Advantages of a homemade tool

On the farm, very often there is a need to cut boards, chipboard, fiberboard, plywood and other similar materials. It is most convenient to perform such manipulations using a stationary machine, which is popularly called a circular machine. You can even cut firewood on such a machine, so you don’t have to think long about the rationality of its manufacture.

An angle grinder or grinder has gained wide popularity as it is a universal tool for cutting metal, stone, concrete, plastic and even wood. However, wood processing requires not only special skills, but also caution. After all, it is when processing wood that an effect such as a reverse blow occurs. That is why experts recommend using the tool only as a circular saw, which eliminates the possibility of a kickback and also increases the efficiency of using power tools.

Making a stationary machine from a grinder for sawing wood has a number of advantages:

- Savings on the purchase of a stationary machine, which consists of a frame and a powerful electric motor. The cost of such a machine is at least 10 thousand rubles, while a grinder can be used to make a circular saw without additional investment

- Ease of manufacture - to create a machine you only need a power tool and a base, which can be made from a wooden workbench or boards

- High efficiency - the angle grinder develops a rotation speed of over 9000 rpm, which has a positive effect on the speed and quality of sawing material

- The ability to use an angle grinder at any time by removing it from the machine

If you came to the site, then you are probably wondering about the purpose of making a homemade circular saw from an angle grinder. There is no doubt about the rationality of such an idea, but we will find out later how to make a stationary machine for sawing wood.

It's important to know this in advance!

Operating rules

The use of such a design as homemade saws with discs when processing wood imposes certain obligations on tool owners. In addition to the excellent table fixed to the floor surface and the protective casing on the surface of the disk, it is also necessary to organize the supply of sawmill material on both sides - from left to right and vice versa. It is impossible to move slats and boards by hand along the frame when using a hand-held circular saw, and for this it is better to use a block or its analogue made of wood.

It is better not to be close to the rotating disk at a distance of less than 0.250.3 meters. Do not keep your hands close to the saw to avoid damaging your fingers. The circular hand saw from the grinder should be turned off and on using the button located on the side or front of the device. When the disk is rotating, you should under no circumstances stand in front of it or behind it.

What you will need to convert an angle grinder into a circular saw

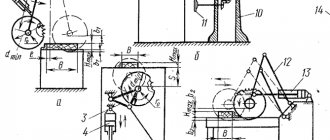

The principle of manufacturing a stationary machine for sawing wood from an angle grinder is that the power tool must be rigidly fixed, securing it to the base of a table or workbench. Implementing this will not be difficult, but for this you will need the following tools and consumables (depending on the scheme):

- Angle grinder or grinder. Moreover, for this it is recommended to take a powerful power tool, since the capabilities of a stationary machine will depend on this parameter. If you use a small grinder, then you can only saw thin materials with it, so this should be taken into account at the stage of manufacturing the device

- Drill - needed to make holes that will be used to fix the brackets holding the power tool

- Welding machine for joining metal plates

- Chipboards

- Clamps and fastening connections

You need to install a special disk for cutting wood on the grinder. It will not work to use a disk from a circular saw on an angle grinder, since it will not fit the outer and inner diameters. The disk installed on the grinder for cutting wood must correspond to the diameter of the mounting hole. In addition, the outer diameter must have protrusions - teeth, the number of which directly depends on the tool itself.

There will be no difficulties in choosing a suitable disc for an angle grinder, since they are sold for the corresponding models of angle grinders. In addition to an angle grinder with a circle for cutting wood, you will also need to prepare a table on which the power tool will be fixed. Even a frame or workbench is suitable as such a table, the main requirement for which is stability.

This is interesting!

An angle grinder creates vibrations during operation, so to increase safety, the base or bed must be highly stable.

If you have a ready-made table, then you only need to attach a power tool to it. If there is no table, then you can make one from available materials. You can use boards or fiberboard as a tabletop. The tabletop also acts as a stop.

To ensure the immobility of the power tool, it is necessary to make an appropriate fastening using bars, boards or metal plates. The bracket for an angle grinder can be movable or fixed, which affects the quality of use of the tool. The movable mount allows you to adjust the size of the cutting wheel. If the bracket is stationary, then it will not be possible to adjust the cutting depth. As clamps, you can use clamps, metal plates and other materials that securely and effectively secure the angle grinder to the base.

After the grinder is installed on the base, the only remaining action is to check the operation of the homemade tool in action. To do this, a short-term test run is performed, which identifies all the defects and shortcomings of the design. If there are none, then you can perform a test cut of wood.

Step-by-step instruction

To assemble the system, there is no need to create even a diagram, since the procedure is quite easy.

How to make a circular saw from an angle grinder - instructions:

- Make a small tabletop from available materials. The supports must be long enough so that a grinder can be placed under the frame. They are attached to the stiffeners - small boards that are mounted at the corners of the table at intervals of approximately 125 mm from the bottom angle.

- It is recommended to make the external working platform from laminated chipboard. When the table is completely ready, it needs to be turned downwards with the front part in order to make marks for mounting the cutting disk (in the future, the gap is determined by this unit of the grinder - it should be greater in length and width of the cutter itself). Using a drill, 2 forming marks are made.

- Using a ruler, connect the joints of the gaps, drawing 2 parallel strips across the entire width. Then the markings are removed using a grinder. The slot for the disc is made.

- You need a fresh disc that locks into the angle grinder. The best solution for interaction with wood is 125 mm. The disc must have carbide teeth. The interval is selected by the specialist personally.

- At the bottom of the functional platform it is necessary to attach a plate for mounting the grinder. You can't do without a clamp here. The unit is installed using clamps and tightened with nuts.

- You can insert a fresh disc into the gap. It should be placed so that the central area is slightly higher relative to the coating.

- It is recommended to make fastenings for the protective canopy. It is available in every specialized retail outlet.

- The thrust bar is made from any steel angle. It needs to be attached to plywood or chipboard. The dimensions of the plate must correspond to the parameters of the tabletop. Installation is carried out at intervals of approximately two centimeters from the disc teeth. At the ends of the rail you need to make several gaps for installing screws or screws - for good fastening to the tabletop.

- Place a clamp for an electrical outlet on the inside of the structure. As a rule, fastening is carried out from the outside (on the stiffeners), but it can be arranged in a way that will be comfortable for the specialist.

After assembly, you need to organize a test run and try to cut a small beam.

How to quickly and easily make a circular saw from an angle grinder

It should be noted right away that there are many options for making a homemade circular saw from an angle grinder, and it all depends on the imagination of the master, as well as the availability of consumables. Initially, we will consider the simplest option for making a circular, using a sheet of chipboard and other consumables. The principle of making such a circular is as follows:

- Take a sheet of chipboard measuring 1x2 m, to which the legs are attached. The result is a table to which you need to attach the grinder. The tool must be fastened exclusively from below

- A bracket is made to secure the power tool. For this purpose, metal plates with a thickness of more than 1 mm are used.

- The plates are attached to the tabletop using threaded connections

- To be able to adjust the cutting depth, the bracket should be made of a movable type. To do this, the movable and fixed parts of the bracket should be connected using a bolt with nuts

- To fix the tool in the appropriate position, you will need to make an additional bracket. It is based on a long bolt or pin. The nuts on the stud will ensure the fixation of the angle grinder in the appropriate position, and the sleeve welded to the movable bracket is responsible for the connection

- It is necessary to make a slot in the tabletop through which the saw wheel will protrude. For this, a drill with a drill is used. You need to make holes along the edges of the future slot, and then straight-line sawing along them with thin blades

- Additionally, a stop for the table top is also made, due to which the sawed workpieces are aligned

As a result, we get a stationary machine for sawing wood, made with our own hands at home. Now, knowing how to make a circular grinder from an angle grinder, you can get down to business. Video instructions for making a homemade machine are presented below.

Manual circular grinder

When making a homemade machine, you need to take into account that they can be stationary and portable. The angle grinder is not large in size, so there are no difficulties with its transportation. However, if it is necessary to transport a homemade circular saw, then this can only be done if it is portable. If a metal or wooden workbench is used as a basis, then transporting the tool will be quite difficult. This factor must be taken into account at the design stage of the circular saw. Before you start work, you need to prepare drawings that will help you understand what exactly needs to be constructed.

So that the tool can be transported, it is recommended to make a mini-circular from a grinder. The principle of its manufacture is simple, and consists of the following steps:

- A sheet of metal 1-2 mm thick is prepared, which will be used as a base. Sheet size 80x80 cm

- A bracket of metal plates is welded on the back side of the sheet, which will serve as the basis for installing the power tool.

- You need to make a slot in the steel sheet for the protrusion of the cutting disc

- Attach the grinder and test it in action

The principle of manufacturing a machine for sawing wood is simple, and everyone can cope with the task of arranging a circular saw from an angle grinder. There are a large number of options for making homemade products, and which one to choose depends on the preferences of the master, as well as the work that is planned to be performed.

Compliance with additional safety measures

A powerful engine and working parts that rotate at high speed are very dangerous not only for the person working at the machine, but also for others. Sloppy work and thoughtless actions can lead to the workpiece being easily torn out. Such a flying product becomes an unguided weapon. At the same time, such a failure can lead to the destruction of the saw blade. The scattering of small fragments entails dangerous injuries. To minimize risks, when creating a machine, mandatory rules should be taken into account.

- Do not place the on/off button on the work table of the bed. It should be placed on one of the side surfaces.

- Provide a protective cover.

- It is prohibited to operate such equipment without securely fixing it on a stable surface.

Which grinder should I use to make a circular saw?

There are no special comments here, since you can use both low-power and powerful angle grinders, which differ in size, weight and diameter of saw wheels. The greater the power and size of the blade, the higher the efficiency and productivity of the sawing machine. If you use a small and low-power angle grinder, then in the end you can use the machine exclusively for cutting chipboard, thin boards and plywood.

If a household tool is used as a drive mechanism on a sawing machine, then the features of its temporary operation must be taken into account. If a household grinder overheats, the motor will quickly fail. When planning to frequently use a sawmill for wood, it is necessary to purchase an appropriately powerful power tool.

How to make a power button for a circular saw

After making a stationary machine, you will need to perform one more modification - this is a push-button station. It is necessary to make a button to turn the saw on and off, as this will allow you to quickly interrupt the operation of the tool at the right time. In addition, it is almost impossible to operate a stationary circular saw by pressing a button on the body of a power tool, so you need to take care of installing a push-button station at the design or completion stage.

To make a power button, you will need to remove the wires from the body of the instrument and connect them to the switch located in the structure of the manufactured base. If you do not plan to use the grinder on the machine, then you can use a simpler method - fix the button in the pressed position using a clamp, and turn on the tool by connecting the plug to the socket.

How to work correctly and tips for use

Using an angle grinder as a circular saw does not at all make this tool safer, which is why work must be carried out strictly in protective clothing and safety precautions must be observed. When working on a homemade circular saw, you need to consider the following recommendations:

- Work should begin only after the tool reaches the operating spindle speed

- The duration of continuous operation should not be more than 15-20 minutes to prevent the motor from overheating

- The grinder should only be used with a protective cover, even though its main part is located under the tabletop

- If the spindle speed of a power tool is higher than 10,000 rpm, then this speed will cause wood smoke in the cutting line, and as a result, damage to the appearance and even fire. To eliminate the occurrence of such a drawback, the spindle rotation speed must be reduced using a special voltage reduction device. Reducing the voltage, the number of revolutions drops

- If during the sawing process there is a decrease in speed or a complete stop of the cutting wheel, then you must quickly remove the workpiece, freeing the disc from contact. If you neglect this recommendation, the motor on the angle grinder may burn out.

Making a circular grinder with your own hands is not difficult, and to achieve the result you will need a minimum of investment and a maximum of imagination. The finished tool can be used for sawing boards, beams, logs, fiberboard, chipboard and plywood. With such a household assistant, you can quickly eliminate the need to use a hand hacksaw.

Factory attachments

Now on sale there are special attachments for grinders in addition to discs. The grinder comes with a device that can be used to turn it into a chain saw in a short time. Supplied in two separate boxes containing an angle grinder and a chain saw.

Set of nozzles

The estimated cost of this set is $83.