Materials and tools

- gasoline engine from a chain saw;

- gearbox with metal gears from a powerful grinder;

- profile steel pipe of square section;

- drive wheel with bearing and inner bushing;

- bicycle fork with wheel;

- round steel tube;

- paint in a can or regular paint with a brush;

- steel and aluminum sheets.

Tool: electric welding; angle grinder; drill press or drill; wrenches and pliers.

Rules for operating a homemade moped

To extend the life of a moped with a trimmer motor, its owner needs to adhere to a number of important rules.

Their list includes:

Also, the owner of a bicycle with a trimmer motor will need to monitor the weight of the cargo transported on the homemade product. If the luggage is too heavy, it can lead to overheating and serious damage to the engine, as well as other mechanisms of the device.

Source

Control

The scooter controls consist of a power switch, gas and brake handles. It is better to make gas in the form of a hook, because it is safer. In case of an unforeseen situation, such a handle is instinctively released.

The brake handle must be equipped with a switch that will turn off the engine when pressed.

Now let's look at a few instructions on how to make an electric scooter using different engines.

Main stages of work

At the next stage, we cut the blanks from the profile pipe to size. Then we start making the frame.

Next, we cut off part of the frame with the front fork and handlebars from the unnecessary bicycle. We weld it to the frame of the scooter.

Additionally, the master strengthens the bicycle frame using scraps of steel pipes. We clean the weld seams with a grinder.

After this, the frame will need to be painted. We cut out a platform for the feet from sheet metal, the back of which is used as a platform for the engine. We attach it to the frame with rivets.

We make brackets for mounting the engine. We install it on the back of the site.

At the last stage, all that remains is to make the chain of the required length and pull it onto the sprockets. We recommend using a bicycle chain squeezer. You can do it yourself.

For more information on how to assemble a motor scooter with a gasoline engine from a trimmer and bicycle parts, see the video below. The idea was shared by the author of the YouTube channel Dr.Hacker.

[Votes: 69 Average rating: 4.2 ]

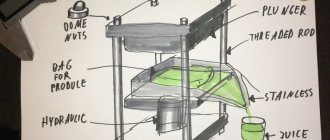

Do-it-yourself motor scooter from a chainsaw

An equally famous homemade product that the domestic “Kulibins” learned to make. To recreate it we will need:

- a scooter designed to support the weight of the person who will operate it. It is desirable that it initially have a manual braking system. The pneumatic wheelbase of the scooter must be durable;

- a chainsaw from which the engine is removed - medium and high-power models are suitable.

The process of assembling a scooter looks simplified compared to previous homemade products:

- First, remove the motor base and secure it to the back of the scooter frame. Make sure that the motor and wheel sprockets match;

- we attach a manual accelerator with ignition of the chain saw - this way the operator can control the moving process;

- If necessary, the scooter is equipped with a brake pedal, but in most cases, the lever for manual control of the scooter is enough for its full operation.

- testing a scooter made from a chainsaw - if it is working properly, the new motorized device is ready and can be used.

How to create a scooter with an engine from a lawn mower?

Not only a bicycle, but also a scooter is supplemented with an engine.

The process of making homemade products is relatively simple and does not require much effort. To create a motor scooter you need to acquire the following parts:

- An unnecessary scooter. You can make it yourself;

- Motor from a brush cutter;

- A chain from a bicycle;

- Bicycle wheels that will be disassembled for spare parts;

- Metal pipes;

- A cable that controls the throttle;

- Welding machine;

- Bulgarian;

- Keys, screwdrivers and fasteners.

The process of creating a gas scooter:

- The specificity of a homemade device in the rear wheel, which is connected to the motor through a bicycle hub. Therefore, if a certain speed is gained, you can simply roll by inertia. This saves the fuel mixture and prevents overheating of the power plant. The rear wheel of the bicycle is disassembled, the carriage is removed, and the spokes are cut off. Only one star is left. The optimal speed needs to be determined. When connecting the carriage, gaskets, bushings and other devices may be needed;

- The sprocket is installed on the motor. You need to choose a lawn mower with a centrifugal clutch. It allows you to use the scooter at idle speed; it will only move when the crankshaft begins to increase speed. A part of the shaft behind the clutch is cut off from the lawnmower motor, to which the sprocket needs to be welded. It must be carefully centered, often using a bushing;

- A frame made of steel pipes is welded. A mount is made from a steel plate under the motor. A hole for the hitch is cut in its center, four slots are drilled to secure the engine;

- The finished elements are assembled together. If everything is done correctly, there will be no problems with assembling the structure;

- Motor connection. The chain is tightened so that it does not fly off. Before starting, spin the rear wheel to check the center position of the sprockets. The ignition button and control cable through the throttle valve are connected. You can do without a button. The cable can be taken from the brake system of the bike or from the gear shift. The gear shifter is disassembled until you have a throttle handle that will spin freely.

Upon completion of the work, tests must be carried out to evaluate the operation of the scooter. There shouldn’t be any particular difficulties when creating motorcycles. Homemade products without complex electronic circuits, therefore no special skills or knowledge are required.

Preparing to assemble a scooter from a lawn mower

In its basic design, a scooter with a power unit from a household trimmer is very similar to a motorbike. The difference between them lies in the weight and dimensions of the homemade product - a motor scooter is much lighter and more compact than a moped, so for its manufacture the designer can use engines with a power of up to 3-4 liters. With.

In addition to the power unit from the trimmer, to assemble the scooter the manufacturer will need:

All assembled elements, especially the frame used by the scooter, will need to be checked for rust and defects. There should be no signs of corrosion on them, otherwise the homemade trimmer will quickly become unusable.

Features of bicycle hybrids

A do-it-yourself motorbike made from a lawn mower is not a new thing for a long time.

Can be used as the main means of transportation in small villages. Advantages of bicycles:

- The speed picks up quite quickly;

- Electric motors operate from the network. Therefore, they are economical, environmentally friendly, and easy to use;

- Maneuverability and compactness, which is especially important if there are frequent traffic jams in the city;

- Endurance;

- Components and repair work are not expensive. The necessary parts can be purchased in specialized stores;

- The equipment does not require special care. The main thing is that the engine is always dry;

- Ergonomics due to easily removable trimmer motor;

- If the motor is connected correctly, the noise level during operation is minimal.

How to make a motor scooter from a trimmer?

To design a scooter with a brushcutter engine, the manufacturer will need a strong welded frame. You can take it from an old scooter, or you can make a frame from metal pipes. Their individual pieces need to be welded to each other with a thick continuous seam. For additional reliability, steel spacers and ties must be welded to the main parts of the frame. The joints must be treated with an anti-corrosion agent. The finished support frame will need to be coated with a thick layer of primer and painted.

The further order of work should be as follows;

After assembling the scooter, the operator must test it. To do this, you need to take the homemade product out onto a flat surface and check it for maneuverability and smoothness. It is important to detect in time any extraneous sounds that may come from the wheels or engine. If they are not there, then the homemade scooter from the trimmer is ready for further use.

What is needed to make a motorbike?

A homemade bicycle from a trimmer must be assembled from a certain list of parts and mechanisms.

To construct a motorbike from a lawn mower with your own hands, the manufacturer will need:

- A fully functional 2-wheeled bicycle with a strong frame with no visible rust on the surface. If they are, then the problem areas must first be coated with a primer and several layers of paint;

- working power unit from a gasoline trimmer. The rated engine power should be 3–6 hp. With. It is not advisable to use more powerful engines, as they will require more fuel mixture;

- belt or drive chain;

- tension roller for a bicycle from a trimmer;

- sprocket - must match the motor used. If possible, you can turn a star on a lathe with your own hands;

- clamp – necessary for stable mounting of the motor on the bicycle frame. You can make the clamp yourself using an all-metal piece of steel;

- a cable that will serve as a connecting link between the power unit and the throttle handle of the bicycle;

- several fuses and a controller;

- exhaust pipe - the length of the standard exhaust pipe from the trimmer will not be enough, so you need to take an additional piece of pipe of the appropriate diameter and weld it to the element of the brush cutter;

- screws, washers, bushings and other fasteners.

Along with the motor from the brush cutter, the manufacturer will need the entire fuel system along with the carburetor, factory clutch, ignition and gas tank. All internal mechanisms must be carefully prepared for assembling the bicycle - their faulty components must be washed and replaced.

The most popular homemade products from gasoline and electric trimmer engines

For everyday household work, outdoor activities or travel, using a motor from a trimmer, many craftsmen can independently make various devices:

- cultivators;

- motorbikes;

- snow scooters;

- snow blowers.

Homemade products are much cheaper than their factory counterparts, but are not inferior in power and efficiency. Using the necessary set of tools and a minimum of knowledge, you can achieve great results in making motorcycle equipment with your own hands. Such units are characterized by simplicity of design and minimal financial costs.

Other homemade options

Thanks to its economical and reliable engine, the trimmer is the basis for many other homemade products. Below we will briefly describe the possible options and provide video instructions for their implementation.

Converting a trimmer into a chainsaw

A gasoline brush cutter can also be turned into a chainsaw. To bring the rationalization idea to life, you will need old models of devices. All details will be taken from them. The video below shows the result.

Converting a trimmer into a gasoline saw involves installing this part from a brush cutter instead of its own engine.

Making a snowmobile for children

The trimmer can also be converted into a snowmobile. The process involves installing the engine on a structure equipped with skis. Due to the insufficient power of the motors available on brush cutters, the independent equipment created is capable of transporting only a relatively small weight. It also moves on relatively flat terrain. This homemade product will serve as an interesting and useful toy for children.

The movement of the snowmobile is carried out using a screw or chain drive.

The videos below show some possible options for homemade equipment:

Home craftsmen have come up with many different ways to adapt the motor from a trimmer to a snowmobile. Here the limitations are related to personal imagination and the existing list of unnecessary devices and equipment that can be used to create homemade snowmobiles.

Motor drill

Brush cutters can be converted into a motor drill, which can also be used as an ice drill if necessary. As a result, construction work will speed up and require less labor. A motor drill is used to make excavations for fence posts, pile foundations, and for erecting other structures.

Both electric and gasoline trimmers are converted for this purpose.

Motor scooter

In addition to the bicycle, the motor of the brush cutter is also installed on the scooter. The assembly principle is similar to creating a motorbike, only the design features of the scooter are taken into account.

The video below shows an airplane whose engine is taken from a gasoline scythe.

Having at your disposal an old working and unnecessary trimmer, you can make various technical devices with your own hands, not only those discussed above. Your own imagination will suggest different options. But when creating any device, you should remember that it is safe for those around you and those using it.

Snowmobile or snow scooter

Based on a motor, the trimmer can be converted into a self-propelled vehicle for moving on snow-covered flat terrain or a simple snow scooter (motorized sled) for a steep descent from a mountain.

Self-propelled gun is a frame structure, including:

The frame is made of welded side members, onto which racks of 30x30 cm corners and cross members are welded. A steel pipe with a diameter of 14 mm is used as the drive shaft. Skis - support-steering. The snowmobile is moved by a screw or chain drive.

A modern trimmer is much more than just a garden tool. The high power of most brush cutters makes it possible to use them as a basis for assembling all kinds of homemade products, not the least of which is a bicycle with a trimmer engine. This self-propelled device is distinguished by its simplicity of design, high traction parameters, and ease of maintenance. The relatively low fuel consumption of the moped makes it possible to cover significant distances on it, and its high repairability allows you to independently eliminate almost any homemade malfunction.

000_moto_1011_084

Mountain bike with a motor - the topic is in the air. However, in metal it is embodied either in the form of concepts or built by enthusiasts (the French are especially successful in this). Mountain bike with a motor - the topic is in the air. However, in metal it is embodied either in the form of concepts or built by enthusiasts (the French are especially successful in this).

Of course, it was not possible to assemble the ideal structure the first time; I treated childhood illnesses for another year. I selected the optimal materials and design solutions, tried different layouts, and rode, rode, rode...

After completing modifications to the design, I have already driven more than 4,000 km and during this time I only changed the drive chain once, twice the spark plug, and once cleaned the fuel system - a good indicator of reliability and unpretentiousness.