When working with wood, one of the most popular tools is a circular saw. This device, characterized by productivity and convenience, can significantly speed up the process of sawing moldings or sheet materials. When carrying out work in significant volumes, it makes sense to think about making a special stationary structure with a saw, which will improve the safety, speed and quality of the work.

DIY table for a circular saw - drawings

Materials

When assembling a cutting table from chipboard with your own hands, you should maintain an optimal balance between functionality, safety, time and money. This can be achieved by selecting parts and materials with the necessary parameters. It is possible to reduce costs by using old parts of other structures - furniture, frames of wooden houses and outbuildings.

Tabletop

The main requirements for a saw table are resistance to heavy loads, shocks and vibration. The tabletop must be smooth enough to move and not bend under a weight of 50 kg or more. Suitable options might be:

- Metal (steel or duralumin) 3–5 mm thick. The advantages of metal countertops are high strength, almost unlimited service life, the disadvantages are heavy weight, decent cost.

- Laminated chipboard or moisture-resistant plywood with a thickness of at least 2 cm. The cost of this option will be the most profitable, but the strength is noticeably reduced.

- Textolite 15–20 mm thick. The material is more durable than plywood, but inferior to metal. In terms of cost, textolite countertops are also between metal and plywood sheets.

Plastic, chipboard or OSB are not recommended as countertop materials. A structure made from this raw material will be unstable to vibration from the saw. It is possible to make a table entirely from natural wood, but it is too expensive.

Metal

laminated chipboard

Textolite

bed

At the base of the table for sawing boards there can be wooden beams, secured under the lid to increase rigidity. Elements with a cross-section of at least 5 x 5 cm are placed at a distance of 50–90 mm from the edge of the tabletop. For the sawing table, it is recommended to choose bars made of hard wood - beech, hornbeam, oak. The advantages of wood are low cost, easy installation using self-tapping screws. Disadvantages - less strength and service life, high probability of fire.

The upper part of the table frame for cutting chipboard and other materials is often made by hand from the same sheets that were chosen for the table top. For the legs of a wooden structure, it is recommended to use timber, securing it with metal corners. The pros and cons of wooden supports are similar to the features of a frame made of the same material.

The basis of the table for cutting and sawing boards can be metal. Stability increases when choosing metal corners or channels with sides of 25–50 mm. To save money, they are purchased at scrap metal collection points or replaced with profile pipes. The frame parts are connected by welding. The use of bolted connections is not recommended due to the possibility of loosening due to vibration. The reasons for choosing a metal frame are maximum strength, reliability, and easy maintenance. Disadvantages: high cost, need to use a welding machine.

Metal

Wooden beams

Chipboard plywood

Additional accessories for convenient work

On the tabletop parallel to the disk, lines are drawn every 10 cm to help cut the wood to size. Markers alone are not enough; you will need a longitudinal stop. It is convenient to use a profile pipe for its manufacture. It should move freely on the tabletop to install the required size and be fixed in the desired position.

One of the design options: transverse grooves 10 mm wide need to be made in the surface of the structure. In the thrust strip, 2 holes are drilled along the edges for M10 bolts. They fix the stop, threading the tabletops and planks through the body. This method weakens the product a little.

Use another option. The stop is cut 20 cm longer than the length of the table. On each side, 10 cm of timber is glued, the thickness of which is equal to the base of the structure. Iron plates of 3–5 mm are fixed to them with self-tapping screws. It turns out to be a bracket that clings to the table. Drill holes and weld an M8 nut. Screw in the bolts, preferably with wings. They fix the stop in the desired position.

For convenient cross-cutting, a sled is made. The structure is pressed against the table and moves along the disk.

Features of a circular saw

Knowledge of these features is extremely important; you must take into account the operating modes of the saw, know the type of loads and take all possible measures to strengthen the most important components. Only with this approach can long-term and safe operation of a homemade machine be achieved.

What are the common features of woodworking machinery?

High speed saw teeth. This ensures the quality of sawing. But high speeds of the saw blade cause serious injuries; during the manufacture of the machine, great attention must be paid to safety precautions. All devices available on industrial copies must be installed without fail. Do not think that some of them are superfluous, and you will be able to modernize factory samples for the better. All safety rules are written in the blood of injured people, do not repeat tragic mistakes.

Strength of all nodes

This means the inability to withstand significant static loads, although this is very important. The table can easily absorb large forces of this type, but at the same time vibrate under the influence of even relatively minor dynamic multidirectional loads. This condition does not have a negative impact on safety, but noticeably deteriorates the quality of the cut.

Marks of teeth are noticeable on the surface of lumber, it is difficult to maintain specified linear dimensions, etc.

Fire and electrical safety. Absolutely all electrical devices, motors, starters and other special fittings must be installed in strict accordance with the requirements of the PUE. You need to know that dry sawdust not only burns well, but also forms an explosive mixture at a certain concentration in the air. By the way, burning sawdust is difficult to extinguish; it floats on the water and continues to burn.

There is no need to make the simplest machine at the expense of safety devices; strictly follow the recommendations of the designers. Decide what you need, a woodworking machine or fresh problems?

Device

Stationary saws are installed on a base - a frame, the rigid design of which, coupled with the engine power, allows sawing large workpieces up to logs.

To install such a massive unit, floor preparation is required. As a rule, a concrete foundation is made for the machine.

The polished work surface is also made of steel or cast iron. In lighter versions, the table top can be made of aluminum; a groove is provided in its surface, allowing the saw blade to rotate freely.

The working surface is equipped with various kinds of guides necessary for adjusting the width of the workpiece being cut, the inclination of the cut, etc.

Under the tabletop there is an electric motor that transmits torque to a pulley, which serves as a support for the saw blade. On stationary machines, the engine force is transmitted to the gearbox and only then to the pulley. A belt drive is most often used, but there are models with a cardan method of transmitting torque.

The disk is covered with a protective casing. On many models, a riving knife is attached to the tabletop immediately behind the disk, which prevents the sawn workpiece from coming back together under the influence of the elasticity of the wood fibers - this is another element of the tool’s safety system.

There are models with the ability to tilt the saw blade, allowing you to cut at different fixed angles.

Sometimes additional expanding elements are provided for the main work table to increase the working surface of the machine.

Some models are equipped with a redundant emergency switch.

Adviсe

- Before you start using an electric saw on a table, you should check the blade of the saw itself using a square, since some unscrupulous manufacturers do not install the blade exactly at an angle of 90 degrees, as a result of which the cuts end up beveled.

- If during work you plan to use the table also to store tools on it, then the dimensions of the tabletop should be larger than a square meter in area.

- For manufacturing it is better to use high-quality and durable materials, otherwise the table will not last long.

- The table can be supplemented with anything you like, for example, some manage to attach a special vacuum cleaner or a riving knife with protection for the disk to it, so that shavings and residues from cutting wood do not fly to the sides.

- Select a place to install the table in advance, and also make sure that the floor where the table will be installed is level.

- If you have the desire and certain skills, you can make a folding tabletop or a lifting table, but this will require more time and materials.

- If the table wobbles or vibrates during operation, adjust the height of the legs using suitable pieces of rubber.

The benefits of making it yourself

The table is made taking into account the fact that the hand tool will be installed and secured on the table, thereby turning into stationary equipment

Constructing the element with your own hands allows you to make the saw most suitable for individual conditions. There will be no difficulties in the process if you carefully study the issue. You can adjust the product to the desired size, distribute everything so that it is convenient for you.

Making a table for a circular saw is within the capabilities of every craftsman.

A handcrafted model will be one of a kind, which makes it unique.

Small table stand for circular saw

Table saw

When choosing a circular saw, you need to be guided by the following characteristics:

- Saw power. If the amount of work is quite large, it is advisable to take a tool with a power of at least 1.2 kW.

- Cutting depth. The thickness of the material to be processed depends on this parameter. For hand saws it is 40–70 mm. But when installing it in a table there will be a decrease of around 10 mm.

- Button placement. The design of the sawing table must provide free and safe access to all control buttons, otherwise it will be necessary to modify the control system yourself.

- Rotational speed. For cutting wood, high rotation speed is preferred. This affects the cutting quality. For plastic, for example, this is not very good. Due to the high rotation speed of the circle, the plastic heats up. You need to choose average characteristics. 3-4 thousand rpm will be enough.

Blueprints

Diagram for making a table for a circular saw

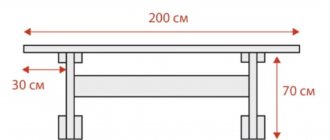

Before starting work, it is recommended to go through the preparatory stage. You should definitely make a drawing. This will make the design creation process easier. First, calculate the dimensions of the table, then transfer the data obtained to paper. The hole made in the structure must exactly match the dimensions of the saw. It all depends on the brand of equipment. Therefore, it is impossible to make a universal hole. The base must be stable and withstand mechanical loads well.

DIY table drawing for a circular table

It is unacceptable to overhang the structure to one side. The dimensions of the tabletop must be suitable for the sawing flow. The final option is determined based on individual desires. Some people work comfortably with a folding table or a product with small dimensions.

Drawing of a universal tabletop machine

An important point should be taken into account in the drawings. If you plan to leave tools or materials on the table while working, then the dimensions of the tabletop need to be increased to a square meter in area. A suitable size would be 120 by 120 cm. You should draw the drawing carefully and slowly in order to do everything correctly.

Table diagram for a circular table with a detailed description

Selection of dimensions

It is worth choosing the size of the sawing table depending on the square footage of the workshop. The small area of the room allows you to use a tabletop of 50 x 50 cm. Making the sawing table smaller does not make sense - it will be difficult to use it when processing long workpieces. The universal size, ensuring convenient sawing of laminated chipboards, is 80 x 80 cm.

To comply with safety requirements, it is recommended to place the saw in the middle of the tabletop at a distance of at least 25 cm from the edge - it is this indicator that leads to the minimum width of 500 mm. The location of the saw blade also depends on how it will be used. There are three types of design:

- for longitudinal sawing;

- for cross cutting;

- universal.

The depth and location of the disk installation depend on the workpieces processed on the machine. For boards and plywood, it should protrude above the tabletop by 50-80 mm, for logs - by 110-125 mm. The height of the upper part of the frame made of sheets of plywood or chipboard can be in the range of 35–40 cm. If you make the frame only from timber, this parameter depends on the cross-section. The remaining part of the structure consists of wooden legs, the size of which craftsmen usually choose to suit their height. The overall height of the sawing table is about 1.0–1.1 m, but can be reduced to 900 mm.

Manufacturing technology - step-by-step instructions

Take a sheet of plywood and mark the dimensions of the tabletop. The edges are carefully cut with an electric jigsaw, then the edges are processed with a router. The workpiece is sanded with medium and fine sandpaper. On the lower plane, mark a place for a circular saw: remove the disk, apply it with a sole and trace it with a pencil. Using a milling machine, a recess is selected, the size of which depends on the thickness of the base of the tool.

Table diagram for manual circular saw

The saw is installed at the mounting location and adjusted if necessary. If everything fits, 4 holes with a diameter of 10 mm are drilled in the sole. Again, apply the tool, mark the fastening points in the tabletop and make through holes. On the side of the working plane, recesses are made for M8 bolts with a countersunk head. The hat should be hidden in them. Cut a slot for the disk 1–2 mm wider than its thickness. If you plan to cut at different angles, it is made trapezoidal with the top pointing down.

Start making stiffeners with your own hands, starting with the longitudinal ones. The location is 10 cm away from the edge of the table; it is marked with lines at this distance. The boards are cut to length, applied to the tabletop, and outlined. Mark a central line along which the location of the screws is indicated. The extreme ones are 5 cm away from the end of the ribs, the intermediate ones are 20 cm apart.

Through holes are drilled and countersunk on the front side of the tabletop for the caps. Coat the workpieces with wood glue, install them in place, and tighten them with clamps. The transverse stiffeners are fixed in the same way. They are fastened to the table and to each other with self-tapping screws.

The legs are shaped to provide maximum support for the frame. Typically, the height for comfortable work is 1–1.1 m. They are wider at the top and narrow towards the base. To do this, one side of the bars is cut lengthwise at an angle. They will stand a little apart in relation to the tabletop. Steel corners at the joints will help increase rigidity. For fastening, bolts are used, which are installed with the heads outward, and washers are placed. Braces made of beams are also used.

Some budget tools have a defect - an imperceptible tilt, which differs from the required 90°.

Before putting the saw in place, use a square to check the position of the blade relative to the sole. If it differs from a right angle, strips of tin are placed under the base on one side to achieve alignment. The circular is attached to the tabletop with M10 bolts, and growers are placed under the nuts.

Safety requirements

One of the most common causes of injuries when using a circular saw is a cluttered workplace.

In addition, it is important to monitor the stability and strength of absolutely all components of the system, and if there is imbalance, take measures to eliminate difficulties. Before connecting the saw, you must make sure that it is well secured. If necessary, tighten the screws/bolts. It is strictly forbidden to hold the material close to the cutting site! This is dangerous due to the rebound of knots and shavings into the eyes or onto open parts of the body.

Be sure to wear glasses before work and clothes with sleeves.

Making your own saw table is not as difficult a task as it might seem. If you have good material at hand, its characteristics are chosen correctly, and the power of the device ranges from 500 to 1000 W, the above instructions will be the basis of the work.

You should not lose sight of the fact that at any stage of table production you should control the accuracy of your own operations. Otherwise, if deviations in size or deformation of the legs appear when the ribs are tightened, it will be very difficult to restore stability. Nevertheless, making a table for a circular table with your own hands is an absolutely realistic task that will take several hours.

Deciding on design and construction

The simplest version of a table for a circular table is a design made of fairly thick plywood and boards

The base can be made of wood or metal. Leaf tree species are chosen for the tabletop. A special hole should be made in it for the disk. The key property of the created table should be convenience.

Circular machine bed

Care should be taken to ensure its stability. No loosening is allowed, otherwise it will negatively affect safety. The tabletop should have as smooth a surface as possible. This will reduce the likelihood of injury while working.

A table for a circular saw requires the presence of guides

The structure can be supplemented with a special riving knife. He can be removed. It is equipped with a special disk protection that allows you to get rid of chips flying at the worker.

Table guide carriage for circular saw

Some people remove the factory cover and replace the factory platform with a homemade one. If you are not going to cut at an angle, you can remove the parts that adjust the tilt of the blade.

Other types

If for some reason the plywood rail does not meet your requirements, you can make the guide of a more complex design. Below are a few more examples of guides for a manual circular saw that anyone can make with their own hands.

Aluminum profile tire

This type of tire differs from a simple plywood tire in that a U-shaped aluminum profile is installed in the guide gap. Its advantage is that the rigidity of aluminum slightly increases the cutting accuracy.

For better sliding of the saw along the bar, as limiters, you can attach not thick plywood to the guide groove of the sole, but a pair of cylinders of suitable height made of fluoroplastic or other material with a low coefficient of friction.

Ruler from a building code

There are long aluminum rules that are used by finishers to level walls. To make a guide ruler with your own hands, rules are suitable, the design of which provides a groove for the free movement of the handles.

The main advantage of such a line is the absence of elements protruding above the surface of the workbench. To do this, you need to take two collapsible clamps and slightly modernize them.

The handles are removed from the rule, and their upper parts from the clamps, which are replaced with polypropylene or fluoroplastic inserts. The profile of these inserts must be T-shaped so that they can be installed with the wide part into the rule groove and be held there.

The result is a ruler that is attached to the workbench only at the bottom. This will allow you to move the saw freely in the work area without fear of getting caught on something.

However, such a tool cannot be called a full-fledged tire. This is the ruler that needs to be adjusted before each cut.

Rail miter box

This device is most often used for cross cutting (trimming) of material.

Usually it consists of two parallel metal corners, the ends of which are rigidly fixed to a plywood or metal base.

The saw platform moves freely along the corners, as if on rails.

The corners are secured with bolts or studs, which are also used to adjust the height of the “rails” relative to the base. The height should be such that the material to be cut fits freely under the corners.

To make the saw movement smoother, the corners on the inside can be glued with a material with a high slip coefficient. For even smoother movement, you can install the saw sole on a platform with metal wheels.

External carriage on bearings

A circular saw on an external carriage is more like a stationary format-cutting machine. This design is highly stable and, accordingly, provides high cutting accuracy.

The remote carriage is made of a metal I-beam, which is firmly attached with its lower plane to the workbench. The carriage itself moves along the upper plane - a platform, the lower edges of which are bent inside the I-beam and are equipped with bearings that allow it to slide freely. These same bearings, tightly pressed to the I-beam axis, eliminate lateral play of the carriage.

The saw sole is attached parallel to the carriage on the external guide. The guide can be made of two parallel angles or pipes - thus, by moving the sole of the saw, you can adjust the size of the cut of the material.

This design is good because the saw support platform is adjacent directly to the workpiece, which means the cutting depth is not reduced.

Expansion of functionality

In conclusion, let’s touch on the topic of expanding the functionality of the working structure you are making. If there is free space on the operating surface, additional woodworking equipment (an electric plane or router, for example) can be mounted. Having a plane and a wood router will allow you to expand the functionality of the machine and turn it into a full-fledged woodworking center.

In addition to this, such a milling cutter can be equipped with a special mechanism for adjusting the position of its working part, which can be changed within specified limits (the so-called elevator).

Stationary mount for circular saw

This simple device slightly increases the cost of the saw, but significantly expands its functionality. This is especially true for powerful, heavy devices. The stationary mount is:

- a pair of clamps that secure the mechanism to the workbench;

- a pair of legs;

- plate fixing the protection;

- clamp for the start button (the button is clamped in the “ON” position).

There are holes for fastenings in the upper part of the tool body. Once installed, three support points are formed that hold the saw securely and firmly with the cutting teeth up. The result is a mini-circular machine with a working surface equal to the platform. Very convenient for cutting a large number of small parts.

Installing the saw on a stationary mount

- Attach the legs: take out the plug-bolts and instead screw in the bolts to secure the legs.

- We attach the plate that secures the protection. The protection must be inserted into the body and pressed with a plate.

- Using clamps, we attach the tool to the workbench, inserting the hooks into the special holes.

clamps for fastening

Only specially designed models are installed upside down! Otherwise, the tool may be overloaded or the disk may jam, leading to expensive repairs. Many manufacturers of hand-held circular saws warn against using the tool upside down. Look for information about this in the operating instructions.

There are few models on the market with the possibility of permanent installation. These are mainly domestic products. Distinctive properties are the large diameter of the circle and a powerful electric motor.

| Soyuz TsPS-50200 | EPD caliber - 2100+St | Craft CCS 2200 | Baikal | Rebir RZ 2-70-2 | Interscope DP-2000 | |

| Power, W | 2500 | 2100 | 220 | 1500\1800 | 2150 | 2000 |

| Idle speed, rpm | 6000 | 4800 | 5500 | 3700\4100 | 6000 | 4200 |

| Disc diameter, mm | 200 | 200 | 200 | 200 | 205 | 235 |

| Max. cutting depth, mm | 58 | 65 | 68 | 70 | 72 | 85 |

| Tilt angle, degrees | up to 45 | up to 45 | — | up to 45 | up to 45 | up to 45 |

| Weight, kg | 7 | 6,6 | — | 5,7 | 6,7 | 7,8 |

Table 1. Characteristics of some models of circular saws with table mounts presented on the domestic market

Finishing

After manufacturing and assembling the circulation table, to simplify working moments, it is advisable to apply markings .

It is this that will make it easier to cut materials. To extend the life of the product and increase its aesthetics, a hand-made table can be primed and varnished . These manipulations will also prevent the lumber from sliding on the surface and protect the product from increased moisture.

Ergonomics

When designing a circular saw, manufacturers try to arrange all the components in such a way that the tool is as convenient to use as possible. Some manufacturers do this better, others worse.

To appreciate the convenience, it is enough to pick up several different models. Even with the engine not running, the difference in weight and arrangement in the center of gravity will be immediately noticeable.

Everything matters - how comfortable the handle is in the hand, what kind of coating it has, the total weight of the tool, whether the saw hangs freely in a horizontal position, or whether you have to make an effort to level it into the working position.

Especially for left-handers, there are models on sale that are made in a mirror arrangement.

The availability of an overview of the sawing direction risks in front of the platform is also important. They are guided by them in order to make an even cut according to the markings.

Sawdust removal for all models is organized through a pipe. If desired, you can attach a bag for collecting sawdust or a vacuum cleaner hose to it so as not to clog the workspace.

The vacuum cleaner is connected quite rarely. But without it, some budget models already have a disadvantage during operation - the outlet pipe can constantly become clogged with sawdust, especially when sawing raw wood. This happens more often if the pipe is small in diameter and has a complex shape.

Guide rail functions

When using high-performance hand-held power tools, the question of the quality of the work performed is always relevant. High quality largely depends on the professionalism of the craftsman working with the tool. Therefore, in addition to the basic configuration of most electric circular saws, it is recommended to use additional accessories. These devices make work easier and ensure high quality work, even when used by beginners.

The circular saw guide has many features that make working with the tool much easier. Among these important functions it is worth noting:

- ensuring high accuracy when cutting large material;

- the guide allows you to ensure correct cutting with high accuracy;

- when working with the device, you can not only cut in a straight line, but also perform work on making a curved cut;

- When using a guide, the workpiece is easily and accurately cut both in the longitudinal and transverse directions;

- with this device it is easy to process workpieces to one standard;

- the device makes it possible to process several workpieces using one template;

- Working with a guide bar ensures a high degree of operational safety.

Saw wheel compatibility

Saw blades vary in number, shape and size of teeth, material, seat and outer diameter. 32 discs cannot be mounted on a 30 mm cartridge. A large disk with a diameter of 200 mm will not fit on every low-power circular saw.

The number of teeth on a wheel determines the capabilities and quality of work. So, with more teeth, a better cut is obtained. For cutting pressed boards, discs with 36 - 48 teeth are optimal. To work with a board, 20 - 24 teeth are enough. Discs with carbide surfacing are more durable; they are capable of sawing even a nail accidentally driven into a board.

Based on the shape of the teeth, discs are divided into active (sharpened at a positive angle) and passive (sharpened at a negative angle). The alignment of the teeth along the direction of movement of the saw wheel is characteristic of a positive sharpening angle. And the wiring against the movement is for negative. Solid materials are sawed with passive discs (metal alloys, tin), and wood and plastic with active discs. If you cut wood in a circle with a negative sharpening, the cut will turn out torn, with protruding fibers.

Videos about the design and modernization of the manual circular saw Baikal 514: