People use bolts very often because they are a convenient fastening method. However, when they have not been loosened for a long time, it seems almost impossible to unscrew the nuts with torn edges. In these cases, it is still possible to solve the problem by using special techniques for this purpose. To be fully equipped in such situations, you need to know the existing methods that could help in such a case.

Using heat to unscrew Source moy-instrument.ru

Reasons why you cannot unscrew the nut

It is often easy to unwind if you use the right tools. However, sometimes this creates problems. The reasons why it is difficult to remove the nut in most cases are the following:

- Over a long period of time, the connection rusts, seizing the nut and bolt.

- Sometimes the person doing the twisting makes too much effort. This can happen, for example, in cases where the wrench has a large lever.

- Sometimes, due to mechanical influences, parts become deformed.

To cope with the problem, it is enough to use one of the suitable methods.

Drilling a screw Source moy-instrument.ru

Classification and design

To unscrew old bolts and studs with broken heads, you can use one of three types of extractor.

Wedge-shaped rod - has the shape of a faceted cone. It is hammered into the prepared hole in the end, wedged and unscrewed. The wedge extractor is easy to use, but requires precision in drilling the center hole to extract effectively. Once completed, it can be difficult to remove the extracted part from the turnout.

Mechanical options include, for example, the following options:

- Using leverage to exert greater force.

- Use of different types of wrenches. For example, instead of carob ones, you can use cap ones.

- Pointed application of significant effort.

- Application of impact force aimed at destroying rust.

An example of exploiting the physical properties of metals is the use of heat. When exposed to high temperatures, the nut will expand and its grip will weaken. Another way to do this is to reduce friction. This can be achieved, for example, by wetting the parts with water.

Sawing off a screw with a grinder Source moy-instrument.ru

The most common chemical means is the use of substances that destroy rust. For example, various types of acids are suitable for this purpose.

The last category includes methods that have a destructive effect on the connection. An example is using a grinder to cut off a screw and nut.

Torn or licked nuts are difficult to unscrew Source moy-instrument.ru

Extractor kits

Extractors for removing bolts are sold in specialized stores. They can be purchased individually or as a set, which is much more practical. Tool sets are very popular because they already provide everything necessary to minimize time and physical costs when removing broken fasteners. Such kits contain devices of different diameters and additional tools necessary for unscrewing, among which it is worth noting the presence of:

- wrenches or wrenches;

- drill;

- bushings for using wrenches;

- bushings to ensure that the drill is guided in the center of the broken stud.

The use of such kits is characterized by versatility, convenience and efficiency in removing broken parts . Particularly reliable and durable are products that are predominantly composed of chrome-plated or hardened steel.

Detailed consideration of various techniques

Here we will talk about the most effective and common ways to unscrew a bolt if it is spinning or a stuck nut. Among them, you can choose the appropriate ones for each specific situation.

Application of various wrenches

The use of open-end wrenches can be called very popular. However, when using them they encounter the following disadvantages:

- The gap between the key and the nut is not always tight. It often exceeds half a millimeter, affecting the grip density.

- This tool only covers three of the six faces.

Therefore, when using it, it is easy to tear off the nut instead of unscrewing it. Other types of keys may not have such disadvantages. For example, a socket or socket wrench covers all six edges, allowing for a tight grip and increasing the chances of successfully unscrewing a frozen part.

Using a long-handled tool may help. In this situation, having good leverage will allow you to exert more force. The length of the handle can be increased artificially, for example, by using a long pipe. However, in the case considered, it will be less convenient to perform the necessary movements.

Using a gas nag is an effective means of loosening nuts Source moy-instrument.ru

Heads for unscrewing bolts with torn edges

Hi all! In today's review, I want to share with you my impressions of a set of sockets for unscrewing bolts (nuts) with torn edges, ordered on eBay. I think many of us have at least once encountered the need to unscrew a bolt or nut with torn (licked) edges. I am also no exception and such problems periodically get in my way. There are several ways out of this situation: starting from cutting off the nut and ending with welding pipes or a key to it. True, such methods are not always convenient and practical, and therefore are often not very effective. In general, at one fine moment, an almost round nut completely pissed me off. It was decided to look for a suitable tool and, to be honest, I thought I would run into problems. But, as it turned out, there are no problems - there are plenty of all kinds of things to make life easier. I opted for a set of matching heads.

At the time of purchase the set cost $14.50, now it has increased in price and is on sale for $18.58. I don’t know why this would happen or what caused it, but I think you can find an option at a more attractive price without any problems. The parcel was sent with a full track, all tracking information can be found here.

The heads are supplied in original packaging, which is a metal case. It looks very nice and is made well. In general, it’s nice to hold it in your hands, and there’s no shame in presenting it.

It closes with a latch, so that it cannot open spontaneously. Let's open it and see what's inside:

Here we have 10 universal heads, each of which is placed in a corresponding cell with a number. On the lid there is an insert with a size table: head number, internal size, external size. That is, head No. 1 is suitable for 9 mm bolts/nuts, the outer size of the head is 16 mm. In principle, everything is simple, there should be no problems with perception.

A number is duplicated on each of the heads. It is stamped on one of the outer edges.

In general, there are no questions about the quality of the heads, just like there are no questions about the quality of the packaging. The metal is processed with high quality, there are no burrs, curved edges, or traces of corrosion. Everything looks beautiful. The only thing I don't quite understand is the design of the heads. As you can see in the photo, these are socket heads or wrenches. Why not make a regular quadrangular hole for a wrench/ratchet instead of a round hole? The Chinese engineer clearly made a mistake somewhere. Although, if you use these sockets in conjunction with ring wrenches, then their small height has one clear advantage - it is not convenient to use full-size sockets everywhere, not to mention elongated ones.

The “inner world” of these heads deserves special attention: the internal profile resembles an inverted extractor for unscrewing broken bolts. That is, they are “rifled” inside, and the mounting hole goes under the cone. Due to the combination of these two factors, the heads must firmly hold the stripped nut due to the spiral inner surface. Also, due to the design feature, the fixation of the nut/bolt in the head is constantly strengthened: the greater the applied force, the stronger the head cuts into the body of the nut/bolt. But there is a minus here: due to the spiral-shaped internal thread, these heads only work for unscrewing and are not suitable for tightening.

In principle, there is nothing more interesting in their design and appearance. This means you can move on to practical tests. The test subject was a nut on a bolt holding a lock on a garage door. First, the nut was tightened with maximum possible force. Then, using a wrench one size larger, all the edges of the nut were torn off. He did everything in good faith, and didn’t leave out whole edges.

Take a suitable socket from the kit and put it on the nut. For a more reliable fixation, hit it with a hammer.

Next, take a key or head of a suitable size and begin to unscrew. The head, crashing into the nut, inevitably begins to rotate it. A nut with stripped edges can be unscrewed without any problems. This is what the nut looks like, securely fixed in the head.

Actually, another drawback is that the nut sits very securely in the head, and picking it out is very problematic. The easiest way is to start screwing it onto some short bolt so that it rests and stops rotating, then the head will unscrew itself.

This is what the nut looks like after execution:

As you can see, the heads are working. And quite effectively. The desired effect is achieved without any problems. Yes, due to design features, the heads are not without shortcomings and you have to put up with this. I think it would be easier to work with Super Lock heads, which are based on an improved hex head profile with flat edges of the working profile. a head with such an internal profile does not apply the load to the corners (as happens when using a standard head), but closer to the middle of the profile where there is space for reliable contact as the load increases. Thanks to this design, they successfully cope with fasteners with damaged edges, and the absence of sharp corners at the joints of the edges has increased the strength of the heads (stress concentrators have disappeared). But Super Lock heads are a completely different price category...

Overall, I was pleased with the purchase. I hope that in actual use of the head I will perform the same way as during this test

That's probably all. Thank you for your attention and your time.

Video description

How to unscrew a rusty nut? Penetrating liquid test.

Using a Hammer and Chisel

This method allows you to apply high force for a short period of time to unscrew it. In this case, a notch is made using a chisel. Then the hammer is struck at an angle. The sudden force can break up the rust and help the part begin to release.

It is important to note that this method can also work if the edges are torn off. The short duration of the force impact means that the impact will not be able to destroy the screw and will ensure normal unscrewing.

Using a lever to unscrew Source yborka.online

Light tapping

If you gently tap a stuck nut with a hammer, it will end up making small and sharp movements, which can result in the adhesion to the rust being disrupted. After this, it is possible that unscrewing will occur without significant effort. Sometimes tapping can damage the threads. In such a situation, the fastener parts will need to be changed.

WD-40 rust remover Source yborka.online

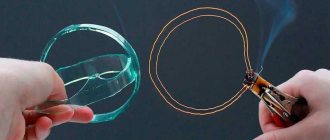

Heat

The principle of operation is that after heating the nut will expand and will be easier to unscrew. Sometimes they resort to simultaneous processing of the screw as well. The result may be the destruction of rust stains.

In order to provide heating, it is permissible to use an available heat source. To do this, use a gas burner, a candle flame, a soldering iron, a hair dryer and any other similar option. Even, for example, a burning torch can help. When carrying out work, you must remember that the use of thermal appliances should not be carried out near flammable materials.

Coca-Cola can sometimes dissolve rust Source yborka.online

Modern types of wrenches

Just like several centuries ago, the tool is designed to perform the work of unscrewing and tightening nuts. But progress in the form of designing ever new, more advanced machines, equipment and various equipment required changes in modifications and expansion of the existing model range.

To carry out various repair work, you need to have a minimum set of wrenches, which includes the following varieties:

adjustable wrench

The main advantage of this type is the ability to capture various modifications of fasteners, even non-standard ones. The disadvantage of such a device is the low grip reliability, which is caused by backlash when adjusting the tool.

The disadvantage makes it impossible to firmly grasp the part. This can lead to trouble when the device breaks off, damaging the edge or causing injury to the technician. Such situations occur especially often when dismantling old, rusty nuts, when unscrewing which the master makes considerable effort.

To ensure that the edges of the fasteners are not damaged, the tool should be used carefully, controlling the force used. It may be worth choosing a different type of tool that is more suitable in size and shape to the fastener.

Video description

How to unscrew a rusty nut?

Penetrating liquid test. Interestingly, phosphoric acid is included in the Coca-Cola drink in very low concentrations. As a result, in simple cases it can be used as a weak reagent. Please remember that processing may take longer.

To unscrew the nut, rubbing with kerosene will help Source 7vaz.ru

If all else fails

The methods described here will help you unscrew the nut even in the most difficult situations. However, although rare, it happens that they do not help. In this case, you can resort to more drastic methods that will irreversibly destroy the connection.

If you have a grinder, you can saw off the bolt along with the nut. This must be done carefully, as otherwise there is a risk that the part that was attached will be damaged. The disadvantage of this method is that you will have to somehow remove the remaining part of the bolt, which in some cases can be a difficult task.

Another way to solve the problem in a similar way is to use a drill. This requires drilling a screw. If you do not act accurately, you can damage the hole.

Unscrewing a nut using a hammer and chisel Source 7vaz.ru

Difficulty of choice

It’s worth mentioning right away that the quality of the equipment in question is the determining parameter that should influence the choice. Extractors should not be purchased randomly and without careful analysis of all their operating properties. The characteristics that determine the quality of the extractor include the strength properties of the material used to make it. The steel must be very hard, but not very brittle, otherwise the tool will simply break during operation. Only a few grades of steel from different manufacturers have such characteristics, but in their composition they are more or less very similar to each other. Unfortunately, some manufacturing companies from Asian countries make extractors from almost any type of steel that is somewhat durable. Indeed, such products have a lower cost, but their purchase will not bring much benefit, and the tool itself can only be used a couple of times, then it will break. Therefore, experts advise buying only those sets whose manufacturer does not raise reputational doubts, while at the same time paying attention to the markings of the steel used in the tools.

Modern samples of extractors are sold both separately and as part of various sets. Professionals recommend having a complete set with extractors of different diameters and sizes on hand, and it would also be nice if the kit comes with additional tools. Naturally, the cost of a high-quality and complete set may seem quite high, but all expenses will pay off after the first use.