Classification

There are many options for classifying garden forks - by the shape of the teeth, by materials, width, etc. One of the clearest ways to divide these tools into groups is to classify them by purpose. Gardeners use pitchforks for different purposes: caring for flowers, digging garden beds, spreading compost.

Depending on the “area of specialization,” pitchforks are divided into three large groups:

- for tillage;

- compost/manure;

- hay

What are the advantages of garden forks

During the process of rolling soil, practically no soil particles are poured onto the teeth. As a result, the speed of the work process increases several times.

Such garden tools can be used for digging up crops of potatoes, beets, and carrots. Unlike a shovel, a garden fork does not damage root crops.

Thanks to this tool, it is convenient to carry out seasonal aeration of the lawn. The product removes up to 85% of dry organic residues. During mechanical action, plant roots are not damaged.

For tillage

Tillage forks are distinguished by their massiveness. Their teeth are large and strong, which allows them to be used for the toughest jobs. Such work includes digging out weeds, uprooting bushes, leveling and digging up the ground. Digging models are often equipped with an additional support under the foot - to immerse the fork in the soil.

PALISAD 63808

The forks are made of medium carbon steel and have a non-folding design. The handle is attached to the canvas using manual arc welding. The width of the working surface is 18 centimeters. To increase the service life, the handle and working part are covered with a protective layer of powder enamel. The model is used for loosening and digging soil and digging up tuber crops.

Pros:

- two-component handle;

- protective layer against corrosion;

- metal stalk;

- a light weight.

| Nikolai | Anna |

| Vila showed excellent results in practice. I bought it for digging up potatoes in the garden and loosening the soil. Doesn't slip out or break on clay soil. | I was looking for a light and convenient tool for working in the garden. I chose Palisad because I heard a lot of good reviews about their products - I didn’t regret it. This is not the first season I have been using it, sometimes my husband sharpens his teeth. |

FIT 76994

Equipped with four flat teeth and a wooden handle. Carbon steel was used in the manufacture of the model, which increases strength and resistance to corrosion. The height of the fork is 1.4 meters. Weighing 1.8 kilograms, the product lies comfortably in the hands and does not cause discomfort during prolonged use. The forks are designed for excavating soil in garden plots.

Pros:

- reliable working surface made of carbon steel;

- long service life;

- high-quality assembly materials;

- low price.

| Michael |

| I took the fork for country use - digging beds, carrying straw, grass, etc. The tool copes with its tasks perfectly. The only “but” is the weight, which surprised me. All my previous pitchforks were lighter. |

Which crushed stone forks are best to choose?

The correct choice of fork for crushed stone depends, first of all, on the size of the garden, the type of work and what plants you plan to cultivate. In addition, it is advisable to know in advance what kind of crushed stone you will be working with: large or small, gravel, granite or limestone. So, for example, for granite crushed stone, larger forks are needed (since its fractions can reach 10-12 cm), and for gravel, on the contrary, the forks should be smaller (its fractions do not exceed 3-4 cm).

In any case, each tool of this type should be equipped with a stick and a head with teeth with a special profile at the end, designed to better grip gravel, stones, pebbles and crushed stones. When choosing forks for crushed stone, be sure to pay attention to their profile.

Another element of the tool that we must pay attention to when choosing a fork for gravel and crushed stone is a stick with an appropriate contour and a comfortable handle, preferably in the shape of the letter D. This solution ensures ease of use and precision when working with this tool.

Currently, there are many models of gravel forks on the market that differ in both design and grip. For example, crushed stone forks of the Fiskars brand. Their shaft is bent by 40 degrees, thanks to this solution the tension in the back muscles is reduced, and the whole body is kept in a natural position. Moreover, the handle angle in these forks is 17 degrees, due to which the load on the hands and wrists is significantly reduced when working with the tool.

These types of models are especially recommended for farmers, gardeners and foresters, anyone who uses these tools on a daily basis. Thanks to this solution, you won't have to worry about injuring your back, shoulder or wrist when using the forks. Even long-term maintenance work with such gravel forks does not cause fatigue.

Compost/manure

Composting forks are used for transporting or distributing humus and manure. These models differ from the classic design by curved teeth that form a bucket. This recess makes carrying the compost more convenient, allowing you to grab more product at one time.

COURSE 76991

The welded fork is equipped with four tines and reaches a height of one and a half meters. The handle is made of wood. The work surface is made of steel to increase durability. The model weighs 1.2 kilograms. The fork is considered universal and is suitable for several purposes: digging, transferring manure and compost, and transporting hay.

Pros:

- steel blades;

- a light weight;

- ease of use;

- versatility.

| Irina | Innocent |

| The fork easily penetrates the ground, compost and easily digs up the soil. The quality of the product is at a high level - the teeth do not bend or rust. For now I'm doing without a sharpener. | High quality design with thickened teeth. I take this fork in cases where I need to fertilize the garden with manure. The blades do not bend under the weight and hold the mass well. |

ROS 76992

The four-horned fork is used for gardening and compost processing. The working surface is made of carbon steel, and the handle is made of wood. The height of the fork is one and a half meters. The 27-centimeter width of the product allows it to be used for working with hay. Thanks to its moderate weight, the fork fits comfortably in your hands and is suitable for extended use.

Pros:

- high quality materials;

- optimal height;

- durable carbon steel blade;

- low price.

| Dmitriy |

| Classic fork with wooden handle. The convenient bend of the handle and large teeth work well with both manure and soil. At first the instrument seemed a bit heavy, but I soon got used to it. |

FISKARS Solid 1026687

The forks consist of three elements - a steel handle, hardened teeth (4 pieces) and a D-shaped plastic handle. The height of the fork is 1.2 meters. The ergonomic design allows you to comfortably use the forks for several hours. Stainless steel is protected from corrosion and designed for a long service life.

Pros:

- ergonomic handle;

- durable stalk with round cross-section;

- welded connection of the handle and the working part;

- quality paint.

| Konstantin | Zhanna |

| I took the Fiskars fork to replace the old Soviet one. I had my doubts about the plastic handle, but I bought a good brand. So far I’m happy with the purchase - I’m cultivating the garden with a fork for the first season. For my above-average height, the length seems a little short, but this is not fatal. | Reliable and strong fork, fully consistent with the stated characteristics. There are no problems with it in the garden - it takes soil, compost, and hay. Sometimes I use it when uprooting bushes. |

Advice from professionals

In order for the construction to go like clockwork and not have to regret it later, it is better to take the advice of experienced craftsmen who have made more than a dozen forks. Let's take a closer look at what they recommend to us.

- Don't try to make more antlers

because you won't be able to dig after frost, which will sometimes be necessary, especially when fertilizing the soil before winter. - Do not use pine - this is a very weak material for this case. It is better to take a holder that is heavy but strong.

- It is recommended to immediately make the seat for the holder a little wider, to accommodate the large diameter of the holder, and then adjust it. It can be easily compacted if the cutting becomes too wobbly. But, as practice shows, the holder is never thick. The bigger, the better.

- There is never too much impregnation. Forks for the garden must be completely protected from corrosion, so you can apply impregnation 2-3 times to maximally protect the tool from biological corrosion and moisture.

If you follow these recommendations and make the tool as described above, the hay fork will turn out quite well and will serve you for decades. It is better to store in a dry place, since even with good protection, corrosion will attack over time.

Sennaya

Hay forks or hay forks are used for carrying hay and distributing manure. Their distinctive feature is their long teeth, the number of which varies from 3 to 5 pieces. These teeth reach 70 centimeters in length. They are not suitable for active work with the soil, since they require less load. Sometimes there are universal hay models that are used for several tasks.

PALISAD 63801

The forks are equipped with four teeth, which are made of medium carbon steel (like the tulle). In the manufacture of the handle, the highest grade elm was used, which is responsible for strength and comfortable grip in the hand. The teeth are coated with powder enamel to protect against premature destruction. The handle is attached to the canvas using glue and rivets. The height of the structure is 1.2 meters.

Pros:

- matte finish of the handle;

- protection of steel elements with powder enamel;

- elm cutting;

- simplicity and ease of use.

| Boris | Andrey |

| It's nice to pick up a tool made of high-quality steel. I use a fork to carry grass and hay, and sometimes loosen the soil with it. The design fits comfortably in the hand and weighs almost nothing. | A good comfortable fork that is comfortable to work with for half a day. Perhaps the price is a bit steep. But, given the bad experience with budget models, I'm willing to pay for quality. |

SIBRTECH 63807

The forks consist of metal and wooden elements. The teeth and crown are made of medium carbon steel. To create the cutting, hardwood of the highest grades was used. The wooden handle is varnished for safe use and protection from splinters. The model weighs 1.6 kilograms. All steel parts are treated with powder enamel to prevent corrosion.

Pros:

- ease of use;

- high-quality assembly materials;

- low price;

- efficiency and reliability.

| Tatiana | Margarita |

| A simple fork that is suitable for regular gardening. I chose this model because of the low price and protective coating, because... the blades of the previous fork began to disintegrate. | I spent a long time choosing between a plastic and wooden fork. I settled on wood - the manufacturer’s promise to use only the best wood worked. Over the course of a year of working in the garden, the fork did not bend or crack, as happens with other specimens. |

Drawings, diagrams and dimensions of a miracle shovel for digging a vegetable garden

The drawings presented below allow you to make a reliable and durable miracle shovel with your own hands, as shown in the video.

When designing the device, it is recommended to proceed from the following dimensions:

- The width is in the range of 45–60 cm. You should not do less, since you need to cover as much soil as possible. But it is no longer recommended, because digging will be harder, the structure will be bulky and massive.

- The length of the fork pins is from 22 to 33 cm.

- The interval between the pins is from 7 to 8 cm.

- The length of the handle is according to height (aligned to the shoulder for ease of use).

Important! The interval between the forks should be the same, since they will fit into each other when digging. They are placed so that the pins do not touch in any way.

The most popular schemes:

- Drawing of a miracle shovel for digging with recommended dimensions.

Particular attention is paid to the length, number of pins and the interval between them.

Working forks are miracle shovels for digging.

Dimensions and drawings depend on the types of apparatus. Below are several options.

Miracle shovel with support at the back (only one fork)

There is another popular option - a light cop. It features a lightweight design that is easier to move around the site.

The easy-digger diagram will allow you to assemble it at home

What to look for when purchasing

Once the gardener has decided on the purpose of the fork, it is time to move on to the finer details.

Working part width

The scope of its application largely depends on the width of the fork:

- 120 – 200 millimeters : tools with a narrowed working surface are suitable for loosening soil near bushes and shrubs. Such forks allow you to accurately do spot work on a limited area of land;

- 200 – 300 millimeters : tools with a wide working surface are used for spreading fertilizer and carrying grass or hay. The tines of these forks are usually slightly set apart. Due to the larger surface area, work is completed faster.

Expert opinion

Levin Dmitry Konstantinovich

A common cause of fork failure is their improper use. It is important to understand that wide tools are not always designed for long-term loosening of the soil. Their teeth break on the soil or quickly become dull.

Features of the teeth

There are two types of blades for the working part of garden forks:

- narrow and pointed : designed for working with light materials. These teeth are convenient for scattering sawdust, manure, tops and hay.

- flat and wide : designed for heavy work that requires effort. Flat teeth cope with digging up vegetable gardens and uprooting plants.

Special attention is paid to the shape of the blades. Direct specimens are created specifically for cultivating the land, thanks to their rapid penetration into the ground. Curved ones are used for picking up and transporting light objects (sawdust, grass, compost).

What kind of pitchfork do you use at your dacha?

Three-hornedFour-horned

The number of teeth determines the area that can be conveniently processed using a particular tool:

- three-horned forks are suitable for cultivating the soil around flowers, shrubs and other plants;

- four-horned pitchforks are considered universal. They are used for loosening, digging, fertilizing and harvesting;

- five-horned forks are used for carrying hay and tops or fertilizing the soil. They absorb a large amount of material and speed up the work process.

Working part materials

Manufacturers use steel to make the working part of garden forks.

What type of steel to choose depends on the task the tool performs:

- high carbon steel : used for processing heavy soils, as it is considered the most durable and resistant to destruction. Optimally suited for clay soil;

- Tool steel : suitable for working with soft soil and spreading fertilizer. The surface of such steel is treated with anti-corrosion compounds;

- stainless steel : designed for harvesting hay, tops and leaves. The material is not suitable for cultivating land and is used for simpler types of work.

When choosing a garden fork, it is recommended to pay attention to those models whose working surface is treated with anti-corrosion compounds. This coating makes the steel insensitive to water and wet soil.

Characteristics of the cutting

The cutting has two significant characteristics - length and material.

Garden forks are divided into two categories according to their length:

- 1100 – 1200 millimeters: for digging and loosening the earth;

- 1200 – 1500 millimeters: for spreading and transporting fertilizers, forming a stack, drying hay.

Manufacturers make cuttings in three versions:

- wooden : classic design, which is lightweight and durable. Wood has one drawback - it dries out during use. A varnish coating will help to avoid this consequence;

- plastic : they are distinguished by their low weight (lighter than wooden specimens) and resistance to wetness, sunlight and other external factors. The quality of the cutting depends on the quality of the plastic - it differs from one manufacturer to another;

- metal : ahead of previous options in terms of strength and cope with processing any type of soil. Used for cultivating soil and carrying large portions of fertilizers.

Expert opinion

Levin Dmitry Konstantinovich

Some cuttings have a combined structure. Most of the surface is metal, but for ease of use there are plastic inserts.

We make pitchforks for digging up soil and harvesting crops

Now we will make with our own hands 2 main types of tools that will always be useful to you at the dacha: classic and harvesting forks. If necessary, the first option can play the role of a tool for spreading manure, and the second type can conveniently collect hay. Thus, there is no need to keep a whole bunch of equipment at home. Let's get to work.

Step 1

Making horns.

It is better to buy the metal part on the market, since it is quite difficult to do it yourself. However, it is possible. First you need to find a good steel wire with a diameter of 8 mm and a steel rod with a diameter of 15 mm for the base. Next, cut the wire into 35 centimeters and measure 30 centimeters for the twig

. We sharpen the wire to a cone using sandpaper; the horns should evenly move from 8 mm to 3 mm at the other edge. Next, we simply weld the thick edge to the twig, fusing a wide layer of metal using a welding inverter.

Step 2

We make the mount.

We take a pipe with a diameter of 45 mm, cut off 10 centimeters from it, and weld it to a steel rod. You can make reinforcement on the front side by welding a steel rod.

Step 3

Finishing of the handle.

It will be easier to buy the blank itself at a hardware store or at the market. It is better to give preference to birch or oak, since pine has weak strength properties. It should also be taken into account that digging forks must have a significant margin of safety so that they can dig up hard soil in the fall. We sand the birch cuttings first with coarse-grained sandpaper, then with fine-grained sandpaper. Next, you need to cover the workpiece with stain, wait until it dries and apply a layer of varnish. Very little of it will be used, since the stain has already thoroughly saturated the wood.

Step 4

Securing the cutting in the seat.

We insert the handle into the seat, turn the tool upside down and hit the holder several times on the concrete surface. After this, take an electric drill, drill a 5 mm hole in the mount and hammer in a nail so that the holder does not slip off.

Now the work can be considered completed. You can safely take the tool and go test it.

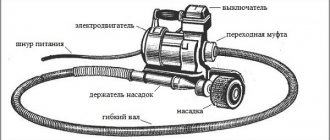

How to make a miracle shovel with your own hands

Making a miracle shovel for personal needs is quite simple if you have the skills to work with electric welding: it is with its help that you can weld all structural elements. The sequence of actions is as follows:

- Make 15 identical sections, each 30 mm long. Sharpen 8 of the 30 segments on one side using a sharpening machine (they are shown in the photo below).

To construct the base of a miracle shovel fork for digging, you will need to take a metal corner 60 cm long and mark 8 identical parts on it (there will be 8 pins).

On a 50 cm corner, mark 7 parts. You will need 7 pins.

Weld the rods to the corners. To the smaller of them (50 cm) also attach metal corners (length 35 cm).

- Make round holes and loops at the edges. 14

- 2 identical fragments (length 125 cm) are cut from a metal pipe (Ø15 mm). They are slightly bent at the edges.

Then you will need to weld the pipe sections. Secure them to the edges of the top corner.The homemade shovel is ready. All that remains is to experience it in action.

Forks can also be made using a ready-made tool by simply straightening the pins. But this option is less durable, since the metal can be very thin, and the diameter of the rod must be at least 8 mm. Another option is to design forks based on suspension springs (straighten) or car springs (cut).

Important! When carrying out welding work, you must strictly adhere to safety requirements.

If you don’t have the skills, it’s better to buy a ready-made miracle shovel: it’s not worth the risk.

Appointment of KUN

KUN is an abbreviation that stands for “universal mounted hay hauler”. Structurally, it is a basic “hitch” with a set of buckets of different sizes and (or) a forklift. This is multifunctional equipment capable of performing a wide range of work:

- transport bulk materials (sand, snow, manure, crushed stone, hay);

- load materials into trailers, mixing tanks, etc.;

- stack hay and straw into piles;

- remove snow;

- transport pallet cargo in warehouses;

- take out the garbage.