A grinder is a fairly popular tool that is often used in the household for sawing wood, metal or stone. When using these angle grinders for a long time, people often encounter the cutting disc jamming. This leads to the fact that the tool begins to work much worse. To cope with such a problem, you need to figure out in advance how to unscrew the nut on an angle grinder and what needs to be done for this.

A grinder is a power tool often used for sawing various materials.

What is causing the problem?

When rotating at idle, it is difficult to encounter a similar problem. Especially when working with light wheels and tools with a soft start function. However, after increasing speed and contact with the surface being cut, the following occurs:

- When material resistance occurs at the wheel, the angular speed of rotation sharply decreases and it slows down.

- The engine, by inertia, continues to operate for several moments at the same speed, dragging the gearbox and spindle with it.

- The locking nut is tightened by inertia more strongly along the threads of the spindle head, thereby pressing in the cutting disc.

That's it, the process of tightening the fixing flange is completed - an emergency situation is obvious. The following factors influence its occurrence:

- Large circle size.

- High power of the tool.

- Massiveness of the rotor.

- A sharp increase in cutting depth, i.e. increase in resistance.

In this case, removing the disc from the grinder can be very difficult. Additional measures need to be taken.

Replacing a circle with counter-rotation

The method given below has several positive aspects: it is possible without using a key, it is possible even with a broken stopper. Most users of grinders believe that if the stopper is broken, it is almost impossible to unscrew the nut securing the disc.

Imagine their surprise when they find out that even a key is not required to dismantle the circle.

The secret is that the circle must be rotated in different directions. The hands are protected with gloves and the palm touches the disc, providing alternating rotation in one direction or the other.

A few sudden changes in the direction of rotation of the circle are enough for the nut to unscrew itself.

The video clearly demonstrates the following method of removing a cutting wheel from an angle grinder without a key and a stopper:

When working with any mechanisms, you should always expect emergency situations, which cannot always be resolved in accordance with the recommendations of the manufacturers. The angle grinder is no exception. During operation, you may encounter excessive clamping of the cutting disc. This problem especially often occurs with large, powerful models with a power of more than 2 kW. What should you do if the disc on the grinder is stuck or the nut cannot be unscrewed? We will deal with this issue further.

Replacing a disk in normal mode

When operating an angle grinder regularly, you need to constantly change the wheels, which are consumables. If the tool is no longer comfortable to work with, then the worn abrasive wheel should be replaced.

Important! Be sure to check the electrical disconnection to avoid personal injury.

Step-by-step algorithm of actions

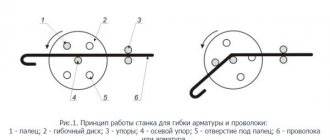

The circle is secured to the spindle head with a locking nut having an M14 thread. The standard configuration includes an open-end wrench with special protrusions for engaging with the holes of the fixing flange.

To unscrew the nut, you need to fix the spindle. For these purposes, there is a special lock located on the back of the angle grinder. By pressing the button, you will secure the gearbox with a cotter pin, eliminating the possibility of its rotation.

Insert the key into the holes. Hold the latch with one hand, and with the other turn the wrench counterclockwise, moving the nut.

The direction of movement of the disk is usually clockwise. However, there are models that may have something different. In any case, unscrewing occurs in the opposite direction to rotation.

Once the nut is in place, it can be unscrewed by hand without any effort.

Remove the retainer and the old circle.

Remove the bottom flange.

After intensive work with a tool with metal inside the casing, you can find a layer of burnt scale with abrasive. Use a steel brush to remove residue.

After cleaning, install the lower flange in place, aligning the grooves of the spindle with the grooves of the flange. A gasket is placed on top.

If your model does not have additional spacers, then such washers can be prepared from plastic or thick cardboard. Next, you need to correctly place the disc on the grinder and cover it with a similar gasket.

Important! Installed spacers allow you to easily unscrew the nut, even if the disc is pinched or broken.

Use your hand to tighten the top clamp counterclockwise (counter-rotation), supporting the cutting wheel. In this case, you also need to tighten the spindle lock and tighten the flange until there is noticeable resistance. Use the open-end wrench to tighten it with a little more effort. Do not over-tighten the fastener, otherwise you can overtighten the circle and it will warp.

Now you can continue to work. However, problems arise from time to time and it is simply impossible to unscrew the disc on an angle grinder. Let's see below how to change the disc on an angle grinder in such cases.

What to do if the disc on the grinder is jammed (bitten)?

Anyone who has experience of intensive work with an angle grinder has probably encountered such a situation at least once.

Usually, this happens if the disk is pinched between parts, it stops or breaks, and the grinder motor continues to rotate and thus irrevocably tightens the nut.

So what can you do if you bite a disc on an angle grinder?

Each master has his own secrets. We learned a few of them especially for you and now we will share the most common ways to get out of the situation.

Method No. 1 to remove a disc from an angle grinder

First, figure out which way to unscrew the nut.

The flange should always be rolled in the direction in which the disc rotates.

For this kind of work you will need either two gas wrenches or two clamps.

Here's what you need to do: destroy the remains of the disk, fix the washer located behind the disk with one key, and unscrew the flange with the second.

Method No. 2 to remove the disc from the grinder

This method involves the use of the famous VD-40 lubricant.

It’s probably like duct tape, applicable in all situations in life.

You need to spray the flange, wait about 5 minutes and try to unscrew it with a wrench.

Method No. 3 to remove a disc from an angle grinder

This method is used in extreme cases.

When no other methods help, you can try to cut the flange with a tool such as a hacksaw, and then purchase a new one from a specialized store.

The nut is stuck - how to unscrew it?

Removing a disc on an angle grinder if it is bitten is not so easy, especially without damaging the cutting element or tool. We will also consider several options for action.

Replacing a counter-rotating disc

This method has several advantages - it can be done without a key and with a broken spindle lock. Beginners in working with angle grinders mistakenly believe that if the stopper breaks, it is almost impossible to unscrew the nut. However, this is not the case. You don't even need keys.

The point is that the abrasive wheel needs to be rotated in different directions. Wearing thick gloves, you need to hit the cutting edge of the circle several times. This is what will ensure variable movement in different directions. As a rule, a couple of sharp blows are enough so that the nut can be easily unscrewed.

Read also: DIY tire recycling machine

Open-end wrench and socket head

In this case, you will have to slightly modify the existing standard tools - a 17 mm open-end wrench and a 24 mm socket. The thickness of the key is ground down to 4 mm. 4 protrusions are machined on the head and fit into the holes of the retaining nut.

After preparation, the key is placed in the space under the disk, and the head is put on the flange of the angle grinder and rotated in the direction opposite to the rotation of the wheel. After this, you can easily remove it and install a new one.

Heat

This is one way to remove a disc from an angle grinder without a key. The fixing nut is heated with an industrial hair dryer or a gas burner. After this, the flange will unscrew much easier. However, there is a risk of damage to the plastic parts of the angle grinder or gearbox.

With a nail

For these purposes, a 100 mm nail is best suited. It should be bent into a U-shape so that the ends fit freely into the holes of the clamping flange. The tip and cap are removed. By inserting a nail into the holes, the latch is unscrewed. If the manual effort is not enough, then add a nail or screwdriver in the form of a lever.

Using a gas wrench

The use of this tool is justified by an increase in the applied moment of force due to the increased arm. Using a gas wrench will make it much easier to unscrew a jammed connection. However, when eliminating snagging, it is important to remember that if you apply excessive force, there is a risk of damaging the spindle lock or clamping nut.

Using a rotary hammer or drill in chiselling mode

You can unscrew the disc on an angle grinder without a key using a drill or hammer drill, having first switched it to jackhammer mode. A suitable drill, most often 6 millimeters, is used as a working attachment. Place the drill against the edge of the hole in the clamping nut, fix the movement of the spindle and briefly turn it on to move it from place. This method allows you to turn away even very complex snacks.

Tapping the nut

This method is similar to the previous one, only you can use a suitable metal rod or chisel. Having fixed the spindle head, tap along the edges of the clamp holes in the direction of movement of the wheel. By slightly moving the lock from its dead point, you can unscrew it by hand. However, the method is not the most harmless for the tool - the mounting holes for a standard key are damaged.

Cutting wheel destruction

You can unscrew a jammed nut by completely destroying the disk. If there is already damage, you can break it off with your hands, but most often this will not be possible. It’s better to take a hacksaw or metal blade and cut it. This will leave you with a center ring and hard-to-reach pieces. Having found a suitable plate, holding it in a vice, grind off the remaining abrasive on it to a metal ring. After this, it will be easily unscrewed with a standard key.

The most radical way to unscrew a jammed clamp nut is to cut it. It is advisable to resort to it only in extreme cases. Of course, you can find a new one, but you will have to spend your time and money. It is not uncommon for spare clamping elements to be included in the delivery set of an angle grinder.

How to unscrew it if it is tightened, jammed, clamped, and will not unscrew

During the operation of household angle grinders, even experienced users, not to mention beginners, experience jamming of the working tool. The difference between them is that an experienced user knows how to fix the problem and will calmly, without excessive fanaticism, bring the angle grinder to its original working condition. For a beginner, the following theoretical information should be studied and applied in practice depending on the specific case.

Why does he snack?

The reason for the disc biting is deviations in the choice of operating modes of the grinder. If, for example, you sharply increase the pressure on the grinder while working, then increased torque will appear . Taking into account the fact that the direction of rotation of the disk coincides with the direction of tightening the nut, the torque helps to press the clamping device into the body of the disk, the magnitude of the friction force reaches a value capable of causing seizure of the adjacent surfaces. Typically, this problem occurs when cutting thick metal, if the direction of movement of the grinder is carried out only in the vertical direction, without additional movements back and forth.

How to unscrew the disk mount

Options for unscrewing the clamping nut of an angle grinder depend on its design.

On household angle grinders, a special pin wrench is used, which is inserted with pins into 2 (4) holes made in the plane of the clamping device, thereby creating unscrewing forces through them. The floating nut, whose head is made in the form of a hexagon, uses a regular wrench, and may also have holes for pin pins. Before the unscrewing process, do not forget to secure the spindle shaft with a special lock, which is located on the gearbox housing.

Angle grinder (grinder) MAKITA GA6040C with disk and key. Photo 220Volt

Professional angle grinders do not require any keys; the design of the nuts (quick-clamping, flange) makes it possible to unscrew the disc using the efforts of your hands alone.

A way to unscrew/unscrew a jammed/tightened nut on an anchor, in which direction to unscrew

Before you begin to unscrew the clamping device, especially if it is jammed, you should clearly understand the direction in which the force is generated.

You should start unscrewing the clamping nut of a household angle grinder using a standard auxiliary tool - a pin or spanner (spanner) wrench. If the clamping device is clamped very tightly and standard methods fail, you should use other proven methods.

Keyless

Users of household angle grinders have come up with many ways to unscrew a jammed clamping nut without keys. Among them there are options, the use of which can negatively affect the performance of the angle grinder.

The safest way in which the grinder will retain its functionality is the option of completely destroying the jammed, and most likely broken, disk. The following video shows the basic steps to resolve the jammed disk problem:

There are other similar videos on the Internet, such as the following one. However, there is a fundamental difference between them related to the safety of work. So the author of the video suggests holding a grinder in a vice and removing the remains of the disc using a metal plate in the user’s hand. Caution: Never use this method, any incorrect movement of the hand can lead to injury.

If a diamond disc is clamped instead of a regular cutting disc, then you should take advantage of its design features. It has slots around the entire perimeter for more efficient heat dissipation. Using self-tapping screws, the grinder is firmly attached through these slots, for example, to a wooden base. Now the body of the angle grinder will be the place where the unscrewing force is applied and carefully, as shown in another video, it should be turned back and forth to loosen the clamping of the diamond blade. Continue as usual.

How to avoid pinching

The possibility of pinching the disk can be reduced by correctly installing all elements included in the fastening system.

This installation procedure will ensure that the clamping device of the household angle grinder is unscrewed/tightened in normal mode for the longest possible period.

The correct mode of operation of an angle grinder, which primarily affects the jamming of the nut, will be honed with experience.

Measures to prevent jamming

By taking care of the safe operation of the angle grinder in advance, you will save yourself from the need to take measures to eliminate an emergency situation. Such events include:

- Place cardboard or plastic washers between the disk, flange and spindle head. They do not allow the tool to jam, but even in the event of a corkscrew, they can be removed/melted and the element can be easily unscrewed.

- The abrasive wheel must be installed correctly. To do this, place the front side of the circle on the support flange (with the picture facing the gearbox). It should not come into contact with the clamping nut. In this case, the standard metal ring in the center will act as a washer preventing jamming.

- Weld a regular nut onto the clamping flange, which allows you to press the installed disk using a regular wrench.

- Check the tightening force. No excessive effort is required to install the cutting element. Otherwise, it will jam under intense loads.

Do-it-yourself quick-release

A quick-release nut can solve the problem with a standard clamping nut jamming on a household angle grinder. When buying it in a store, you will need to invest considerable financial resources. However, if you have mastery of turning and welding techniques, you can decide on the possibility of making a quick-release nut yourself. The following video shows a manufacturing option.

Welding machine BlueWeld Gamma 3250. Photo VseInstrumenty.ru

The author needed the following basic materials and equipment:

The procedure is as follows.

The author, performing the technological operation of making holes on a quick-clamping nut, eliminates one of its advantages - the refusal to use a special key. Further testing of the homemade nut in operation will certainly help the author conclude that it is possible to operate the quick-clamping device by tightening/unscrewing it only by hand. There is no need for large clamping forces to securely fasten the working tool; it will be enough to apply a moment of force using the user's hand.

The main function of preventing disk jamming is performed by bearing balls. The clamping force does not change during operation, since the threaded part rotates along with the balls.

Source

Safety regulations

When working with an angle grinder, it is important to remember that this tool has an increased risk of injury. Accordingly, you should not lose vigilance under any circumstances, even when disconnected from the power supply. When using auxiliary tools and materials to replace the disk, pay close attention to them. Plumber tools can also cause significant injury.

An angle grinder (angle grinder) or grinder has proven itself to be a very effective tool with which you can perform a wide range of work. However, during its operation, you should adhere to safety precautions, since the disk speeds are very high and you can get injured. Judging by numerous reviews, many home craftsmen have problems with the discs; they often split, and the nuts with which they are clamped become jammed. The reason for this may be the human factor or simply marriage. As a result, such a nozzle cannot be used for its intended purpose.

It would seem that there is nothing difficult about replacing the disk with a new one. However, at this stage the master is faced with a problem - the nozzle is tightly clamped by a fixing nut that does not want to unscrew. How to remove a jammed disc from an angle grinder? What methods are used for this? What means can be used if the standard key is lost? You will learn how to remove a jammed disc from an angle grinder from this article.

Read also: What is the pressure in a 50 liter Gilex hydraulic accumulator

What solution to the problem is offered by specialists and amateurs + (Video)

What is a newspaper gasket? This is a paper washer the size of a nut. It is put on the installed disk, and a nut is screwed on top. This piece of paper was a stumbling point, because the safety inspection always spoke about the harmfulness of such a decision.

Representatives of safety authorities treat the installation of gaskets made of any other materials in the same way:

But there is a solution that does not contradict safety requirements and allows you to install and remove the disk normally. This is a special nut that consists of two elements - a nut and a pressure washer. The use of such a nut does not require any shims, because with it the disk does not jam.

If you don’t have a special key at hand, then craftsmen suggest doing without a key. This does not mean that you can do without a key at all, but use a “gas key” or other device. To do this, you need to hold the latch, tighten the nut with a gas wrench and unscrew it. This way you can replace a jammed disk, but this is a very inconvenient operation for one person.

There are also suggestions to hold the disk with your hand and unscrew it. Maybe, but it’s unlikely that you’ll be able to change broken disks this way. It is better to use wrenches that are designed for removing and installing disks.

Some foreign power tool manufacturers, such as Bosh, produce grinders with easily removable nuts. They securely fix the disk on the tool shaft and are easily and quickly removed to replace the disk.

What is the cause of the problem?

Before asking how to remove a disc from an angle grinder, experts recommend understanding why the nut on an angle grinder bites. It has been noticed that this problem is mainly observed in angle grinders that have a significant disc size. A disc over 18 cm is considered large. During operation, torque is generated. Next, when the master begins cutting, a small impact occurs. In other words, a force is exerted on the disk. If the size of the nozzle is no more than 12 cm, then this impact will be insignificant. If the disk is large, then the nut is tightened more by inertia. As a result, it is not possible to dismantle it in the usual way. Read more about how to remove a disc from an angle grinder below.

In which direction does the nut on the grinder unscrew?

The clamping nut is unscrewed by the grinder

The disk rotates clockwise. screw

should also turn clockwise or counterclockwise.?

The nut is clockwise, never unscrewed, but quite the opposite.

Construction. This is about always doing something.

Nut

tightens clockwise.

When closing the shaft, generally do not overtighten. More often than not, such oil does not want to be unscrewed

, but does not fly. At one point I had to disassemble the entire head of the grinding machine (at the same time I did not remove it and did not lubricate it), in order to unscrew it, it broke the disk not during tightening, so that it bent two buttons (they are fictitious).

ZY Don't be lazy in defense

When he took the head apart and squeezed it in a vice at the other end, he unscrewed it only with a gas wrench

It is naive to believe that construction will ever be completed.

Cardboard circles help with biting, I almost always roll 99% of them by hand. You stop it with a button and turn it after the disk, there were no problems.

And I heard that the welded ones are specially made so that the disk rotates in the other direction, but why? I don't know.

An arrow is stamped on the grinding machine (on the body). Here, in what

she is shown to the side.

Before that, the side

and the disk rotate.

And in this direction it is necessary to tighten the disk. To do this, simply turn the dial by hand. All nut

Tightened with the right hand thread on the nut.

If sparks fly. Then with the right thread and upon impact (pulling out from the hands of the grinder), the thread is automatically tightened.

If there are sparks from you. Disc when it is not fully tightened. It will unscrew. To avoid if your grinder is knocked out of your hands and the nut is stuck. You should put a cardboard spacer between the disk and the nut (it will even come from a pack of cigarettes)

First way

How to remove a disc from an angle grinder if it is broken and tightly clamped with a clamping nut? Of course, you can try using a special wrench for angle grinders or a gas wrench. However, judging by the reviews, after making enormous efforts and wasting time, the master may not get the expected result. Dismantling can be easier and faster. To do this, use pliers to completely break the disk. Due to the fact that small fragments will fly away during the work, the technician will need protective glasses (mask) and gloves.

Then you need to take a metal plate, the thickness of which is less than that of the disk. With the help of this plate its remains will be ground off. To do this, you need to turn on the grinder and firmly clamp the metal piece with pliers. After completing these steps, the nut can be unscrewed even by hand.

How to prevent re-clamping?

To avoid getting into a similar situation in the future, carefully read the following recommendations from experienced professionals:

- when tightening the disk nut, do not apply excessive force by pressing the key, since at the moment of rotation the nut will tighten itself to the desired level;

- Before installing a new disk, place a cardboard or plastic washer under the nut; it can be cut from any available material;

- the side of the abrasive disc with the label pasted should touch the support flange, not the nut; if this condition is met, the metal ring of the circle will protect it from jamming;

- Weld a regular hex nut onto the flange, which can be unscrewed with a simple wrench.

Cutting stones or discs for grinders are not always of good quality and exact size. This can lead to a situation where the nut gets stuck. But if this happens to you, do not despair. Useful advice from experienced craftsmen and your own ingenuity will always help you out in difficult times and tell you what to do in a given situation.

To learn how to unscrew the nut on an angle grinder without much effort, watch the video below.

How to remove a disc from an angle grinder with a key?

If the special key that comes with the angle grinder is not lost, then the task will be easier to cope with. For those who are interested in how to remove a disc from an angle grinder, experts advise first of all to fix the spindle. It is on this that the disk is located and pressed using a flange. It is dismantled with an open-end wrench. To make this technically possible, the flanges are equipped with special holes into which the key pins are inserted.

To lock the spindle, you need to press the button, which is located on the body on the back side of the disk. While working with an open-end wrench, the lock must not be released, otherwise the spindle will continue to rotate. If the disc in the grinder rotates clockwise, the open-end wrench should be turned counterclockwise and vice versa. It is important that the flange gives way and moves out of place. Now you can unscrew it completely and put it aside. Then the old disk is removed and replaced with a new one.

How to unscrew it if it's tight?

First, let’s answer a common question: “In which direction does the nut on an angle grinder unscrew?”

Remember! You need to unscrew in the direction of rotation of the disk. Those. If the disk rotates clockwise, then you need to unscrew the nut clockwise.

The easiest way to unscrew the disk mount is to place a key and then hit it with a hammer several times with medium force.

If this does not help, there are alternative methods to solve the problem:

If a situation arises where you are left without a key, you can cut off the stuck fastener with a chisel or grind it off with a second grinder with a metal disc. After this, you will have to restore the threads and also look for a spare nut. If the circle still doesn’t give in, you can try combining different methods. For example, treat the shaft with machine oil, and then begin to unscrew the nozzle using a lever or tap the mechanism with a hammer.

Important! Do not unscrew the fastener with great force. This can lead not only to thread failure, but also to breakdown of the angle grinder body itself.

How to remove without a key?

Judging by numerous reviews, the grinder disk can be dismantled using a large pipe wrench, which is popularly called a gas wrench. First of all, the master needs to spread it so that it can completely wrap around the flange. While turning the gas wrench with the flange clamped in it, the spindle is held by some metal object. According to reviews from home craftsmen, this method is considered very effective. If this does not help, then experts advise “tapping” the nut with a metal rod or a thin chisel. The spindle is also fixed. The nut will move if you lightly tap the flange at the very edge. Strikes should be made in the direction in which the disc is spinning. According to experienced craftsmen, this method cannot be called safe. The fact is that you can damage the flange, namely the holes into which the open-end wrench pins are inserted.

Rotary hammer or impact drill

To be honest, it is not the best or easiest option to unscrew a jammed nut on an angle grinder, but it is used if other methods do not work. As an attachment for a drill or hammer drill, you need a drill of a suitable diameter, most often 6 mm. If you are using a drill, you need to set it to jackhammer mode in advance. It is better to fix the grinder in a vice, clamp the spindle stopper, insert the drill into one of the holes of the clamping nut with emphasis in the direction of unscrewing, and briefly press the “Start” button. This method allows you to move even a tightly clamped flange. The disadvantage is that this can break the mounting holes for a standard key.

PHOTO: i.ytimg.com Insert the drill into one of the holes in the nut and turn on the drill in impact mode

Dismantling with a nail

Removing a damaged disk will not be difficult using a key made from a nail. According to experts, its optimal size is at least 100 mm. First, the nail needs to be bent into a U-shape. It is important that the distance between its ends corresponds to the two holes in the flange. Then, using a hacksaw from a weave, you need to carefully cut off the cap and tip. Now the homemade key can be inserted into the flange, fix the spindle and unscrew the mount. If it turns out that the nut is tightened very tightly, you will need a larger lever. You need to insert another “hundred” between the two vertical ends.

The nail will help you

Another effective way to unscrew a jammed nut on an angle grinder if you don’t have a key. To do this, you will need a nail 100 mm long, the head of which needs to be bitten off, and then given a U-shape. The distance between the ends of the nail must correspond to the holes in the clamping flange of the angle grinder. Insert the resulting structure into the holes of the nut and turn it. If the flange does not give in, you can use a screwdriver as a lever or pliers.

PHOTO: i.ytimg.comYou can use a nail if you don’t have a key at hand

What else can you do?

If the above methods do not work, then the nut will have to be heated with a gas burner. Under the influence of high temperature, the nut will expand and begin to rotate. You can also use a rather barbaric method, namely sawing the nut with a hacksaw. Then you will have to buy a new one. Some technicians use WD-40 penetrating lubricant. It is used for processing threaded connections. Judging by the reviews, after just a few minutes the nut can be turned.

Main uses of angle grinders

- Cleaning surfaces, stripping off old paint. It is performed with brushes with steel rods or sandpaper petals. There are no difficulties in operation, except that brushes with sandpaper require compliance with the direction of rotation.

- Sanding with sandpaper. A concentric attachment with Velcro is screwed onto the grinder, onto which the abrasive in turn is attached. Before use, check that the direction of the threaded fastening and the rotation of the tool shaft are consistent.

- Grinding with abrasive wheels. These attachments require careful handling, as under high load, the abrasive may break. You cannot cut material with such discs; shock loads are unacceptable.

- Cutting metals, stone, gating concrete. Performed using cutting discs.

It is with such attachments that emergency situations most often occur.

Let’s take a closer look at cutting wheels

The question of which side to place the disc on the grinder does not have a correct answer. Abrasive wheels do not have a programmed direction of rotation, so it doesn't matter how you set it. The direction of rotation (from yourself or towards you) is determined by the position of the protective casing. The choice depends on the position of the tool that is convenient for the operator.

In addition, the direction of the flow of sparks (or stone dust) depends on the position of the casing.

To install the disk on the shaft, the kit includes a dismountable flange. The lower part is rigidly fixed with chamfers, the upper part is a regular self-tightening nut. It is she who determines in which direction the disc on the grinder should rotate. During operation, the threaded connection is tightened, preventing the nozzle from coming off.

Sometimes the kit includes spacer washers designed to dampen transverse vibrations. You can make them yourself from thick electrical cardboard or paronite.

To secure the flange, a special open-end wrench is included with the tool. The shaft is fixed with a clamping button to create the necessary tightening force.

Ignorance of a simple question: how to install a disk correctly for inexperienced users can lead to equipment damage or injury. First of all, when changing a disk, it is necessary to clean the shaft and the inner surface of the protective casing with a steel brush.

A layer of metal particles is riveted onto these elements (when cutting the material). The thickness can reach several millimeters, as a result of which the disk loses alignment or jams.

Large attachments do not simply overload the electric motor. Installation requires removal of the protective cover. If an angle grinder disc shatters and the protection is not installed, the fragments can seriously injure the operator.

Another controversial issue is whether it is possible to put a wood disc on an angle grinder. If you hold the instrument with your hands, the clear answer is no. The circular saw can easily get stuck in the fibrous structure of the tree. A tool that escapes from your hands will cause a lot of trouble, including fatal injuries.

Nuts for angle grinders

The design of the clamping nuts depends on the type of grinder on which they are used. On ordinary, inexpensive household angle grinders, they mainly use standard nuts with a special open-end wrench included or floating ones, which can be unscrewed/tightened with a regular wrench. On more expensive professional angle grinders, where efficiency is required when replacing consumables, nuts of a special design with self-clamping elements, flange type with a freely rotating internal part, and nuts with additional automatic balancing to eliminate vibrations are used.

Quick-release nut for angle grinder Makita 115\125\150\230. Photo 220Volt

What to do if you have lost your open-end wrench?

More precisely, how to unscrew a disc on an angle grinder without a key? There are three ways:

- Make a bracket from a rod of suitable diameter (a nail will do). With this device you can loosen the flange using manual force. If the tightening is too strong, insert a lever into the bracket.

- Use a gas wrench. Having grasped the outer radius of the threaded flange, it is enough to touch the nut, and then it will unscrew by hand.

- Stroke the thread with precise tangential blows. To do this, you can take a core or punch, install it in the hole for the open-end wrench, and lightly hit the hammer to rotate the flange.

All manipulations to change the nozzle are carried out after disconnecting the power cord.

Why does the lock nut tighten?

Almost every foreman who has to periodically work with an angle grinder has encountered the fact that the nut on the cutting disc begins to tighten. Before you try to unscrew it with a key, you need to figure out why the latch begins to tighten.

During operation, the disc on the grinder can spin up to 12,000 rpm. In the process of contact with an iron or stone surface, it encounters quite serious resistance. Because of this, the rotation speed begins to decrease significantly. In this case, the rotor continues to rotate in the same way as before. It is because of this that the nut can be clamped so tightly that it cannot be unscrewed with a regular wrench for unscrewing angle grinder discs.

Additional Information! If the nut does not budge, do not try to unscrew it by hand. You need to familiarize yourself with the recommendations that will help you unwind it without much effort.

Removing a split disk

There are times when the cutting wheel jams during operation. Not only have you lost the nozzle, in such a situation the flange (its threaded part) is clamped with repeated force. How to remove a disc from an angle grinder in such a situation?

First of all, the tool should be securely fastened. Use clamps and a sturdy workbench. Then you need to lock the shaft lock key. If the force of your hands is not enough, lengthen the handle of the open-end wrench: for example, with a piece of steel pipe.

There are cases when the flange is jammed tightly. Then there is a possibility of damage to the locking key. To save the tool, disassemble the gearbox and clamp the output shaft in a vice.

Then we continue disassembling using the above methods: a reinforced open-end wrench or a gas wrench. The disadvantage of this method is that the shaft can be damaged and nicks will remain on it.

If the shaft is completely removed from the gearbox, the bottom of the flange can be chamfered using a traditional wrench.

Then the risk of damage is minimal. For any method, it is recommended to use a penetrating lubricant: WD-40 or regular kerosene. Waiting a few minutes after application will significantly reduce the force.

Bottom line: It is easier to prevent any problem than to deal with the consequences. By following the operating rules and tools, you will minimize the possibility of emergency situations.

How to avoid snacking?

To avoid trouble when changing the grinder attachment, it is recommended to prepare for work in advance. To do this, you can insert a small spacer between the disk and the nut. Suitable materials include cardboard, a piece of linoleum or plastic.

If the fastener is constantly being tightened too much, it is advisable to use a circle with a smaller diameter. It is also important to monitor the cleanliness of the tool, treat the threads with oil and WD-40 in a timely manner.