In some situations, owners of private houses may need a pressing device with an impressive pressure indicator. Buying such a tool is irrational, since it requires significant financial investments, and the device will not be used so often.

This article will discuss the drawings of a hydraulic press and describe the algorithm for its manufacture at home.

Mechanical type of unit

The most common presses made at home are:

- Mechanical presses

- Hydraulic presses

These types of tools are best suited for use at home or in the garage as they take up little space.

This type of installation is quite popular due to its small dimensions. You can make a mechanical press of any mode (automatic or manual) with your own hands. The simplicity of the design ensures its reliability and provides good resources.

An approximate model of a mechanical press made by yourself can be seen in the photo on the Internet.

A mechanical press is capable of processing:

- Cardboard

- Rubber

- Plastic (and other polymers)

- skin

- Metals

Advantages and disadvantages of using different types of wax press

Manual wax presses, despite the simplicity of assembly and control, have a number of positive aspects:

- compact in size;

- relatively light in weight;

- economical;

- gives a good wax yield.

The disadvantages include such points as the labor intensity of the heating process itself, because it is not easy to control the constantly high temperature of the raw material in the mortar. However, due to the low cost of components, such fireboxes are the most common in amateur beekeeping. Kulakov’s device is an optimized option between a manual and industrial pressing mechanism. Its advantages include:

- guarantee of purity of the extracted wax;

- high degree of productivity;

- process automation;

- ease of maintenance.

VPK 1 has practically no drawbacks, except for one thing: buying a new device is quite difficult, and its cost will not be small (from 10-12 thousand rubles).

Jack and its features

The press is based on the mutual work of two cylinders of different sizes. From the chamber that has a smaller size, with increasing pressure, the liquid is transferred to a chamber with a larger size.

The interaction of these cylinders with pistons having different diameters constitutes the work of the structure. In this way a strong pressing effect can be achieved.

A version of a homemade garage press can be seen in the photo on the Internet.

To make a hydraulic press, a glass jack is most often used. It has a relatively low cost and is capable of producing a pressure of 20 tons.

There are two ways to assemble a jack-based hydraulic press in your garage:

- Position of the jack at the base of the mechanism (pressing upward)

- Position of the jack at the top of the mechanism (pressing down)

Jacks have a parameter for the correct position. Some jacks cannot be used in an inverted position. Therefore, before starting work, you need to make sure of the capabilities of the selected equipment.

General information

Raw materials should be brought to the required temperature level

Hot wax in a special bag is placed in a pressing compartment, where, under the influence of pressure or even by centrifugation, they try to expel the liquid raw material fraction. Wax in its pure form should be drained through a special chute or even through created holes into a pre-designated container. The remaining solid waste will be removed. All elements of the mechanism should be thoroughly washed and dried.

Please note that care must be taken when working with hot materials as wax is a flammable substance

Compound

A homemade device is an economical way to obtain a substance of sufficient purity. The operating time of all kinds of wax presses is almost the same. Full 1 cycle of push-ups takes from 3 to 4 hours. However, the quantity of processed products differs:

Necessary materials

To make a press, prepare:

- channel P-14;

- pipe 40*40 mm round or square section;

- corners;

- steel sheets (optimal thickness - 7 - 8 mm);

- centimeter thick metal plate;

- a piece of pipe measuring 10 - 15 cm.

Areas of application

In addition to working with PET bottles, such homemade presses can be used for compaction:

- other types of plastic waste;

- paper;

- cardboard;

- aluminum cans.

They may be useful in:

- Shops and cafes . The amount of packaging material in these objects is colossal. A solution is needed to organize their storage.

- Small workshops . Various goods and raw materials are packaged in boxes and bags, which also need to be folded and transported somehow.

- Reception points for waste paper , rags and other bulk recyclables.

Structural design and assembly features of the vacuum model

The design of the vacuum-type model has certain specifics, which it is advisable to study in advance. Preliminary familiarization with this information will allow you to better understand how to build such equipment.

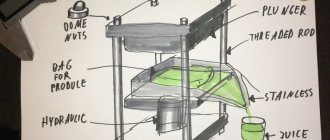

Looking at the pictures of a vacuum-type hydraulic press, we can distinguish three basic units:

- Bed or frame.

- Working surface.

- Pneumatic system.

The model under consideration has the following structural nuances:

- The tool is designed for manual operation.

- Assembling the press does not require the use of any unavailable materials or complex devices.

- In terms of efficiency, do-it-yourself hydraulic manual presses do not differ from industrially assembled equipment.

Should I buy an industrial one or do it myself?

Answering this question, one can develop a long discussion, but if we proceed from everyday realities. When choosing a wax press, you need to decide on the following:

Production volumes - a manual pressing machine can easily handle 2 kg of honeycomb in 3-4 hours. VPK 1 processes 3.5 kg of raw materials in 2-3 hours. A full-fledged industrial press can handle 10-12 kg in a couple of hours. Processing conditions - if collection is intended directly in the apiary, the use of factory industrial equipment is impossible

It is also worth paying attention to the power supply; if there is no guarantee of stable voltage in the apiary, then the VPK1 will not function as expected. Quality of the finished product - the Kulakov press produces high-quality wax 90% from brown honeycombs and up to 70% from black merva, which can be sold at a good price. When pressed by hand, the purity of the finished product is lower, but it is also suitable for sale in the food, cosmetics and medical industries.

How to calculate parameters and make a mechanical press

Mechanical devices are needed to process leather and metal products. They can also be used to recycle cardboard boxes and foam.

Here are instructions on how to make a mechanical-type hydraulic press yourself:

- Cut the steel corner into 4 pieces of 90 cm each and weld to 4 corners, 55 cm long. You should get two metal rectangles

- Secure them with steel pipes.

- Strengthen the made box using crossbars and steel plates.

- Organize a small gate in one of the walls to remove processed parts.

- Start forming the piston. For this purpose, weld channels measuring 55 - 65 cm together. Reinforce the workpiece with a steel cross member, attach a flange to its middle, into which insert a metal rod ahead of time. Next, weld the channel structure to the previously made box.

- Place a washer with a nut and a bearing on the rod.

The principle of operation of the Kulakov wax press

The device is much more effective than the manual version, as it works as follows:

- water is poured into a metal tank, which heats up on its own to 90 degrees;

- The wax must be thoroughly crushed to be placed in a linen bag located in the separator. The advantage of this design is that you do not need to adjust and control the temperature, it is set automatically;

- a sieve is installed;

- a push mechanism is used;

- the separator must be placed at the bottom of the tank; by that time the raw material becomes hot and molten. Pour in a small amount of water to boil for 30 minutes;

- When a characteristic film appears on the surface of the water, you can proceed to the next step.

It is important! The pressing process in such a device is quite long. It continues for forty-five minutes

As a result, the beekeeper receives very high quality and pure wax.

- excellent and high performance;

- excellent quality of finished products;

- automatic operation;

- industrial production.

As for the use of Kulakov’s wax extraction, this process is complex and problematic. It is best used in special enterprises involved in the production of foundation and wax.

How to make your own hydraulic press with electric drive

Equipment such as an electro-hydraulic press, due to its versatility and high efficiency, is actively used both in large manufacturing enterprises and in small workshops, as well as at car service stations. Using a hydraulic press equipped with an electric drive, you can solve many technical problems, which include:

- pressing, pressing out of gears, bearings and shafts;

- stamping, straightening and bending of metal products;

- pressing of products made from wood shavings, plastic and metal.

The electro-hydraulic press R-342M is intended for performing work on pressing, straightening and pressing in repair shops

A serial electro-hydraulic press will be quite expensive, but you don’t have to buy it, but make it yourself.

Serial hydraulic presses with electric drive are quite expensive, so it makes sense to think about how to make an electro-hydraulic press with your own hands. To do this you will need the following tools and equipment:

- welding machine;

- lathe;

- drilling machine;

- Bulgarian;

- electric drill.

This press will be able to produce a maximum pressure of 35 tons

The supporting structure of the electro-hydraulic press, which is subjected to the main mechanical loads, is the frame, the strength of which should be given special attention. A T-beam made of metal of such thickness that it can withstand the loads created by a hydraulic press without bending is well suited for these purposes.

Press frame made of I-beam

Structurally, the frame of a homemade electro-hydraulic press is a U-shaped frame, welded from T-beams and installed on a base, for the manufacture of which thinner channels and angles can be used. In the middle part of such a frame (along its height), a working platform is welded into it, for the manufacture of which thick-walled channels are used.

Particular care should be taken when attaching the hydraulic cylinder to the frame of a homemade electro-hydraulic press. In order for such fastening to be as reliable as possible, it is better to fix the hydraulic pump on a 20 mm metal plate using a flange. The metal plate itself, which will absorb all mechanical forces, is mounted on two T-beams.

The rigidity of the structure is ensured by high-quality welding seams

The process of installing a hydraulic cylinder on the frame of a homemade hydraulic press is carried out in a certain sequence.

1. Adjustment of hydraulic cylinder, flange and plate

The body of the hydraulic cylinder, so that it can be placed in the inner part of the flange, is turned on a lathe.

The flange, which can be made from a car hub, is also processed on a lathe.

In order to make a hole in a metal plate that will be used as a base for installing a hydraulic cylinder, it is necessary to weld a round boss to it. With the help of the latter, such a plate will be fixed in the lathe chuck.

20 mm thick plate with a welded boss in the center

After the hole in the slab is bored out, it is welded to the beams of the base frame.

The flange, in which the mounting hole has already been prepared, is put on the hydraulic cylinder and welded in a circle.

Flange welded to hydraulic cylinder

It is very important that the flange and hydraulic cylinder are connected as smoothly as possible; for this, the adjacent surface of the flange must be machined on a lathe. 2. Installation of upper beams and hydraulic cylinder

The plate, which is already connected to the beams, is installed on the frame and connected to it by welding.

Through the holes on the mounting part of the flange, holes are drilled in the plate, which are necessary for placing the mounting bolts.

The installation of the upper beam is carried out strictly perpendicular to the supports

The hydraulic cylinder should not be attached to only one point, so it is necessary to make another flange, put it on the top of the cylinder and weld it to the beams.

Installing the Top Flange

T-beams installed in the upper part of the frame are connected to each other by welding.

3. Installation of the frame and oil station

In order for the hydraulic press you have made to fully function, you need to install an oil station on it and connect it with a hydraulic cylinder using hoses.

Installation of a frame and a two-flow hydraulic station delivering a pressure of 700 bar

Thus, it is not difficult to make a hydraulic press with an electric drive with your own hands. At the same time, you will have at your disposal equipment that can solve many technical problems.

Operating principle of a manual wax press

Manual wax press is used by both professional beekeepers and amateur beekeepers.

The melted raw material in a durable bag is placed in a pressing apparatus, where, under the influence of a screw, the liquid fraction of the wax is gradually squeezed out. The cleaned wax comes out through the holes into the prepared container, the waste remains in the bag.

When working with a manual wax press, an inconvenience may be the need to tightly tighten the bag of molten wax.

This must be done with caution, but the procedure is necessary: the tighter the bag with raw materials is twisted, the more purified wax the beekeeper will receive at the exit

A manual wax press differs from a factory wax press or from Kulakov’s apparatus in less power and productivity. The wax obtained is of decent quality, but it is not always possible to squeeze it dry. From 15% to 40% wax remains in the waste. Some beekeepers sell waste at a reduced price to owners of automatic or industrial wax presses that squeeze the wax dry. However, for amateur purposes, manual mechanisms are the best choice in terms of price-quality ratio.

Specifics of manual wax press

The manual wax press is quite easy to use. The characteristic difference is compactness. The shape is conical and tapered, and the height does not exceed 43 centimeters.

A manual wax press consists of the following parts:

- pressed gratings;

- wooden frame;

- pressure screw;

- iron mortar.

The conical iron body includes 5 socket frames. A wax press like this continuously processes bee honeycombs without much time investment. Due to the fact that the iron part is made of steel, there is excellent susceptibility to high temperatures. The pressing screw has a specific shape, thanks to which it is possible to obtain a sufficient amount of beekeeping product.

Operating principle of a manual wax grinder

The apiary wax press works as follows:

It is necessary to melt the appropriate raw materials in a special container. Take a special bag and place 2 kilograms of beeswax in it. Before doing this, place the pressing grid at the bottom of the bag, then pour water into the mortar. It should be remembered that the water level should not exceed the height of the wax bag. Heat the mortar over the fire until the contents boil thoroughly. After twenty minutes you will get a homogeneous structure. The next step is the pressing procedure. The mortar is removed from the heat and placed under the appropriate screw intended for pressing. A special grid is placed on top, a screw is attached, and then the bag containing the raw materials is pressed with all force. At this moment, you can notice the appearance of wax in the water in the mortar. The water is drained into a separate vessel, and the process continues further.

It is important to note that the wax remains in a liquid state, so hot water is periodically added and the mortar is heated on the stove. Manipulations are performed until the wax runs out.

Advantages of a manual wax grinder:

- efficiency;

- compactness and lightness;

- high performance.

We create a press with electric drive

To make a power press, you will need an electric motor. Let's consider an approximate sequence of actions:

- Make a frame from 2 guides made from square steel pipes.

- Drill holes in the pipes to attach the platform.

- Create a “lift” to allow the press platform to move (use steel angles).

- Make a pressure platform using a high-strength channel.

- Install the jack and connect a pedal to the structure to control the power of the pressing device.

Specifics of manual wax press

The manual wax press is quite easy to use.

The characteristic difference is compactness. The shape is conical and tapered, and the height does not exceed 43 centimeters. A manual wax press consists of the following parts:

- pressed gratings;

- wooden frame;

- pressure screw;

- iron mortar.

The conical iron body includes 5 socket frames. A wax press like this continuously processes bee honeycombs without much time investment. Due to the fact that the iron part is made of steel, there is excellent susceptibility to high temperatures. The pressing screw has a specific shape, thanks to which it is possible to obtain a sufficient amount of beekeeping product.

The nuances of making a mini-pressing device

Many craftsmen give their preference to small-sized designs. Such people will certainly like the mini-press, which offers a desktop installation method.

Such a device is easy to manufacture, but it is rarely used due to its low practicality. For example, it is used if you need to chop walnuts or compress containers made of tin or plastic.

The frame of the mini-press is assembled from durable lumber. A rectangular frame is made from 4 boards. A mobile wooden pressing surface is installed in its upper part. The hydraulic system is made from standard medical syringes.

Advantages and disadvantages of using different types of wax press

Manual wax presses, despite the simplicity of assembly and control, have a number of positive aspects:

compact in size; relatively light in weight; economical; gives a good wax yield.

The disadvantages include such points as the labor intensity of the heating process itself, because it is not easy to control the constantly high temperature of the raw material in the mortar. However, due to the low cost of components, such fireboxes are the most common in amateur beekeeping. Kulakov’s device is an optimized option between a manual and industrial pressing mechanism. Its advantages include:

- guarantee of purity of the extracted wax;

- high degree of productivity;

- process automation;

- ease of maintenance.

VPK 1 has practically no drawbacks, except for one thing: buying a new device is quite difficult, and its cost will not be small (from 10-12 thousand rubles).

Home use options

Use a hydraulic press if necessary:

- squeeze the metal part out of the shell;

- press out or compress the bearing or rubber-metal hinge;

- straighten an element or connect two products end to end;

- bend any piece of metal.

The device is also suitable for producing fuel briquettes used to light the stove. The advantage of using compressed sawdust is long-lasting combustion and the absence of smoke formation, as well as the creation of intense heat.

To form briquettes from coal chips, you will need to slightly change the mechanism. The main parts of such a press will be the work table, base, bed and drive.

Excellent results are achieved by using pressing equipment for recycling plastic bottles and cans. It easily transforms containers into neat layers.

The hydraulic type device can be adapted for a hay pick-up. To do this, you need to supplement it with a cobblestone or steel frame without an upper fragment. Using special fasteners, this structure must be attached to the front. You will also need a transport pick-up and a running element.

Basic principles of operation of the Kulakov wax press

Voskopress kulakova

- It is necessary to pour water into the metal tank; it will heat up to 90 degrees Celsius.

- Grind the wax raw material and place it in a linen bag, it should be located in the middle of the separator. There is no need to adjust the temperature, it will be adjusted automatically.

- Installation of the sieve, use of the pressing mechanism.

- Lower the separator down the tank, so the raw material should already be hot and melted. Be sure to add water to it and boil for about an hour.

- When you notice a characteristic waxy film on the water, you can perform the next step.

The wax may gradually rise, then it needs to be drained. After you have worked with the device, you must unplug it from the outlet and thoroughly wash the sieve, bag and separator. Dry and you can start working with other raw materials again.

Why do bees drive out drones?