To build a smooth brick wall, you will need not only certain skills or a team of builders, but also devices for laying bricks. Such tools and templates will allow you to do the work faster and with better quality. They can be purchased in stores or made independently. Let's look at the most commonly used devices for making brickwork.

Using a cuvette Source dom-i-remont.info

Brick laying equipment

The choice of tool determines the worker's preferences. Commonly used bricklaying tools:

- Trowel or trowel . A small spatula, has a flat surface and a tapered end. Use it to pour the binder mixture and spread it over the surface. Use a trowel to remove excess at the junction of bricks.

- Joining . This is a narrow groove with a handle. With its help, seams are formed, their thickness is adjusted, and excess mortar is removed. The groove has a curved or convex profile.

- A small hammer is used to trim bricks to the desired size and shape, trim the masonry, putting the warped brick in place. This can be done with an uncured binder solution.

- Construction level for bricklaying . An important element for ensuring the horizontal and vertical position of the wall and base. Bubble and laser designs are used.

- Plumb . A metal weight suspended from a non-elastic thread. The plumb line checks the verticality of the building structure.

Plumb Source yandex.net

- Order . A ruler determining the width of a row of a brick wall.

- Mooring . Non-elastic tape. It is stretched along the wall and defines the boundary of brick laying, secured at the beginning and end of the row with metal corners.

Among other devices, a rule, a template for laying bricks and laths are used. They are necessary to control the shape of the masonry.

See also: Catalog of companies that specialize in designing country houses

Advantages of the template

The advantages of using a form at work include:

- Significant savings in masonry mortar used.

- Maintaining the same thickness of the applied layers.

- Facilitation and increase in productivity of the labor process.

- Simultaneous use of the frame during the laying of facing works.

- Obtaining straight lines along the horizon and vertical.

- Affordable price of the design (especially homemade).

Judging by the reviews on construction forums, builders do not note any disadvantages of using templates, although not everyone uses them. Many people are more accustomed to working the old fashioned way. Forms are recommended for inexperienced craftsmen to gain experience and skills .

We buy or make tools for bricklaying

The easiest way is to purchase a tool in a store. One of the professional devices is bricky. We can assume that this is a template for a novice mason; the result is a neat wall, but the speed of action does not suit a professional.

For different types of masonry and brick sizes, various modifications of the template are available. Currently it is made of plastic, but you can make it yourself from wooden or metal strips. A good option would be a brick consisting of sliding planks, which is suitable for various wall designs and brick blocks.

Bricky template drawing Source 100uslug.com

Conductor for obtaining smooth masonry

This bricklaying device includes a rectangular frame made of durable plastic, it has holes and projections for easy operation. We install the frame on the laid row, pour the solution inside, and remove drips from the sides. As a result, we get a layer of the same thickness, onto which we place the brick and lightly press it. We use the same smaller device to connect the end surfaces of the elements.

Set “Your own mason-2”

The device helps to lay a layer of masonry mixture of the same thickness in a brick row, with its help we obtain high-quality, neat masonry, save mortar, and increase the productivity of the mason. The set of templates is suitable for erecting a structure of half a brick or more, laying brick columns and columns, and performing facial finishing. Used to work with standard brick elements, sizes 250x120x65 and double 250x120x88 mm.

Set for bricklaying “Your own mason-2” Source plastsmart.ru

Set includes:

- horizontal template, 70 cm long for laying out the solution on a horizontal surface, equipped with two levels and graduations in mm;

- horizontal template of 40 cm, used in places of limited length;

- vertical template for ordinary bricks;

- vertical template for laying one-and-a-half bricks;

- supports for installing a horizontal template 70 cm in the amount of 8 pieces;

- strips required for laying pillars in the amount of 2 pieces.

All components are packed in a box and supplied with instructions.

Devices for dosing the binder mixture

Dispensing devices allow you to avoid excess consumption of masonry mortar when constructing brick structures. We use the following constructions:

- A cuvette helps to measure the required amount of solution in the selected area and get a beautiful seam of the desired shape. This is a simple container with walls without a bottom.

- Dispenser order. Container with a marking mechanism, adjustable length. Attached to the conductor frame using screw support clamps.

- Complex dispenser.

Dispenser order Source nagdak.ru

How to make a device with your own hands?

As mentioned above, template structures can be factory-made (plastic) or home-made (plywood, wood, metal).

You can make a template with your own hands from scrap materials . To do this, you need to decide on the consumables and tools that will help you make them.

In the process of work, you will need a hacksaw (jigsaw) or a saw (grinder with an attachment) for metal, basic wood (plywood, beams) or metal material (square profiles made of good grade steel), various types of fasteners (bolts, self-tapping screws, long metal rods, screws ).

The steps to create a form are as follows:

- Frame parts are made from wood or metal (steel, aluminum) according to specified dimensions.

- They take steel or wooden bars and connect them to each other, according to the design drawing, using bolts or self-tapping screws. Here it is important to securely connect the side strips.

- The metal parts of the profiles are welded to each other along the connection lines.

- The guide parts are secured to the surface part of the strip with adjustable bolts.

Frames can be made from plain and laminated plywood. For ease of use, door handles can be attached to them.

Important! A metal template is considered the most durable of those made independently. Its surface can always be coated with an anti-corrosion agent (from rust) and painted, due to which its service life will significantly increase.

We make a device for laying bricks

We make a template for a specific brick size - single or double. For finishing bricks you will need a different template. The structure consists of:

- frames with parallel walls, the distance between which is equal to the thickness of the wall;

- handles for transportation;

- diameters.

The simplest version of the template is a plastic box of appropriate size. We cut its walls to the required height, cut off the bottom and get a frame. We attach it to the wall using the protruding strips. The use of this template eliminates uneven masonry and warping of the wall.

Conductor with sliding bars Source gidlestnic.ru

You can make a split design with adjustable dimensions. To do this, drill a hole in the wooden planks and insert metal guides. The width of the jig is adjusted with wing nuts.

We make the device for a joint thickness of 10 mm, this is suitable for laying one and one and a half bricks. For the finishing brick layer we make another template. We coat the wooden elements of the frame with wear-resistant varnish. After each use, clean the instrument from any remaining solution.

Forming methods

Factory molds for preparing cinder blocks are made of reinforced concrete or steel.

Such parts can easily withstand the weight of a large volume of solution. As for do-it-yourself molds, they are most often made of wood or steel sheets. Such elements largely play the role of special formwork. To save on raw materials and free time, molds are mainly assembled without a bottom. You can put a simple film under them. Thanks to this method, the entire process of block formation can be significantly simplified. It must be remembered that the forms themselves must be made of perfectly smooth wood parts. The working surface will be a concrete base, a table with a flat and smooth tabletop, or a sheet of iron, which also does not have any defects.

Let's take a closer look at how to make a mold for slag blocks:

- you need to choose sanded boards 14 cm long (the width should be a multiple of this parameter);

- then, using a hacksaw, you need to separate the segments, which will then play the role of transverse partitions;

- then you will need to connect the segments with longitudinal elements to form a rectangular frame;

- Next, you need to cut a sheet of steel or any other material with a smooth surface into separate plates measuring 14x30 cm;

- in the inner part of the resulting structure, cuts are made that will act as grooves, the width of which is equal to the dimensions of the dividing strips;

- then the sections responsible for the separation are fixed in cuts, creating a mold for the production of 3 or more slag blocks.

In order for the resulting container for hardening the solution to serve as long as possible, at the final stage it is recommended to coat both metal and wood structures with oil-based paint. This form is suitable for preparing cinder blocks, the dimensions of which are 14x14x30 cm.

Briefly about the main thing

Various tools are used to perform brickwork. For a professional mason who has laid thousands of bricks, a trowel and jointing is enough. However, to control the quality of work, a plumb line and level are necessary. A novice builder will need templates. There are enough of them for every taste. Templates for double, single and finishing bricks, for straight and end seams are available for sale. Conductors simplify the laying process, making it smooth and neat. Anyone can purchase the necessary equipment or make it themselves.

Principle of operation

The template for laying cinder blocks has the following operating principle:

- A device is installed on an even row of cinder blocks carefully laid according to all masonry rules. Its dimensions are adjusted using screws located on the sides.

- The cavity of the base of the mold is filled with mortar and carefully leveled with a trowel, removing residues, with periodic checking of the level of the masonry with a marking tool.

- If the device is made of metal, it is placed with the welded profiles facing up so that the solution is laid along the height of the pipes. Such construction “sleds” are pulled to the side without much effort.

It’s easy to use different types of templates, the main thing is to choose the most convenient one for yourself.

Description of the design for carrying gas blocks

Since the weight of one cellular concrete block can reach a maximum of 30 kg, the question arises about the advisability of using special manual and mechanical devices that will help easily transport the blocks to the installation site. This type of device is considered to be a grip. It is designed in such a way that it is capable of grasping, with a specially created mechanism, a block of aerated concrete of any weight and size, and carrying it with the help of a handle (grip), like regular luggage.

The gripper has the form of a metal clamp and is a hinge-link mechanism that can facilitate labor during construction work on the construction of buildings made of aerated concrete blocks.

The advantages of using the tool are:

- the ability to raise gas blocks to different heights;

- significant acceleration of construction time;

- noticeable reduction in labor costs;

- ease of use and quick turnaround of products;

- careful operation in relation to the surface of the blocks;

- reliability of the clamp enclosing the product;

- assistance to ensure the accuracy of masonry installation;

- ensuring reliable coupling of the mechanism with the block;

- multifunctionality of the device (lifting, transporting, turning over, transferring, etc.);

- compliance with safety and technological standards.

The standard mechanical gripper device (pictured) includes:

- Rocker.

- Clamp (levers).

- Stand.

- Suspension.

- Traction 1.

- Traction 2.

The clamp is represented by 4 levers with a “scissor mechanism”, connected by a hinge element that allows the mobility of the parts. Some types of grips (multifunctional) have, in addition to levers, a ring for hanging from the forklift hook. The picture does not show the handle that comes from the pendant, by which you can use the tool manually. But the handle (grip) helps to use the device manually.

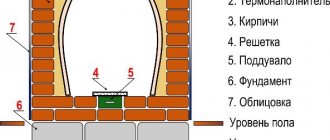

Lintels in a block wall

In a block wall, lintels must be installed above the openings of doors and windows.

In load-bearing external walls, a depth of embedding into the wall of 200 mm is possible; with an opening width of more than 1.5 m, at least 250 mm is permissible, in other cases 350 mm.

You can fill them with concrete, but it takes a long time and is not convenient. To do this, install the formwork, reinforce it with a spatial frame and pour it.

Reinforcement frame of a concrete lintel

But in this case the masonry stops. If you lay it yourself and are not in a hurry, then you can absolutely safely use this method, it is the cheapest, but also the most labor-intensive. But nothing sticks out of the wall.

The finished lintels are heavy and are placed several in a row to match the thickness of the wall. This method is faster, but it is difficult for one or two people to install jumpers on the scaffolding. And the money is no longer so cheap. Again, nothing will stick out from the plane of the wall.

During construction by a private developer, corners and reinforcement are often used as lintels.

In the partitions, they use 10-12 mm reinforcement, 3-4 pieces, which are embedded in the masonry, a board is tied from below and it is pushed apart from below with a stand, and a solution is applied through the rods. When the solution more or less loses its mobility, blocks are placed. Doorways are easy to make this way.

Rebar lintel over doorway

But in external walls, which are usually much thicker than partitions, a corner is used.

To do this, the corner is cut to size, welded together through a strip and reinforcement in 3-4 places. Then they prime it with a metal primer (otherwise it will rust) and install it on the block. The solution is applied to the shelves and the blocks are installed, only with the holes facing up. This is the most expensive method; the corner shelf extends beyond the wall. But also the most reliable. And fast.

“Device” for forming an adhesive layer

The essence of this product is very simple - maximum acceleration of the application of the adhesive layer for laying blocks. To do this you need:

- Make a box on a skid. It should move easily along the row of the wall and will not move off it. To do this, the side walls should hang from the row by 1-2 cm

- The device is equipped with a spatula for uniform application of the solution - it is better to use a notched trowel. At the same time, fix it at an angle of 40-50° - this way it will be better to apply glue to the row

- Since the width of the adhesive layer is needed to be somewhat narrower than the block row - excess glue will not be squeezed out when installing the block - the device must be equipped with restrictive bars from the inside.

To make it you will need:

- Notched trowel

- Board 100-150 mm wide and about 1 m long

- 10-20 mm block, about 40-50 cm long

- Fastening: self-tapping screws

- Wood hacksaw

- Screwdriver

- Axe

Light version

As can be seen from the above description, finishing with plaster, mesh and putty takes a lot of time. You can cheat and apply only putty to the walls. The best choice for this case is Glatt+Full putty from the German company Pufas. It evens out and fills uneven areas, creating a thick layer thanks to its composition - Glatt+Full consists of cellulose mixed with gypsum.

Work with putty must be done quickly, as it sets very quickly. After just 60 minutes this putty hardens. Once cured, Glatt+Full can be floated in the same way as regular putty.

Before applying the composition, you should first treat the wall with a primer. In this case, it is better to choose Ceresit CT 17, a water-dispersed primer that does not reduce the vapor permeability of the base. After the primer has dried, a layer of putty is applied to it. The mixture is leveled with a grater. After a day allowed for final drying, the putty is wiped off with a grater.

Reciprocating saw

Demonstration of a reciprocating saw when cutting foam blocks.

The electric saw makes cuts with flat blades that look similar to the blade of a saber, which is why it got its name. The amplitude of movement of the canvas can be different, it all depends on the model. They vary from 3 to 5 cm. An electric hacksaw easily copes with gas and foam concrete blocks and makes cuts quite quickly. Using the saber model is easy. The operating principle is similar to that of a chain saw.

Models may vary:

- frequency of movements per minute (2.5-3 thousand);

- range of motion (1.9-2 cm);

- Block cutting depth.

Using a reciprocating electric saw, you can quickly and efficiently cut aerated concrete blocks. The speed in many models is controlled by an electronic unit. Cooling occurs through the existing ventilation holes. The vibration level is adjusted and low. The reciprocating saw weighs about 4 kg. Replacing the blades is quite simple.

Planer for aerated concrete based on sandpaper

The basis of this version of the plane is moisture-resistant sandpaper 20 cm wide with an abrasiveness of about 40 (for rough work). In addition to this, you will need:

- a piece of flat multi-layer plywood;

- board for making a pen;

- screws, jigsaw, drill, stapler.

The handle can be cut with a jigsaw and then sanded. It is more convenient if it is higher on one side than on the other. The dimensions of the narrow side of the plywood base are determined by the width of the sandpaper strip, and its length can be made equal to the transverse size of the block or slightly larger.

The handle is screwed to the base with two screws. A countersink should be made for the screw heads, and it is advisable to drill holes in the handle so that it does not crack. Then a piece of sandpaper of the required length is cut and stapled to the ends of the base. The paper fastening may be different. The planer-grater for aerated concrete is ready.

Materials used

The planer for aerated concrete is made on the basis of available materials:

- boards, 10-15 cm wide and length corresponding to the size of the product;

- thick plywood or board used to make the handle;

- screws, the dimensions of which allow you to securely fix the handle;

- carbide files, which are the cutting element of the device;

- glue that allows you to reliably glue metal to wood.

To make a plane, it is necessary to incorporate the maximum available materials into the design.

You will also need sandpaper, which is used to round the edges and sand the surface of the product.