Aluminum boats are quite often used for fishing and just outdoor recreation.

They themselves are much more convenient than wooden ones. They are light, but at the same time strong, durable, since they can be easily repaired if necessary, and do not consume much fuel. Due to the fact that such boats do not have a stem or keel, they can easily sail to creeks and quiet places on a river or lake. There are a large number of varieties of aluminum boats, they differ in shape, size and weight.

The most popular models are presented by manufacturers - Smartliner, Winbot, Vyatka, LAKER, Tactics, Lund and so on.

Homemade aluminum boat

Aluminum boats are quite often used for fishing and just outdoor recreation.

They themselves are much more convenient than wooden ones. They are light, but at the same time strong, durable, since they can be easily repaired if necessary, and do not consume much fuel. Due to the fact that such boats do not have a stem or keel, they can easily sail to creeks and quiet places on a river or lake. There are a large number of varieties of aluminum boats, they differ in shape, size and weight. The most popular models are presented by manufacturers - Smartliner, Winbot, Vyatka, LAKER, Tactics, Lund and so on.

Materials for building a displacement boat

Wood lumber for building a boat should have an air-dry moisture content of 13-16%, be as straight-grained as possible, with a minimum number of knots. It is advisable to select fine-layered material with a dense structure of annual rings. Plywood - FSF brand, at least. If you want to have a luxury boat, you can use plywood with an outer layer of mahogany or other decorative wood for frame frames and interior furniture. Under varnish these materials will look very beautiful. Fasteners are mainly stainless steel screws of various sizes. Fiberglass fabric with satin weave, suitable for impregnation with epoxy resin. The body is assembled using epoxy resin, and the gluing is also done, or in extreme cases, polyester. You will also need a certain amount of stainless steel - for the rudder stock, pipes for the helm port, and sheet steel - for practical things. Lead for ballast in a marine version of a boat can be replaced with cast iron shot, but this is worse.

General information

The main advantages of aluminum boats:

- Lightness of construction,

- Strength of the material

- Durability of use.

Aluminum boats are simply transported by car to the most inaccessible places. Due to the low weight, low-power motors can be used in the design, which allows for good savings on fuel. Aluminum alloys do not corrode, are not mechanically deformed and do not oxidize when in contact with water. The boat does not require specialized and constant maintenance or a separate place for storage in winter.

Details

It is not difficult to build such a boat

In this case, you can take into account all your wishes for the design in advance. For example, create comfortable places on the boat for a couple of people, install boxes for bait, rods or lures in the right place, and so on.

IMPORTANT: if it is planned to install a motor on the boat, then the project must be approved by the State Inspectorate for Inspectorate.

Materials for creating an aluminum boat

The optimal material for creating a boat made of aluminum can be a solid rolled sheet of aluminum or duralumin.

For a medium-sized boat, you will need a sheet of 300 centimeters by 20,000 centimeters with a thickness of 2-3 mm. But the size of the final structure can also be calculated based on what kind of material you have available. IMPORTANT: the height of the sides of the boat must be at least 30 centimeters, the length of the front flange must be 60 centimeters. It is this design that will allow you to create the required angle of inclination of 35 degrees to the surface of the water.

It is better to make the first sketch of the boat from thick cardboard. After the boat model is created on cardboard, the dimensions of the parts will need to be transferred to metal sheets for cutting.

IMPORTANT: when transferring parts to metal, you must remember to allow allowances of several millimeters on all parts.

Process of creation

Before starting connection work, it is necessary to prepare a slipway (base for a boat).

It can be made from a 100x100mm square of steel, then pre-bent aluminum blanks can be attached to it. Before you start connecting the structural parts, you need to coat all the elements that you plan to combine with thick paint.

During assembly, it is necessary to make specialized holes in a checkerboard pattern at the stern of the vessel.

The parts are connected with special aluminum rivets, which have a diameter of 3 millimeters. After connecting the hull parts, you need to turn the boat over and place rivets on its bottom.

As soon as the work is completed, the boat should be turned over, spruced up and the necessary elements installed, such as boxes, seats, and then (if you were planning a motor boat) you go with it to the GIMS to obtain numbers and a ship's ticket.

Installation of patterns

It is recommended to start the process of installing blanks from the midship frame. Before securely fastening this element, it is very important to make sure that the pattern is strictly vertical and perpendicular to the DP. It is attached to the beams that serve as the base. After all the other workpieces have been mounted, the stand located in the transom DP has been installed, and all the elements have been braced with braces to avoid any movement, you can proceed to the stage of covering the inner surface of the matrix using longitudinal slats.

To perform this task, material with a thickness of 12 to 15 mm and a width of 50 mm is most often used. To equip the bottom of the boat, it is better to use slats with the same thickness, but greater width - up to 100 mm.

Criteria for choosing an aluminum boat for fishing

The most important thing you need to know before choosing an aluminum boat is the performance and strength characteristics that will help you find what you need. It is necessary to choose a boat so that it is light enough that it can be transported to a reservoir directly on the roof of the car, excluding the use of a trailer.

It is also necessary to understand that the weight of the boat at its maximum load should not be critical for the outboard motor. It is thanks to this that the angler can develop the necessary speed.

You need to know that many fishermen choose aluminum boats due to the fact that such a lightweight hull has a high level of durability and that, importantly, such boats are not subject to rotting and destruction.

Aluminum boats are very maneuverable and simple, not at all capricious, which allows them to be used in various weather conditions.

Today it is believed that an aluminum boat is the best choice for fishing.

Types of boats and choice of materials

The ideal option is a boat purchased in a store, but, alas, this is not affordable for everyone. That’s why you have to get out and invent something, having little construction skills.

To make a boat, you can use any material at your disposal, for example, it could be:

As for the optimal characteristics, all of the listed materials have their pros and cons, but wood is most often included in the list of preferences when making boats.

And this is no coincidence; its choice is justified by such properties as:

- Environmental friendliness

- Strength

- Long service life

- Excellent buoyancy

- Light weight

- Possibility of equipping a wooden boat with a motor, sails and oars

If the choice fell on wood, then you must immediately make a choice in favor of one of two models:

- 1st is a keel boat;

- 2nd flat-bottomed boat.

The second option is a higher priority among fishermen. This model is more stable on the water, which allows you to fish even while standing. In addition, its spaciousness can be envied; all the necessary gear will fit into the vessel and there will be room for a comfortable stay for the fisherman himself. Despite this, the design is very maneuverable, which allows you to choose the most convenient place for fishing and, if necessary, easily change it.

As for keel models, they are more maneuverable and fast, but fishing on them is not very convenient. The main disadvantage is the ability to maintain balance, which is not very convenient during fishing.

Construction of a boat. Project of a displacement motor boat for self-build

Project of an 8-meter multi-purpose trailer displacement motor boat for self-build

| Basic data of the displacement motor boat "Crab-800" | |

| Maximum length, m | 8,0 |

| Length according to vertical line, m | 7,4 |

| Maximum width, m | 2,5 |

| Width along the vertical line, m | 2,2 |

| Total displacement, t | 2,7 |

| Lightweight displacement, t | 1,9 |

| Draft at full load, m | 0,66 |

| Engine power, l. With. | 27 |

| Water reserve, l | 100 |

| Fuel capacity, l | 300 |

| Galley: gas stove with oven, sink, refrigerator, cold/hot. water | |

| Latrine: latrine with shower and washbasin, cold room/hot. water | |

A multi-purpose displacement wooden motor boat with a length of 8 meters and a relatively small size is an ideal vessel for comfortable navigation along rivers, lakes, reservoirs and coastal areas of the seas with a small crew. The scope of application of the boat is very wide: it can be used as a pleasure boat, as a family boat for long cruises, a charter boat, a traveling service boat or a fishing boat. Main engine - Vetus M3.28 - 27 hp. With. provides an economical speed of up to 7 knots (13 km/h) and has sufficient power reserves to increase the speed and combat headwinds and waves. At the transom you can install a folding platform with a low-power outboard motor for trolling. A separate cabin plus salon, galley and latrine provide ample amenities for a crew of 4 on a multi-day cruise and up to 10 on a weekend excursion. An option with a shortened deckhouse and a more spacious cockpit is possible. The boat's width of 2.5 meters fits into the vehicle's dimensions, so it can be transported on a trailer to uncharted waters.

The displacement motor boat project was developed according to the idea of Viktor Natsyk based on the architectural design of Yuri Antipov. The boat has a wooden structure - slatted pine sheathing (diagonal laminate) on a longitudinal frame and plywood bulkheads. It is possible to develop a body with Charpie plywood sheathing. An amateur self-builder with certain skills in working with wood can build such a boat on his own and become the owner of a real vessel.

Review of the best aluminum boats for fishing

We will discuss the best Russian-made aluminum boats and not only for fishing in great detail in this chapter. Let's look at the following models:

- LAKER Basic 363.

- RusBoat 45.

- Malyutka-N 2.9m.

- Tactics-370.

- Msta-N 3.0m with boules.

- Romantika N – 3.5 m.

- Msta – H 3.7 m.

LAKER Basic 363

The model has retained its utilitarianism. She acquired an even more prominent keel and a fairly wide stern, and improved stability and seaworthiness. A wooden floorboard was added to the kit. Moving around is now much more comfortable.

I have long dreamed of purchasing a boat for recreation. I spent a long time comparing and choosing. When I saw her, I realized - mine! I have never regretted it. I recommend to everyone!

Making a boat with your own hands

The main material from which standard boats are made is considered plywood . There are no difficulties with finding it on sale.

First, it is worth remembering that any activity that is associated with the independent creation of a certain tool (whether it is a tractor or something else) must go specifically according to the chosen scheme. In this case, you should have drawings of homemade models with you. Sometimes drawings can be replaced with a special design.

To create the body you will need to take simple boards with a thickness of 2 cm and a 6 mm sheet of plywood. The width of the material for the stern and sides should be 30 cm. These are the most suitable dimensions for the boat. All other parts that will be inside the product (seats and spacers) are made of material with a width of 2.5 cm and a length of 86.4 cm. It must be remembered that the dimensions of all these parts must be fully maintained, since they are all attached to to the model body only with self-tapping screws. Creating all the parts of this design will definitely not cause any problems.

This can be explained by their light geometric shape. During the work process, you need to pay attention to the fit of the joined parts and the frill. All joining parts must be level and have only small gaps along the entire length. Various self-tapping screws are used as fasteners. Regarding the size of such fasteners: it all depends on the place of use. They may be as follows:

- 3 by 26 and 3 by 18 mm - for covering the vehicle;

- 4 by 60 and 5 by 64 mm - for all other parts of the structure (for example, seats, feed and side).

Beginning of work

Starting the construction of a small fiberglass boat is no different from building from any other material. The first step is to lay out the theoretical frames, as well as the contour of the stem, on a plywood panel or on a sheet of cardboard. The breakdown should be carried out in the actual size of these parts.

It is also important to note that the board or plaza on which the layout is made must have a width corresponding to the width of the boat, plus 300 mm. The height of this object must be 400 mm higher than the expected height of the housing. Experts recommend first creating drawings of the boats, on which all the necessary parts will be marked with dimensions. This is done in order to avoid mistakes during the manufacturing process.

Another important detail is that the upper ends of all frames must be extended to the height that is shown as a horizontal line on the plaza. It is perpendicular to the DP line and is called the Shergel line.

River boats

All aluminum boats are divided into several types, depending on their purpose:

The most important differences from each other are:

- strength characteristics of the body;

- boat dimensions;

- capacity (single, double).

In addition, there is such a characteristic as the method of subsequent use of the boat, which is determined depending on the engine power.

Also, aluminum boats can have sides of different heights, the presence of cabins, or a number of other features and characteristics.

Today, boats made of aluminum are quite versatile and are widely used in travel and fishing.

These types of boats are made from a special alloy of magnesium and aluminum, which in turn guarantees high strength of the hull and structure, as well as resistance to corrosion and excellent weldability.

In many ways, the structure of the boat is connected by special roller or argon welding, and some elements are made by resistance welding.

It is worth considering when choosing a boat that a model with high sides is not afraid of high waves and can be used in a storm.

The hull of an aluminum boat is always characterized by high quality fastening of additional elements. All models of such boats differ from each other in the thickness of the starting material used.

Boats for river fishing are often characterized by a thin metal thickness, therefore the mass of such models is very small, which facilitates trouble-free transportation of the boat to the fishing spot.

Building a boat

The construction of a wooden boat hull is carried out using the usual methods for modern wooden shipbuilding, and this is within the capabilities of amateur self-builders. The structure of the wooden hull consists of a longitudinal set - a keel, fenders and stringers, fastened to the stem and transom, and supported by a transverse set of frames and bulkheads. Sheathing the hull can be done using different methods. The most preferred is a three-layer diagonal laminate made of pine slats. It is possible to have a single-layer cladding with longitudinal slats, or a combined one - one longitudinal and two or one diagonal layers. The construction of the boat's hull is carried out in the keel-up position, and after placing the frames on the slipway, covering and covering the hull with fiberglass, the hull is turned to its normal position, the internal arrangement of the hull is completed, the deck is laid, the cockpit is mounted, and the completion of the deckhouse is completed. Building such a boat will require the builder to have some carpentry skills, the ability to read blueprints, hard work, motivation and perseverance, as well as a certain amount of common sense. You can build a boat with a Sharpie hull out of plywood.

Aluminum water boat

The low cost of raw materials, as well as lathes, has led to the fact that many owners have decided to independently manufacture certain parts and elements from metal. It is believed that the production of an aluminum boat is one of the most difficult tasks, which is practically impossible, but at the factory they are created without difficulty, since they have special tools for this. However, this is not so.

The most difficult thing in making this type of boat yourself is making its pattern from metal. This term refers to the marking of exactly how it is necessary to cut out the necessary parts from aluminum.

When making such a unit from metal, the whole process comes down to assembling a kind of construction set. This is true if the blanks are not cut out yourself, since this still requires a lot of skill and high-precision equipment, but a computerized model of the boat is purchased. Yes, the cost of such a model will also be quite high, but if you compare it with buying a ready-made vessel, you will see significant savings.

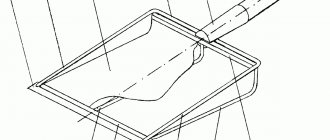

How to make a boat: plating and matrix

Next, before assembling the existing patterns into a matrix, it is necessary to attend to the creation of the outer cladding of the structure. In order to create the most comfortable conditions when working with the outer skin of the boat, it is necessary to provide a part that ensures the tilt of the matrix on both sides of the ship.

If you do everything correctly, you will be able to work while standing on the floor next to the workpieces. The matrix itself, in any case, must have a very strong and rigid structure. This is necessary so that during the construction of the unit the shape of its body is not distorted.

How to make a boat with a strong matrix? Large structures are assembled from longitudinal beams, which will form the horizontal base of the boat. Inside the resulting frame, it is necessary to install walkways that will facilitate the work of gluing the body. After the longitudinal beams, which are the base of the matrix, have been installed, the future position of all the patterns is marked on them, and a steel wire is stretched along the beams, which will be a string indicating the vessel’s DP.

How to choose?

Anglers prefer aluminum boats because of their durability and ease of maintenance. They withstand significant mechanical stress. All maintenance consists of drying after use. The lightness of aluminum makes the boat easy to transport.

Let's study the main features before purchasing.

- We decide in advance how to transport the boat. When transporting on the roof of a car, we take into account the width, weight and length.

- We count how many passengers will board the boat. We hope to accommodate everyone. Don't forget to leave room for the engine.

- Decide where to operate the boat. For calm rivers, streams and lakes, choose a flat bottom. This type of boat glides easily through shallow water, over underwater plants, logs and rocks. Punts are less stable when fishing in deeper, rougher waters. A boat with a V-shaped bottom will work in these areas.

- Decide which additional options you want. A simple boat with benches is the least expensive. In more expensive ones you will find comfortable seats, windshields and storage compartments.

Types of metal boats

According to the manufacturing method, products are divided into:

- riveted;

- all-metal (welded).

Riveted models are easy to transport and repair, because no welding machine required. However, it is necessary to take into account their low tightness, as well as the need to cover the surface with protective compounds. In winter, watercraft are stored indoors, sheltered from precipitation.

Welded products are strong, durable, resistant to deformation as a result of mechanical influences. The models are heavy and require complex work to dismantle elements during repairs.

Watercraft are divided into:

Single-console products are small-sized, compact, and optimal for fishing in calm rivers and lakes. The length reaches 4.55 m.

Double-console boats made of aluminum are more spacious, their length exceeds 5 m. The watercraft are suitable for installing powerful motors.

Cutting, making parts

All markings are made on plywood sheets, after which the material is cut along it. For this you will need an electric jigsaw. Do not attempt to cut plywood with other tools. Otherwise, it will result in poor cut lines and chipped material.

The tailgate and frames are glued to the required thickness and strength.

At the beginning of assembling the boat with your own hands, you need to make calculations, and then mark and cut the plywood with a jigsaw.

If it is still a boat or motor boat, then the transom must be additionally covered with fiberglass and reinforced. A hardwood board will help with this. To increase strength, some connections can be further reinforced with self-tapping screws.

Professional advice: if you still decide to do the design yourself, do not make a mistake with the calculations of the carrying capacity, otherwise later you will only be able to boast of a decorative “vessel”.

Additional accessories

Now there are many different additional accessories to suit every taste and budget. It all depends on your wishes.

- An echo sounder is an indispensable thing for fishing and boating. An excellent navigation device. Identifies fishing spots and evaluates bottom topography.

- Steering racks will make it much easier to control your aluminum vehicle.

- Anchor and mooring equipment will help you stay in the chosen place, regardless of the current and wind. An anchor is an essential part of great fishing.

- Comfortable seats and pads on them will ensure comfort.

- Don't forget about safety. Buy a life jacket.

Choose additional equipment based on your needs.

Buy an aluminum fishing boat from Motomarine

There are many stores where you can easily purchase an aluminum boat. The choice of tourist and specialized departments is huge. Manufacturers' websites offer a wide selection. You choose, place an order and voila - your order is delivered, without wasting time going to the store. Use it!

We present some of the stores:

- vodomotorika.ru;

- adrenalin.ru;

- prolodki.ru.

The store is geographically located in St. Petersburg, but we also accept orders from other cities. Each product is covered by a warranty from the official manufacturer. The purchase can be made in any way convenient for you: cash, bank transfer, credit or installment plan. You can count on:

- Free delivery within St. Petersburg;

- The most complete catalog of products;

- Average market prices;

- Availability of any components (from screws to echo sounders);

- Expert advice on purchase;

- Help in calculating the dimensions of the vessel/motor power;

- Seasonal promotions (including summer sale).

Advantages of aluminum boats over competitors

According to generally accepted characteristics, boats made of aluminum belong to the class of small vessels.

Initially, such boats were supposed to be used for romantic walks on the lake or trips along reservoirs, i.e. in places where there are no particularly high waves and strong winds.

Today, aluminum boats are fully adapted for fishing and allow you to move freely around the boat along the side.

The advantages of such boats over analogue models are the following characteristics:

- High level of strength of the body and structure as a whole;

- Quite comfortable conditions for the fisherman;

- Guaranteed durability;

- Corrosion is completely eliminated;

- Light weight of the boat, which facilitates its transportation and movement;

- The capacity of the boats is quite large, allowing two or three people to fish.

However, like any design, an aluminum boat also has its drawbacks, for example, the rather expensive price of repair work and spare parts. In this case, it will be necessary to use argon arc welding.