DIY roller shears for cutting sheet metal

How to make a roller cutter for sheet metal with your own hands. What can you make a homemade roller knife from?

Cutting metal at home is a rather tedious process. And its quality often leaves much to be desired, forcing additional processing of the resulting edges.

The situation can be corrected in many ways by using special devices, including those made by yourself.

We will talk about one of these devices, namely the roller knife, today.

Roller shears and sheet metal cutting features

In the metalworking industry, roller shears or knives are used to process sheet material. This tool is called knives because its operation is based on the use of two cutting discs.

The cutting process is based on the fact that rollers are pressed into the sheet material from two sides - top and bottom. In this case, it is cut without the use of any sharp knives.

The role of cutting and sharp knives is played by rollers, which touch the walls to each other on both sides.

Rollers not only cut sheet material, but also facilitate the process of moving the tool along the surface of the sheet. This means that cutting with a roller knife is not only convenient, but also effective. If we compare the operation of the device with hand scissors, the following advantages should be noted:

- Speed - cutting a sheet of steel with roller shears can be done in a matter of seconds, but using scissors requires a lot of time, which depends on the length of the material being cut

- Cut quality - the roller knife cuts not only quickly, but also with high quality. There are no chips, bends, bends, etc. at the site of the cut

- Physical fatigue - cutting with hand scissors requires physical effort, while using a roller tool eliminates this need. To cut, you only need to move the roller shears along the guides, thereby cutting the steel sheet

Roller shears are classified according to the types of knives into three types:

- They are located in parallel. The most popular type of cutting tool, which is intended exclusively for cutting material into strips, that is, cutting is performed in a straight direction

- They have one slope. They are intended for cutting not only even strips of sheet material, but also for cutting round and ring-type workpieces

- With several slopes. Such roller devices are intended directly for cutting workpieces of various shapes - ring, round, curved, etc.

After cutting, the edge of the material does not need additional processing, as it turns out smooth, without chips or burrs.

Recommendations for use

Guillotine, lever, manual, electric, hydraulic types of shears are widely used in the fields of metal processing.

Once you have lever shears at your disposal, you should familiarize yourself with the basic rules for using them. This will not only allow you to cut metal workpieces correctly, but also keep your own hands intact.

- Wear strong protective gloves before you begin. This way you will protect yourself from sharp metal sheets. They themselves can cause injuries, unpleasant cuts, if you simply pick them up to place them on a cutting machine.

- Securely secure your lever attachments according to the manufacturer's instructions. Different models of scissors may have their own installation features on the desktop. Therefore, first of all, study the factory instruction manual.

- Place the sheet of metal you are working on perpendicular to the blades of your lever shears. Hold the base with your right or left hand, depending on whether you are right- or left-handed.

- Gently and gradually press the handle of the scissors from top to bottom.

- Remember to wear closed shoes to avoid being injured by falling metal scraps.

- For a desktop, choose designs with a strong and stable base.

How to cut sheet metal at home

In industry, roller shears are used to cut factory-produced sheet metal. Their distinctive features are high accuracy, long service life, and the absence of the need to make them yourself.

Often in the household there is a need to obtain even strips of sheet steel, which are used for various purposes. If you need one strip, then there is no need to buy or make such a device, since you can use ordinary metal scissors.

If you need to cut the entire sheet or carry out cutting work regularly, then it is imperative to acquire a roller knife.

There is no justifiable sense in buying such a factory-made device, since the price ranges from 15 thousand rubles or more, which depends on the design, size and quality of the device.

Roller shears for cutting sheet metal can be made with your own hands at home, using available consumables for manufacturing.

Although this method requires time, it allows you to save money, resulting in a universal cutting tool for cutting sheets of stainless steel, galvanized steel, etc.

!

It should be noted that roller shears are only suitable for cutting flat sheets, and they cannot be used to cut sheets with protrusions and recesses, for example, corrugated sheets in the transverse direction.

Console (pendulum)

The cantilever part of a metal cutting machine is one of the most important. In addition to the fact that it must be carefully balanced, securely welded in compliance with all the required dimensions, it must also move strictly perpendicular to the work table.

The basis for mounting the pendulum are two vertical posts with slots for the pendulum bushing (diameter 10-12 mm). It is best to make them from a steel square of 40x40 millimeters. The height is approximately 80-100 millimeters, but you can calculate your own version.

A bushing shaft is installed horizontally in the holes of the racks, to which a rocker arm is welded, consisting of two levers, the ratio of which is one to three. A platform for installing the electric motor is welded on the short arm. On the long arm there is a cutting wheel drive shaft.

The ratio of the lengths of the levers is approximate; it must be calculated so that in the non-working position the weight of the engine outweighs the weight of the assembled saw part (with protective covers).

To bring the disk of the switched-on machine into contact with the metal, it is necessary to apply a small but noticeable force.

For ease of operation, a return spring is attached to the bottom of the engine platform, and the upward deflection angle of the pendulum is adjusted by a cable or chain, fixed at one end to the table and the other to the bottom of the long lever.

Features of making a tool yourself

If you are tired of cutting sheet metal with scissors or a grinder, then a roller cutter is an excellent alternative to replace these tools.

The advantages of this device include quiet operation and lack of energy consumption.

In addition, having such a device in your home arsenal, you can even make money when your neighbors need to cut sheet metal material.

The purchase of a tool is justified only in one case, when it is necessary to perform work in large quantities. And even in this case, you can make the device yourself to use it for professional purposes. There are many designs for the devices in question, so making a device yourself is not at all difficult if you understand the principle of operation of the device.

When making a homemade tool, the following properties must be taken into account:

- Cutting knives - there should be two of them, one located on top and the other on the bottom. Knives must be made of high-quality alloy, which has a strength higher than the materials being cut. Bearings that fully meet the described requirements are used as knives.

- Base - simultaneously acts as a surface on which the steel sheet is located, as well as a guide for moving the roller shears when cutting the sheet or cutting strips

- Body of the device - for manufacturing, a steel angle with a thickness of 3 mm and a wall size of 40-60 mm is usually used

- Auxiliary tools - they are designed to secure the sheet material to the table surface while cutting it

!

The service life of homemade roller knives is quite high, and is almost equal to that of factory models.

The service life of factory devices is at least 25 km, but provided that the thickness of the cut steel does not exceed 0.5 mm. The thicker the steel, the shorter the service life of the tool. The service life of a homemade device is influenced by such an indicator as the quality of its manufacture.

Moreover, this even applies to the quality of bearings, so if you get down to business, you will need an appropriate approach.

Design

Roller metal shears, assembled at home with your own hands, have a common essence that remains unchanged - the presence of a cutting knife. It is made from steel alloys with a maximum strength threshold and other characteristics that should be higher compared to similar parameters for steel that will be processed on a cutting machine.

Roller knife device

In practice, it is known that roller knives produced at the factory for cutting metal have a service life of about 30 km of steel sheets, with a caveat to the maximum sheet thickness, which will not exceed 0.5 mm.

Accordingly, if the thickness of the material is higher, then the durability of the tool is reduced. However, nothing prevents you from sharpening the tool and thereby extending its service life.

What to make a roller knife from

There are no difficulties with purchasing roller shears, since such a machine can be found in an online store and ordered.

The only difficulty is that you will have to shell out a considerable amount of money to purchase it, which will not pay off soon if you do not use such equipment often.

Making your own will not require any costs, but the biggest difficulty is choosing the necessary materials and assembling full-fledged roller shears from them.

Using a homemade machine allows you to cut the following types of materials:

- Cink Steel

- Stainless steel

- Aluminum

- Steel sheets up to 0.5 mm thick, for example, window slopes of metal-plastic windows

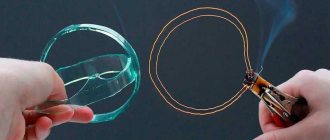

Bearings are used to make cutting knives. The diameter of these bearings depends on the size of the roller blade housing, but 20-30mm ball bearings are commonly used. In order for the bearings to ensure cutting of material, it is necessary to grind off their end faces, making them strictly at an angle of 90 degrees. The effectiveness of the tool depends on this.

!

The diameter of the bearings affects the cutting speed.

The larger the size of the bearings, the correspondingly higher the cutting speed. Before you make a roller-type cutting tool, you need to understand its principle of use. The application is based on the fact that a homemade knife moves along guides. The corner part of a workbench or table is used as such guides.

The sheet to be cut is placed on the surface of the table, and in order for the cut to be smooth and neat, it should be fixed in a stationary position. This can be done using two clamps and a wooden block of appropriate length.

A block is placed on the sheet, and then it is fixed on both sides with clamps, thereby ensuring immobility during processing.

Necessary materials

A machine for cutting sheet metal, constructed with your own hands at home, requires knives, the range of materials for which is very wide, and the choice of one of them mainly depends on the type and thickness of the material that will need to be cut.

If you have to work with not the most durable, thin sheet steel, such as aluminum, then the simplest bearings will be the ideal option.

But for the required functionality of a roller knife, they lack sharpening, which should be carried out independently along the entire end of the future tool.

How to cut sheet metal at home

In industry, roller shears are used to cut factory-produced sheet metal. Their distinctive features are high accuracy, long service life, and the absence of the need to make them yourself. Often in the household there is a need to obtain even strips of sheet steel, which are used for various purposes. If you need one strip, then there is no need to buy or make such a device, since you can use ordinary metal scissors. If you need to cut the entire sheet or carry out cutting work regularly, then it is imperative to acquire a roller knife.

There is no justifiable sense in buying such a factory-made device, since the price ranges from 15 thousand rubles or more, which depends on the design, size and quality of the device. Roller shears for cutting sheet metal can be made with your own hands at home, using available consumables for manufacturing. Although this method requires time, it allows you to save money, resulting in a universal cutting tool for cutting sheets of stainless steel, galvanized steel, etc.

This is interesting!

It should be noted that roller shears are only suitable for cutting flat sheets, and they cannot be used to cut sheets with protrusions and recesses, for example, corrugated sheets in the transverse direction.

How to make roller shears for cutting sheet metal with your own hands

Metal cutting is one of the most popular and widespread methods of processing such material. In this case, it is mandatory to use special tools that provide the ability to cut sheet metal, since it is unrealistic to do this without the use of additional devices.

Cutting technology consists in the fact that a workpiece made of a particular material is exposed to the cutting edge of a tool. The sharp cutting edge of the tool moves along the surface of the metal, cutting it. During this process, the cut layer undergoes plastic deformation.

Metal cutting at home

The main tools for cutting at home are cutters, discs, and drills. The use of such tools makes it possible to give the part the required shape, polish the metal surface, bringing it to the required dimensions.

When using such methods, a knife or other machine acts on the surface of the metal. In this case, it is very important that its cutter has a higher hardness than the workpiece, otherwise no cutting will occur.

The most common method of cutting metal in a home workshop is mechanical cutting. This method of processing the material is quite economical and can provide a very smooth edge to the workpiece. Its only drawback is that it usually only allows for straight-line cutting of metal.

Roller knives for metal

Very often in the modern metalworking industry, roller knives are used for cutting sheet metal.

The operation of such a tool consists of the work of its two main elements - cutting discs. Rotating in different directions, these roller discs are pressed into the material, cutting it.

Due to the friction of the metal and the knives among themselves, the workpiece moves along the tool.

The most common are roller knives for metal, which consist of two rollers. This tool has two rotating disks - lower and upper. Nowadays there are three types of knives:

- with parallel position;

- with one inclined;

- with several slopes.

The first group of such cutting tools is mainly intended for cutting material into strips.

The second group is intended for cutting metal into strips, as well as for round and ring workpieces.

The third group is mainly used for cutting annular, round and curved workpieces with a small radius.

All of these knives are well suited for quickly cutting sheet metal. In this case, the cut edge of the material does not require any additional processing.

Homemade roller knives

Design of a homemade roller knife

The cost of even the simplest models of roller knives is now very high. Therefore, it makes sense to purchase such a tool only if such processing of sheet metal will be carried out very often. Otherwise, for one-time or periodic use, such a purchase will not justify itself from a financial point of view.

In such a case, the more correct solution would be to try to make such a tool with your own hands.

There can be a lot of designs of roller knives, so making a knife yourself will not be difficult. But the main part of the tool - the cutting knives - must be made of the highest quality and durable alloy, the strength of which exceeds the material being cut. Otherwise, the quality of the cut edge will be very low and additional processing will be required.

Usually, even in factory models of roller knives, the resource is within 25 km of sheet metal 0.5 millimeters thick. If you cut sheet metal with greater thickness, then the service life of the tool will decrease. But after this, the rollers can be sharpened, as a result of which the tool will be ready for use again.

As for the service life of homemade roller knives, it directly depends on the quality of the material from which the cutting parts of the machine are made.

What can knives be made from?

Roller blade made of bearings

In the case of making such a tool yourself, the main problem is to choose the appropriate material that will cut metal workpieces.

So, if it is necessary to cut not the most durable sheet metal - aluminum, galvanized steel, etc., a good solution would be to use ordinary bearings, the ends of which must first be sharpened.

To cut such knives into metal, one of the rollers, the drive one, must be installed on a handle with which you can press the knives to the material. After this, all that remains is to pull the metal, holding the handle of the homemade machine pressed to the base.

The larger the diameter of the bearings, the higher the cutting speed of such a hand tool.

Thus, now you can find many designs of homemade roller cutting shears. The most difficult thing is to find parts that can be used as knives. To make it more convenient to use a do-it-yourself machine, it can be additionally equipped with guides that will allow you to cut the workpiece smoothly.

In this case, the finished tool, if necessary, can be installed on any metalworking equipment, for example, on a sheet bending machine.

Review and comparison of factory models

| Knife model | Trim Cutter 3017 | RNK 098A | for LBM machine |

| Cutting thickness, mm | 0,7 | 1 | 0,8 |

| Weight, kg | 4 | 1,11 | 7,92 |

| Dimensions, mm | 220*180*260 | 180*150*200 | 460*250*300 |

| Price, rub | 27163 | 39390 | 21019 |

Trim Cutter 3017 RNK 098A for LBM machine

Operating principle and design features

Unlike sheet metal shears with an inclined knife (guillotine), the movement of the knife in lever shears most often occurs not along a translational path, but along a rotational path. In addition, the main actuator is not a crank-slider, but a lever.

Lever scissors, assembled according to the single-arm lever design, have become most widespread. When cutting thin metal, with a thickness of no more than 0.7...0.8 mm, hand-held shears are used, and when cutting thicker metal, chair scissors are used, the lever of which is much longer. In addition, the chair scissors designs provide for the possibility of integrating an intermediate gear drive. This increases the length of the moving knife path, but reduces the resulting force, which is important if the unit is manually driven.

The largest versions of chair scissors allow cutting rolled steel sheets with a thickness of up to 8...10 mm, and long products with a diameter of no more than 22 mm.

Manually operated chair lever scissors are designed so that the driving arm is shaped like a saber. This makes it possible to bring the trajectory of movement closer to the operation of guillotine shears: the introduction of the moving part of the working tool into the metal being cut also occurs gradually. As a result, the current cutting force value is reduced. Non-powered (manual) chair-type scissors can cut steel up to 2…2.5 mm thick.

The typical design of desktop lever scissors is a combination of the following components:

- beds;

- eccentric or screw clamps, by means of which equipment can be permanently attached to a bench;

- lower support frame on which the fixed part of the equipment is installed;

- saber-shaped rotary lever with handle (for manual models). a movable part of the equipment is installed on it;

- axles with plain bearings.

In the drive lever shears, in addition to the above components, there is also an electric motor, a V-belt drive, as well as a crank mechanism, which converts the rotational movement of the motor shaft into the rocking movement of the lever. Sometimes such equipment is equipped with an activation mechanism (clutch and brake), and in this form they are not much different from stationary alligator-type scissors. Their only advantage in this case is the absence of a balancer to compensate for the inertia of massive parts.

We make roller shears ourselves from bearings

Various cutting tools, both manual and electric, are used to cut sheet steel. To cut a straight sheet of galvanized or stainless steel, you can take hand-held metal scissors, a grinder or a jigsaw.

But all these devices are not always convenient to use for cutting sheet steel. For such purposes, roller shears for cutting metal are also produced.

To avoid having to buy such a tool, you can make it yourself.

Instructions on how to make roller shears from bearings with your own hands

As already mentioned, there are many options for making a homemade roller cutting tool, but which one to choose for yourself depends not only on the capabilities, but also on the availability of the necessary consumables.

If you need a simple homemade roller knife, you can make it from bearings.

The manufacturing principle is simple, and first let’s figure out what tools and materials will be needed to make it:

- Two bearings 204 or 205. You can use other bearings that are available. They don't have to be the same size

- Corner 50-60 mm up to 30 cm long

- Threaded connectors, washers, nuts and other small consumables

- Steel tube from which to make a handle for roller shears

- The tools you will need are a welding machine, as well as a drill and grinder

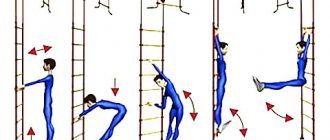

When all the necessary materials are ready for work, you can get down to business. Instructions for making a roller knife yourself are as follows:

- First you need to prepare a corner, since it will act as a body on which additional elements will be placed

- We grind the edge of the bearings. Moreover, this must be done in such a way that the resulting edge has an acute angle. On both bearings it is necessary to “remove” the edge, since the possibility of using the roller shears for their intended purpose depends on this

- Next, you need to drill a hole in the corner and attach one bearing to it. A bolt with a countersunk head is used for fastening. A washer is also used to secure the bearing, which will ensure reliable pressure against the wall of the angle

- The bearing is attached so that its outer race protrudes 1-2 mm from above the edge of the angle. It is important to provide for the possibility of adjusting its contact with the second bearing by placing washers on the inside

- On the reverse side, when securing the bearing, it is necessary to ensure that the head of the fastening bolt is recessed into the base of the angle. This is necessary so that the homemade tool can move freely along the edge of the workbench. If you can’t drown the hat, you can make a groove for it in the workbench design, which is also quite appropriate when using homemade scissors

- The first part of the work at this stage is considered completed, so you should proceed to the manufacture of the second part. This is the handle, the second bearing, and also the sheet bender

- Using a similar corner that is 2 times shorter in length, you need to attach the second bearing to it. First, using a grinder, you need to cut the corner into the shape shown in the photo below.

- It is necessary to attach the bearing to the end part of the resulting workpiece by first drilling a hole

- Weld the corner piece to the main part as shown in the photo. It is important to take into account that the upper bearing must be in close contact with the lower bearing, and its outer race must be located at a distance of up to 1 mm from the base of the angle

- Finally, you need to attach the handle to the resulting installation so that it is convenient to work

The result is a homemade cutting tool for cutting metal sheets up to 0.5 mm thick. When using the device, it must be taken into account that it is intended exclusively for working with sheet materials.

During operation, the edge of the bearings will wear out, so it is advisable to provide during manufacturing the possibility of adjusting the contact of the bearings.

All the details of the manufacture and use of such a tool are in the video below.

!When you rotate one bearing by hand, the second should also rotate, which indicates that the homemade product was manufactured correctly. The greater the distance between the end parts of the bearings, the lower the quality of the tool.

In conclusion, as an example, it is worth giving an example of how much a factory roller blade costs, as well as what technical parameters it has. For example, consider a Trim Cutter 3017 brand machine and its technical parameters:

- Maximum sheet metal thickness - 0.7 mm

- The weight of the device is 4 kg

- Overall dimensions - 220x180x260 mm

- Cost from 25,000 rubles

Based on the above, it can be noted that making roller shears for cutting thin sheet metal with your own hands is not at all difficult. This does not require a lot of effort and consumables.

With just 3-4 hours of free time, you can make a highly effective cutting tool at home.

With roller shears, you don’t need to think about how to cut a metal sheet when installing window slopes or how to cut galvanized sheets into strips, since with it any similar work is carried out easily, quickly and efficiently.

Lever shear device

The operation of manual metal shears is based on the principle of leverage. The cutting of the material is carried out by two cutting surfaces about 20 cm long. In this case, one surface is rigidly fixed to the base, and all the pressure is applied here. The movable cutter is also fixed to the frame. A groove is selected in the fixed blade to move the slider. It moves like a hinge in one plane.

The movable part of the scissors is attached to the slider. The working stroke of the slider is 15 - 32 mm. The movable panel is equipped with a long handle (about 50 cm), which increases the applied force by 20 times or more. Therefore, metal is cut quite easily.

The body of the lever scissors is metal, the cutting surfaces are made of tool steel. On average, the dimensions of the instrument are 56 x 18 x 45 cm and weighs about 30 kg. Using such equipment, you can cut a steel sheet with a thickness of 0.5 cm, aluminum or brass 0.6 mm, a profile with a section of 6x70 mm or a steel rod No. 13 with your own hands.

Homemade scissors for cutting thin sheet metal

Sheet metal cutting can be characterized as a technological process, as a result of which a metal product is divided into parts, acquiring specified shapes and sizes.

The article describes the processing of sheet metal, talks about methods of cutting metal, describes roller shears, automatic lines, etc., and also discusses special equipment for processing sheet metal (machine, cutter, etc.).

Cutting methods are divided into two main groups: mechanical and thermal.

Before choosing a specific type of cutting, you need to know the advantages of each type, the essence of the process, and in what cases a particular type of cutting is used.

Mechanical types of cutting

The basis of mechanical cutting is a cutting tool that has characteristics of strength and hardness higher than those of the metal being processed.

This processing method is also called cold. Mechanical processing includes guillotine, band saw, water jet and grinder cutting.

Cutting with scissors and grinder

To cut metal using this method, special guillotine shears are used, which can be used for thin sheet metals (profiled sheets, galvanized).

The cutting element is a knife. Guillotine shears can be mechanical, automatic, pneumatic, or hydraulic.

Manual and pneumatic guillotine shears have the lowest prices of all types of equipment designed for straight cutting of metal.

However, an inexpensive tool has low productivity, so you have to put in a lot of effort.

Therefore, preference is most often given to special power tools or industrial equipment, which are much easier and faster to work with.

An electric tool is an angle grinder (angle grinder).

Cutting and bending with a grinder is highly not recommended for metal with polymer coatings, for example, metal profiles, metal tiles.

This is due to the fact that abrasive wheels reduce the protective characteristics of the metal. When cutting with a grinder with your own hands, you must follow safety precautions: your eyes and hands must be closed.

The main danger when working with an angle grinder is the flying of fragments.

Effective cutting with a grinder is carried out by the heel of the disc - the near lower part of the circle. The tool must be turned off every 5 minutes to avoid overheating.

If you are cutting long pipes with a grinder, you need to start from the hanging edge. Thick parts are cut straight with a grinder.

Guillotine shears work according to the following principle: the sheet for cutting is located on the table between the knives.

The metal must be pressed against the table with a beam, and then the upper knife must be moved.

Guillotine shears provide precise cutting of metal, which is explained by the clamping mechanism. Guillotine shears are designed for longitudinal and transverse cutting of sheet metal. This slitting device is the most popular.

Another type of tool is applicable for square, round and angular metal, due to the fact that the knife is positioned at any angle. The main characteristics of the device are the length and thickness of the cut.

Guillotine shears provide an even cut without roughness; the knife does not spoil the paint and polymer coating and the characteristics of the product being processed.

There are also disc shears for longitudinal cutting, which is carried out with rotating round knives.

The lower and upper disc knives rotate in different directions at the same speed. The movement of the workpiece is ensured by friction against the knife.

:

Disc shears work like this: the sheet being processed is placed on the machine and inserted between the support and clamping rails.

Then the sheet is fixed with clamps and the disc shears move along the cutting line. When the disc shears begin to rotate, the knife cuts the product.

Disc shears are easy to use when slitting metal yourself (especially if the cutting lines are pre-marked). The knife produces precise and high-quality cutting.

This tool is intended for longitudinal cutting only. Automatic lines are quite popular.

Automatic lines consist of a feeding device, an unwinding device, a material feeding mechanism, a cutting unit and a control panel.

Automatic slitting lines have the main advantage: there is no need to involve people, since all operations on the line are carried out under the control of one person.

Roller shears are often used. The roller knife is used for straight and shaped cutting. The roller knife is suitable for cutting round, oval, and square shapes.

Types of lever scissors

The designs of lever cutters do not differ in variety; the main difference is in the type of drive:

- manual - the most primitive device; by pressing the lever, the cutting blade is set in motion;

- electric - they work very quickly and are highly efficient. Cutting metal on such equipment does not require any effort from the worker;

- hydraulic - powerful, driven by a hydraulic drive. Widely used when large forces are required, for example, for cutting reinforcement or rods.

Hand scissors are divided depending on their purpose and design:

- with straight blades - used only for cutting in a straight line;

- with curved cutters - they are used to cut out complex shaped elements and holes;

- chair - used for cutting thick layers of paper;

- finger - make holes with very thin incisors;

- lever - permanently mounted on a workbench.

The manual lever attachment allows for through or straight cutting on a straight line only.

In addition, the tools differ in the length of the actuators:

- with short blades for through cutting;

- with long cutting surfaces - for straight cutting;

- combined scissors for all types, including contour scissors.

Cutting small parts with lever scissors is impossible; they are convenient for large cutting or chopping work.

The tool can be stationary or portable. For work, both types are firmly fixed on a workbench or bed. This is the only way to cut metal accurately and safely. To secure portable scissors, use clamps or bolts.

Characteristics of scissors

The intended purpose of roller knives is to cut steel sheets up to 1 mm thick. They are necessary at the site for the production of ventilation ducts, when working with roofing metal, when building a fence and arranging the roof.

The mechanism is used to produce semi-finished products for subsequent bending of profiles for various purposes. The equipment is installed in car body repair shops. In auxiliary production, blanks are prepared for the assembly of racks and cabinets.

Roller scissors can successfully replace the manual version or guillotine due to a number of advantages:

- Compact dimensions and light weight.

- Simple device.

- Convenient to use.

- Just getting set up.

- Suitable for working with sheets of different materials: aluminum, tin, steel, roofing iron.

The processed product is obtained with a clean cut and no burrs or bends. It is easy to cut sheet metal with such a device.

Scissors can be purchased at a specialized store or made independently. It all depends on the volumes performed and the economic component. With a daily cutting rate of 30–50 meters or more, an industrial design will be required.

Manufacturing instructions

Factory models of cutters sold in stores, even in standard configuration, will cost a large amount. The price of models offered on the market starts from 20,000 rubles. Such conditions are not beneficial for purchasing a tool for home use or a small workshop, and it will be used extremely rarely.

To begin with, the main body of the instrument is designed, which everyone chooses for themselves. The main attribute of the machine is manufactured - a roller knife for sheet metal. The material from which the part is made directly affects the durability and performance of the unit. As mentioned above, the strength characteristics should be significantly higher than the similar characteristics of the material being cut. Otherwise, the minimum problem will be a low-quality cut, forcing the craftsman to clean and process the edges of each cut piece.

Scheme for assembling a roller knife

Do-it-yourself roller metal shears are mostly made from bearings. Sharpening the ends of the part forms the cutting surfaces. The main roller, connected to the drive, is attached directly to the handle. The lower one is installed on the fixed lower part of the machine. If you have skills in processing iron alloys, manufacturing such a device will take a maximum of a little more than a week, including setting up the unit.

Industrial design or own design

Circular knives for cutting metal are produced industrially, but you can make them yourself. To decide whether to create a tool manually, you need to consider a number of factors:

- Intensity of equipment operation. For an enterprise that produces goods in serial and medium-sized batches, it is better to purchase an industrial design. Combined with the quality of the workmanship, you will have the ability to fine-tune the instrument. An additional plus is the ergonomic design, which improves ease of use.

- Required cut quality. At home, creating a device that provides accuracy of tenths of a millimeter is quite a difficult undertaking.

- Economic component. An industrial product costs 20-70 thousand rubles (knife only). The real costs of making your own instrument (except for labor) rarely exceed 5 thousand rubles. Moreover, this amount includes the supporting part (machine).

- Time factor. Designing and manufacturing a knife will take up to two weeks. A factory product is purchased in one to two hours. Your own knife will cost less, but there is a proverb that came from abroad: “time is money.”

Hence, solving everyday problems or a small workshop is a tool created on your own. Intensive operation: daily cutting length is more than 20-50 meters - it is necessary to purchase industrial equipment.