The injectors of an injection engine must be cleaned approximately once every 40,000 km.

Dirty injectors create increased fuel consumption, sluggish acceleration, and a jump in idle speed.

It is not recommended to use chemicals to wash injectors, because... They are the ones that cause increased contamination of injectors.

The cost of cleaning injectors at car services is approximately 1,500 rubles, but you can clean them yourself.

To clean the injectors yourself you will need:

- Carburetor cleaner (about 2 cans);

- Brake hose;

- Insulating tape;

- Plastic clamps for electrical wiring;

- A piece of 2-core wire;

- 12 Volt light bulb;

- knife (stationery or other)

The cost of everything above is approximately 300-400 rubles.

Problems that arise when injectors malfunction.

An injector is an element of a diesel engine that supplies fuel to the combustion chamber.

Owners of diesel cars often blame the fuel pump for a malfunction; however, the injector is the final element of the equipment on which the operation of the internal combustion engine depends. Solid deposits may form in the spray part of engines - this is a normal process characteristic of any engine with an injection system. The problem gets worse if the technology for producing and transporting fuel is disrupted. Deposits that form in the channel and injector nozzle disrupt the very shape of the spray pattern, and the fuel throughput is reduced. To troubleshoot the problem, you need to look for a number of signs:

- significant deterioration of the starting system of diesel engines, especially noticeable in the cold season;

- when accelerating, as well as in transient modes, twitching and dips occur;

- engine dynamics and power deteriorate;

- fuel costs increase;

- At idle, the engine runs unevenly.

If such signs are identified and operation continues, certain consequences arise:

- the exhaust gas converter overheats and is damaged;

- high-voltage components fail in the ignition system;

- parts of the cylinder-piston group are damaged.

With such consequences, the car comes for repairs.

Test bench for injector operation diagnostics

Cleaning Frequency

Car manufacturers usually indicate in the technical documentation after how many kilometers the injector needs to be cleaned. But here it is worth noting that they do not take into account the peculiarities of car operation, or rather, the fact that the fuel that we sell at gas stations is not always of high quality. And such gasoline primarily affects the rate of clogging of the injectors.

injector cleaning

Experienced mechanics have found that in our conditions, injector nozzles need to be cleaned approximately every 10 thousand kilometers. But this figure is conditional, since everything depends on the quality of the fuel being poured. Some may not need such an operation even after 15 thousand km, while others are forced to clean it after 5 thousand km. Therefore, it is better for the car owner to navigate the car itself, whose behavior itself will tell you that there are problems with the power system.

The main signs of clogged injector nozzles are:

- “Dips” appeared when pressing the gas pedal;

- The power plant functions intermittently;

- Increased smoke when the engine is running;

- Decrease in power and dynamics;

If all this is present, and the on-board computer does not show any errors, it is most likely that the injectors are clogged and require cleaning.

Diagram of a stand for washing injectors 3 modes

Anyone can do engine diagnostics using a smartphone.

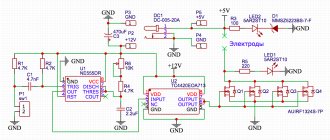

Essentially, the FORSAGE wash stand control unit performs the simple operation of opening the nozzles during the wash procedure using Wynn's cleaning fluid. Of course, the same can be done with a simple NE555 generator + transistor to control the injector coil. But “FORSAGE” in addition allows you to conduct comparative testing of washed injectors, perform cavitation washing with changing frequencies (helps to “rip off” heavily contaminated injectors) and evaluate the serviceability of the coils without additional equipment. devices. The scheme does not contain anything scarce or very expensive. Quite ordinary, widely available parts.

The electronics of the injector washing stand are mounted on a simple board made of one-sided foil fiberglass or getinax. It is powered by a transformer with an output voltage of 18-22V and a secondary winding current of up to 3A.

Since the device requires a significant current to operate the nozzle, the wires should be thick enough. And do not forget to use a protective fuse in the power circuit - it will be safer.

How to assemble the stand and wash dirty injectors on it can be clearly seen from this video:

Hi all! I propose an effective scheme for an injector cleaning stand, very easy to assemble and inexpensive in terms of finances.

I went to the radio parts store, bought everything I needed, and it cost about 300-350 rubles. Here is the diagram itself.

There are no switches for each injector in the diagram; I added them myself for convenience!

Next we need a soldering iron, straight arms and that’s it...

I think there is nothing more to add, everything is clear here. Good luck everyone!

Video of the stand:

Author; Alexey Tekmaev Chistopol, Republic of Tatarstan

Necessary materials

Car enthusiasts repeatedly have to deal with deception, which is present in many car services, so you can make a stand for washing injectors with your own hands. In this case, the stand will require the following:

- A wooden shield is used as a base.

- To solder the comb you will need polypropylene.

- A certain container (tank) is also used.

- An appropriate number of hoses will be required.

- An appropriate pressure gauge is required here.

- You will also need a small plane for placing containers.

- You will also need to use a special filler valve with distribution.

- You will need wiring for connection, as well as a pulse generator.

Of course, the stand for subsequent washing of the injector will not be complete if you do not use the injectors themselves, which are to be cleaned. Installation of all components occurs in strict sequence.

Important. A stand for washing injectors can be made using other elements, but this option is the most low-cost and easiest to manufacture.

Scheme for an injector cleaning stand

After all the components are prepared, all that remains is to combine everything into a single circuit, and also check for functionality. Here you should pay attention that the cleaning solution is distributed evenly across all four compartments where the nozzles will be placed. This scheme is suitable for simultaneous cleaning of 4 components, however, if you use a more powerful pulse generator, you can always increase the number to 6. The scheme itself is quite simple, but to perform it yourself you will need to have some skills and visual guidance. Simply using a homemade installation will allow you to significantly save on such a procedure, which costs quite a lot of money in the service.

Important. All work in such a situation is carried out on a flat surface so that the cleaning composition is evenly distributed in individual directions and enters the nozzles prepared for cleaning.

How does a stand for washing injectors work?

DIY common rail injector repair

The washing stand performs two functions: the first is to supply electrical voltage to open the nozzles and the second is to supply liquid under pressure to the nozzles, removing dirt accumulated in the nozzle.

The design of the stand consists of several elements, the main one being a drainless fuel rail. The stand also has a filter mounted at the ramp inlet that prevents dirt or any particles in the liquid from reaching the injectors, a power supply, a pump, and containers for clean and waste liquid.

The housing from a blowtorch is used as a container for the flushing liquid, and a foot pump with a pressure gauge is pumped through a nipple and the pressure in the stand is maintained.

Special liquids for bench washing of injectors cost approximately 400 rubles per liter, and in practice you will have to experiment a little with different degrees of concentration and types of liquids in order to choose the best option for your injectors.

For such a purpose as washing the injectors with your own hands (when you only need to open the injectors and be sure that they will not burn out), three volts is enough. The described design uses a power supply that produces 3V and is connected to a regular 220V network.

With the nominal characteristics of the power supply taken from the tape recorder being 7 volts and 0.7A, in reality, under load the voltage dropped to 3V, this voltage was quite enough for the design to operate. However, if you make a new stand, it is better to use a more powerful power supply.

With a constant supply of direct current, the controlled nozzles are always open and operate at maximum performance, passing a large amount of cleaning liquid.

Assembling the device

Let's move on to the assembly. It will remind you of the program “Crazy Hands” (who remembers such a program)