DIY turbine spinner

Let's tackle perhaps the most labor-intensive process - making petals. To do this, we need sheet material made of non-ferrous metal with a thickness of 0.4 mm.

A brass plate from a photo glosser (you can buy it through an advertisement) is ideal for our craft. The size of the workpiece is 25x8 mm. I tried to experiment and increased the size to 28x9 mm.

But such a turbine spinner flies worse and is more stubborn, and this did not affect the behavior of the fish in any way. Small spinners with a small tee can be useful for catching small fish such as bleak.

I strongly recommend making a couple of these spinners and fishing for a bleak from a distance of 80 meters (asp hunting position). Such entertainment broadens the angler’s horizons and gives an idea of the capabilities of the gear and the situation on the reservoir.

Material for production

White spinners

This type of tackle is the most popular among spinners. The white spinner is similar in color to a fish with white scales. And the predator comes at her willingly. Typically used for manufacturing:

- steel;

- zinc;

- cupronickel;

- silver.

The first two materials are easy to manufacture, but have one significant drawback - they give a bright reflection, especially in sunny weather. This may scare away the fish. Therefore, steel and zinc are used for fishing in cloudy weather.

But cupronickel and silver do not react this way to sunlight, and in general, many fishermen endow especially silver with magical properties of catchability.

Brass

Sometimes, for completely inexplicable reasons, predatory fish stops noticing white spinners and starts chasing yellow ones. Basically, they are made of brass. To do this, you can purchase standard brass sheets or use old utensils that were previously made.

Craftsmen make good spinners from copper.

Aluminum

Excellent workable material, easy to polish. But due to the lightness of such blanks, they often have to be weighed down. And this metal quickly oxidizes in water and acquires a gray tint. Therefore, it is recommended to paint lures made from this material.

However, the same lightness of this bait provides an excellent opportunity to arrange an exciting game with it both in winter and summer.

Stainless steel

Has a high safety margin. Easy to cut and bend. Hobbyists often use stainless steel tubes that are weighted with lead. A very catchy tackle in winter with vertical trolling.

Many people note the good sinking speed of this bait.

It is believed that it is especially good at catching pike perch.

How to make a turbine spinner?

We will need a caliper to mark the workpieces. It is convenient and fast to work with, which cannot be said about a ruler with a scriber. Please note that the caliper must have sharp jaws for marking.

I used ShTs-II brand calipers. Now from the edge of the sheet you need to mark strokes with a caliper at intervals of 2 mm. There should be 4 strokes.

The center line is at the 4 mm mark, the edge of the workpiece is at the 8 mm mark, and we will need the 2 mm and 6 mm markings in the process. But we'll talk about them later.

From the end of the strip, with a step of 13 mm from the center line, we place marks as many as will fit. Using a sharp core on the first marking and then every other marking, we mark the locations for the holes and drill them out with a thin drill.

The holes should be round, and the diameter should correspond to the thickness of the axle wire. If the diameter of the hole is larger, the petal will beat and rub its edge against the support bead.

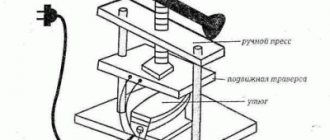

This can cause the bait to twist the line. I do this: with a sharpened dowel I mark the locations for the holes and with a drill with a diameter of 0.7 mm, clamped into a miniature collet clamp, I drill out the holes.

If you don’t have such a clamp, you can wrap foil around the tail of the drill and clamp it in the chuck of an electric drill. Since I haven’t yet acquired a small electric drill (I have an SDS plus hammer drill with an adapter chuck for a regular drill), I had to drill a hole with this monster.

As it turns out, this is possible. It is enough to place the tool on its side, turn on low speed, and feed the workpiece by hand. I will say more: holes can be drilled manually using a drill.

Next, set the size to 12.5 mm on the caliper and measure it from the hole on both sides. This is necessary to obtain a symmetrical workpiece. Using metal scissors, we cut off a strip, straighten it and cut it along the +-12.5 mm marks.

If a small gap forms between adjacent marks, we categorically cut off the excess with scissors. At the ends of the workpieces, I mark 3 mm from the edge and cut off the corners of the workpiece with metal scissors.

Now we won't need scissors anymore. The “finest hour” of a semicircular file and a small vice has come.

information for fishing enthusiasts

Side Column

Site search

Navigation

Main sections

Goods for fishermen

Everything for fishing

Hurry up to buy!

Backpack with folding chair (-24%)

News by E-mail

By subscribing, you agree to the privacy policy of this site regarding the data you provided.

Newsletter

By subscribing, you agree to the privacy policy of this site regarding the data you provided.

Tags

Recent Entries

New items

Rod insurance

Recent comments

- 4rdpwed on Fishing in Russia

- a drop to the post Catching pelengas

- Darrincycle on How to catch grayling

- RobertNug on How to catch grayling

- Maria on How to catch crabs correctly? Stone and grass crab.

Archives

Community

Side Column

Categories

- Types of fishing (720) winter fishing (171)

- vertical fishing (12)

- match fishing (11)

- sea fishing (50)

- fly fishing (22)

- float fishing (158)

- other types of fishing (50)

- spinning fishing (203)

- feeder fishing (119)

- swamp (4)

- main courses (32)

- boilies (3)

- sinkers (4)

- buzzbait (1)

- Altai Territory (4)

- Australia and Oceania (1)

- shark (3)

- spring (71)

- camera (2)

- mothless (1)

How to make turbine blades?

The workpiece must be clamped horizontally under the hole in a miniature vice and a notch is made with the semicircular side of the file in the middle, not reaching 2 mm from the stroke.

Next, using the straight side of the file towards the right, remove the corner almost to a vertical stroke of 3 mm and grind off the two protrusions formed after cutting the corner.

Then we turn the workpiece 180 degrees and perform the same manipulations (we grind a notch in the center of the product, grind off the protrusions formed after cutting the corner with scissors);

Next, turn the workpiece over with the markings facing away from you and grind off the protrusions at the corners and protrusions on the right;

Again, turn the workpiece 180 degrees (marking away from you) and use a rasp to perform the usual manipulations.

By always grinding the upper right quadrant, the petal will be symmetrical in relation to the hole. If you grind the workpiece around the perimeter, it will be difficult to achieve such a result: errors in the hand and an imperfect eye can ruin everything. Use fine sandpaper to “lick” the petals.

Bend turbine blades

Using pliers along the edge of the small jaws, the petals are bent 60-80 degrees. The blades should form the same angle between themselves.

To prevent the blades from coming into contact with the support bead, the area between the blades must be made at least 3.5 mm wide.

The flat exit side of the workpiece hole should be adjacent to the support bead. Don't panic if the blades bend further. The petals easily acquire the desired bend angle if you bend the support pad with the hole.

After this, a recess is formed on it for the divider bead. Regarding the angle between the blades, I can give some explanations. When throwing a bait with a bombard, it will fly head first, and the pressed blades are better flown around by air, and by the way, by water too.

When the spinner moves, the turbine resembles a spinner and thus becomes more noticeable. Our device has 2 blades, they are flat, due to which the light is scattered over long distances, attracting the attention of the fish.

Now let's look at choosing the direction of rotation of our invention. A floating bombard against the current can twist the line, more often this happens with a stubborn bait or accelerated retrieval.

The bombard rotates against the current, since part of it is on the surface of the water. If the spoon and bombard rotate in the same direction, then the line may twist.

In calm water, with a current and in the case when the turbine and bombard spinners rotate in opposite directions, spinning does not occur. Therefore, think through places for fishing in advance or adapt to the direction of the current to avoid possible incidents.

Types of tubular spinners

- Hollow baits are the easiest to make. Used for deep fishing or in strong water currents. The “tube” has low lateral maneuverability, and therefore it is possible to quickly navigate through the bottom layers.

- Tubes made with a sealed end are not used so often. This type has increased resistance at the end, and therefore, when wiring, the displacement reaches 30 or even 40 centimeters. But there is also an advantage of this bait - a passive predator may be interested in the prowling game, as well as the specific sound that the hollow part of the bait makes.

- The loaded spoons are half or a third filled with material. Lead makes a good filler. This type of bait is rarely used. It is customary to take this tackle only when you need to cast over a long distance during strong winds. The device has just enough weight for a long throw.

- Another common modification is the noise type. To make it, the ends are sealed and a lead pellet is placed inside. When wiring is carried out, the tackle will make rattling sounds that will interest the predator. Such tube spinners, for example, work well for pike perch, as well as for pike or perch.

How to make an axis for a turbine spinner

We will need thin elastic wire with a diameter of 0.45–0.5. You can use thicker wire, but then all the drive and meaning of the lesson is lost. I use 0.45 diameter wire from old stock.

You can order 0.51 mm Worth wire online. This is perhaps the most affordable option for purchasing this material. Hooks for our spinners should be taken according to Western numbering No. 8.

I prefer the Owner ST‑36BC and ST-41BC. Of course, you can install hooks from any manufacturer, but I recommend choosing something similar in size and weight.

For example, let’s take a hook made of thinner wire ST‑21ВС. It is lighter, so it can cling to the fishing line as a result of unbalanced work with the spoon.

For clarity, I will take wire and 3 hooks of 36 and 41 series. On a piece of wire (Worth has 127 mm cuts, but 80 would be enough), using small pliers and round nose pliers, I make a bottom loop with a tee and twist.

I cut the rest with a file and break it off. I use a pyramid file. It has one edge with a working notch, but the other two have no notch.

Sometimes on homemade and store-bought spinners you can find excess wire sticking out on twists. I think it's better to get rid of them with a needle file. Using a file, we cut the excess wire under the root and break it off, polish the break by cutting along it a couple of times.

How to make a spinner core?

Well, we finally got to the core of the spinner. The core is a symmetrical and smooth support for the bead and acts as a weight, ensuring the penetration of the spoon into the water column.

We will use polyethylene insulation from the field wire P-274. The outer diameter of the insulation is 2.3 mm, and the inner diameter is about 1.3 mm.

All these are approximate parameters, since the clearance of the internal insulation hole is made in the shape of a hexagon. Unfortunately, I cannot suggest what can replace such insulation.

Most often, cambrics are made of PVC, since this material, unlike polyethylene, is not so slippery and does not deform under the influence of high temperatures. You can use cocktail straws from Soviet times, although you will have to adjust the sizes and joints.

Insulation

I heat the end over a candle and then cool it in a metal recess. Now I’ll tell you how to make a notch. I take a steel ball with a diameter of 5 mm, place it in a pre-drilled hole in a metal plate and hit it with a hammer. The plate can be made of lead, copper or duralumin.

So, we have a frozen fungus, the length of which varies between 8–10 mm. I advise you to prepare cores for future use, devoting an hour or two to this activity.

Next, we measure the thickness of the bottom twist and use a drill of the same diameter or a smaller drill to adjust the core from the bottom to a depth of 2–3 mm to the diameter of the twist.

Although the supporting side of the core is sealed, it can be easily pierced from the inside by twisting and pushing the axle clamped with pliers. The axis comes out in the center of the supporting part.

I pierce the support with an axle with insulation strung on it. I remove the burrs formed from the puncture with a knife. I screw the core onto the bottom twist. The twist has the same lead as the thread, formed from a needle file.

To make the load, I use thin solder 1 mm thick. I pull a smooth metal rod several times on both sides of the segment and get flattened solder.

This will allow the load to be secured using a 4 mm diameter heat-shrinkable casing in the future. A piece 70 mm long is cut and inserted into the lower hinge of the axle in the very middle.

Both ends are wound onto a plastic core in the direction of twisting and cut diagonally near the fungus with a paper knife or scalpel.

A piece of heat shrink with a diameter of 4 mm is put on the solder and melted with hot air or flame. In principle, this is not necessary: the solder holds tightly and unwinding it is not difficult.

If you decide to use heat shrink, I advise you to make a device to hold the tee. It is much more convenient to work with it. Rotate the assembly over the soldering iron or on the side of the candle flame and frame it.

This must be done quickly so that the support does not melt. Or you can line an elongated piece covering the top of the support and covering the ring of the bottom twist, and then carefully trim off the excess with a knife.

Final assembly of the turbine spinner

Final assembly is the most enjoyable part of the process. We take support beads with a diameter of 4 mm. Glass beads are best. They are the most popular and have small diameter holes. Metal beads will also work, but they will be more difficult to obtain. I use Worth Solid Brass .

They have one drawback: a large hole. It seems that all store-bought beads have this vice in common. At worst, you can use plastic beads.

The assembly process is very simple. A bead is strung on the axis with a core, then a petal is placed, and a divider bead with a diameter of 2 mm is placed on top. made of plastic.

By covering the petal support area, it reduces drag and also gives the structure a complete look. The divider bead must be selected with a small hole, otherwise it may get stuck on the top twist, or even break completely.

When performing an upper twist, the petal should be centered relative to the axis or slightly lower. There is no need to shorten the free part of the axis: with a shortened axis, the spinner is more likely to overlap. In our case, the axis length reaches 45 mm. The upper twist is performed in the same way as the lower one.

Feathering on the tees may or may not be done. It's a matter of taste. I take this absolutely calmly, since I did not see a correlation between the behavior of the fish and the presence or absence of plumage.

Therefore, I leave the right to be considered the key object of interest for fish to the bombard turbine.

Design features of rotating spinners

For a predator, this type of spinner is attractive not only for its visual characteristics, but also for the powerful flow of vibration waves created by the rotating working body of the accessory. The design features of rotating spinners are based on the circular rotational movements of a tin petal loosely strung on a metal rod through the pressure of the water column when guiding the product, carried out by winding the cord with a tackle reel. The resistance of the petal to the flow of water creates vibration waves that arouse the active interest of the predator, which, together with periodic glimpses of a moving spinner, provokes the fish to attack the object.

Spinners

Rotating spoons are made of curved metal plates, which are mounted directly on the axis (rod).

At the moment of immersion, and then when guiding such an original bait through the water, the illusion of movement of the petals is created due to circular rotation around an axis. The material for the rod is rigid wire. The location and fastening of the axis occurs at the level of the fishing line, and the brass petal itself can be either fixed to the rod using a clamp or simply put on it. The hook is secured through a winding ring on one side and a swivel on the other. The frequency of rotating movements depends on the depth of the petal's bending. Spinner baits are among the most common and versatile types of artificial baits. It is important to use rotating spoons in spring and summer. Popular manufacturers of turntables are:

- The Menoc company produces spinners of various colors: yellow, white, red, black with dots, stripes and spots on the petals, also equipped with a bunch of red hairs that mask a sharp hook;

- French companies produce spinners of fairly good quality, their main feature is the use of different angles of deflection from the rod of the petal itself during wiring;

- American turntables (sinners) are deservedly in great demand;

- Rotating spoons from Russian manufacturers are also presented in a wide range.

Devons

Devon is a special spinner in which the body with inclined blades quickly rotates around an axis.

Considering that in calm weather even the angler can hear the sound of a Devon walking along the surface, then in the water this bait literally “squeals.” In addition, the blades create a powerful turbulent breaker from water and air bubbles, which seems to envelop the entire bait.

It is the squealing sound and turbulent wake during fast retrieval that are the main attracting factors for fish.

It is clear that such a specific bait is intended for the same specific fishing. And indeed, this is perhaps the best lure for asp during the “fight”.

Devonian species

There are quite a few varieties of Devons. They differ both in the cross-section of the body and in the location of the blades, which can be in front or behind. But since the rear lobes did not “take root”, we will only talk about Devons with anterior lobes (Fig. 1).

Fig.1. Devon models: a) round, b) flat, c) oval, d) oval with a notch.

The simplest is round Devon, when wiring it goes straight. Square Devon, triangular, etc. also go in a straight line. – however, these models also splash the water with their edges.

But remember the bleaks fleeing from the asp, jumping out of the water and rushing in different directions. Therefore, other Devon models were created: flat and oval, with a transverse asymmetry of the body relative to the axis of rotation - which also “yaw” slightly when driven. In addition, an asymmetrical body creates louder acoustic waves when rotating. And if an oval Devon has a notch on one side, then these effects are even more pronounced.

It is calculated that the optimal angle of attack of the blades to the oncoming flow is 45-60°.

A modern Devon, if you look at it from the head, should rotate counterclockwise: this at least slightly compensates for the twisting of the line by both the bait itself and the spinning reel.

To see the ease of rotation, blow strongly on the Devon from the front - a good model should make several turns.

Features of the Devon game

Devon with front blades, even with fast retrieve, goes with its “backside” lowered. Perhaps the asp sees only this part of the bait, because everything else is hidden in the turbulent wake. Or maybe it’s more convenient for him to attack a sagging spoon: remember the “upper” mouth of a predator. This position also makes it easier to bring heavy bait to the surface, which is especially important when fishing for asp. One way or another, the front-lobe Devons are alive, while the “non-sagging” models with the rear lobes are almost a thing of history.

Devon line twisting

All Devons have a fast rotation, so they twist the line strongly. This is the main and quite serious drawback of such baits. Usually, after 10-20 casts, loops appear on the fishing line; when casting forcefully, they can get caught in the ring, and... the Devon flies much further than usual. Or, if the line doesn’t break, it comes back like a bullet.

Therefore, you have to seriously struggle with twisting. Methods of struggle can be “internal” - with the cause of the phenomenon, and “external” - with the effect. The former reduce the transmission of rotation from the body to the axis, and the latter prevent the twisting of the line from spreading further.

Let us first consider external measures as more accessible.

The main method - the use of anti-twist agents - does not solve the problem, but temporarily delays it. The simplest anti-twist can be obtained from a thin transparent plastic plate by passing a fishing line through its top. But it’s better to immediately make a plate with a “stepped” wire and two swivels (Fig. 2).

Fig.2. Anti-twist: a) plate with holes, b) plate with a wire rod.

A radical solution to the problem is alternating when fishing two Devons: right-handed and left-handed. The difficulty here is to find a suitable anti-model. If it is not there, you can make the so-called “reverse blank” yourself. This is the simplest semblance of a Devon without a hook, but with reverse rotation and a body fixed on the axis, which allows you to neutralize the twist of 10-20 casts of a normal Devon in 1-2 casts.

There are also internal measures to combat curling, but these are already for Devon manufacturers. After all, twisting occurs because the rotation of the Devon body due to friction is transmitted to the wire axis, and along it further to the fishing line. This means that, ideally, the rotating part of the Devon should be light, well centered, and in contact with the axis at single points through gaskets with a low coefficient of friction.

Or the twisting must be compensated by some opposite force. Variants of such Devons are presented in Fig. 3.

Fig.3. Devons with constructive measures against twisting: a) tandem, b) half, c) “snake”.

For example, a Devon tandem consists of two parts, front and back, rotating in different directions. But due to the same sagging, the back part becomes longer. This means that the blades there should be larger, and they already work in a turbulent flow.

Once upon a time I was interested in making Devons, and a fisherman I knew sharpened me a variety of blanks. I cut out the brass blades to spare, soldered them into the bodies and, slowly filing them, adjusted them to suit the game. As a result, it was possible to obtain several “double” Devons that practically did not twist the line. If it were not for the complexity and duration of the work, this path could be recommended to everyone.

Then a “half” solution came to mind - to make only the front part rotating. This Devon turned out to be quite viable: it catches the same, but the line spins about three times less.

The Devon “snake”, in which the light “shirt” rotates quickly, does not give a strong twist, and the lead core does not rotate much less. It is this arrangement that seems optimal to me. The championship here belongs to the Swedish company ABU, but ours also produced a similar model with the name “Lama”.

Another way to avoid twisting is to use an eccentric weight. This Devon has a light plastic rotating body and a stationary weight in front or behind (Fig. 4).

Fig.4. Devons with an eccentric load: a) in front, b) behind.

Perhaps in the near future we will see acoustic innovations: many anglers are experimenting with the blades, adding teeth and holes, as well as with the body, where various channels and grooves are made.

Devon wiring options

For Devons, exclusively uniform wiring is used, differing only in speed and depth.

In our country, Devons are intended mainly for asp fishing. Moreover, during the “fight” we use high-speed retrieving along the very surface of the water, often even with jumping out, simulating an escaping bleak. If no fish are visible, we lower the Devon a little deeper (about half a meter), but still drive at high speed.

Retrieving at normal speed at different depths is also possible. At the same time, other fish can take Devon. For example, I caught pike and perch - though not on purpose, but along the way, when when catching an asp already near the shore I slowed down my reeling and the bait sank deeper. In the northern rivers, salmon and brown trout, known for their aggressiveness, were biting well in the Devonian. Let us remember that this bait was invented in England for salmon fishing, but there are no asps there at all.

Fishing for Devons

An asp can be caught “in a tight trap” when we see a predator hunting, or “blindly” when no fish are visible.

In the first case, the angler, having noticed the blow of the asp, quickly tries to determine where the fish is going, and casts the Devon not at the splash itself, but 2-3 meters in the right direction. After this, wiring immediately begins at maximum speed along the very surface of the water, but only in the battle area. Near the shore, the bait simply gets exhausted. If unsuccessful, several more throws are made into the splash sector, and the angler waits for the next blow.

If a predator does not “hit”, but is certainly somewhere nearby, we methodically fish for all interesting places “blindly”. A solitary asp likes to visit fallen trees or other obstacles, behind which the fry are “quiet.” It is to such places that you need to pay special attention. Once on Akhtuba, for three days in a row, in the morning and evening, I “took” the “duty” 2-kilogram asp behind a fallen tree. Devon had to be carried downstream very quickly, but the fish (maximum on the third cast) easily caught up with him.

I still equip most of my Devons with a tassel of white wool on the tee. Probably, such a tail-wab stands out more under the seething wake, and the asp “aims” at it.

Devons for beginners

Devon “Lama” has proven itself very well, but recently it has disappeared from the shelves, which is a pity. Although, if you wish, you can easily make such a Devon yourself (Fig. 5).

Fig.5. Devon SATURN "Lama".

I usually grind and round the back of the core on the Lama - the weight becomes eccentric and the twist is minimal.

If you have a boat, you can make a floating Devon from hard foam by gluing plastic blades into it (Fig. 6). For strength, you can glue a tube from the refill of a ballpoint pen into the axial channel.

Fig.6. Floating Devon: a) simple, b) tandem.

All that remains is to float the bait to the right place and drive it back and forth in the fishing area.

Moreover, it is better to immediately make a tandem or a pair of simple, but different in shape and play of Devons with different rotations. Then, testing various samples, we will unwind the fishing line along the way.

"Propellers"

There are special spoons with an eccentric sinker and a rotating element in the form of a propeller. Such baits resemble Devons, but here only the propeller rotates, and the body remains motionless. By bending the propeller blades, you can easily change the game of the spinner, speeding up or slowing down the rotation.

The propeller can be installed in front, behind or on both sides of the sinker (Fig. 7).

Fig.7. Spoons with a propeller: a) in front, b) behind, c) on both sides.

If the sinker has the shape of a fish, then such spoons are quite catchy on their own. But more often they are used in combination with other baits: fly, twister, octopus, etc. (Fig. 8).

Fig.8. Combinations of a loaded propeller: a) with a front sight, b) with an “octopus”.

Spinner spoons with a propeller are easy to make yourself and leave a wide field for creative activity. For example, the shape of the propeller alone has a lot of varieties: regular, acoustic, bubble, etc.