Just a few decades ago, owners of country houses and summer cottages spent their leisure time in the fresh air, tending vegetables in their own gardens. With the advent of fashion for recreation areas with green lawns, many are sure to devote part of the garden or local area to arranging such areas where they can cook barbecue, splash in the pool, sunbathe in the sun on a sun lounger, or just have a good time with friends or family.

To make the grass on your lawn look beautiful and thick, you need to sow it correctly. For high-quality sowing, it is better to use a special seeder.

What it is?

A lawn seeder is a manual or mechanical device that not only facilitates and speeds up the process of scattering seeds over the area, but also allows them to be evenly distributed over the entire area.

Hand sowing of grass is not very convenient and can cause uneven entries: in some places the grass may grow too thick, while in others bald spots often form.

Design Features

There are various designs, but the main elements are:

- frame;

- container for seeds;

- opener, with the help of which furrows are formed;

- mechanism for feeding seeds into the seed tube.

Some models also come with a built-in dispenser that allows you to adjust the amount of seed dispensed.

Range of modern seeders

If making a planting unit yourself causes difficulties, it is recommended to immediately purchase ready-made structures. The assortment on the market is quite large. The American model of precision seeding “1001 - B” is equipped with 6 replaceable discs. With such a seeder you can plant 28 types of vegetable crops. Using the adjusting screw, you can change the planting depth.

Newtechagro seeders are single-row types. Designed for sowing beets, carrots, onions, and cabbage . But such designs are expensive.

But there are also cheaper analogues - precision seeders "SOR - 1/1". They are also single-row, can be equipped with a bush or brush sowing unit, the row marker is 0.5 m. This is quite enough for an average garden.

Using a manual seeder can significantly reduce labor costs, increases the speed of the planting process, simplifies the technology, significantly improves the quality of crops, and hence excellent harvests in the future.

Functions

Unlike agricultural crops, lawn grass does not need to be replanted every year. It is enough to sow once and enjoy the beautiful appearance of green, fresh and lush grass for many years. For this reason, many may consider buying a seeder not a practical solution.

In fact, this device can be used not only to create a lawn , but also for sowing other crops, spreading granular fertilizers or lime if necessary to lim the soil.

Please note : the technology for sowing lawn grass involves simultaneous scattering of seeds with special fertilizers, which are necessary for the normal development of young seedlings.

If there is an overdose of fertilizer, due to its uneven distribution over the soil surface, areas with burnt grass often form on the lawn.

Another function that a seeder can perform is to better treat plants with drugs against pests and diseases.

Sowing complexes

The production sector in agriculture is based on the intensive use of heavy machinery and high-quality equipment. Modern seeding technology is known for its versatility, high productivity and efficiency. With its help, mechanization processes become easier and faster. Manufacturers of agricultural equipment do not cease to improve the equipment supplied to the market, focusing on the growing and expanding needs of the industry.

Testing of new models of sowing equipment occurs constantly, and preference is increasingly given to automated units, the use of energy saving technologies and the modernization of the most advanced types of agricultural equipment.

Sowing complexes are among the modern equipment that is widely in demand in agriculture. These units are irreplaceable and are an important aspect of successful agricultural activities. With the help of a good model of a seeding complex, you can achieve significant cost reductions when growing grains and other types of crops.

Why are units such as a sowing complex so economical and beneficial for the agricultural industry? Firstly, because they are universal and replace many other types of sowing equipment. Naturally, fuel costs are reduced, and there is no longer a need for a large staff.

In one pass across the field, seeding complexes perform several operations at once, and thanks to this, operating time is significantly reduced.

Regardless of the model, the seeding complex is equipped with coulter arms, similar in appearance to arrows. They are the ones who prepare the soil for planting seeds by forming hollows in it. The depth of such pits for seeds can be adjusted by changing the height of the front wheels of the unit and reinstalling the adjusting elements on the hydraulic cylinders located at the rear.

The seeds are placed in the dispenser of the sowing complex, from where they pass into the pneumatic wire. Already there, the flow of seed material is regulated by special screws. Next, the built-in fan generates the required air flows, with the help of which the seeds fall into the distributor, and from it to the claw openers, which place the seeds into beds made in the soil.

When seeding of the material is completed, the strips are buried with a three-row harrow, and rollers help compact the soil at the seeding site. The undoubted advantage of seeding complexes is that they can work fully even on fields with very uneven terrain.

Varieties

There are three types of sowing devices:

- Manual.

- Mechanical.

- Professional.

The latest models are used only to create large football fields and golf courses.

The first two types of seeders are used in households. Depending on the model, such structures have different loading hopper volumes and different working widths . The devices can sow seeds in rows or scatter them in a circle using a special rotating mechanism.

Manual

Such devices are a small unit, which in most cases is made of plastic. It is made in the form of a container for loading seeds, at the bottom of which there is a built-in distributor. The container is equipped with a handle, the rotation of which powers the device. Some manual models are equipped not with a rotating handle, but with a button, when pressed, the seeds begin to be ejected from the distributor.

This unit is designed for use on small plots of land . It allows you to easily and quickly disperse seeds, lime, fertilizers, sand or animal and bird feed.

The advantage of manual models is their compact size, ease of use, and budget price.

Another important advantage of a manual seeder is the ability to sow uneven areas where it is impossible to roll units on wheels.

The disadvantage is that the seed distribution is not very high quality and is not always uniform. In addition, in some manual models the shaft may periodically become clogged if so many seeds fall into it at the same time.

Mechanical

With the help of mechanical devices you can easily and quickly sow large areas, but before using them you will need to give the area a perfectly flat surface.

A mechanical seeder is a container with holes at the bottom for seeds . There are wheels under the container, and at the top there is a handle, holding which you can roll the seeder around the site.

More complex mechanical models are equipped with a furrow opener.

One of the advantages of such models compared to manual ones is the larger volume of the seed compartment. Depending on the model, it can range from 10 to 40 liters. A mechanical seeder is capable of scattering seeds over a width of 45 to 300 cm.

The only drawback of such units is their higher cost compared to manual devices.

REVIEW OF TECHNICAL FEATURES OF SEEDERS FOR COMPLIANCE WITH NO-TILL TECHNOLOGY (DIRECT SOWING)

Direct sowing technology is a unique farming system in which sowing is carried out in unprepared soil, i.e. into soil that has not been subjected to any pre-treatment. In Russia, direct sowing is often also called zero technology or “no-till” (from the English “no-till” - do not plow).

In this work we will identify these concepts. The key ideological point of the technology is to minimize the external impact on the soil. The sowing itself is carried out with a special tool - a direct sowing seeder. With its help, a number of agrotechnical operations are carried out: cutting the soil and plant residues that are present on the field; fertilization; sowing seed material to a given depth; simultaneous sowing of a binary component – small-seeded crops; rolling the furrow and closing the furrow to create better seed-to-soil contact. Thus, direct seeding technology should be considered as a system consisting of many interrelated elements, each of which is very important and cannot be considered in isolation from the rest.

In countries with developed agriculture - such as the USA, Canada, Brazil, Argentina, Australia, and some countries of the European Union - direct seeding technology is a sign of farm quality and an indicator of effective resource conservation when growing major crops. An alternative to traditional plowing not only appeals to many farmers, direct seeding can simultaneously increase productivity and protect the environment.

Switching to direct seeding technology allows for more production at lower costs. Currently, this technology covers almost 170 million hectares in the world, of which 63 million hectares in North America, more than 60 million hectares in South America, 22.3 million hectares in Australia. The use of this technology in Russia is not yet so widespread. However, in the current economic conditions, this need is becoming more and more obvious for Russian farms. The commitment of domestic farmers to traditional technology is due to the established structure and favorable market conditions, when entry to foreign agricultural producers is practically closed.

New knowledge and experience of one of the founders of this farming system in Russia, Doctor of Agriculture. Sciences, Professor Nikolai Andreevich Zelensky are the basis for positive changes. In order to minimize the number of possible errors when switching to and working with Noutil technology, it is necessary to do serious preparatory work. It is recommended to visit farms that have already achieved results using the new technology. Online courses and webinars on the topic of direct sowing will also be useful (for example, this can be done on the Agrarum website at the link: www.agrarum.ru).

The development of direct seeding technology is inextricably linked with the development of plant protection products, the emergence of new fertilizers and the necessary seeders. In many ways, the history of the emergence of companies that are considered old-timers of direct seeding technology is based on economic premises. However, this was a forced transition. Since it was precisely the crisis phenomena in the economies of Latin American countries, which were faced with an acute shortage of energy resources, that led to the formation, in fact, of a state system of resource-saving agriculture. The rapid transition to knowill has made it possible to achieve significant success in the agricultural sector in these countries. This allowed us to take a leading position in the world in the field of agricultural production.

Carrying out a retrospective analysis, we can note that at the same time, the seeders of the traditional farming system served as the prototype of the first direct seeding seeders. Initially, no one developed a seeder specifically for zero technology. First there was a theory. Then practical methods began to develop. For a farmer who is just switching to a new farming system, versatility is more interesting. This gives you peace of mind that if things don't go according to plan, you can always return to traditional plowing. Therefore, seeders that can work using both traditional and new technology look like a more attractive farming tool in the eyes of such farmers. Another type of seeders - specialized seeders, designed for difficult conditions, were initially developed with a margin of safety and operation in the noutil system. They had to work in conditions of an uncultivated field, which means that other requirements were placed on them.

Today in Russia there is an acute issue of increasing agricultural productivity and the need to put fallow and waste land into circulation. At the state level, it is planned to introduce up to 12 million hectares of such land by 2030. Therefore, further we will talk about specialized seeders capable of working in the knowill system and introducing fallow fields. After all, they are the ones who are able to solve this seemingly complex and expensive task in the best possible way and with minimal effort.

In order to understand what requirements a modern seeder must meet, let’s consider the main components that ensure compliance with the technology.

The classic noutil seeder has two main organs.

- Openers (coulters) are devices that introduce seed into the soil.

- A dispenser that is responsible for adjusting seeding and maintaining set values throughout the entire sowing.

We can consider 2022 the year of formation of the Russian market of noutil seeders in the following system:

- Foreign manufacturers who have representative offices in Russia and/or have localized production. As a rule, such seeders are the most expensive and are available only to medium and large farms and holdings. Inflation and rising exchange rates of foreign currencies make such equipment, its components and consumables less accessible.

- Foreign manufacturers who do not supply seeders for direct sowing to the Russian market. This is due to the internal corporate policies of such companies, as well as existing trade restrictions and sanctions.

- Russian manufacturers who declare that their seeders comply with Noutil technology, but in fact they are converted traditional seeders. These are the cheapest seeders. However, it is after their use that many farmers become disillusioned with the technology, believing that it does not work as it should under the conditions of their particular farm. This thereby discredits all technology in Russia.

- Russian manufacturers who have managed to ensure that their seeders comply with Noutil technology and maintain production standards.

Understanding the variety of offerings requires some experience and understanding of how the technology works. Therefore, we will sequentially consider the types of seeders and the basic requirements imposed by the technology. The direct seed drill replaces most of the agricultural implements and techniques that are used in the traditional farming system - plowing, disking, cultivating and harrowing, etc. Consequently, these seeders have to withstand hard, uncultivated soil and still sow well. What unites all the seeders under consideration is that, within the framework of direct sowing technology, they must be able to perform at least three operations in one pass: create a seed bed in hard soil, sow seeds, apply mineral fertilizers and cover the furrow with high quality and, if necessary, perform binary sowing with small-seeded crops. This is the subject of the work and many years of experience of Prof. Zelensky N.A.

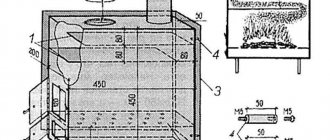

Figure 1 – Anchor opener

The first type of seeders is anchor seeders (Fig. 1.) They appeared at the dawn of knowill in the 70s of the 20th century in the USA. This appearance was due to the need to introduce seed into uncultivated soil. The main way to achieve this, at that time, was to place the seeder on a conventional cultivator. The cultivator made it possible to cut into uncultivated soil and sow, as if to till the soil a little, after which the seeds were laid behind it. Their subsequent development was aimed at reducing the cultivator foot, and in some cases, even their complete exclusion from the organ, i.e. Only the stand remained in order to reduce soil damage. The advantage of anchor seeders is that they can work in any farming system. They are easy to maintain and easy to use. A consumable can be an anchor that wears out or breaks when encountering an insurmountable obstacle in the field. The main disadvantage of such seeders is that they have a great impact on the soil and create a plow sole, which is not permissible with noutil. Currently, anchor drill manufacturers have reached their limit in optimizing the anchor or “claw”. The size of the paw has reached its limit and it is no longer possible to make it smaller (thinner). Consequently, the impact on the soil cannot be reduced any further.

Figure 2 – Disc seeders with coulter

The next type of seeders are disc seeders with a colter (Fig. 2.) These seeders appeared in the 80s in Latin America by installing a “cutting knife” in front of the traditional opener, which is also called a “turbo disc”, “turbo knife” or “coulter”. That is, in front of this ordinary classic coulter there is a cutting disc, like a cutting knife, which cuts a furrow and loosens the soil, and the coulter following it just needs to widen it and place the seed.

From its inception to the present day, many varieties of turbo discs have been developed: from a simple pointed disc to a wave-shaped one. Depending on the mechanical composition of the soil and its moisture content, a turbo knife is selected. Here lies the main weak point of disc seeders and the source of many of their problems. Since the quality of operation of such seeders significantly depends on soil moisture and a correctly selected coulter, there is a need to have several sets of such discs. Some discs work well in semi-dry soil, while others work well in wet soil. There is no golden mean. Therefore, it is necessary to re-equip the seeder whenever the humidity changes. For example, if it rained. Ideally, the farmer changes the discs twice a year, for spring and autumn sowing. But weather conditions can affect this seasonality. At the same time, disc seeders, especially their coulter units, are not suitable for quickly replacing disc with disc. This makes this technological operation difficult. In general, all disc seeders with coulters have less impact on the soil than anchor ones. The coupling assembly, consisting of a hub, disk and bearing, must have greater strength, since it experiences the greatest loads from the soil.

Figure 3 – Diffuse opener

The next type of seeders are seeders with a diffuse coulter (Fig. 3.) These seeders are a continuation of the development of disc seeders with a coulter, but in which the coulter was completely abandoned and the strength of the coulter was increased. The role of the coulter, in this case, was taken over by one of the opener discs. The diffuse coulter is a conventional two-disc coulter, similar to the coulter of the SZ-3.6 seeder, it is distinguished by greater strength and the fact that one of the discs is larger in diameter than the other. The larger diameter disc cuts the soil and creates a furrow. Here the diffuse vomer can be compared to a surgeon's scalpel. Like a surgical incision, it leaves a thin, neat groove. The impact on the soil is minimal. The angle at which the two discs are located is chosen so as to effectively cut the soil. Manufacturers strive to minimize this angle as much as possible. This affects two parametric characteristics, namely reducing the impact on the soil and the energy consumption of the seeder. In such conditions, it is easier for the coulter to cut through the soil, and it is easier for a tractor with such coulters to drag and operate the seeder. With a colter seeder, the disc runs in a straight line, so it is easier for it to cut through the soil than with a diffuse coulter. But on the other hand, this leads to the fact that there are many more planter organs in the soil. Thus, there are one and a half to two times more organs that create obstacles. All these organs can be a source of damage. Therefore, the costs of consumables increase proportionally. The bearing assembly is reinforced, so it is also more expensive than on coulter seeders. It should also be noted that coulter seeders and seeders with a diffuse coulter operate at speeds no higher than 8 km/h, since at higher speeds the seed material is captured by the discs of the coulter from the seed bed and thrown to the surface.

Figure 4 – Monodisc opener

The last type of seeders are monodisc seeders (Fig. 4). Here, it was not the disc harrow that was excluded from the unit, but the seeder coulter. The seed supply was brought to this disk unit. Thus, there is only one disk there. It goes at an angle, that is, it simultaneously cuts and creates a groove. It turns out something like an anchor foot. One part of the groove looks as if an anchor seeder went through there, and on the other side of the groove there is a disc seeder. The advantage of this device is the small number of components that can be a source of breakdowns and equipment failures. The foot does not wear off, it does not destroy the soil cover. The disk handles this task. The speed is higher than that of seeders with coulters and diffuse coulters. We also note that such seeders are less afraid of wet soil. At the same time, the mono-disc coulter damages the soil more than a coulter seeder.

The second main unit, which has been completely transferred from traditional seeders, is the sowing mechanism. According to this mechanism, seeders are divided into: mechanical and pneumatic.

Figure 5 – Mechanical seeder

Mechanical seeders (Fig. 5) are seeders in which seed dosing is carried out by a reel apparatus, and the seed material is fed under its own weight through seed tubes down to the coulter. The reel apparatus for mechanical seeders was created in the 50-60s. Since then, it has undergone a minimal number of changes, as it is as simple and reliable as possible. The existing changes were in the direction of reducing injury to the seed material (transition from metal to plastic).

In turn, mechanical seeders can be divided into several types according to the method of adjusting the seed sowing hole.

Mechanical seeders, with adjustment of the rotation speed of the coil in the device. This is realized by installing a variable gearbox or variator on the seeders. The advantages of this method are the possibility of a wide range of adjustment of the seed sowing rate and uniform wear of the coil and the body of the apparatus along the entire length. The disadvantages are: portioned seed ejection at low speeds and severe injury to seeds at high speeds of rotation of the coil; stepwise adjustment of the seeding rate on seeders with a variable gearbox; complexity and demandingness in servicing a variable gearbox or variator.

Mechanical seeders, with adjustment of the reel extension length by moving inside the device. The advantages of this method: simplicity of the design of the adjustment mechanism; optimal coil speed to eliminate portioning and injury to seeds. The disadvantages are: uneven wear of the coil and housing, as well as a small range for adjusting the seeding rate.

Combined mechanical seeders - when both previous methods are used simultaneously. The advantages of this method are: an optimal range of coil speeds to eliminate portioning and injury to seeds, a large range of adjustment of the seed sowing rate. The main disadvantage is the difficulty in setting the seeding rate.

The common advantages of all mechanical seeders are simplicity of design and maintenance, distribution of the weight of the seeds across the entire width of the seeder. The disadvantages are also known. The number of sowing units corresponds to the number of openers, which increases the number of consumables, low accuracy of seed placement, also limited dimensions of the seed hopper and the relatively small working width of the seeder (up to 10 m).

Figure 6 – Pneumatic seeder

Pneumatic seeding complexes and seeders (Fig. 6.) are seeders in which seed dosing is carried out by a reel apparatus of a different design, and the seed material is supplied to the coulters using compressed air. The advantages of pneumatic seeders are: one device in which settings are made; high precision of seed placement; the ability to create seeders with a large seed hopper and a large working width (more than 10 m). The disadvantages are: complexity of design and repair; The weight of the seeds in the hopper is usually concentrated closer to the center, which also leads to certain problems.

Thus, there are two main requirements for high-quality seeders:

- high-quality introduction of seed into solid soil to a given depth and its subsequent covering.

- minimal soil damage and impact.

Secondary requirements include:

- the ability to copy field unevenness (anthills, mole and mouse holes, etc.);

- maintainability and availability of components;

- Seeder energy consumption.

From these requirements it is clear that the noutil seeder must have a number of important characteristics (design features), which are as follows.

1. Heavy weight. A knowill seeder must be heavier than a seeder for a traditional farming system. This is necessary to ensure high-quality penetration of the coulters into the soil, so a light seeder will rise up regardless of the power of the clamping mechanism and the coulters will not be able to place the seed at the required depth. Also, the distribution of seed weight across the width of the seeder plays an important role. If the weight is concentrated in the center of the planter, this results in more force on the openers in the center than at the edges. If the weight of the seeds is evenly distributed across the entire width, then the force is also distributed evenly.

2. The presence of a powerful clamping mechanism. The clamping mechanism is a mechanism that creates a clamping force on the coulter to penetrate it into the soil and at the same time allow it to follow the topography of the field. The simplest clamping mechanism is springs, which create clamping force due to their rigidity. Changing the clamping force is done by changing the stiffness of the springs; there are many ways to do this. The advantages of this method: ease of design and repair; reduction of loads transmitted from the coulter to the seeder when moving over an uneven field. The disadvantages are the difficulty of adjusting the clamping force or their complete absence.

Since the force on the soil must be minimally sufficient to penetrate the coulter, and the soils, even in the same field, can be different, hydraulic and subsequently pneumatic clamping mechanisms were created. Instead of springs, such mechanisms use hydraulic cylinders or sometimes air springs. Thanks to their wide adjustment range, they allow you to create the required minimum force for cutting into the soil. The advantages are: easy adjustment of the force and creation of the minimum required pressure force; the ability to change the force for each coulter separately during operation of the seeder using sensors. Disadvantages: complex design and repair, especially if each section is controlled separately; increased demands on the tractor hydraulic system.

There are also combined clamping mechanisms of hydraulic cylinders and springs. In such a mechanism, the force on the coulter is created by springs, and their compression is regulated by a hydraulic cylinder. The advantages of this method: ease of design and repair than a purely hydraulic mechanism; reduction of loads transmitted from the coulter to the seeder when moving over an uneven field; easy adjustment of force. The disadvantages include the inability to change the force on each coulter separately during operation of the seeder.

3. Coulter mounting mechanism. Like the opener itself, this mechanism should be stronger than that of a traditional seeder. Structurally, there are two main types of such a hinge. The first type is the so-called pendulum type. (Fig. 7)

Figure 7 – Pendulum linkage

It is a beam with one axis of rotation and a pressure spring or hydraulic cylinder installed on top. The advantages of this type are simplicity of design, easy repairs and a small number of consumables. A seeder with this type of coulter replicates large uneven fields well, as it has a large working stroke. The disadvantage is that the coulter moves along a radius when copying field unevenness, which reduces the accuracy of seed placement. To reduce the curvature of the coulter movement, its beam is made longer, this leads to an increase in the dimensions of the seeder. The second type is a parallelogram. (Rice.

Figure 8 – Parallelogram linkage

The parallelogram design is more complex and consists of two cross beams and four pivot points, but it is more common. This is due to its parallelogram connection. The advantage of which is that the coulter moves when copying the soil vertically - up and down, which in turn increases the accuracy of sowing. Therefore, parallelogram placement is often used by seeders for row crops when it is necessary to place the seed at an equal distance between the seeds. Anchor coulters cannot work properly if they operate on a pendulum fastening. The advantages are the accuracy of seed sowing and small dimensions. The disadvantages include the complexity of design and repair due to the large number of rubbing pairs, as well as a relatively small working stroke when copying the surface.

4. The presence of support wheels, which provide control of the depth of seed placement and provide additional support. Seeders of traditional farming for the most part do not use support wheels on coulters, since they work on cultivated soil and the coulters in them are suspended, as it were. In seeders that comply with knowill technology, the load on the soil from the weight of the seeder is divided between the wheels of the seeder and the support wheels. This reduces soil compaction by the seeder. To ensure depth adjustment, the support wheels are equipped with a special adjustment mechanism, which makes the repair design more complex. On noutil seeders, flanges are sometimes used to control the depth of seed placement. The flanges are also a wheel that is installed on the axis of rotation of the disk. This is a simple design that does not require maintenance, but depth adjustment is only possible by replacing the flange with a flange with a different diameter. There is another option when rolling rollers or press wheels act as support. This makes it possible to simplify the design of the opener and reduce the number of components in it. Since the pressing wheels are located behind the coulter, the quality of following the field relief is reduced. It turns out that the coulter encountered an obstacle and passed it, but the wheel only reacted. In the case when the rolling wheels act as a depth limiter, they steal up to 1/3 of the force from the pressing mechanism.

5. Availability of pressing wheels. Press wheels are very important as they perform two functions: filling the furrow and compacting the soil above the seeds. There are several types of them, and the selection depends on the type of soil, like coulter discs. The development of press wheels continues.

6. The speed of coulters and seeders with a diphase coulter is limited to 8 km/h. Due to the design of the opener, to increase speed, a packer and press wheels are installed on the opener. Their task is to ensure uniform placement of seeds and reduce the release of seeds to the surface. Installing these elements allows you to increase the speed to 10-12 km/h on dry soil. However, with increasing humidity, the compactor rollers and packer worsen the situation with the ejection of seeds; dirt also sticks to them and they cease to perform their function.

7. Availability of markers. The big disadvantage of a marker is its impact on the soil, essentially disking at its location. A more correct approach to a resource-saving system is to install a navigator. It will be a universal device that can be used on other equipment, for example, on sprayers or a combine. Thus, the marker is an obsolete device that has a negative impact on the soil and which should also be monitored, especially when turning the seeder.

8. The seeder must have minimal pressure on the soil. This is achieved by increasing the width of the seeder, as well as increasing the pressure in the impellers.

9. Maintainability. Since various tools were excluded from direct sowing technology, the noutil seeder had to take advantage of manufacturability and absorb the necessary elements. The seeder took precisely the weight from the plow and harrow. The desire of some manufacturers to create specific components can negatively affect repairs in the field or even on the farm. How unified are these units, can they be found on the open market or can they only be found at the manufacturer or its representative offices. You should also pay attention to the material used to make a particular unit. For example, cast iron hubs. When destroyed, a cast iron part is almost impossible to restore. Therefore, it is important to have a larger number of relatively simple steel weldments. They are easier to restore. Steel parts are less durable, but they are easier to restore.

10. Consumables. They should be available and have analogues from other manufacturers. This is necessary so that you can use the seeder without wasting time while waiting for the original part. For example, each company makes discs that are used in a specific seeder, which is not entirely convenient when searching for spare parts. It is also desirable that the bearings be of a common model.

11. Volume of adjustments. Many people say that noutil seeders have many adjustments. However, the quality of sowing depends on the adjustments. The fewer adjustments a seeder has, the more likely it is that the seeder will not work as it should in your field. Thus, a small number of adjustments for a noutil seeder is rather a minus. Ergonomics is also important. However, the more convenient the adjustment, the higher the price. But you have a knot that you can conveniently adjust. There may be some adjustments that seem redundant now. However, they may be more useful in the future if the seeder contains them. This will allow you to avoid the need to modernize or purchase new necessary equipment.

12. High ground clearance. Ground clearance is especially important in the transport position. When a seeder is transported between fields, the higher the ground clearance, the more cross-country ability the seeder has. Along with the increase in ground clearance, the requirements for the strength and reliability of the entire transport system increase.

Thus, if the seeder meets the requirements stated above, then it will perform high-quality sowing using Noutil technology. It should be noted that the sowing process using noutil technology is fundamentally different from sowing using traditional technology and much depends on the motivation and knowledge of the machine operator.

The review was prepared by the team of authors:

Sukhinin N.V. - chief designer of Agrarum-tekhnika LLC,

Moshkin I.V. - Ph.D. in Economics, Executive Director of Profobrtekh LLC

Edited by Zelensky N.A., Doctor of Agricultural Sciences, Professor DSAU

The following sources and materials were used in preparing the review:

- Passport of the State program for the effective involvement of agricultural lands in circulation and the development of the reclamation complex of the Russian Federation, M. 2022.

- State Council, December 26, 2022, Patrushev Dmitry Nikolaevich, on the involvement of unused agricultural land in circulation / Transcript. [Electronic resource] Access mode: https://special.kremlin.ru/events/president/transcripts/62418, free (07/09/2020).

- Innovative technologies of direct sowing, M. 2019

- Portal "Agrarum" [Electronic resource] Access mode: www.agrarum.ru, free (09.10.2020).

- Economics of soil fertility conservation and agribusiness development // Moshkin I.V., Shurkin A.Yu., Babak Yu.V. / APK News. 2022. No. 11. pp. 88-91.

- Economic efficiency of no-till technology // Moshkin I.V., Shurkin A.Yu., Abramov A.A. / APK News. 2022. No. 5. P. 61-64.

Models from different manufacturers

There is a fairly wide range of seeder models on sale from different manufacturers. The most popular among them include WE-B from Wolf-Garden, Comfort 800 from Garden, CS 2500 from Texas, Brigadier 86020, PALISAD.

WE-B

The unit is from the German company Wolf-Garden, which has a portable container equipped with a dispenser and a spreading disc mechanism.

The device is also equipped with a battery and batteries. For ease of control, there are keys on its handle. The seeder is capable of scattering seeds at a distance of 0.5-2.5 m.

Thanks to the sufficiently spacious container, one load of seeds is enough to sow lawn grass on an area of about 750 m².

The cost of such a model is about 4,000 rubles.

Comfort 800 from Gardena

The dotted type unit from the German brand is made in the form of a trolley , equipped with a hopper for loading seeds, as well as a handle and two wheels.

The seeder evenly disperses fertilizers and seeds thanks to a special scraper built into the cylinder hopper.

Depending on the model, the volume of the bunker can range from 3 to 20 liters, which allows you to sow areas ranging from 90 to 800 m².

To start the seed feeding process, just turn the lever located on the handle. The device is also equipped with a metering unit that ensures precise seeding frequency.

The price of the model is 2500 rubles.

CS 2500 from Texas

The seeder from Texas (Denmark) is made in the form of a two-wheeled cart with a handle, which is equipped with a hopper for loading seeds. The hopper has a spreading centrifugal mechanism with a dispenser , and there is a control lever on the handle.

The device is activated when it moves forward. The hopper holds about 22 kg of lawn seeds. This amount is enough to sow a plot of 750 m². Seeds are scattered over a width of up to 2 m.

The price of the model is 14,900 rubles.

Brigadier 86020

A manual compact seeder whose weight does not exceed 5 kg. The device is intended for sowing lawn grass and applying granular fertilizers in small areas. It can also be used to spread reagents on roads in the winter.

The seeder has a built-in distributor that allows you to distribute seeds evenly. To control the volume of spilled seeds, it is possible to adjust the size of the hole in the hopper.

The price of this model is 1000 rubles.

PALISAD

The mechanical device of the German manufacturer is made in the form of a trolley on wheels with a hopper . The model consists of steel and plastic. The hopper volume is 12 liters.

The price of the seeder is 2500 rubles.

Additional types of seeders

There are many methods for planting seeds. Carrot seedlings present the greatest difficulty for gardeners. They are quite small and difficult to plant evenly. After germination, a very large number of young shoots have to be removed. Therefore, it is recommended to use different methods for planting:

- Sowing with toilet paper - numerous seeds are glued to a piece of toilet paper in a random or strictly defined order. Later this area is covered with a small layer of earth. When the sprouts sprout, they do not need to be discharged. The only thing is that weeds sprout abundantly among them. The disadvantage of this method is the long-term gluing of small seedlings onto a piece of paper;

- A seeder from an egg container is an original and simple way. The advantages of this method are its simplicity and evenly planted seeds at the required distance. To do this, you need to press the tray into the ground and pour 1 or 2 seeds of planting material into the resulting holes;

- Using tape - in specialized stores you can find a special tape for planting carrots. The seedlings are already glued to it in the required order and at the optimal distance. Planting is easy - tape is applied to the furrow made and sprinkled with earth.

Thus, it is easy to plant carrots without a seeder at home, but before doing this you need to either spend money or be patient by placing small seeds on toilet paper. But to get a rich, and most importantly, even harvest, you can make any sacrifices.

How to choose?

When choosing a seeder for lawn grass, you need to consider the following parameters:

- Plot area - for a small lawn, a manual seeder is suitable, but for large areas it is better to purchase a mechanical device in the form of a cart on wheels.

- The presence of unevenness on the soil surface - for working on hilly, uneven terrain, it is better to use a manual seeder. If the surface is flat, then a unit on wheels is suitable.

- Manufacturing materials - when choosing a seeder, you should give preference to models made of metal, as they are more durable and durable. However, their cost will be significantly higher compared to their plastic counterparts.

- The presence of a dispenser that will allow you to sow seeds in an even layer and ensure their economical consumption.

Carrot seeder - choose store-bought options or make it yourself

- Store options for seeders

- DIY carrot seeders

No vegetable garden is complete without healthy carrots.

If a person has a garden, then he tries to grow his own products on it.

This is correct, because only by planting crops with our own hands can we be sure of their quality and usefulness. The work of a summer resident cannot be called simple; during the season you need to do a lot of different things, without which you cannot get a harvest.

To make your work easier, you can use different devices - a carrot seeder is a good example of this. You can buy it in a store, or make it yourself, there are many options and let’s get to know them.

! Nowadays, there are more than 60 varieties of orange root vegetables; its homeland is the original Afghanistan. Europeans learned about carrots around the 10th century.

Can I do it myself?

If you have certain skills in making various mechanisms and devices, you can make a seeder with your own hands. Although homemade models are usually inferior in appearance to store-bought ones , carefully thought out details of the future design and its correct manufacturing will result in a fully functional seeder.

What tools are needed?

To make a homemade product you will need:

- drive wheel;

- two small wheels;

- opener, boards;

- 2 sprockets from under an old bicycle;

- canister;

- metal strip;

- small diameter metal pipes;

- welding machine;

- Bulgarian;

- spanners.

Process of creation

Manufacturing work is carried out in this order:

- To power the seeder, you will need a drive wheel. It can be removed from a drive that is no longer needed.

- Using a welding machine, the wheel must be welded to the hub, which is located on one of the opener disks.

- Next, you will need to tension the chain from the bicycle onto the sprockets.

- Then you need to bend thin pipes and make a base from them, and then attach to it a canister with holes made at the bottom for seeds, and a handle made of a metal strip.

- 2 wheels are attached to the bottom of the seeder.

Pros and cons of the solution

The main advantage of the decision to make a seeder yourself, from improvised means, is the opportunity to significantly save money on the purchase of a ready-made unit.

The disadvantage of this solution may be any error made during the manufacturing process of the device and its ineffective operation. Another disadvantage is the insufficiently aesthetic appearance of the homemade structure.

Advantages

A manual seeder for small seeds with your own hands allows you to save money and simplifies planting crops. Its characteristics are not very different from cheap purchased devices.

Positive aspects of self-production:

- from scrap materials,

- cheap.

Flaws:

- seeds of only one diameter (one crop),

- single row planting.

Note! Several seeders with different hole diameters practically automate seeding. A universal device is more difficult to make; manufacturing will require skill in working with metal and plastic.

Rules and technology of application

Sowing work must be carried out in calm weather , and the soil must be dry.

Before sowing, the surface of the lawn is leveled with a rake and compacted with a roller.

Then the seed is poured into the hopper and the unit is put into operation. To do this, you will need to push it forward and at the same time begin to rotate the handle.

Tip : to ensure uniform sowing of the entire area, you can use the cross method, in which the seeder is first rolled along the area and then across.

Possible mistakes

The following problems may occur during use::

- Poor seeding in difficult terrain with depressions and mounds when choosing a wheeled spreader. The smaller the wheels, the more difficult it will be to roll on uneven ground. For such areas, it is better to use a hand seeder, or carefully level the surface first.

- Choosing a planter that is too small with a small hopper capacity for a large lawn. In this case, you will have to spend much more effort and time to sow than when using a device with a large hopper, which allows you to scatter the seeds over a width of 1.5-2 m.

- Incorrect adjustment of the intensity of seed dispersal can cause too thick seedlings and high seed consumption, or the formation of bald spots and insufficiently dense seedlings.

PRINCIPLE OF OPERATION OF THE GRAIN SEEDER

While the seeder is moving with the coulters lowered, the seeds and fertilizers contained in the boxes and bins flow by gravity into the receiving compartment of the sowing devices, from where they are grabbed by the rotating coils of grain and fertilizer mechanisms, directing them into the necks of the seed tubes.

From the seed tubes, the grain is delivered to the inter-disk space of the coulters and, through the structures guiding its movement, is placed on the bottom of the recess formed by the disks.

Following the placement of seeds and fertilizers, their incorporation into soil is carried out by the shelf mechanisms of the seeder.

Advantages and disadvantages

When sowing a lawn manually, without using a spreader, it is important to adhere to the correct planting technology and ensure that the seeds lie on the soil surface in as even a layer as possible.

Using the seeder allows you to:

- achieve uniform seedlings and get a beautiful, high-quality lawn;

- significantly simplify the work and reduce the time to complete it;

- simultaneously with sowing the seeds, treat the area with fertilizers for lawn grass;

- use the seeder in the future for lawn care: treat the grass against diseases and pests, scatter fertilizers.

The disadvantages of using a spreader include the need to spend money on its purchase.

Rules for planting carrots

The carrot seeder makes it possible to sow seeds in pre-prepared shallow grooves, at an even distance of 1.5 to 2.0 cm from each other. The recommended distance between the rows should be from 15 to 20 cm. For industrial planting, carrots are best planted in the form of double rows with a distance between them of up to 20 cm and a wide row spacing of 40 to 50 cm. It is recommended to place the rows perpendicular to the long side of the bed, for convenient subsequent plant care.

The best models of sowing complexes and prices

Sowing complexes constitute a separate category in the market of modern agricultural machinery. Manufacturers offer many models of such units, annually creating new lines of high-quality and functional equipment. It is interesting that foreign-made units predominate, but domestic manufacturers are not lagging behind. Along with such types of sowing complexes as Agrator, Kerner, Horsch, you can also see products created in the CIS countries (for example, Orion, Vector).

The table below provides an overview of the most famous and popular models of modern sowing complexes.

| Model name | Characteristics |

| Great Plains | The design of this sowing complex was developed by English and American engineers. The basis of the unit is a Great Plains Centurion 600 disc seeder with cultivator functions. It is ideal for both minimum and conventional tillage in the field. Works under different operating conditions, on different types of soil. Its coulters are equipped with 2 powerful discs offset by 8 mm relative to each other. This device allows the unit to form an optimal furrow for planting seeds. The openers have reinforced levers, which provide pressure on the ground up to 160 kg, and the paws easily penetrate deep into it. The volume of the seed hopper reaches 4100 l. Only seed or seeds mixed with fertilizers can be immersed in it. The machine helps to plant any seeds, including legumes. The seeding complex works effectively in combination with a tractor, the power of which varies between 150-400 hp. |

| Kuhn | The Kuhn CSC 6000 model seeding complex has a volume of up to 2000 liters and is equipped with a TF 1500 front-type hopper. The unit has a built-in system that helps cool the oil. Manufacturers also equipped this model with a folding frame, a vertically positioned cutter and a SEEDFLEX seeding section. All elements of the latter individually exert a pressure on the ground of up to 45 kg. This ensures uniform seeding depth even when the working speed is too high. The front hopper of the unit is located in such a way that the operator of agricultural machinery has a good view at a low loading height. In some modifications of the presented model, the bunker is equipped with a soil compactor located at the front, or a supporting frame capable of withstanding up to 1200 kg of loads. |

| Horsch | This category includes the universal modifications Pronto 6 DC and Pronto 12 NT. They will cost approximately 185 thousand euros. Horsch seed drills are suitable for planting seeds directly or in mulched and well-plowed soil. Sowing occurs at high speed, and the quality of seed placement is maintained at a high level. The fulfillment of all these conditions becomes possible thanks to the equipment of the units with compaction systems that ideally level the soil after the passage of sowing equipment. The working width of the machine varies between 3-12 m. The unit is compatible with tractors with a power of at least 110 hp. As for the capacity of the seed hopper, it can reach 12 thousand liters. |

| Kverneland | The standard Kverneland Accord U-Drill universal model has a working width of no more than 6 m and is equipped with a seed container with a volume of 4350 liters. The manufacturer of this machine emphasized that at an operating speed of 10-18 km/h, the sowing accuracy should be as high as possible. Kverneland Accord U-Drill equipment is equipped with disc harrows installed in 2 rows, as well as wheels with a diameter of 457 mm. The depth of seed placement (as well as the pressure of the coulters) is regulated by the operator from the tractor cabin. |

| Maschio Gaspardo | The Gaspardo Corona 600 sowing complex is represented by a modular device that gives the unit universal properties. With the help of such a machine, a farmer can plant seeds of grain crops and other types of agricultural vegetation. The seed tank in this machine has a volume of 3500 liters, the working width of the equipment is 6 m. The device operates at a speed of 10-15 km/h, demonstrating productivity within the range of 6-9 ha/h. Compatible with tractors operating with a power of 300 hp or more. |