Everyone knows the abilities of superglue, which can cope with urgent work at home. Using it, you can glue various materials, but still, the difference from special compounds is significant. You can strengthen the bonding of the necessary parts by adding baking soda to the glue. The combination of moment glue and soda leads to heating and speeds up the gluing process. The method is popular and will be covered in this article.

Combo set

Interaction mechanism

Superglue has been produced since the 50s. It contains cyanoacrylate, and there are no solvents in the glue. Superglue hardens instantly, so the product is often used in emergency situations. Most often, the glue is one-component, sold in one bottle. They will not be able to glue large surfaces due to the high setting speed. Superglue also comes in two components:

- the first tube is the glue itself;

- the second is an alkaline agent.

When the contents of the tubes are combined, an adhesive mass is obtained that has special strength characteristics. The principle of combining cyanoacrylates and baking soda is based on the ability to react to the introduction of alkalis. Under the influence of a weak alkali, the liquid monomer instantly sets - a polymerization reaction occurs. The finished substance resembles acrylic in appearance and properties. Due to its similarity to plastic, the superglue plus baking soda combination is most often used to repair plastic products.

During polymerization, elevated temperatures are generated. This increases the degree of adhesion; as a result, the fixation with the part will be even higher. The composition is so strong that it can be used to glue plastic to complex materials, fill defects and cracks, and restore worn areas in mechanisms. Using glue with soda will be useful for computer engineers, car enthusiasts, and will also be useful in everyday life.

Formwork

Let's continue the associative series: instant glue, soda and... regular adhesive tape. It is made of polypropylene, and cyanoacrylate ignores it. This means: don’t tear it off, just remove it. Taking into account the transparency and self-adhesiveness, ordinary “adhesive tape” produces an excellent formwork, giving the part its shape even at the polymerization stage. Since the part is poured layer by layer, the process is reminiscent of 3D printing in the steampunk genre (instead of water vapor there are toxic fumes of cyanoacrylate). The tape is then easily removed, remove it a little with a file, and you're done! You can do both repairs and strange art (only with safety glasses and a respirator mask, perhaps).

Part of the armrest of one of my cars. Thin hinges made of ABS plastic were broken “with meat”. The basic shape of the new hinges was given by transparent tape, which was easily removed.

Instructions for using the mixture for repair

Bonding products with cyanoacrylate glue and sodium bicarbonate will help in many types of repairs. The mixture can hold broken parts together, fill a chip, repair a machine screw and similar replacement parts. There are a number of rules for gluing products during the repair process:

- take a suitable abrasive, clean both surfaces of the products (this will help remove dirt and open small pores into which the adhesive mass will penetrate);

- moisten a cloth with alcohol or solvent, degrease the surfaces (otherwise the fats may cause the material to peel off);

- pour baking soda into the defect or sprinkle it on the surface;

- pour soda with glue;

- connect the parts as quickly as possible (if required);

- blow off the remaining soda;

- After 15 minutes, you can begin grinding, polishing, and other actions with the resulting adhesive seam.

Once again about storing cyanoacrylate

UPD:

(about dental materials, very interesting)

www.bondic.com - liquid photocurable polymer in a tube, and immediately assembled UV LED

Then another crazy idea came to my mind: a hybrid chemical “jet” 3D printer

, printing cyanoacrylate with an aqueous solution of a slightly alkaline agent, with an FDM extruder for printing polyethylene or polypropylene formwork. A drug addict's holiday, in short.

Problems

- Print speed (not clear what).

- Poisonous a.

- Difficulty storing consumables (a barrel of Cosmophene, they say, dries out in 8 months).

- Difficulty in printing in domestic conditions (the air is humid).

- Heating the workpiece (exothermic polymerization reaction).

- Part destruction at 80..100 degrees Celsius.

- Delamination of formwork, shrinkage during cooling.

Advantages

- Powerful adhesion of the part to the printer “table”.

- Larger dimensions

of printed products. - Products of complex shapes, with easily detachable formwork.

- Relative availability of consumables.

Absurd? Yes, I only fix armrests :-) Help with comments if you have the desire and experience.

Not many people know that superglue and baking soda can be a great pair. Superglue has firmly entered our lives and has found application in various areas. Its adhesive properties can be supplemented with regular soda.

Using cleaning adhesive

In apartments you often find old cooking utensils, for example, cast iron frying pans and pots. Over the years, soot and hardened fat particles accumulate on them outside. There is a method that allows you to quickly get rid of dirt using improvised means. In this case, you need to use silicate glue, baking soda, and laundry soap. The finished product will be even more effective if you use soda ash instead of baking soda.

Instructions for use are as follows:

- take a large container and fill it with water;

- put on fire, let the water boil;

- grate a bar of soap, throw the flakes into the water, stir;

- Reduce heat, leaving a slow simmer;

- pour in 100 ml of silicate glue, pour in a glass of soda;

- immediately open the window for good ventilation of the room (it is better to carry out the cleaning procedure using household gas in an open veranda);

- lower the contaminated dishes into the solution, after removing the plastic parts;

- boil for about an hour, then turn off the heat;

- leave the dishes in the water for another 2-3 hours.

After the specified time, you can take out a saucepan or frying pan and easily clean the carbon deposits using a scraper or aluminum sponge. After finishing work, rinse the dishes with clean water. This method is only suitable for metal products; it is absolutely not suitable for plastic!

How to store and care

Do-it-yourself slime is very capricious and short-lived. To extend its service life, it is worth remembering a few recommendations:

- To store the product, use a tightly closed plastic container.

- Keep the toy away from heat sources and the sun so that it does not dry out.

- If the product is too soft, you can put it in a container with a small amount of salt and close it tightly. Salt can draw out excess liquid, this will restore the slime's elasticity.

- A toy that is too hard can be softened with a few drops of water added to the storage container.

- It is necessary to avoid contact with surfaces made of pile, as this will render the toy unusable.

Glue and soda are not only good helpers in everyday life, helping to repair plastic objects, but also means with which you can make an exciting toy. This product develops fine motor skills, calms, and relieves stress. Additionally, it can be used to clean your keyboard and clothes.

Home repairs

To repair various products, you need to prepare baking soda and superglue. Some people believe that any bulk substance is suitable instead of soda, but this is incorrect. You can replace baking soda with caustic or other alkalis, but it is better not to experiment.

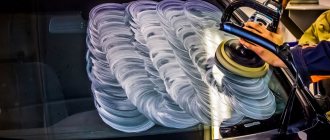

Bumper repair

Car bumpers are made from modern thermoplastics, thermosetting plastics, so they can be repaired using adhesive mass. Minor chips and defects can be eliminated without contacting a car service. Typically, such repairs are carried out for internal chips.

First, you should remove the bumper from the car and clean it of dirt and deposits using fine sandpaper. Next, you need to wipe the damaged area with an organic solvent (acetone, white spirit), and fill the defect with superglue. Then pour baking soda directly onto the superglue and repeat several times using small portions of the powder. To achieve maximum strength, leave the product without moving for 30 minutes. Afterwards, the excess composition must be removed, the part must be sanded and polished. In addition to the bumper, this method can be used to repair armrests, headlights, and other plastic car parts.

Monitor repair

Monitor failures often occur due to damage to the stand. This happens when the object is handled carelessly, as well as when the design is poorly thought out, when the weight of the display does not correspond to the weight of the fastening sleeve. Epoxy may not be suitable for repairs as it is more suitable for bonding metal. You can repair the product with superglue and soda. The instructions are:

- remove all fragments so that there are no weak connections left;

- clean the area with sandpaper to enlarge the pores;

- degrease the surface with alcohol;

- sprinkle the edges of the crack with sodium bicarbonate;

- pour superglue liberally into the powder;

- after final hardening, brush off excess soda and treat the area;

- carefully sand the “patch”;

- drill new holes for screws;

- reassemble the structure;

- if necessary, paint the white patch with dark acrylic paint.

Filling the cavity

Superglue and baking soda in combination are an excellent tool for filling cavities formed during a breakdown or impact. This mass can also eliminate unnecessary recesses and depressions on various products. Before such a mini-repair, plastic is not sanded; it is quite easy to treat it with alcohol. All other materials should be sanded to improve adhesion.

First, the required amount of soda is poured into the cavity. Next, use superglue - add it drop by drop, soaking the soda well. It is important that a sufficient amount of superglue is immediately available, otherwise there will not be enough of it. It is better to fill large cavities layer by layer, because dry soda may remain at the bottom, which will greatly reduce the quality of the repair. Cleaning and polishing of the new surface is allowed after 20-30 minutes.

Restoring the figured part of a part

You can use a mixture of superglue and soda not only to level the surface or glue parts, but also to restore the desired relief of products. This is usually required when blades or clamps in various mechanisms or devices break. The operating procedure will be similar at first - cleaning, degreasing. Afterwards, you need to apply glue to the base in small portions and carefully sprinkle it with soda powder, without missing a drop. You need to repeat the steps until the desired relief of the product is formed. More mass may have to be placed in some areas than others. Grinding and polishing will help to finally give the product the desired look.

Bonding plastic

How to glue two parts together if they are made of plastic? You can also use superglue and baking soda. Be sure to do cleaning to remove dirt and open micropores. Afterwards, the parts must be degreased with an alcohol-containing liquid. Next, apply a thin layer of glue, sprinkle with soda and instantly press the second part. After 20 minutes the product can be used.

Features of superglue

The main component contained in superglue is cyanoacrylate. Thanks to it, the parts are fastened several times faster - one might say instantly. It also contains plasticizers, stabilizers and other auxiliary components. It should be noted that superglue does not contain solvents, which is an advantage when fastening metal products.

Among the features of the quick-drying mixture, the following should be highlighted:

- After contact with air, the glue hardens very quickly. Therefore, when working with it, you do not need to leave the tube open.

- For fixation, the parts to be glued are treated with a thin layer of adhesive and pressed against each other with force. It is enough to hold in this position for no more than 1 minute.

- Bonded surfaces treated with super glue, provided the products are sufficiently strong, can withstand heavy loads - up to 150=250 kg/cm2.

- Cured glue has no color.

The miracle composition can be used to glue cracks or small gaps. First you need to fill the space with plaster mixture or concrete dust. Then treat with super glue, which will adhere well to the filler.

Precautionary measures

Polymerization of the adhesive mass occurs in literally 3 seconds, so you need to work very quickly. You should wear gloves, otherwise your fingers may stick together, which can cause skin damage. If glue gets on an unintended surface, you must immediately remove it by dissolving it with acetone.

Proceed in the same way when gluing the skin: apply a cotton ball moistened with acetone for half an hour, then remove the dissolved mass. To avoid pouring too much baking soda, it is better to do this using a small funnel or take the powder literally a pinch at a time. It is important to ensure good ventilation in the room to avoid poisoning by cyanoacrylate vapors.

Why else is instantaneity needed?

But let's get back to soda. I had to drill a thin hole twice the length of the drill itself, and even with the drill stand I bought, it's not as easy as it looks. Again I remember the joke about two tunnels. This is where the main property appears: the rate of polymerization. Missed? No problem, we carefully “bury” the hole back, adjust the drilling rig and drill again, luckily everything hardens instantly. Not every material forgives mistakes so quickly and easily.

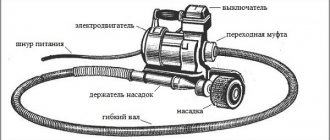

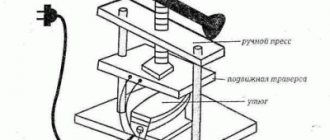

By the way, about the stand for the drill KWB Profi 7778-00. The backlashes are really removed, a powerful cast rod, a new level of processing materials at home, delight! And the silumin frame spoils the effect :-) However, to drill my part I had to borrow for a couple of days from a DIY supermarket this add-on made of 5mm steel, used for fastening house beams (and what, you don’t even need to drill holes):

almost free add-on

sorry for the quality

What are the use cases?

You can use superglue in combination with baking soda to repair a variety of things. After this composition hardens, a solid substance similar to plastic is formed. It is believed that its strength surpasses even epoxy compositions, including those reinforced with fiberglass mesh. In everyday life, superglue with soda is most often used for repairs:

- broken car headlights and bumpers;

- fastening mirrors (if the ears break) and radiator fittings;

- chair legs on wheels;

- uninterruptible power supply housings;

- monitor brackets;

- shoe soles;

- various small household items.

If desired, superglue with soda can be used to repair glass, wood and even metal products. But it is still believed that this composition is best suited for joining plastic parts, including shaped or very small ones.

Reviews

Evgeniy, 45 years old

When I learned about the amazing effect of combining two simple, cheap components, I grabbed my head: how many things were thrown into the trash completely without reason.

Igor, 31 years old

One day I found my neighbor in the garage tinkering with his car with a tube of superglue and a pack of regular baking soda. He lifted the veil of secrecy about the combination of two substances, after which I don’t go to a car dealership for minor repairs.

Elena, 27 years old

I learned the recipe for the wonderful interaction of simple components from the Internet. Since then, I have been repairing children's toys and small household utensils myself.

Superglue and soda: how to glue plastic tightly

sh: 1: --format=html: not found

What's more powerful than superglue when it comes to repairs? It's hard to imagine, isn't it? But there is such a remedy, and it is a tandem: glue and baking soda, which can be found in every home. If you want to not just glue plastic, but glue it forever, try know-how technology.

The secret of interaction with soda

Baking soda is a great assistant for superglue.

Why does tandem work better? It's a matter of chemistry: cyanoacrylate with sodium bicarbonate, after reacting, produces heat that improves gluing, making the joint more durable, and the process itself is accelerated. The composition and action of the combination of two substances is similar to acrylic-like plastic, which is capable of filling the joint space so monolithically that the junction itself may become inaccessible to view.

When it is necessary to tightly glue plastic, to compensate for missing small parts, this tandem has no equal. And if you consider how easy it is to use such a composition, then it can be safely called a leader among similar products.