be given to lamps of 6 - 10 W.

- To carry out small work at the table, the workshop should also have a mobile directional light lamp. Standard office equipment with toggle joints or clamps can be used. These luminaires are easy to install in any convenient location.

Important: on sunny days, natural light can create difficulties in working. To prevent such situations, it is better to take care of possible shading of the balcony room in advance. Adjustment of the light flux is ensured using conventional horizontal blinds, which also need to be equipped on the balcony.

DIY - English to Italian WordReference

WordReference English-Italian Dictionary © 2022:

| Basic translations / Translation principles | ||

| DIY adj. adjective : describes a noun or pronoun—for example, “a tall girl ,” “an interesting book ,” “a big house .” | ([sth] made by amateur) | fai da te loc agg locuzione aggettivale : Espression di più parole che descrive o specifica un sostantivo: "C'è del tonno in scatola " - "Ho seguito il metodo fai da te " |

| Note : Hyphens are used when the term is or precedes a noun. | ||

| Have you seen this patio? - that must have been the case - Independent work! | ||

| Hai visto quel patio? Dev'essere stato un lavoro fai da te. | ||

| DIY n noun : Refers to a person, place, thing, quality, etc. | UK (home improvement) | fai da te nm sostantivo maschile : Identifica un essere, un oggetto o unconcetto, which presupposes genere maschile: medico, gatto, Strumento, Assegno, dolore |

English-Italian Dictionary WordReference © 2022:

| Basic translations / Traduzioni Principali | ||

| home improvement n. noun : refers to a person, place, thing, quality, etc. | US (DIY) | bricolage, fai da te nm sostantivo maschile : Identifica un essere, un oggetto o un Concetto, which presupposes genere maschile: medico, gatto, Strumento, Assegno, dolore |

| Note : Often used as an adjective. | ||

| I go to the home improvement store to get a screwdriver, concrete blocks, and a can of spray paint. | ||

| Vado al negozio di fai da te a comprare un cacciavite, qualche mattone di cement and un barattolo di vernice. | ||

Creating comfortable conditions

Any building structure, especially in a new building, has a number of flaws that have to be eliminated. We must try to seal the cracks in the seams of the loggia with foam, inspect the glazing and frames, and foam the cracks here too. If there is open space under the loggia or balcony, the floor will freeze in winter. The floor needs to be insulated. The simplest and most effective option is polyurethane foam yoga mats. If this is a carpentry workshop on the balcony, then linoleum should be laid on top of the rugs for ease of cleaning.

In areas with long and cold winters, such as Siberia and the Far East, there is a need for an electric heater. Nowadays many economical and compact models are produced. The choice of model is up to the owner, but it is better to place the heater on the wall of the loggia, so you need to choose a model with the possibility of such mounting. The location of the loggia on the street wall is more rational, heating occurs more quickly and the influence of street temperatures is immediately cut off, and the apartment wall is warm by default.

Heating issues

When using a workshop regularly, it is very important to choose an efficient method of heating the room. In the case of a workshop, the most optimal solution will be those heating devices that will not take up much space and work with maximum efficiency. Therefore, you will have to choose from a “warm floor” system, ceiling and wall heating units.

Floor heating option.

A combination of several heat sources, for example, underfloor heating and an infrared heater, is also quite possible.

Ceiling infrared panel.

It is not recommended to install a separate radiator on the balcony connected by pipes to the central heating system, since in this case, before starting work, you will need to coordinate everything with utility services, which very rarely give permission to install radiators in non-residential premises of city apartments.

For independent expansion of the heating network in an apartment, current legislation provides for a fine, as well as work to dismantle an illegally installed radiator.

In addition, when placing the radiator and pipes, it will be difficult to install a workbench and other equipment for the workshop, since the heating system will hide the free space.

Desk dimensions

To understand what size the workbench should be, take measurements of the balcony. Based on the data obtained, we begin to design technical furniture.

The main size is the width of the table. Usually the workbench is placed on one of the sides of the balcony or loggia. The distance between the front wall of the house and the front fencing of the balcony or loggia will be the width of the table. The height of the table depends on the individual physical characteristics of the owner. The standard height of this type of furniture is 750 mm. The depth of the tabletop can be any convenient for the user.

An opening for the worker’s feet at the table is required. In the absence of one, the workbench will be very inconvenient, especially if a person stays at it for a long time.

Workplace in a workshop on the balcony

Next, for the workshop on the balcony you will need a workbench table. The table must be made of a durable structure that can withstand all working methods. An excellent option would be an antique table made of metal or wood.

The next step in organizing a workshop on the balcony with your own hands is a convenient location of the tool. You should have easy access to all the tools you need. I have a wooden shelf on my desk, just the width of the table. On some of the shelves I installed a horizontal bar on which various tools are attached. The fastenings are different, depending on the type of instrument.

For example, for screwdrivers in a workshop, you can drill through holes in a block. For keys, hammer in small nails to secure them. There are plenty of options here, the main thing is that you are comfortable.

All kinds of drawers for every little thing will also be useful. Make separate containers for nuts, washers and other small items. For power tools such as a drill, jigsaw or sander, it will be useful to attach hooks where they are not in the wall. Thus, they will not be lying around anywhere, and easy access to them will make work much more convenient.

Arrangement of the premises

The workshop on the balcony needs special finishing. Increased attention should be paid to the floor covering - it must be resistant to serious mechanical loads, pressure, and falling metal objects. The use of parquet, laminate and linoleum is somewhat questionable, because... they can hardly even withstand a workbench.

A workbench, especially a metalworking one, can be quite heavy, but you can make it yourself or buy a folding one, as in the video below.

If you also put a tool cabinet on the balcony, then you need to provide a reliable base that will bear the resulting loads.

Cabinet for tools and workpieces.

Instead of a heavy cabinet, you can consider a stationary or retractable stand for hand tools. Video below.

In the workshop, you can consider installing a floor made of monolithic concrete, special ceramic tiles, engineered wood, porcelain stoneware; all these coatings can easily withstand a workbench. At the same time, you need to take into account that the load-bearing slab of the balcony will receive a significant load (finishing materials, tools, a workbench and much more - everything will create serious loads).

Tiles on the balcony floor.

That is why, before carrying out finishing work, you need to check the condition of the load-bearing slab, assess how much weight it can withstand and how safe it is to operate under high loads. Utility service specialists can provide similar information. In some cases, without additional strengthening or major repairs of the load-bearing slab, specialists may impose a ban on placing heavy materials and equipment on the balcony.

This is simply dangerous, the balcony may break!

A workshop on a balcony can have a very different focus:

- Wood and metal processing (a workbench is a must here);

- Modeling clay products;

- Creation of hand-made souvenirs;

- Making soap and the like.

- Sewing workshop.

Related article: Do-it-yourself folding table for a balcony

Simply put, you can equip any workshop on the balcony. It is not at all necessary that this will be a place for metal or woodworking. That is why the workshop will not always have heavy equipment and tools. If you don’t plan to use anything like that, then you can choose any floor covering, such as laminate or linoleum.

Naturally, if the workshop is planned to be made strictly for men, the center of which will be a workbench or some kind of machine, then special attention should be paid to the quality of the load-bearing slab and the type of floor covering.

Site preparation and installation

Before you start making and installing a workbench on the balcony, you need to prepare a place for it. First you need to install electricity. You can simply make a hole in the wall between the balcony and the room. And as a battery, you can use a carrier of the length you need, connecting it to the nearest outlet in the next room. Then you need to insulate the balcony (so as not to shiver from the cold in winter) or simply equip it with sheets of plywood in the place where the workbench will be located.

Now let's proceed directly to manufacturing. For a standard single workbench, the dimensions used are 80x80x150 cm (regardless of its type and purpose). If your balcony is wider, then you can expand the central area of the workbench. Be sure to eliminate all possible cracks and extra holes.

At the base of the workbench there is a tabletop, which is attached to the bench. Its width should be such that all tools that are suspended at the opposite end are at arm's length. The wooden tabletop must be made of hardwood (oak or beech) and its thickness must be at least 60 mm. For a metal tabletop, dense aluminum with a thickness of about 6-10 mm is quite suitable, and the underbench can be placed on steel or cast iron legs. It is advisable to securely fix a wooden tabletop, and weld a metal one to ensure maximum strength!

The surface of the workbench should be protected with an additional wall on three sides. This is necessary so that waste cannot fly out of the workplace during work. One of the walls will serve as a good place for attaching tools. On the other wall you can nail hooks or shelves for quick access to necessary things. In addition to this, you can build small drawers and niches under the tabletop or even put a bedside table if free space allows. In terms of organizing useful space above the workbench, it is advisable to limit yourself to shelves and lighting so as not to overly clutter the workplace. Finally, a wooden workbench must be treated with an antiseptic, and a metal workbench must be coated with a primer.

I make wooden parts

- First, I cut a piece of board measuring 5.08 x 15.24 cm, which exactly matches the height of the table surface as a mounting base.

The vise itself will be attached to the table leg, and its length will provide more reinforcement.

- I also needed a second piece of 5.08 x 15.24 cm, and a clamping board 60 cm long.

- Next, I mark and drill a hole for installing a threaded bushing and a hole for the screw itself

The higher the bushing is to the edge of the vise, the greater the clamping force, and the lower it is, the greater the range.

- I insert a nut into the hole for the screw and drive it in tightly. When tightening the vice, the nut must be securely fastened.