For those who are interested in hunting, fishing, or raising pets, a smokehouse will provide an opportunity to process food for long-term storage. It is not always possible to purchase a finished product, and probably everyone has thought about the question of how to make a smokehouse with their own hands. Products prepared with your own hands at home have better taste and can be stored much longer than unprocessed ones.

Finished products have a good taste and a long shelf life Source umelieruchki.ru

What are the features of the smoking process?

Nowadays, excess food can be canned or frozen for a long time. But in earlier times, in the absence of freezers and other devices, the only way to preserve fish and meat was smoking. This technology made it possible to prepare food for future use.

Using smoking technology, you can prepare products for future use Source tortini-msk.ru

Today, smoking is used as a way to add a richer flavor to foods. The technology makes it possible to prepare for future use not only fish, meat, cheese, but also fruits. Smoking is a technology for processing products using smoke. There are two types of cooking technology - cold and hot. Hot smoking occurs at temperatures of 50° and above. The limit for cold smoking is at the border of 40-50°, but usually the temperature does not exceed 35°.

A brick smokehouse can be used for several decades Source barbeku-kamin-i-pech.ru

During cold smoking, moisture loss occurs, and products processed using this technology can be stored for a year.

The smoking period varies significantly when using different methods. Hot processing time can be from 6 to 10 hours. When using cold smoking technology, the processing time for products can last from 5 days to several weeks. Cooking time depends on the products to be processed.

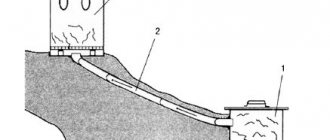

For cold smoking, special preparation of the smoke is used, and its cooling to the required temperature. For this reason, if you decide how to make a cold smoked smokehouse with your own hands, then you should study all the requirements for this device and carefully fulfill them. This design should have two chambers - for cooling the smoke, and for smoking products.

The fire should not be very intense, otherwise the food will become saturated with toxic substances Source bestpechi.ru

The smoke is transported through a pipe 8 to 12 meters long. A smoke generator or fan is used to control the temperature and provide draft.

Recommendations for production and operation

The tree needs to be treated with an antiseptic.

Initially, you need to choose the right place for construction. The smokehouse should not be located near residential buildings or above underground utilities. It is advisable that the smoke does not reach the neighbors. Lumber needs to be treated with an antiseptic, this will significantly extend its service life.

Since the structure must operate continuously for several days, the smoke generator should be covered with thick burlap or tarpaulin so that the smoldering does not stop, but the fuel does not quickly run out.

While the structure is not in use, it is advisable to cover it with a cover to protect it from dampness, sun and insects.

Advantages of smoking technology

And there are several of them:

- Products that have been subjected to the smoking process retain more useful microelements and other substances that are destroyed at high temperatures.

- Exposure to smoke kills harmful bacteria and other organisms that pose a health hazard.

- Smoke acts as a preservative on food, and as a result, its shelf life increases significantly.

When arranging a smokehouse, it is important to follow fire safety rules Source samogon82.ru

Pros and cons of wood

Among the main advantages of wooden smokehouses are the ease of assembly with your own hands and the ability to give the structure any shape. The camera body can be decorated with carved decor or tinted with special impregnations.

Wooden buildings are lightweight and mobile. If necessary, they can be moved; even one person can cope with such a task.

pros:

- environmental friendliness of the wooden blanks used;

- quick replacement of damaged structural fragments;

- the ability to assemble a structure without the use of welding tools;

- low cost and availability of building materials and components.

Minuses

- Wood is susceptible to fire, but this can be avoided with proper operation of the smokehouse. To reduce the negative impact of atmospheric manifestations and sudden temperature changes, the external structure should be treated with special varnishes and impregnations.

How to choose the right firewood for each product

Each type of wood has its own combustion characteristics and imparts its own flavor to products. The choice of sawdust and firewood depends on the product to be prepared. Do not use only firewood or wood chips. For proper combustion and the formation of smoke in sufficient quantities, it is necessary to take sawdust and firewood in equal quantities:

- Alder is ideal for meat, fruits and vegetables.

- Oak sawdust is suitable for red meats such as pork or beef.

- If you need to cook game or fish that lived in the swamp, you should use willow for smoking.

- Cherries or wood from other fruit trees are used to smoke berries, nuts or vegetables.

An open fire is not suitable for smoking Source build.4-u.info

Sea buckthorn, maple and juniper wood is also suitable for a smokehouse.

If you use birch, alder and bird cherry wood, you must first get rid of the bark, otherwise the finished product may taste bitter. Aspen or conifers cannot be used for smoking.

During the smoking process, you should carefully select firewood, otherwise the taste of the product can easily be spoiled Source www.dzivei.lv

It is very important to solve the problem of how to make a cold smoked smokehouse safe. To do this, it is necessary to take into account the following point.

During the smoking process, the wood must not ignite or char, otherwise the finished product will contain harmful carcinogens. To avoid this situation, it is necessary to close the chamber lid tightly to block the access of oxygen to the fire.

You can prepare sawdust for smoking yourself or buy it Source i1.ytimg.com

Stationary and mobile smokehouses

Today you can buy a cold smoked smokehouse in two versions – stationary and mobile. A stationary smokehouse is usually delivered on a turnkey basis. Most often these are houses like these with a smoke cooling system. They are installed on a pedestal on a personal plot or the territory of a country house.

Stationary cold smoking smokehouse Stationary cold smoking systems can be made to order in different versions, for example, they can be monolithic brick buildings.

Custom brick smokehouse

Types of smoking structures

The vertical or shaft structure has the shape of a hut, where the hearth is located below and food is hung at the top. In such a smokehouse it is impossible to use the fumigation method and regulate the formation of smoke.

A tunnel smokehouse requires a suitable location for the hearth and chimney. Despite the installation time, this design can be used even in wet weather. The tunnel smokehouse is suitable for hot and cold smoking.

Cold smoking technology is best used in cool weather; the smoke will cool down better. In hot weather, a temperature sensor should be installed in the smoking chamber Source swoidom.com

The chamber smokehouse is large in size, and when installing it, you should ensure an inclination at an angle of 10° to 30°.

Common components for cold and hot smoked smokehouses:

- Firebox. It burns wood chips and sawdust of special species.

- Cover for smoke generator. This component can be installed on the front or side wall, or on top.

- Chimney pipe. The length of the chimney duct allows the air to cool to the required temperature.

For cold smoking, a long chimney should be installed Source krrot.net

See also: Catalog of companies that specialize in grills and barbecues

- Smoking chamber. This is where the smoking process takes place.

- A metal grate with small cells of about 3 mm is installed at the entrance to the smokehouse, and does not allow soot to penetrate into the smoking chamber.

- Crossbars . They act as hangers on which you can hang hooks with food.

- Lid . It is necessary to install a chimney in it.

- Pallet . It collects fat and other liquid.

To accumulate fat at the bottom of the smoking chamber, install a tray Source img.youtube.com

Smoking recipes: fish, chicken, lard, meat

To prepare low-fat products, it is better to use the hot smoking method with a smoke temperature of at least 43 °C. Meat and fish of fatty varieties are cold smoked, in which the smoke temperature does not exceed 25 °C.

During smoking, products become colored and acquire an unusual taste and aroma. The upper part dries and becomes shiny. The finished product must be cooled and left hanging for at least 5 days.

Smoked fish

For hot smoking, the fish is first cleaned, washed well and rubbed with plenty of salt. After a quarter of an hour, the workpiece is washed and placed on a wire rack in a hot smoked smokehouse.

Recipe No. 1. Buy fresh or frozen mackerel at the store. Carcasses must be intact, without damage. Thaw frozen fish and gut it. Rub the carcass with salt, sprinkle with spices and leave for 24 hours. Use alder shavings or wood chips for smoking.

First place small apple tree branches, currant and raspberry leaves on the grill of the smoking chamber. Place prepared fish carcasses on top. It only takes 20 minutes to cook mackerel.

Recipe No. 2. To get a high quality product from this recipe, you will need an electric smoker . Clean the mackerel and rub with salt both inside and on top. Place the dish with fish in the refrigerator for 2 days.

Place fruit or alder sawdust moistened with water on a tray in the electric smoker. The highlight of this recipe for cooking fish in a smokehouse is adding a small amount of black tea, a lump of sugar and juniper berries to the sawdust.

Blot the salted fish with a napkin and drip lemon juice into the cut belly. A piece of lemon placed inside will give the fish a piquant taste. Grease the carcass with vegetable oil. Place on a wire rack.

Cooking mackerel in an electric kettle begins without a tray with sawdust. 10 minutes after the start of cooking, place sawdust in the chamber. Cook the fish for another 20 minutes with smoke. Turn off the device and leave it closed to cool. After 30 minutes you can taste the amazing taste of fish.

Smoking mackerel in a smokehouse, video:

Now you know how to smoke fish in smokehouses of different designs.

Smoking chicken in a smokehouse

The most important point when preparing smoked chicken is marinating . Wash the carcass well and remove excess fat. Dry with napkins. Make small cuts in the skin and push the cut garlic cloves into them. Mix your favorite spices with salt and thoroughly rub the chicken inside and out with this mixture. Prepare foil, wrap the chicken in it and place in the refrigerator to marinate for 24 hours.

Remove the chicken and let it come to room temperature for at least 2 hours. Prepare your home smokehouse for use. Free the carcass from the foil, tie the legs and wings together so that they do not stick out to the sides. Place the chicken in the smoker and begin cooking. When hot smoking, one hour is enough to cook chicken.

Recommendation! Check the chicken carcass for doneness by making test cuts. If the meat is ready, clear juice will be released without blood. Before use, remove the skin from the carcass - it has absorbed many substances harmful to the human body.

First, the fire in the smokehouse must be stronger in order to reach the desired smoking temperature and make the wood chips smolder. Then you just need to maintain the smoke formation process and the cooking temperature until the meat is cooked. Now you know how to smoke chicken in a homemade smokehouse.

Smoked lard

You already know how to build a smokehouse for cold and hot smoking. Now the time has come to get acquainted with recipes for making lard. The marinade will help add flavor and a special aroma to the lard. It is best to make a dry marinade. For 2 kg of lard you will need 250 g of coarse salt, a spoonful of ground black pepper, chopped dry bay leaf (1/2 pack), 5-6 cloves of garlic and fresh dill. You can take dry dill.

Cooking steps:

- Cut the lard into strips . The width of the pieces should be no more than 6 cm.

- Mix salt with dill, bay leaf and pepper.

- the resulting mixture well onto the pieces of lard on all sides.

- Place strips in a row, skin side down, and sprinkle seasonings on top. Place chopped garlic cloves between the pieces of lard.

- Cover the lard on top and press tightly with a weight.

- After 3 days, remove the salt from the lard and hang it on hooks to dry. The lard should not be exposed to sunlight.

This smoked lard recipe is the simplest. To prepare the product by hot smoking it will take only 20 minutes.

It takes longer to smoke lard in a smokehouse using the cold smoking method. Sometimes the smoking time reaches 36 hours.

Recipe for smoking homemade sausages:

Make homemade sausages using your favorite recipe. To prevent the sausages from leaking juice and losing their taste, they must be smoked immediately after filling. Smoking takes about 3 hours. All this time, you should maintain a small flame in the hearth and sufficient smoke production. It is best to use firewood from fruit trees.

Smoked meat

To prepare delicious pork, make a brine. Add 50 pcs to 11 liters of cold boiled water. black pepper, 0.5 liters of coarse salt and 15 pcs. bay leaf. The salt should completely dissolve.

Pieces of meat are placed in a cold marinade. In the cold season, the preparation for smoking is kept in brine for 5 days, and on hot days the meat is soaked for 3 days.

Important! Be sure to ensure that the pork pieces are completely covered with the brine. The dishes must be intact, without chips.

The meat, ready for smoking, is stuffed with garlic and tied with twine. The time has come to learn how to smoke meat in a smokehouse yourself. If you have a barrel smoker, hang the meat on hooks at the very top of the chamber and cover the barrel with burlap.

DIY wood lathe. - there is more useful information here.

Place a bucket of water next to the barrel to periodically wet the burlap. During the entire smoking period, swap the pieces several times.

Arrangement of the smokehouse

Cold smoking technology involves saturating products with smoke as a result of fumigation. Before entering the smoking chamber, the smoke is cleared of carbon monoxide. Before organizing cold processing of meat or other products, you should carefully study the instructions on how to make a cold smoked smokehouse.

Drawings of structures for smoking Source stroylegko.com

Preparing the site

The smoking process involves the use of fire. First of all, you should choose a place where, in the event of an emergency, the fire will not harm people or buildings. There should also be a place near the smokehouse to place food.

It is also worth considering the length of the chimney (3 m), width (30-50 cm), and height (25-27 cm). There should be good traction between the fireplace and the chamber. Sometimes it can be affected by differences in the temperature of the smoke and the environment. In order to increase draft, smoke exhausters are used.

It is best to install a tunnel smokehouse on a slope Source pbs.twimg.com

Smokehouse from a barrel

There is a simple way to solve the question of how to make a smokehouse from a barrel. It involves using a trench as a chimney. The beginning of the trench is located as deep as possible in the ground. This will give you the opportunity to get good traction. The walls of the trench are reinforced with sheets of iron, slate, or lined with bricks. The top or ceiling of the chimney is sprinkled with soil. At the end of the chimney there is a barrel. At the bottom there should be a sheet of metal with holes made through which smoke should penetrate. This sheet is designed to store fat. It should be smaller than the barrel itself so that smoke can freely penetrate into the smoking chamber. In the barrel itself it is necessary to place a grate on which meat or fish should be hung. The top of the container is covered with burlap, a wooden lid or a sheet of metal. You can also use a pipe instead of a trench.

Before use, the smoking barrel must be thoroughly cleaned Source ad-cd.net

If the question arises of how to make a smokehouse with your own hands at home for long-term use, then you should give preference to a brick building. This structure can be used for its intended purpose for several years.

Place for the hearth Source i.ytimg.com

See also: Catalog of companies that specialize in gazebos and grill houses

The design of a brick smokehouse is no different from a regular one, and consists of a place for a fire, a chimney and the smokehouse itself. The fire chamber and chimney pipe inside are lined with refractory bricks, and the upper part of the structure can be made of wood. The smoking chamber is equipped with grates for fastening products and a door. Clay is used to strengthen the chimney. A ceiling should be installed in the chimney, which will make it possible to control the draft.

Also, to solve the problem of how to make a smokehouse at home, you can use the body of a refrigerator that has failed. You can use a potbelly stove as a place for a fire. Sometimes smokehouses use an electric stove. Sawdust is placed on it and kept on until smoke comes out. This method requires special attention.

Any available materials are suitable for arranging a smokehouse Source 270076.ru

How to clean a stainless steel smokehouse

After operation, the smoking unit must be washed to remove carbon deposits, soot and food residues. A device made of stainless steel is easier to clean than one made of other materials. To do this, it is allowed to use steel wool, brushes and any of the most aggressive chemicals.

Good results are obtained by using detergents for kitchen stoves and automobile internal combustion engines. This cleaning should be done with rubber gloves, and after finishing work, all elements should be thoroughly rinsed with hot water.

The process of cleaning the smokehouse and accessories is simplified if it is done immediately after smoking, without allowing the fat drips to dry out.

Step-by-step cleaning instructions consist of the following points:

- Remove the grates and tray from the housing.

- Clean the inside of the device from ash and residual sawdust and wood chips.

- Wipe off grease and moisture stains with a disposable paper towel, rag or toilet paper.

- Fill the housing with warm water with added detergent.

- Return the tray and grates to the box.

- After 1-2 hours, wash all elements using a steel wool or sponge and dishwashing detergent.

To make cleaning easier before smoking, the tray is lined with food-grade aluminum foil.

In addition to washing the elements of the smokehouse in the kitchen along with the dishes, it is allowed to use other methods:

- When fishing or near a river, after smoking, all elements are tied with a rope and placed in the water. In water, contaminants become soaked, and small fish eat leftover food and fat. After 12-24 hours, the remaining carbon deposits are cleaned with sand and clay.

- In the field, nettle stems twisted into bunches clean stainless steel well. After washing, the installation must be rinsed with water and work with gloves.

- The smokehouse is washed clean in a car wash using a high-pressure pump and special products. This can be combined with car washing.

- All internal parts can be washed in a freestanding or built-in dishwasher. This process can be combined with washing dishes, and repeated if necessary.

- Fill the smokehouse with water and detergent and leave for 1-2 weeks. During this time, the multiplying bacteria will give the water an unpleasant odor, but will destroy the contaminants. The same method can be applied to worn jeans and other clothes.

You can clean the smokehouse from carbon deposits using a cleaning agent.

How does the cold smoking process work?

Cold smoking technology is used to prepare fatty foods. First, the meat or fish is sprinkled with salt and left for 5 days. Then the raw materials are removed from excess salt. To do this, you need to fill it with cold water and let it sit for several hours.

The soaked pieces of meat and fish are dried with a towel and hung indoors to dry a little. During this period, it is worth carefully monitoring insects that may lay larvae.

For cold smoking, 20% firewood and 80% sawdust are used. Firewood is laid out in the center of the hearth, and wood chips and sawdust are poured on top. Do not spread sawdust in an even layer on the bottom, otherwise they will quickly burn. The mixture should smolder slowly and produce a lot of smoke.

As a result of the cold smoking process, the finished products retain their elastic texture and acquire a pleasant aroma Source countrel.ru

Drawings and models

Below we provide drawings and models for making smokers (smokers) with your own hands. You can also contact companies that will manufacture the product to order. You just need to provide the drawing (model) file.

Drawing of a large grill-smoker-smoker in PDF and SLDPRT format

Drawing of a smokehouse with a lid-house and a water seal in DXF and CDR format

Drawing of an octagonal smoker-smoker in STP, IPT formats

Drawing of a simple smokehouse with a water seal in PDF format

Drawing of smokehouse No. 1 with a water seal in DXF, PDF, KOMPAS formats

All drawings of smokehouses

Organization of the hot smoking process

Very often, site owners wonder how to make a hot smoked smokehouse with their own hands. The design is practically no different from the previous one, with the exception of a shorter chimney. A container with sawdust is placed above an open fire or electric oven. They should not burn, but smolder slowly. Smoke penetrates into the smoking chamber where the products are located. A tray must be placed at the bottom of the barrel or other container to collect fat. There must be holes in the roof of the structure through which smoke can escape.

Design options for hot smoking Source 1000000diy.ru

To solve the problem of how to make a hot smoked smokehouse, you can use a regular barrel, inside of which the firebox will be located.

Firebox inside the smokehouse Source stroy-podskazka.ru

Making different types of smokehouses - step by step

Brick or block smokehouse

A smokehouse built from brick or foam concrete blocks is perfect for building on a country plot for those who are going to start selling high-quality delicacies, as it is intended for preparing a large number of smoked products at once.

Such a structure may well become not only a functional adjoining building, but also a decoration of landscape design. However, before proceeding to the purchase of material and construction of the smokehouse, it is necessary to develop its design and determine its specific location on the site. Based on the selected size, the amount of material required is calculated.

From building materials for the construction of this version of the smokehouse you will need:

- Red brick or hollow foam concrete blocks.

- Sand-lime brick for building a firebox, or you can purchase a combustion chamber with doors built into the fireplace.

- Cast iron or steel firebox door.

- Glass blocks or a window frame glazed with frosted glass, if the building provides a source of natural light. However, it should be noted that ultraviolet rays have a negative effect on smoked products, so it should be ensured that the window faces the north side of the building.

- Cement and sand for making mortar for masonry and foundations for walls.

- Wooden beam with a section of 60×60 or a board 20×100 mm - for arranging a rafter system for the roof.

- Sheets of plywood or OSB for continuous sheathing of the rafter system.

- Roofing material - it can be metal tiles, corrugated sheets or soft roofing, depending on the wishes of the owner and the general design of the site.

- Tongue and groove board or wooden lining 10÷12 mm thick.

- Chimney pipe with a diameter of 80÷100 mm - for installation on the roof or gable side of the rafter system.

- Chimney metal pipe with a diameter of 120÷150 mm.

- Door leaf with frame, approximate size 750×2000 or 800×2100 mm.

It is best to choose a place to build a smoking chamber on an elevated site, and in this case the firebox can be located at a distance of 2000 mm at the bottom of this hillock.

| Illustration | Brief description of the operation performed |

| Illustration | Brief description of the operation performed |

| The first step, as for any building, is to clear the area for a smokehouse made of bricks or blocks. To do this, first the site for the foundation is marked, and then the top fertile layer of soil is removed from this area, approximately 150÷200 mm (on the bayonet of a shovel). | |

| Next, on the site prepared for the foundation, it is necessary to find the middle, since the chimney duct pipe will subsequently be located here. A metal bucket or box without a top covering can be used as a pipe, into the side of which a chimney pipe will be inserted. Therefore, you need to make a hole in it corresponding to the diameter of the chimney. Through this channel, smoke will enter the smokehouse. You will need to dig a trench from the center of the site, and in the case when all the elements of the smokehouse are located on a flat area, then the ditch needs to be dug at an angle of 15–20 degrees, so that it goes deeper as it approaches the combustion chamber. Before laying the foundation, a pipe will be laid in the ditch that will connect two chambers - the smoking room and the combustion chamber. | |

| The next step is to lay the pipe, one end of which will go into the smokehouse, and the other is embedded in the back wall of the firebox. After this, the trench is buried, and you can proceed to installing the formwork for pouring the foundation. Since the construction will be relatively easy, there is no need to make a deep foundation. It is enough to raise the formwork walls by 200÷250 mm. The bottom inside the formwork is covered with sand, a layer of 50 ÷ 70 mm, and then crushed stone, 80 ÷ 100 mm thick. Each layer is well compacted. | |

| Then, a coarse cement-gravel mortar is poured on top of the crushed stone. The surface of this layer should end 50÷70 mm from the edges of the formwork walls. It must be leveled so that the solution is located approximately at the same level. The next step is to lay a reinforcing mesh with cells of 50×50 mm on top of the set concrete. | |

| A good cement-sand screed is placed on top of the mesh, poured from concrete mortar prepared in proportions of 1:3. For the plasticity of the solution and additional strength of the screed, it is recommended to add liquid glass to the solution. The screed is aligned using a rule along the walls of the formwork, which will serve as beacons for this. The screed is left to dry completely and the concrete gains strength. | |

| While the screed is drying, you can work on the combustion chamber. To build a firebox, it is also necessary to prepare the foundation. First, a recess is also made under it, which is filled with the same layers of sand and crushed stone, and then filled with concrete mortar, leveled and left to dry and gain strength. The walls of the firebox are best built from two layers - the outer one of red brick and the inner one of heat-resistant silicate brick. | |

| Another option is a ready-made metal combustion chamber designed for installation in a home stove or fireplace. Whatever firebox is chosen, it is best if the chamber is deepened into the ground - this factor will contribute to a longer cooling of the walls, which means it will help save on fuel. | |

| After the screed has finally matured, they proceed to the construction of the walls of the smokehouse. In the example under consideration, they are built from foam concrete and also hollow blocks. It should be noted that this building material has good thermal resistance, that is, clearly low thermal conductivity, and this is important from the standpoint of maintaining optimal temperature conditions in the smoking chamber. | |

| Each of the laid out rows is controlled according to the construction level. The masonry is made using ordinary cement-sand mortar or mounting adhesive for gas silicate blocks. During the work, control is carried out to ensure that the wall does not collapse from the vertical plane - this can be easily checked with a plumb line or the same building level. | |

| It is very important to move the doorway straight and carefully, otherwise the frame will fit into it at an angle, and the door may not fit at all. | |

| The next step is to install floor beams at the end of the walls, and then the rafter system. Since in the example under consideration a soft version of the roof is used for covering, a continuous sheathing made of plywood sheets is attached to the rafters. Detailed information about soft roofing and all the nuances of the process is presented in the article published on our website, a link to which will be given below. | |

| When the roof is installed, the gable sides of the roof are “sewn up” with boards or clapboards. A ventilation pipe is installed through one of the gables to remove smoke and excess moisture from the room. Then, door and window blocks are installed in the remaining openings. If you decide to cover the window opening with glass blocks instead of a window frame, then instructions for their installation can also be found on the website. To ensure that the door closes tightly without leaving gaps, you can apply a felt seal around its perimeter and install a lock or latch. | |

| Interior finishing inside the smokehouse is not mandatory, however, it should be remembered that fat and moisture will drain from meat, fish and other smoked products onto the floor. Therefore, to facilitate indoor cleaning, it is recommended to lay ceramic tiles with a ribbed surface on the floors. This illustration clearly shows how metal mesh racks are arranged for laying out prepared products. In addition, you can consider the hole in the floor through which smoke cooled by passing through a long channel enters the smokehouse. Ideally, this hole should be covered with a fine mesh that will trap soot particles. Such a mesh should be easily removable so that it is easy to clean it from accumulated dirt. |

Modern soft roofing – reliability and beauty!

Soft roofing, which includes flexible tiles on a polymer-bitumen base, is an excellent and very attractive covering for houses and outbuildings. The procedure for self-installation of a soft roof is described in detail in the corresponding publication on our portal.

Is it difficult to build a foundation yourself?

If you follow all the technological recommendations, this will become a completely feasible task. If you need information about the types of foundations, which of them can be optimally suited for small and light buildings, or about building a foundation with your own hands , then it can be found by following the recommended link to a special publication on our portal.

Wooden smokehouse

Another material from which the smoking chamber can be made is natural wood, which is environmentally friendly, does not create unpleasant odors and does not emit toxic fumes. The most suitable wood for building a smokehouse is deciduous wood - alder, oak, pear, cherry, apple tree and others. The main thing is that the material itself has a dense structure that will well withstand various negative environmental influences.

To manufacture this model of smoking chamber, which has a size of 800×450×450 mm, the following materials will be required:

- Wooden beam for the frame of the structure, with a cross-section of 50×50 mm, the total length of which will be 8000 mm.

- A well-processed board 100 mm wide and 8÷10 mm thick. Here you need to take into account that the lining will be mounted on the frame in two layers - longitudinal and transverse. They will help make the chamber more airtight, which will allow smoke to remain in it for a longer period of time without leaking through the cracks.

- In addition to covering the walls and making the door, the board will be needed to form the roof slopes.

- Roofing material. In this case, the master did not use any materials other than boards to build the chamber. However, if the smokehouse is covered with a waterproof roof, the risk of moisture penetration through small cracks between the boards, which can form under the influence of atmospheric moisture and ultraviolet rays, is significantly reduced.

- Canopies for securing the door, door handle with latch.

- Red brick for building the base for the smoking chamber, and heat-resistant silicate brick for the walls of the firebox.

- Cement and sand for masonry and arrangement of the bottom of the combustion chamber.

- Waterproofing material for covering the furnace roof, as well as sealing the joint with the pipe.

- A pipe with a diameter of 80÷100 mm and a length of 2000÷2500 mm and a piece of pipe with a length of 500 mm and a diameter of 100÷120 mm. The pipe can be metal or fire-resistant ceramic.

- Metal sheet for flooring in front of the combustion chamber.

The step-by-step execution of all construction and installation operations is presented in the instruction table below:

| Illustration | Brief description of the operation performed |

| Illustration | Brief description of the operation performed |

| The first stage of work on the site is to select a suitable location for installing the smokehouse and combustion chamber. In this case, the suburban area has a distinctly rugged terrain, which will help for optimal placement of the smoking system on the site. | |

| On the marked area, two pits are dug at a distance of 2000÷2500 mm from each other. One of the pits is located on a hill - it will serve to arrange the foundation for the smokehouse itself. The second one is placed below the first one along the slope - this is where the combustion chamber will be. The depth of the pit for the firebox should be 200÷250 mm, since it requires a reliable, solid foundation. | |

| Next, the pits are connected to each other by a trench into which the chimney pipe will later be laid. | |

| It is recommended to deepen the pit intended for arranging the smoking chamber by 300÷400 mm - this depth will help trap smoke in the pit and cool it. At the same time, the smoke is further purified and in this form rises upward into the smokehouse. Smoke purified from soot fractions will make products more aromatic and environmentally friendly. The bottom of the pit for the smokehouse and firebox is strengthened in the same way using concrete mortar and reinforcing mesh - this process will be described below. | |

| Before filling it with concrete, the bottom of the pit intended for the firebox needs to be thoroughly compacted, then covered with a 5-7 cm layer of sand and then crushed stone. The next layer is poured and leveled with a coarse cement-gravel mortar, which will penetrate between the crushed stones and, after hardening, bind the bedding. When the solution has set, it is recommended to lay a reinforcing mesh card with 30x30 mm cells on it - it will strengthen the screed well. Next, a solution consisting of cement and sand is poured. The layer of this fill should be 30÷40 mm thick. | |

| Then the bottom of the trench is compacted, and a long pipe of smaller diameter is laid in it. It should not reach the end of the trench by 180÷200 mm, so if necessary it will have to be trimmed. Next, a concrete solution is applied to the extreme part of the long pipe, and a piece of pipe of larger diameter is put on it, with a mutual overlap of 100÷150 mm. This design of pipes of different diameters will contribute to optimal cooling of the smoke when the channel expands before entering the chamber. | |

| As a result, the edge of the larger diameter pipe should extend into the combustion chamber area by approximately 150÷170 mm. Two bricks are installed along the edges of the pipe, after which the walls of the firebox can be laid from them. In this case, the walls are laid out half a brick thick. | |

| The sides of the pipe laid in the trench are filled with solution and temporarily covered with boards until it sets. After laying two rows of combustion chamber walls, a combustion door is mounted between them. However, it is best to install the door at the stage of laying the first row of walls, since in this case it will be possible to secure it with wire between the rows of bricks. | |

| A ceramic slab covering the firebox is mounted on top of the side rows and the door, as well as two bricks installed on both sides of the pipe. If one is not found, then you can use instead a sheet of metal 3–4 mm thick or metal strips, which are laid with the edges on the side walls. The strips will become the basis for the final covering of the chamber with bricks. | |

| A blower door with a size of 308×198 mm is perfect for installing a combustion chamber into this design, since such a window will be quite sufficient for laying a sawdust-shavings mixture, which, when smoldering, will produce smoke. | |

| Now that the combustion part of the structure is equipped, you need to leave it until the solution dries completely and hardens. This time can be used to work on the construction of the base walls for the wooden smoking chamber. The foundation for it is laid out of brick, the first row of which is laid on a well-hardened concrete base layer. Each row will consist of six bricks, so the side of such a plinth, taking into account 10 mm seams, will be equal to 500 mm. Therefore, a wooden smokehouse measuring 450x450 mm at the base will sit very firmly on the base. When laying out brick walls, the horizontality of each brick row must be controlled using a building level, otherwise the smoking chamber will not be level. | |

| The base should consist of 9–10 rows, 5–6 of which will rise above the ground. Raising the brick base, the chimney pipe coming from the firebox is built into the front wall of the base. It is very important to fill the gaps around the pipe well with cement mortar, since the inner walls of the lower part of the smokehouse must be relatively smooth and resistant to possible penetration of moisture from the soil. | |

| When the brick base is erected, the trench with the pipe laid in it is filled with concrete mortar. It is especially important to check that the solution is filling the area where two pipe sections join and the chimney channel enters the firebox. However, it must be remembered that the solution should not be filled to the very top of the trench, since it will then be filled with soil, the thickness of which should be 70÷80 mm. | |

| After the cement mortar has dried, it is recommended to fill the gaps remaining between the walls and the ground with clay, compacting it well. If there is no clay, then they are filled with soil, which is also compacted well. | |

| Now you can test the created system for the quality of smoke flow from the firebox to the smokehouse. To do this, you need to place brushwood or sawdust in the firebox and set it on fire using paper. Smoke should escape freely through the hole in the base without encountering any obstacles. If the system check was successful, then the trench with hardened concrete is finally filled with soil, which must be thoroughly compacted. | |

| Next, they move on to making the wooden smokehouse itself. First, you need to cut all the necessary structural parts from a wooden beam: these are 4 pieces of 800 mm each, 8 pieces. – 350 mm each, 3 pcs. – 550 mm each, 2 pcs. – 200 mm each. The structure can be fastened using nails or black wood screws 70 mm long. The first step is to assemble the front and rear frame frames. To do this, 350 mm pieces of timber are laid along the edges, between parts 800 mm long, and then they are all fixed together. This should result in two identical frames, which are connected along the upper and lower edges by segments of 350 mm. | |

| The finished structure is installed vertically and pieces of timber 550 mm long are fixed along the upper side edges. They should protrude beyond the perimeter of the frame forward and backward by 50 mm - this will be the basis for securing the roofing boards. Next, you need to find the middle of the upper crossbars of both frames, front and rear - at these points pieces of timber 200 mm long are vertically fixed. These racks will become the basis for securing the ridge beam of the smokehouse roof. A third piece of timber is fixed on top of the racks, which should also protrude beyond the frame by 50 mm back and forth. In order to give rigidity to the structure of the future roof and ensure convenient installation of roofing boards, you need to find the middle on the ridge beam and fasten one board along it on two slopes. One of their edges meets on the ridge beam, the second forms an overhang protruding beyond the perimeter of the frame by 150÷170 mm. Next, the formed roof frame is completely covered with boards. | |

| The next step is to sheathe the walls of the frame. The first layer of boards is installed and fixed with self-tapping screws in a vertical position. They need to be fitted as tightly as possible to each other. You should not use clapboard to cover the smokehouse, as the wood will undergo thermal expansion, which can lead to deformation of the grooves, causing the boards to crack. | |

| It is very important to accurately calculate the size of the doorway - it must be 5 mm larger than the door itself so that it fits freely into it. This factor is taken into account in connection with the thermal expansion of wood, as well as taking into account the influence of moisture on it, since the smokehouse is installed outdoors and will inevitably be exposed to precipitation. | |

| All but one side wall of the frame is covered with boards. It is also left temporarily open so that crossbars can be secured inside the smokehouse to the vertical posts of the frame for laying metal rods on them, on which the products intended for smoking will be hung using hooks. To ensure that the rods are fixed in one place and do not move, symmetrical cutouts are made in the crossbars. You will need two or three pairs of such crossbars. After this, a round or square hole is drilled in the roof for the ventilation pipe, which should have a small diameter - only 50÷70 mm. It is fixed on top of the roofing boards. It is very important that there is no gap left between the pipe and the roof boards, so if one has formed, it must be sealed - for this you can use tow and wood glue. These materials, by the way, are also well suited for sealing gaps between boards. | |

| Next, the door is made according to the dimensions taken from the opening. Its design is quite simple, and will also consist of two layers of boards - vertical and horizontal. They are fixed on two frame, horizontally installed crossbars. The next step is to mark the location of the door on the front wall, and then all the walls of the smokehouse are sheathed with a second layer of boards, which are placed horizontally. The joints of the boards at the corners are closed with wooden or metal corners. To control the temperature inside the smokehouse without opening the door again, a hole is drilled in it into which a special pin thermometer is installed. | |

| The bottom of the structure remains open, since smoke will enter the chamber through it. | |

| It is best to coat the finished wooden smokehouse with a water-based water-repellent impregnation on top to increase the surface’s resistance to atmospheric moisture, giving it hydrophobic qualities. For this purpose, one of the scuba tanks, which are presented in a large assortment in specialized building materials stores, is suitable. | |

| A kind of “culmination” of the construction of a wooden smokehouse is the installation of a chamber-house on a brick base. Fastening the wooden and brick sections of the building together can be done with metal brackets or strips, which are fixed with one edge on the boards and the other on the brick walls. | |

| When finished, the smokehouse looks like it is shown in this illustration. However, it is also recommended to cover the roof boards with one of the lightweight roofing materials - this could be the soft roofing already mentioned above, corrugated sheets or metal tiles. A control test of the operation of the smokehouse should be carried out by placing the first product in it. |

Below in the illustration is another interesting version of a wooden smokehouse, the design of which includes a canopy for storing and simultaneously drying firewood from fruit trees specifically designed for smoking products.

In the photo you can see that the firebox in this case is located at a closer distance from the smokehouse, so the entire structure occupies a smaller area on the site. However, the principle of operation of such a building is completely identical to the option described above.

This model of wood smoker does not have a side door, it opens and loads through the top, so it will be easier to make. In addition, you will not have to purchase hinged hinges and a door handle, and the camera will be easy to open by grasping the slightly protruding edges of the lid. To save space on the site, the firebox can be located quite close to the smokehouse, and in order to lengthen the trajectory of smoke from one chamber to another, the chimney pipe can be positioned at an angle.

Cold smoked smokehouse options from a barrel

A fairly simple way to make a smokehouse for both hot and cold smoking is to use a metal or wooden barrel as a smoking chamber. Moreover, the barrel can be installed vertically or horizontally.

The advantage of this method is that it is possible to make a similar structure without even digging a trench, but simply connecting the firebox and the barrel with a pipe passing above the ground. However, if the smokehouse is planned to be used in winter, then the pipe will definitely have to be insulated, since, otherwise, the smoke in it will cool too quickly, and therefore the product will not be of high enough quality.

When making this device from a barrel, you can do without welding, but in order for the smoke to concentrate in the pipe and not escape through the cracks and at the junction of the pipe and chambers, it is necessary to carefully seal all the gaps.

Smokehouse prices

smokehouse

You don’t have to worry about what to make devices for hanging food from. Rigid wire and wooden crossbars are quite suitable for this, on which hooks with products strung on them will be hooked.

A metal bucket can be used as a firebox if you cut a hole in it for a pipe and part of the wall, making an improvised door out of it.

Another point that will simplify the manufacture of a smokehouse is that most owners of this simple design prefer to use thick burlap instead of a lid, the structure of which will hold the smoke well enough and remove its excess.

The smokehouse will look more “civilized” if you cover the finished structure with heat-resistant paint, designed to protect the metal from external aggressive influences of moisture, oxygen or chemical corrosion, and temperature changes.

If there is very little space on the site, but you still want to install a smokehouse, then by making it from a barrel, you can “disguise” it in the style of basic landscape design by hiding the chimney pipe underground. This illustration shows how the smoking and combustion chamber organically fit into the decorative design of a small courtyard.

A smokehouse made from a wooden barrel will, of course, cost more, but its appearance is more presentable, so it can decorate any area of the yard. In addition, as mentioned above, the right wood, in addition to smoke, adds a pleasant aroma to the cooked smoked meats.

To make such a smokehouse, the top lid of the barrel is removed, and holders for two grates are attached to the inner walls at different heights, on which you can simply lay the products, or hang them on special hooks.

Essentially, a quality smoker can be made from a barrel made from any material other than plastic.

Smokehouse made from an old refrigerator

There is an old refrigerator in many homes: some use it as a cabinet for storing various rubbish or tools, for others it simply takes up space on the property or in the garage, and some practical home owners give it a second life by converting it into a smokehouse . Moreover, from this old device you can make a smoking chamber for both hot and cold preparation of delicacies.

In older models of refrigerators, practically no plastic was used - their internal walls were made of enameled metal, the grilles were made of aluminum, and polymers were used only for removable parts that can be easily removed from the body.

If the refrigerator is not so ancient, and there is a lot of plastic inside it, then such parts will have to be completely dismantled, leaving only the metal body for the smokehouse.

In addition to the refrigerator body with stands for grates fixed inside, you will need a two-meter pipe, bricks for the walls of the firebox and an iron sheet 3-4 mm thick to cover the combustion chamber.

Prices for wooden barrels

wooden barrel

The firebox should be located below the level of the bottom of the smokehouse. The pipe can be run above the ground or buried - the main thing is that it must be installed at a slope. The pipe enters the refrigerator body through its bottom, and into the combustion chamber through its rear wall or ceiling. Smoke from the firebox, passing through the pipe and cooling along the way, will enter the smoking chamber at the desired temperature. However, if the pipe is not buried in the ground, then during the summer heat the smoke will not have time to cool, and in winter, on the contrary, it will become cold too quickly. Therefore, it is best to “dress” the pipe in insulating material, which will create optimal conditions for cooling the smoke at any time of the year.

Grids and hanging hooks are used to place food inside the chamber.

It is necessary to make a small hole in the ceiling or in the upper area of the rear panel of the refrigerator through which the smoke will escape.

In conclusion, it must be said that other household appliances that are out of order and have a fairly large body made of metal can be used for the smoking chamber. For example, the outer metal casing from old round or rectangular washing machines is perfect for a smoking chamber.

Having understood the design of this device and understanding the principle of its operation, it will not be difficult to find material for making a cold smoked smokehouse. Well, after the work on it is completed, there will always be delicious home-made products on the festive table with which you can pamper your household and guests.

At the end of the publication - an example of the manufacture and practical use of a cold smoked smokehouse that is not at all difficult to implement:

Mini smokehouse

For those who are wondering how to make a small smokehouse, a bucket or metal box is suitable.

A bucket smoker can be placed above an electric stove Source o-remonte.com

The sawdust is located at the bottom of the bucket. A grate is installed above them. At the top there are hooks or a grate for food. The bucket is covered with a lid with holes for smoke to escape. The container is set on low heat. After smoldering begins, food is placed in the bucket and the lid is closed. In a mini smokehouse, the smoking process lasts from 30 to 60 minutes.

Small volumes of the smoking chamber allow you to get the finished product very quickly Source stroy-podskazka.ru

Also, a bucket or box can be placed on the grill with burnt coals after frying the kebab.

Ready-made design for smoking products Source stroy-podskazka.ru

Manufacturers

Various brands are involved in the production of such devices. When choosing a smokehouse made of stainless steel sheet, you must first study the characteristics of the model that best meets your needs, and also pay attention to the reviews of those who have tested the unit in practice. We will tell you about some well-known brands that have gained popularity in the market for this product.

Hanhi

The manufacturer produces a modernized smokehouse model of the same name. The unit has a water seal, which allows you to protect the kitchen from food aromas during smoking. The presence of a bimetallic thermostat makes it possible to control the temperature regime.

The popularity of the model can be judged by the large number of positive reviews. Buyers are mainly attracted by the excellent balance of cost and quality of the product, as well as the ease of care and use of the unit. The smokehouse can be used equally both in an apartment and outdoors.

Suomi

Smokehouses from the Finnish manufacturer are successfully sold on the market for these products and delight customers with their reliability and long service life. To produce the product, a sheet with a thickness of 2 mm is used. The device is universal and suitable for any stove.

Reviews from consumers who were able to try the unit in practice note its ability to carry out smokeless smoking. In a city apartment setting, this is a very significant advantage. Another positive point is that the product does not burn when smoked.

We eat and smoke

The brand of the Russian manufacturer is gaining more and more popularity. The company has been present on the market for 10 years. Every lover of hot or cold smoking can find suitable smokehouse parameters for themselves.

Thanks to its own production in Moscow, the company successfully fulfills orders for special projects proposed by the client himself. This individual approach brings positive results - more and more people want to cooperate with domestic manufacturers for mutual benefit.

Aisi

Another brand that has proven itself well. The range of smokehouses includes devices with a water seal and a matte (201) or mirror (430) surface.

Advantages of a DIY smokehouse

Every owner of a summer house or private home has thought at least once in his life about the question of how to make a smokehouse with his own hands. Manufacturers offer a large selection of ready-made designs with additional functions. Such smokehouses are not cheap, while you can make a smokehouse from a barrel or other available materials without additional capital investment.

A barrel is an ideal container for setting up a smokehouse on the territory of a summer cottage. Source cdn.instructables.com

It doesn't take much time to make the structure. Making a smokehouse can take anywhere from an hour to a day.

All homemade devices are easy to use and do not require much effort to prepare food.

If you use high-quality materials and follow the instructions, the smokehouse will serve its owners for a long time.

All designs are very simple, they can be made from the simplest materials.

Before starting work, you should carefully study the instructions on how to make a smokehouse and follow all safety rules during installation and operation of the structure.

Smoking cabinet Source u8.filesonload.ru

Which smokehouse is better: stainless steel or regular steel?

Stainless steel is one of the most common materials, especially in small hot smoking devices.

A smokehouse made of stainless steel has many advantages over a device made of ferrous metal:

- No corrosion. This metal does not rust, so the device does not need to be thoroughly dried after use.

- Durability. Stainless steel does not burn through fire, so devices made from it have thinner walls and an increased service life.

- Attractive appearance. Devices made from stainless steel sheets do not require painting and retain the shiny surface of the smokehouse walls for a long time.

Such smokehouses have only one drawback - stainless steel and products made from it are more expensive than devices made from other materials. Stainless steel is used mainly in small devices and professional installations. A stainless steel smokehouse is assembled with your own hands using electric welding or bolted connections.

Advantages of a stainless steel smokehouse

- minimal amount of burning and soot on the walls, which is also easily washed off;

- possibility of implementing various types of smoking (hot, cold);

- high mobility and safety;

- do not take up much space and do not require specially equipped areas;

- metal resistance to destruction (corrosion);

- ease of use;

- minimum maintenance.

Disadvantages of a stainless steel smokehouse

As such, there are two of them: price and weight. This applies to many modifications of stainless steel smokehouses. Such steel, in principle, is considered not a very cheap material and, accordingly, products made from it cannot boast of a low price. The weight of the smokehouse directly depends on its size and the thickness of the steel sheets from which the walls are welded. The minimum recommended wall thickness of a stainless steel smokehouse is 2 millimeters. As size increases, weight also increases, and mobility also decreases.

| Smokehouse size with water seal in cm | Steel thickness, mm | Weight, kg | Approximate cost, rub |

| 40*20*20 | 1.5 | 7 | 4400 |

| 40x25x20 | 1.5 | 8 | 4700 |

| 40x25x25 | 1.5 | 9 | 5000 |

| 40x30x20 | 1.5 | 9 | 5000 |

| 50x25x20 | 1.5 | 11 | 5400 |

| 45x25x25 | 1.5 | 9 | 5400 |

| 50x30x25 | 2 | 15 | 6700 |

| 50x30x30 | 2 | 16 | 6800 |

| 60x30x30 | 2 | 23 | 7700 |

| 60x40x30 | 2 | 25 | 8700 |

Choosing a ready-made smokehouse

Sometimes there is no time or desire to make a smoking structure. When choosing a ready-made factory-made smokehouse, you should consider the following points:

- the metal must have a thickness of at least 4 mm and be coated with an anti-corrosion compound;

- sometimes the materials for smoking structures may contain toxic impurities;

- when choosing a smokehouse, you should pay attention to the volume of the chamber;

- There are models that simultaneously support cold and hot smoking;

- if the model is equipped with a draft regulator, it will help control the temperature inside the chamber;

- each smokehouse must be equipped with temperature sensors;

- there should be several shelves inside the chamber;

- the buyer must require a quality certificate and a manufacturer's warranty for the product.

A smokehouse manufactured at a factory can be small and compact Source i.pinimg.com

You should not place food in the smokehouse for the first time. The chamber should be saturated with smoke odors, and subsequent use will bring good results.

Recommended types of wood for smokehouses

Only those rocks that have an extremely low resin content are suitable for building a house:

- cedar,

- alder,

- birch,

- oak,

- Linden,

- aspen.

Cedar is suitable for a wooden smokehouse.

When choosing materials, you need to pay attention to the size and number of knots, since when heated they will fall out, which will compromise the integrity of the chamber.

The following wood shapes are commonly used:

- planed boards;

- bars of different sections;

- plywood with a thickness of at least 8 mm;

- lining;

- block house.

It is prohibited to use layered boards saturated with adhesive compositions - chipboard, OSB, MDF. When heated, they will release toxic substances that are hazardous to health. Moisture and high temperatures will cause the fabrics to delaminate.

Wood needs to be pre-impregnated with an antiseptic; compositions such as Pirilax, Pinotex, Senezh Ecobio are suitable. To speed up the work, you need to arm yourself with a screwdriver and a jigsaw; you will also need a tape measure and a building level.

With water seal

Structurally, they are made like everyone else, but only along the upper perimeter of the body a gutter is made from the same material. When smoking, it is filled with water, but not completely, and is located under the lid itself.

When water boils, due to the formation of steam, odors and smoke are cut off; as the liquid evaporates, it must be added. Based on the principle of operation, you can determine the appearance and drawings of smokehouses.Information about smoked products

There is probably no point in talking about the advantages or disadvantages of smokehouses. All of them are designed to perform one function - smoking. But there is something you need to know about the product. Smoking, due to the substances carried by smoke, saturates the product:

- pleasant smell;

- unique taste;

- aesthetic appearance.

The body needs meat products to heal cells and replenish amino acids. All this is introduced with food, including smoked meats.

It also performs smoking:

- bactericidal effect;

- protects against microbiological spoilage;

- protects against the effects of putrefactive microbes.

Smoked products are stored longer and do not lose their taste.

Whether or not to have a smoker in your everyday life depends on the health, taste, desire and capabilities of each consumer. Nature lovers need it. You just need to decide on the design, study the recipes for preparing the products and go to the forest or to the river. And as a result, you will receive products of excellent quality and taste.

Small or portable

Structurally, it is made in the form of a sealed box made of stainless or ferrous metal with a thickness of 2-3 mm. A baking tray is placed inside to drain the fat. It is somewhat smaller in size than the box to allow the passage of smoke. Then the grate for food is installed.

A fire is built at the bottom of the box. After closing the box, combustion products begin to smolder, smoke comes out through a small hole in the lid or in the wall of the box. The temperature inside is 90 0C and above.