Square-shaped holes in workpieces or products made of metal and other materials can be produced using a cutting tool called a square hole drill. It has another name - Watts drill. Square holes are obtained with slight roundings in the corners, which are almost invisible. They are drilled, reamed and drilled into ferrous and non-ferrous metal with a thickness of no more than 16 mm, wood, plywood and other materials, including substances of composite origin. The operation is performed using a drill, hammer drill, or on lathes or broaching machines. They are used in industry, agriculture and everyday life in the manufacture of products, repairs and DIY crafts.

Operating principles and design

In order to drill a square hole, a Watts drill is usually used, the design of which is based on a geometric figure such as the Reuleaux triangle. One of the most important features of such a figure, which represents the area of intersection of three equal circles, is the following: if a pair of parallel reference lines are drawn to such a triangle, then the distance between them will always be constant. Thus, if you move the center of the Reuleaux triangle along a trajectory described by four ellipsoidal arcs, its vertices will draw an almost perfect square, with only slightly rounded vertices.

Property of the Reuleaux triangle

The unique properties of the Reuleaux triangle made it possible to create drills for square holes. The peculiarity of using such a tool is that the axis of its rotation should not remain in place, but move along the trajectory described above. Naturally, this movement should not be hindered by the equipment cartridge. When using such a drill and the appropriate equipment, a square hole is obtained with perfectly straight and parallel sides, but with slightly rounded corners. The area of such corners not processed with tools is only 2% of the area of the entire square.

How to cut a circle in plywood - rules for doing the work

- The diameter range varies from 10 to 60 mm.

- The work is done quite quickly, but the quality of the hole is low, and it is unlikely to achieve an ideal result.

- The maximum drilling depth is approximately 150 mm.

- Products are sold either in sets of 5-6 pieces or individually, so you decide which option is right for you.

- If necessary, you can buy an extension that clamps the drill and increases its length by 300 mm.

Fraser

A furniture router is great for cutting out thick plywood. Of course, you can’t make a complex shape with it, but cutting an arc or circle is easy:

- We fix the standard ruler included in the router in the center of the circle using a self-tapping screw.

- If the length of the ruler is not enough, you can assemble a simple bracket from a metal profile or wooden planks.

- By rotating the cutter along a fixed radius, we select a groove along the circumference, resulting in an almost perfect hole.

Note! When calculating the diameter of the circle, you should take into account the dimensions of the working cutter. The instructions for the device will tell you the exact numbers.

In this way, you can cut not only circles, but also individual arcs - for example, in order to make grooves for furniture brackets.

How to cut a circle in plywood: selection of tools, shape cutting technologies with a jigsaw, router and improvised means

You may also need to cut out the correct circle from plywood for subsequent use of a sheet with a hole:

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

The fact is that now I mean the cutting element and not the machine itself, you need to align the cutter not in the center of the drawn circle. If you want to clarify something, please contact me!

Operating principles and design

In order to drill a square hole, a Watts drill is usually used, the design of which is based on a geometric figure such as the Reuleaux triangle. One of the most important features of such a figure, which represents the area of intersection of three equal circles, is the following: if a pair of parallel reference lines are drawn to such a triangle, then the distance between them will always be constant. Thus, if you move the center of the Reuleaux triangle along a trajectory described by four ellipsoidal arcs, its vertices will draw an almost perfect square, with only slightly rounded vertices.

Property of the Reuleaux triangle

The unique properties of the Reuleaux triangle made it possible to create drills for square holes. The peculiarity of using such a tool is that the axis of its rotation should not remain in place, but move along the trajectory described above. Naturally, this movement should not be hindered by the equipment cartridge. When using such a drill and the appropriate equipment, a square hole is obtained with perfectly straight and parallel sides, but with slightly rounded corners. The area of such corners not processed with tools is only 2% of the area of the entire square.

[question to carpenters] How to cut?

There is a 25mm chipboard 150x200 cm. You need to cut a square hole 100x100 cm in it. The hole should not connect to the outer edge. What and how to do it?

Tools include a drill, a wood saw, a metal saw and files. Buy a jigsaw for 700 rubles. or renting is not a problem, but is it suitable for such work?

- Link

- Link

I don’t know about carpenters, but in a similar situation I made do with a drill and a jigsaw. But it’s unlikely to work out neatly the first time.

- Show answer

- Link

Can't I use a small circular saw here? Drill out the corners and then cut them out, chipboard is still soft

- Show answers

- Link

> made do with a drill and a jigsaw

Drill a hole and saw from it? What is the diameter of the hole? Or are there several of them, and they need to be connected by picking with a chisel?

- Show answers

- Link

Are they cheaper?

- Show answer

- Link

You can try ordering a one-time job from the workshop

- Link

Usually all the corners are drilled and from there they either use a saw or a jigsaw to go from hole to hole.

- Show answer

- Link

And yes, the diameter depends on the files, if we are talking about a jigsaw. You should also take into account that the saw blades swing, although usually on jigsaws the swing can be turned off. 8-10mm behind the eyes

- Show answer

- Link

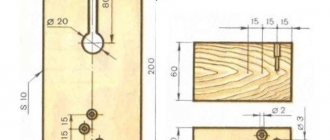

Geometric parameters

The main geometric parameters include the following indicators:

- diameter indicated in mm;

- total length, mm;

- length of the working part, mm;

- sharpening angle in degrees.

In addition, when choosing a square drill, pay attention to the shank, which must match the tool spindle or a set of devices for fastening it. Drilling square holes must be done after preliminary marking and punching the center of the future hole. It is recommended to start drilling at low rotation speeds, and then switch to the speed indicated in the data sheet of the machine or tool.

How to cut round holes

Using Boolean logical operations

We have already discussed this method of cutting a hole in an object in great detail in this lesson. The method is really good in its simplicity, but the mesh after manipulation with the Boolean may turn out to be “curve”. Sometimes using ProBoolean can help solve mesh problems.

Using ProCutter

This tool allows you to make holes in much the same way as Boolean. We create an object in which we will cut holes, and an object, or several, that we will cut out. I have two cylinders.

Now select the large cylinder and apply ProCutter to it. Click Create – Compound – ProCutter.

We select the large cylinder, enter the settings as in my screenshot, then, with the Pick Stock Object button pressed, select the objects that we will subtract.

We get perfectly round holes.

"Manual" method

This method allows you to more accurately fit the circle into the 3-D model grid, but you will have to spend much more time. Create a sphere using Standard Primitives and convert it to Editable Poly.

Let's switch to Vertex mode and check the box next to Ignore BackFacing, this way we won't accidentally catch points on the other side of the sphere.

Mark any grid square, select its three vertices (as indicated in the screenshot) and connect them with a diagonal using Connect. We create two diagonals using this method.

Select a point at the intersection of the diagonals and press the Champfer button, enter the radius.

Go to the Edge level and select two opposing grid lines, then click the Connect button, set 4 segments.

We do this with all the edges adjacent to the circle.

Let's switch to the Vertex points mode; we should have selected points belonging to the future circle. Add the Spherify modifier.

We get a round hole. Now we can convert the object, for example, to Editable Poly, in order to manipulate it.

Using Loop Regularizer

Another way is to use the free Loop Regularizer script, which you can . Download it, then drag the saved file into the open 3D Max window.

I’ll tell you how to use the script with an example. Create a rectangle, give it two segments in height and width. Convert it to Editable Poly. Go to the Edge editing level and double-click to select all the edges dividing the rectangle in half in the vertical plane.

Press the Chamfer button, set the number of segments (the more, the more rounded the hole will be), set the distance.

Now we will do the same for horizontal edges.

Go to the Polygon level and select all the polygons in the center on both sides of the rectangle.

Right-click on the screen and select the Regularize line that appears after installing the script.

The square has transformed into a circle. As I already said, it would have been smoother if we had specified more Chamfer segments.

Now press the Bridge button and get a through hole.

Re: This is what happens when schoolchildren are not taught labor lessons...

> Maybe you’ve never worked on a lathe?

Actually, I had a choice of what to write on my certificate: turner or PC operator