How to cut a balloon safely

When making a gas cylinder from propane or other gas, fairly high quality metal is often used. That is why many are considering the possibility of cutting it to obtain blanks, which are later used to create various products. When considering how to cut a gas cylinder, it is recommended to pay attention to the following points:

- The body can be a good workpiece for making a stove, water tank or barbecue.

- Before actual work, the oxygen gas cylinder should be emptied, since the gas at its high concentration is not only flammable, but also explosive. Therefore, before cutting, you should check the filling level of the gas cylinder.

- As a rule, there are no significant problems with oxygen and carbon dioxide gas cylinders. This is due to the fact that ordinary iron is used in their manufacture.

- Propane gas tanks can cause some pretty serious problems. This is due to the fact that it is quite difficult to empty them completely; this requires preliminary preparation.

Gas cylinder explosion

Before you begin, you also need to prepare the required set of tools. As a rule, it can be found in almost any garage and workshop.

Features of the device and marking of the gas valve

The manufacture and use of gas cylinder installations is carried out according to the still valid Soviet GOST NoNo 15860, 949-73, 9731-79 and 12247-80. The vessels are made from steel grades: 45, 30KhMA, 30KhGSA and 34CrMo4. The maximum permitted pressure varies from 1.6 MPa to 19.6 MPa, and the wall thickness ranges from 1.5 to 8.9 mm. The cylinder is equipped with a cap that screws onto a special thread and completely protects the valve. In some designs it is welded and thus protects the valve from damage.

- metal or composite body of the gas cylinder installation;

- shut-off and control valves;

- protective cap;

- transport fixing rings;

- shoe for structural stability;

- metal plate with technical data.

The standard GB valve is made in the form of a tee with three outlet threaded fittings. The latest models are available with safety devices in the form of an additional protrusion to relieve excess pressure generated by heating or incorrect filling. The fitting at the bottom is connected to the GB, the flywheel is attached to the top, and the one installed on the side is for technological filling and discharge of the medium.

What will you need?

To carry out the work in question, a certain set of tools is required. As a rule, cutting is carried out with a grinder. Other necessary tools are as follows:

- Gas and open-end wrench for working with the valve. In order to remove all the gas from the container, the valve must be fully opened.

- A hacksaw is also used for cutting, for example, in the case of cutting off the neck. It is worth paying attention to the correct choice of a suitable cutting blade, since too soft metal leads to rapid grinding of the teeth.

- Water is used to clean the surface. It is usually poured into a container.

When working with an angle grinder, you should be careful, since the circle is in contact with a small area. In addition, when cutting, you should use safety glasses, as a large number of fragments and burning abrasive are formed.

Cutting a gas cylinder with a grinder

For an angle grinder, it is important to choose the most suitable circle. This is because the wrong abrasive wheel can quickly wear down. Before each cutting, you should check the integrity of the nozzle and its secure fastening. Cutting without a protective cover is not allowed.

Leak test

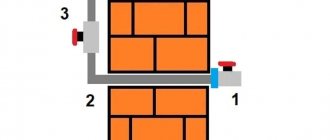

To check the tightness of shut-off valves, gas is pumped into the vessel under pressure using a compressor or two cylinders are connected with a hose - the one being tested (empty) and the other filled with gas. The test vessel is filled with gas up to 2 atm, control is carried out using a pressure gauge. Apply soap foam to the threaded connection and open the valve slightly. If soap bubbles do not appear, then there are no leaks, otherwise you need to re-tighten the valve and tighten the nuts.

The test is performed several times in a row, in the open and closed positions, using new foam. It is strictly prohibited to check the tightness with a match or lighter - due to the risk of fire and explosion of the gas-air mixture. It is important to know about the dangerous mistake that users make with left-handed gearbox threads; if, out of habit, they are tightened incorrectly, then leaks will become larger.

How to proceed?

Once everything you need has been purchased or found, you can begin the actual work. The sequence of actions is usually as follows:

- The valve opens fully to completely release the gas. Do not forget that even a small amount of such a substance can lead to fire or explosion. In addition, all clothes can become saturated with harmful odors. You can make sure that there is no more gas left in the container by covering the valve with a soapy mixture. You can drain the remaining gasoline only after completely unscrewing the valve and removing it, which is not recommended if there is pressure.

- The next step is to unscrew the valve, after which the pins and the fixing element are removed. Removing this locking mechanism is quite difficult in some cases, but if possible, a diameter of 6 mm is formed. If you can’t unscrew the valve, you can cut it off using a regular hacksaw. You can reduce the likelihood of fire by supplying water to the cutting zone, for which it is enough to use a regular hose.

- After this, the gas tank is filled with water. This is required in order to remove any remaining gas that may remain in the semi-closed container. The resulting gasoline solution can be safely drained, as it is absolutely safe and cannot ignite.

- It is worth considering that the resulting liquid has a persistent and rather pungent odor. That is why it is recommended to drain it away from the structure. To speed up the process, you can supply compressed air to the gas container.

- After the container is completely cleaned, you can begin actual cutting. To do this, mark the surface, for which you can use chalk. Many people cut along welded seams, since they are characterized by less high strength.

- Before work, it should be taken into account that in most cases, steel with a thickness of 3-4 mm is used in the manufacture of a gas cylinder. At the joints this figure increases to 5-6 mm. Almost any grinder can cope with such a task.

- You can simplify your task by passing the grinder prematurely when using a 1.6 mm thick disc. By using a wider blade, you can eliminate the possibility of jamming the attachment that will be used for the final cutting.

- Some thicker elements may be cut, and then cut with a chisel and hammer. Due to this, the cutting process is accelerated, but the quality of the resulting cut is significantly reduced.

The cutting methods under consideration are used so that the gas cylinder can be reused in the production of a wide variety of products. If, after cutting it, a pungent odor remains, then the inner surface is burned with a blowtorch. After such processing, the body will be ready for further use.

Aluminum welding.

A few more words can be said about semi-automatic welding of aluminum. Before the advent of the PULSE process in synergistic machines, the industry, as a rule, did not weld aluminum with semi-automatic machines. It was impossible to weld any critical structures - it didn’t work. Firstly, 50% of the wire was splattered, and secondly, the quality of the seams remained indecent. In principle, it is possible to weld some simple, unimportant things, but you need to be an experienced aluminum welder. We had a sad experience when novice users, having listened to the advice of “experienced” ones, came for a semi-automatic transformer and asked to show how it welds aluminum; our advice and arguments had no weight for them. After some time, they returned with a “faulty apparatus” - aluminum does not cook. We had to cook it again, to show that the device had nothing to do with it, they left again, having written down all the positions of the adjustment knobs. But then they spent a long time wondering how they could exchange their used equipment for a device with the PULS function. This has happened more than once, and now I don’t even try to follow the consumer’s lead, I don’t even show welding with a transformer, that’s enough. If you want to weld aluminum, buy PULS or tungsten-arc AC/DC. Don't repeat other people's mistakes.

What should you pay attention to?

There are a few things to consider when cutting. The main ones can be called:

- Cutting must be carried out using special protection.

- Processing along the seams is easier, but often the markings do not match. When cutting on a round plane, you need to put a slight load on the grinder, since a small contact area leads to slipping of the nozzle.

- Many problems arise with removing rust and paint.

In general, we can say that the cutting process does not create significant problems.

Preparation

At the initial stage, you need to fully understand the entire process. You should know that the starting material for manufacturing is stamped car wheels. Cast ones will not be suitable, since welding work will be carried out during the process - cast products do not withstand thermal loads.

The rim width of discs can be increased in 2 ways:

- a steel plate is welded into the middle;

- from two ordinary disks cut in half, one wide one is welded.

You should estimate what width of rims the design of your car allows. For VAZ cars, width 7j is usually chosen. But if you cut or roll out the wheel arches, you can increase the width to 10 j. So, first we need to calculate the width of the rim we want to get.

If we decide to use the method of welding two disks, we need to take this into account and stock up on the required number - for each welding we will need 2 disks.

Examples of using cut gas cylinders

The parts of the cylinder can be used to achieve a variety of purposes. The following cases are examples:

- Furnace body.

- Containers for storing liquids.

- Grill.

- Smokehouse.

Gas cylinder stove

The scope of application is wide, but it is worth considering that the metal is not characterized by high corrosion resistance. An exception is a propane gas cylinder, which is coated with paint using a special technology.

Transportation rules

- Transportation is carried out in specially equipped vehicles marked with warning signs.

- A special permit is issued for the transportation of cylinders with LPG and technical gases.

- Each gas cylinder is designated by its own color: household propane-butane mixture – red, oxygen – blue, acetylene – white, carbon dioxide/nitrogen – black with the designation of the chemical element/compound, argon – gray, helium – brown.

- It is strictly prohibited to transport containers with different gases together, as well as empty/consumed ones together with full ones.

- When transported in a car, they are laid horizontally no higher than the sides, in no more than three rows; in a container - standing, and it is permissible to transport tanks with oxygen and acetylene together.

- Propane-butane containers can be transported standing up without containers, with a spacer between them and a reliable fence.

When loading/unloading gas cylinders, it is prohibited:

- To work alone, there must be at least two loaders.

- Work in overalls and gloves contaminated with fuels and lubricants and vegetable oils.

- Load oxygen tanks into a car body that has spills/stains of fuel and lubricants, as well as debris and foreign objects.

- It is strictly unacceptable to carry containers with gases on your arms/shoulders, roll the cylinders, or move them, dropping them, or hitting them against each other.

- Hold and feed the container with the shut-off valve down.

- Load/unload tanks without protective caps.

Inside buildings, steel containers with any gases must be transported on a stretcher with reliable fastening or a special trolley with wheels with rubber tires; In this case, it is permissible to transport two cylinders together - with oxygen and acetylene for gas welding work.