Circular saws are essential tools for the household. Thanks to their technical and functional properties, today not a single furniture production or carpentry shop can do without them. And in private households there are many problems that would be more expedient to solve with their participation. The only thing that limits their use today is their cost, which is growing every year, as is the human need for them. One of the ways to overcome this barrier and acquire such a universal assistant is to assemble a homemade circular saw,

Considering the load and operating cycle of electric saws, for their home production you will need an equally reliable basic electrical appliance. Craftsmen advise using a grinder or an angle grinder, which almost everyone has. Its traction potential will be sufficient for sawing wood, cutting beams into slats and other tasks that most users set for it. Let's look at several ways to make an electric saw from a grinder at home.

DIY circular saw: the easiest way to make it

In order to start assembling a homemade product, you will need:

- metal clamps;

- electric drill;

- toothed disc;

- several pieces of metal corner;

- bolt ties modifications M3 or M5;

- working gearbox;

- rods made of high-strength steel;

- wrench.

The power base of the future design will be the engine from a household grinder.

Work progress step by step

- the previously installed disk is first removed from the grinder;

- Take a disk with teeth for woodworking, which is tightened with corners. A gap of several millimeters is left, which is adjusted using a bolt tie;

- The body of the grinder - the future electric saw - is covered with clamps. A double metal strip with a thickness of at least 1.5 mm is passed through the bottom of the tool;

- The grinder gearbox is pre-disassembled. You need to make holes in it to attach the handle. The last part can be made of a metal tube, the shape of which should be slightly rounded;

- to adjust the gaps between the side stop and the base surface, 4 holes are drilled in the gearbox for screwing in bolts;

- The handle is bolted to the gearbox. Its end protruding outside the electric saw is given a horizontal position, holes are drilled and the axis is fed. If the handle is D-shaped, an adapter is installed between the handle and the gearbox - a tube made of thick-walled metal;

- the rods are cut into 6 cm pieces, which are given a loop shape;

- washers are fixed in front of the stop, thereby correcting the gap;

- the handle is connected to the body with an electric motor.

By supplementing such an electric saw from a grinder with your own hands with a stationary base made of chipboard or stable plywood, you can make a stationary circular electric saw for a workbench or desktop.

In both options, it is very important not to make a mistake with the choice of disk and to correctly calculate the gear ratio. It is advisable to focus on single-phase asynchronous motors, which are equipped with most angle grinders. Three-phase motor systems, which can also take place in a similar design, should not be used without additional capacitors. A separate button can be used as a starting capacitor. In this option, you will need to consider additional grounding and check the electrical safety of the homemade product.

The nuances of using a homemade circular saw

You should not lose sight of the fact that the grinder’s main purpose is as an angle grinder. Therefore, when using it as a homemade circular saw, you need to pay attention to the nuances.

- The duration of continuous cutting should not exceed 15-20 minutes to avoid overheating of the engine.

- The standard guard on the blade is not suitable for a circular saw. The protective casing can be used from a real circular saw or made independently.

It should be remembered that the rotation speed of the sander can be more than 10,000 revolutions per minute - this is several times higher than the speed of woodworking machines. At this speed, the wood begins to smoke. In addition to the unpleasant odor, fire may occur.

Electric chain saw from an angle grinder: step-by-step instructions

In order to recreate a chain saw based on a working grinder, we will need:

- Bulgarian herself;

- drive sprocket, which is best bought new, but if you have a working spare part from an old saw, you can limit yourself to the used option;

- metal to create a bracket to which the guide will be connected;

- a set of saw sets consisting of a bar and chain;

- a set of tools, including a drill;

- bolts.

The build process looks like this:

- unscrew the saw blade from the grinder;

- make holes in the bottom of the metal casing of the device;

- bolt the bracket to the protective shield;

- a sprocket is screwed onto the motor shaft;

- a guide is secured behind the bracket ties;

- After the chain is put on and straightened, the bracket bolts are tightly fixed.

After this you can start working.

Reciprocating saw or jigsaw? What is the difference?

In fact, the “Sabre” is an electric hacksaw that appeared back in 1927 (of course, not in the same form as it is now). Intended for cutting wood and some metal materials, which it does very well. The narrow and long shape of the tool allows you to work in the tightest spaces. In addition, when selecting the required blade, Saber cuts stone, ceramics, foam blocks, some composites, plastic and glass. Small reciprocating saws are convenient to work while suspended.

The reciprocating saw and jigsaw can be called distant relatives. They are similar in many ways and at the same time they are opposites that complement each other. Therefore, many come to the question: “What is better to choose?” One of the main differences is that the jigsaw allows you to cut oval, round and wavy profiles, while the Saber is only available in rectangular ones. In addition, the jigsaw produces more accurate cuts, while the opponent is a kind of “destroyer”, compensating for sloppiness with speed. Obviously, both mechanisms have their advantages over each other, so it is wrong to say that one is better than the other.

But with a combination of these two devices, perhaps we will get something special. Let's finally find out how to assemble this indispensable household tool yourself.

Advantages and disadvantages of homemade electric saws from an angle grinder

Electric saws, which today can not only be bought in a store, but also made at home, in addition to their main advantage - low cost of their production, have a lot of weaknesses. Namely:

- low level of safety for the health and life of the operator working - in homemade products there is no protection against kickback, which in factory electric saws is taken over by the inertial chain brake. And this increases the likelihood of injury and injury;

- fragility of tire-chain elements due to the lack of automatic lubrication. The only way out in this situation is to periodically dip a homemade saw into a container with chain oil;

- high risk of motor overheating from an angle grinder due to overloads and prolonged use.

What is a reciprocating saw and what is it used for?

The first part of the question is somewhat easier to answer than the second. But let's try. An electric reciprocating saw is a universal tool, similar in appearance to a drill and a jigsaw. According to its characteristics, it is a cross between a chain saw and a jigsaw. The design consists of a body and a cutting blade. The “heart” of this mechanism, the electric motor, as well as all the main components, is located in the housing. We will look at the nodes and their impact on ease of use in more detail below.

So, what is it for? Let us immediately note that it is universal, that is, it cuts almost any material. It can be said, although with reservations, that this instrument has absorbed the qualities of 7 other instruments, and in some cases can easily replace them. These tools are the following:

- - lopper;

- - hand saw for wood;

- - circular saw;

- - jigsaw, especially in cases where the cut size is more than 100mm;

- — electric chain saw (in some cases, depends on the volume and nature of the work);

- - hand hacksaw for metal;

- — Angle grinder or “ grinder ” (also with reservations...).

As you can see, the scope of application is wide, from gardens to professional construction. It should be noted that the fashion for this tool came from the West, and the “there” consumer has one feature: any work should be performed with a specialized tool. There is some truth in this, and not a small one, since, ultimately, it turns out to be both faster and safer. In our mentality, the approach is somewhat different, and there is also some truth here, we are not so rich as to purchase a special tool for a one-time job. We would rather take a different path, and having “raped” the tool available to us, and often spoiling it with this action, we will still achieve our goal. Perhaps this is why clear agreement on the need for this tool has not been achieved.

Read also: Construction of a hexagon circumscribed around a circle

So are there cases when a reciprocating saw will be a faithful assistant? Yes there are, here are the situations:

- Garden work on pruning trees, yes, you can use the old method using a hand saw, but if you can make your work easier by using a reciprocating saw, why not? But there may be one problem here - financial, if it is not there, then this tool will definitely make life easier.

- When dismantling dilapidated wooden structures. A chain saw will be faster, but... If there are metal objects, such as screws or nails, you of a chain saw. However, a reciprocating saw with the appropriate blade is easy and absolutely safe.

- Cutting pipes and fittings in places where other tools cannot be reached. We install the required canvas and the problem is solved.

These are just some of the uses for reciprocating saws. But perhaps one of the most important advantages is its safety. When cutting metal, there are no sparks, like from a grinder, which means there is less possibility of fire. When pruning trees in hard-to-reach places and in awkward positions, it is unlikely to be safe to use a chain saw, and a manual one will have to do a lot of work - but with a reciprocating saw: quickly, conveniently and without much effort on our part.

These are the advantages of this tool . There are also disadvantages, for example, despite its versatility, the same angle grinder will cope with metal faster, and the cut will be more accurate. That is, the main disadvantage, in fact, is the very specialization of the tool - where others cannot work, a reciprocating electric hacksaw will cope with a bang. But there are not many such cases in ordinary everyday practice.

Main characteristics of reciprocating saws

If the above prompted you to purchase, then you need to get acquainted with the most significant characteristics of this tool. And they are as follows:

- The power of the tool or, with an autonomous power source, the battery capacity. Although different parameters, nevertheless, both are the most significant. Its functionality and the time spent on cutting will depend on the power. So, with a power of 800 W, it is more of a garden pruning tool than a universal construction tool. The amount of battery life directly depends on the battery capacity, i.e. how often will you be forced to look for an outlet to charge batteries. And although the concept of power is not entirely correct for cordless reciprocating saws, nevertheless, the capabilities of the tool depend on such an indicator as A/h. The general conclusion is this: the more powerful the tool and the larger the battery capacity, the more opportunities it has. Another thing is that they are not always necessary for everyday use.

- The frequency of rotational and translational movements, or strokes per minute. The higher this characteristic, the harder the material is “too tough” for this tool. The time spent on cutting will also depend on it. When choosing a tool, look for one with the ability to manually or electronically adjust the stroke rate, this is really necessary. If there is no such function, the maximum stroke frequency is set, this will affect both the types of materials available for processing and the quality of the cut.

- Availability of a pendulum system. This function directly affects the speed of work and the safety of the blade for reciprocating saws. It should be noted that the absence of such a system when sawing wood is equivalent in effort to using a hand hacksaw. At the same time, if you need precision cutting, take a tool with adjustable pendulum frequency. Such a tool may cost a little more, but in the long run you will benefit.

- Ease of use. Everything is important here, from the presence of a high-quality anti-vibration system (for example, the Makita JR 3070CT reciprocating saw) to the battery charge indicator (Milwaukee C12 HZ). Without an anti-vibration system , it is better not to take a tool at all; you can forget about the comfort of work and cutting accuracy with such a tool. The function of tool-free replacement of a reciprocating saw blade is also very necessary; it provides not only ease of work - but also the speed of the work performed. There is no need to talk about the ergonomics of the device; it is better to check it yourself when purchasing, holding the instrument in your hands.

Additional Information

Compared to a regular saw, an angle grinder:

- works faster;

- takes up less space;

- increases work productivity;

- noticeably lighter;

- lasts longer (if the tool is used correctly).

To cut wood, you can use special cutting discs with a chain. However, it is very difficult to find the type of nozzle suitable for a particular model. The sawing wheel, which combines the features of a disk and a special chain, is suitable for processing boards no thicker than 4 cm. Extreme care must be taken when using it. It will not be possible to run the angle grinder at higher speeds than the disk allows.

There is also a serious limitation on the size of the processed workpieces. To increase it, you have to use larger disks. However, their use is limited by the size of the insulating casing. And if it does not allow you to install a 125 mm nozzle, problems will arise. But peeling wheels connected to chainsaw chains allow you to remove bark and branches from the trunk.

This device will also help prepare a log house no worse than a high-quality ax. But you should not use such a disk instead of a cutting wheel. The cut line will be jagged and too much wood will be wasted. Another type of attachment - a disk with large abrasive grains - is no longer intended for primary processing, but for rough milling. This accessory is safer than a hand rasp.

For more information about chain saw attachments for an angle grinder, see the video below.

Compared to a regular saw, an angle grinder:

- works faster;

- takes up less space;

- increases work productivity;

- noticeably lighter;

- lasts longer (if the tool is used correctly).

Peculiarities

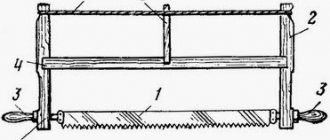

It’s worth considering right away: all experiments with angle grinders should be carried out only by people who are thoroughly versed in this technique. Otherwise, the consequences may turn out to be unpredictable (and hardly pleasant for the “inventors”). To use a grinder for sawing, you will need a special handle, a protective device and a special type of disk. A typical chain saw attachment for an angle grinder includes:

- a tire attached to the tool;

- handle;

- an asterisk mounted on the shaft;

- a set of fasteners and tools for working with them;

- shield isolating the user.

It’s worth considering right away: all experiments with angle grinders should be carried out only by people who are thoroughly versed in this technique. Otherwise, the consequences may turn out to be unpredictable (and hardly pleasant for the “inventors”). To use a grinder for sawing, you will need a special handle, a protective device and a special type of disk. A typical chain saw attachment for an angle grinder includes:

- a tire attached to the tool;

- handle;

- an asterisk mounted on the shaft;

- a set of fasteners and tools for working with them;

- shield isolating the user.