Growing seedlings is one of the most responsible and complex procedures that owners of private or country houses have to perform annually. It begins to be carried out in February, when it is very difficult to create the right conditions for plant growth.

The quality of the seedlings largely determines what the harvest will be this year. Therefore, it is necessary to use special lighting and create optimal conditions for seedlings. To do this, you need to compactly place the seedlings and ensure uniform lighting, temperature and humidity for all varieties and types of plants.

The most practical and convenient way of placement is a rack that takes up minimal space and can accommodate all the seedlings. At the same time, it is unlikely that you will be able to buy a finished product - as a rule, factory racks are not suitable for the size or height of the shelves. Therefore, most gardeners make racks with their own hands.

Let's take a closer look at this issue.

Basic requirements for racking

A rack for seedlings can be made from various materials, but in any case it should be:

- durable;

- suitable for repeated use;

- convenient, i.e. provide comfortable conditions for caring for plants (it is important to have quick access to seedlings for watering, inspection and loosening);

- having an aesthetically attractive appearance.

The dimensions of the structure can be completely different, but racks with the following parameters are considered universal:

- number of shelves – from 3 to 6;

- the length of the shelves is sufficient to accommodate standard fluorescent lamps (i.e., from 50 cm);

- height between shelves – from 40 to 50 cm;

- the distance from the floor to the bottom shelf is from 10 cm.

Often the bottom shelf is used to store various garden tools or household items.

If you do not plan to keep seedlings on the last shelf, the top of the rack can be left open by installing front and rear horizontal supports instead of the top shelf. They will not only support the entire structure, but will also be an excellent place for attaching lighting elements.

Useful tips

LED lamps are not suitable for illuminating seedlings; they do not provide the range of luminescence necessary for plants. Fluorescent lamps are suitable for already mature seedlings. They are less safe to use due to the long glass body. Therefore, the lighting on the housekeeper should be done on flexible hangers and under no circumstances should it be rigidly attached to the surface of the shelf. Otherwise, under load due to the weight of the seedlings, the surface may bend and break the glass.

Halogen lights work well, they give a full spectrum, but they are installed above the seedlings in reflectors and at a distance of at least a meter from the seedlings

Material selection

The rack must be strong, waterproof and durable, which should be taken into account when choosing a material. Let's take a closer look at the possible materials for making a rack:

- Tree . One of the most popular materials, because it breathes, looks natural and beautiful, but has a significant drawback - it absorbs moisture. In this regard, when choosing a breed, preference should be given to hard varieties, since they absorb moisture worse than others. These include maple, ash and oak. In addition, it is worth using special impregnations that help solve the problem of wood getting wet.

- Metal . It is better to choose stainless steel as it will prevent corrosion. You can use profiles and even metal pipes as racks, and the shelves can be made from sheet metal or durable mesh. In general, iron structures are durable and quite reliable, but they will be more expensive and will require significant effort in the manufacture of the rack, since working with metal requires certain skills and the presence of expensive equipment.

- Plastic . This material has many advantages - it is durable, easy to wash, and does not absorb moisture. When making shelving, you can use not only plastic sheets, but also pipes.

- Plexiglas . From this material you can assemble a transparent original design that looks stylish and modern. Plexiglas comes in different colors, so you can assemble a rack with multi-colored shelves.

- Plywood . It is easy to process, but gets wet quickly, so it is not the best choice when making racks for seedlings. However, if you still use plywood, then you should prepare several pieces of film or oilcloth to wrap the shelves with it, otherwise their rapid deterioration is inevitable.

The choice of material depends on financial capabilities and engineering and design decisions, however, if the choice is between plywood, plastic and plexiglass, then it is better to give preference to the second or third option. Such materials have a long service life and do not require any coating to protect them from moisture.

Having prepared the material, you should also acquire the necessary tools for constructing the rack, namely: a saw (regular or end-face), drill, screwdriver or regular screwdriver, etc.

DIY flower stands

The most affordable material for making a flower stand at home is wood. For work, you can use old shelves and unnecessary parts of home furniture.

Classic wall flower stand

In order to make such a design, you will need very little available material, tools and a little patience.

You need to prepare in advance:

- shelf or board made of wood or chipboard,

- a decorative element for connecting the structure (in this case, a strong tree branch of a suitable configuration),

- drill,

- saw or jigsaw,

- screws,

- paint,

- varnish,

- pencil,

- brush,

- roulette

The choice of material and fasteners depends on the future load on the stand. It is clear that the larger the dimensions of the product, the more reliable the fasteners are needed.

Master class on making a stand for indoor plants

- Take measurements of all overall dimensions of the future product, taking into account its location and flower pots.

- Cut out all parts of the product in accordance with the drawing and measurements, drill holes for fastenings.

- Process the parts, cut edges, and the base knot for the stand.

- Connect the parts together in accordance with the product sketch.

- Paint the finished product and varnish the surface.

Stands, racks, shelves or racks for indoor plants made of wood require additional surface treatment to prevent moisture. With a high-quality approach, they will last a long time and perfectly decorate the interior of the room.

Hanging structure for flowers

The hanging structure for pots with hanging plants looks original. It is convenient and easy to make.

To implement your plan, you will need several pre-prepared shelves, a strong rope and a drill.

- In the shelves you need to drill two holes on each side. Their diameter must correspond to the diameter of the rope.

- The rope is passed through the prepared holes and fixed at the desired level using knots.

- The original stand is secured with ropes.

This option for placing flowers is ideal for a window sill or loggia. This design is not massive, so it will not greatly shade the room.

A variety of shelving can be made from wood. Their shape can be classic, in the form of a ladder, asymmetrical, and so on. The design can be straight or angular. The main requirement for the product is its aesthetics and durability.

Metal flower stands

Metal stands and stands for plants are beautiful, reliable and very popular

It is important to take into account that such a stand will be a very original decorative element, so you need to work hard on the idea so that it fits well into the interior

For the manufacture of such products, forging is used or a welded structure is performed. You'll have to work hard on it. Then the product must be carefully treated against corrosion and carefully painted.

Such stands are usually made on the floor or mounted on the wall. They have a large margin of safety and are able to withstand large flowerpots.

The shape of metal stands is very diverse. These can be classic racks for two or three places, familiar from Soviet times, or openwork structures in the shape of an old bicycle, wheel, ladder, and so on.

Plastic stands

Typically, such stands are made from leftover laminate or plastic panels. The material is not at all afraid of moisture; structural elements can be painted in any color using acrylic paint.

In addition, finished plastic products are often used in work, supplemented with decorative elements. This category of products can easily include stands made from used plastic containers.

Glass coasters

They are difficult to manufacture because they require experience and careful processing of sections. In addition, they require constant care and are not able to bear a heavy load.

Combined stands

There are a lot of product design options and materials to realize your plans. Often wooden shelves are mounted on metal supports and racks. This gives the structure additional strength.

These stands look original. They can be floor mounted, attached to a wall, or decorate a window sill. Their size and appearance depend on the installation location.

It’s not difficult to make an original and convenient stand or shelf for flowers with your own hands. In addition, it is much cheaper than purchasing a finished product in a store. In addition, the individually made stand is as comfortable as possible and meets all requirements.

Types of structures

For seedlings, you can assemble the following types of structures:

- Stationary . A suitable option for a specially equipped room for growing plants, since the structure cannot be disassembled, but is fixed in several directions. Its advantages are that it is reliable and durable.

- Collapsible . If free space is limited, then it is better to choose such a design, since it is convenient to move, and after growing seedlings it can be completely removed.

- Window . This design is installed on the windowsill in the window opening. This design is suitable for germinating a small number of seedlings. Window shelving is often used to grow herbs for the table throughout the year.

Each design has its own advantages, so it is better to make your choice based on your own preferences and financial capabilities.

Do you need lighting?

When assembling a rack for seedlings with their own hands, some gardeners think that they can do without additional lighting. It is worth noting that even for a structure that was mounted on a window, it is necessary to provide for the presence of lamps of the appropriate type.

In winter, daylight hours are quite short. Due to lack of natural light, seedlings may not develop well. Photosynthesis processes will proceed slowly. Because of this, biomass growth will not occur at the required pace. In order for plants to develop normally, it is necessary to install additional lighting on the rack. This will provide normal conditions for the seedlings and allow the seedlings to gain strength before transplanting them to the site

It is important to choose the right lamp that will meet all requirements

Wooden rack for seedlings

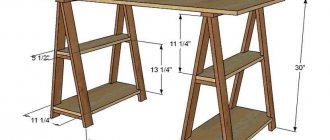

If you are planning to make a shelving unit from wood, you will first need to draw a sketch of it so that you do not forget what dimensions to adhere to. Here is an example of a suitable diagram:

It is better to make shelves from timber in the form of a longitudinal lattice. They will be stronger than plywood shelves, although the structure will be more bulky and heavy.

After preparing the sketch, you need to collect the following materials and tools:

- wooden beams for racks with a section of 45x60 mm (2 pieces of 3 m each, you can immediately ask to cut them into 1.5 m sections);

- wooden beams for crossbars with a cross-section of 20x60 mm (2 pieces, 2 m each, you can immediately ask to cut them into 50 cm pieces);

- wooden board for shelves with a section of 22x100 mm (one shelf takes 5 pieces 75 cm long, then for all 4 shelves you need 4-5 boards of 3 m each);

You can save on boards for shelves if you lay them not end-to-end, but at a short distance from each other. There will be a shelf in the form of a wooden lattice.

- saw;

- screws, nails;

- chisel;

- hammer;

- wood glue;

- roulette;

- pencil.

After preparing all the necessary materials and tools, you can proceed directly to the construction of the rack. This process essentially consists of two main stages - cutting parts and assembling them. We will consider each stage separately.

Cutting parts

The timber purchased from a hardware store must be cut taking into account the following parameters:

- the length of the bars for the manufacture of supporting parts of the rack (racks) is 1.5 m each;

- the length of the bar for the crossbars is 50 cm;

- the length of the shelf boards is 75 cm.

On each beam you will need to measure the required length, draw a line and cut along it using a miter saw or a regular saw. To save overall time, it is advisable to use a circular saw or jigsaw. Based on the cutting results, you need to obtain the following elements of the future design:

- 4 supports 1.5 m long;

- 8 short timber crossbars;

- 15-20 boards for shelves.

To further strengthen the rack, you can prepare bars that will need to be screwed to the finished structure diagonally at the back wall.

Assembly

The prepared boards need to be connected like a construction set to get the finished product. You must act in this order:

- Mark with a pencil where the groove for the crossbar will be located, attaching it to the support block:

The first crossbar should be located at a distance of 23-24 cm from the edge of the support beam, and the subsequent ones - 40 cm from each other. Measurements should be taken from the end of the support beam, which is in contact with the floor. This will ensure that the shelves are at the same height. - At the marking sites, first make cuts taking into account the thickness of the crossbar, and then cut out the grooves using a hammer and chisel.

Please note that the crossbar must be recessed into the groove. - Secure the first cross member between the two support bars by driving it into the groove with a hammer (dimensions in mm in the photo).

It is recommended to pre-treat the fastening points with wood glue and additionally secure them with self-tapping screws.

- After 40 cm, fix another crossbar, and behind it two more (the last crossbar will be at the very top edge). The result should be a kind of staircase.

- Prepare the second side of the structure as described above.

- Lay the boards that will make up the shelves between the two support posts. Secure them to the crossbars using self-tapping screws or nails.

- Cut corners in the end boards so that the support beams fit into them.

- Create the two top shelves in the same way.

- The top shelf can be made longer.

The finished structure will look like this:

If the joints were not treated with glue during assembly, such a rack can be easily disassembled by simply unscrewing the screws. In order not to waste time on disassembly, after growing seedlings, the rack can be moved to another place and used to store books, tools, jars with preparations, etc.

Shelf made of plywood (MDF) for flowers or souvenirs. Scheme drawing

A flower shelf made of plywood for the wall, which you can easily make with your own hands according to the drawings given below.

1) Cut out 5 shelf blanks from plywood (See drawing). To do this, it is convenient to make a template from hardboard or durable cardboard and trace it on plywood, then cut out the parts.

2) On the vertical posts at the back, we mark the location of the hinges and, using a groove cutter (chisel, etc.), carefully cut out grooves for them, all the time checking the accuracy of their location and compliance with the metal hinges.

3) We cover the outer ends of the plywood with veneer edge tape.

4) We assemble the entire structure using PVA glue and self-tapping screws, first check whether the angle is 90 degrees. 5) We cover our wall shelves with stain or varnish and screw in the hinges.

This shelf would also look great if it was made of solid pine or another type of wood. The main thing is interest and desire.

Photo from Woodmaster magazine

Metal structure

This version of the rack is made of a metal corner. It is lightweight, which is its undeniable advantage.

Before you begin assembly, you will need to prepare the following materials and tools:

- metal corner measuring 40x40 mm;

- boards for shelves;

- miter saw;

- self-tapping screws for assembly;

- metal drill;

- electric drill for preparing holes for fasteners;

- roulette;

- marker for marking.

The amount of material needed should be calculated based on how high the racks will be and how long the shelves will be.

Having prepared everything you need, you can cut the metal and begin assembling the rack.

Metal cutting

Cut elements of the future design from a metal corner:

- 4 racks 1.5 m high;

- 4 crossbars 50 cm each;

- 4 shelves, the length of which must correspond to the desired length of the rack.

The length of the rack must be determined taking into account the location where the structure is planned to be placed.

Assembly

The rack is assembled according to the following instructions:

- Drill holes in the places where the elements are supposed to be connected.

- Fasten the parts with self-tapping screws (or you can use rivets).

- Cut the boards using a saw into the required size to cover the space between the supports of each level and create shelves.

- Place the shelves between the rails to create a finished shelving unit.

How to assemble a shelf rack using only metal profiles is shown in this video:

Manufacturing

Classical

First of all, let's look at how to create a classic design on a carved leg.

To do this you will need the following tools:

- Hacksaw;

- Jigsaw;

- Electric drill;

- Pencil;

- Roulette;

- Sandpaper;

- Wood files, etc.

When starting work, first of all you should make a sketch and drawing of the future product. You can also use ready-made drawings. Below, as an example, we give one of the drawing options.

Drawing of the main elements of the stand

The instructions for making this design look like this:

The main and most complex element that shapes the appearance of the product is the vestment leg. This part is turned on a lathe.

If you do not have such equipment, you can order a leg from your nearest carpentry shop. The only thing you need to provide is a sketch of this part.

Next, use a jigsaw to cut out a round tabletop. The material for it can be plywood of suitable thickness or even chipboard.

Sawing a round piece with a jigsaw

- Then the base circle is cut out, as well as other round parts indicated in the drawing.

- Before you begin assembly, you must carefully sand all parts with sandpaper.

- Next, a support disk is attached to the center of the base using self-tapping screws.

- After this, you need to attach the border to the tabletop. To fix it, you can use PVA glue or special wood glue.

- The legs should be attached to the underside of the base. They can be carved from wood or purchased ready-made at a furniture store.

- Then you need to glue the base and tabletop to the leg.

- At the end of the work, the finished wood product should be varnished and polished.

This completes the manufacturing process.

Flower stand made from branches

Window sill rack

The problem of limited space can be solved by a window rack on which you can keep a large number of seedlings.

To make such a rack you will need:

- wooden beam with a section of 20x20 mm;

- a sheet of plywood (if you decide to make the shelves from it);

- jigsaw;

- screwdriver and screws or nails and hammer;

- roulette;

- pencil.

Having prepared everything you need, you can start making the rack:

- Beam into pieces mode: for support you will need 4 bars of 80 cm in length, for crossbars - 4 bars of 27 cm in length.

- Mark each support bar. We measure 5 cm from the top edge, and 37.5 cm from the bottom.

- To assemble the side part of the structure, it is necessary to nail two crossbars to two support bars in the places where the mark was made. For structural stability, a profile can be attached diagonally to each supporting structure.

- Assemble the second side part of the structure using the previously indicated method.

- Nail between the sides of the shelf. They can be made from the same timber or cut from a sheet of plywood. The shelves of the rack can be not only wooden, but also glass, but for reliability they should be secured with adhesive gaskets.

- If necessary, you can attach backlight lamps under each shelf.

The diagram shows standard dimensions that can be adjusted taking into account the width and depth of a particular window opening.

Lighting organization

If there is not enough lighting for flowers during the day, it can, and even needs to be created artificially. To do this, you can use ice lamps, fluorescent lamps and other devices.

Flowers need additional lighting mainly in the autumn-winter period, when daylight hours are reduced.

This is especially true for violets, since lack of lighting affects their development almost immediately. But sources of artificial light have a beneficial effect on them, since Saintpaulias have no intolerance.

If the flowers have wilted leaves or peduncles have stretched out, artificial additional lighting will also be very useful.

How to choose the right lamps?

Ideally, plants should be illuminated with lamps and fluorescent lights. The lighting should be white or slightly yellowish. Also, instead of conventional lamps, you can use lighting units that are recharged from the mains and last much longer.

The problem of lack of lighting for saintpaulias on glass shelves can be easily solved by attaching an LED strip to the bottom of the shelf.

Calculation of required lighting

The lighting required for violets is calculated based on the length of daylight hours. Usually it is direct sunlight from the morning until 10.00, as well as from 16.00 until sunset. The rest of the time, diffused light is recommended for violets.

When it is difficult to comply with natural lighting conditions, artificial light sources are used.

Examples of location and mounting of lamps

Lamps for additional lighting are best mounted in twos, maximum three on one shelf. Metal structures are most suitable for mounting such lamps.

In this case, the distance between the shelves should be at least 20-22 centimeters so that the heat from artificial lighting does not harm the plants.

Lamps placed too close can burn the violets.

LED strips are also often used to illuminate violets that are on glass shelves. Such a device not only provides the necessary lighting to flowers, but is also an interesting decorative solution for any room.

Rack made of plastic pipes

This type of structure is assembled like a metal rack. It has a low specific gravity, so it is easy to move around the room.

To make a rack you will need:

- PVC pipes;

- hacksaw;

- tees (4 pcs.);

- corners (12 pcs.);

- corner crosspieces (4 pcs.);

- roulette;

- marker for marking.

You can assemble the rack according to the following instructions:

- Cut 4 long pipes for supports (180 cm each), 6 crossbars (50 cm each), 4 crossbar pipes (150 cm each) and 4 “short” pipes 30-40 cm each.

- First take one crossbar 50 cm long and put two tees on it at an equal distance from each other. Do the same with the second cross member.

- Take 4 pipes of 180 cm each and cut each in half (i.e. 90 cm). Connect the two parts together using a corner cross. Connect the rest as well. There should be 4 such elements. Place two elements parallel to each other.

- First, insert one assembled cross member into the crosspiece, forming the letter “H” from the pipes. Do the same with the second pair of elements. The result was two separate “H” shaped structures.

- Take two more crossbars 50 cm long. Using corners, secure one at the top and the second at the bottom of the H-shaped structure. You will get a new figure - a figure eight, like on an electronic watch. There will be two such parts. These are vertical supporting walls. Place them parallel to each other.

- Insert a crossbar pipe into the last free holes of the crosspieces. This way the two side support walls will be connected to each other and will be able to stand stably.

- The resulting frame is only missing a “shelf”. Using angle brackets, secure one “short” pipe at each end of the crossbar pipe. The result will be a bracket-shaped structure. There will be 2 of these shelf parts. Insert them into the remaining free holes of the tees, placing the shelf parts parallel to each other.

- Place the pots with seedlings on the “shelf”. You can install a pendant lamp on top, firmly securing it to the side posts.

You can put a sheet of plywood on the bottom of the shelf if you are using pots, but it is better to just choose tall cassettes or spacious boxes for seedlings.

Homemade pallet rack

If the seedlings will be grown in a small apartment, the problem of placing containers with plants can be solved using a narrow vertical pallet structure mounted on one of the walls. To make it you will need:

- pallet (cargo box);

- wooden beams (4 pieces, 3 m each);

- wooden slats;

- hammer;

- nails;

- pencil;

- roulette.

You can assemble the rack according to the following instructions:

- We are making a three-bay rack. Cut the timber 1.5 m long. You will get 8 parts.

- Cut 18 slats as long as the width of the pallet.

- Take two bars and place them parallel to each other. Step back from the top as much as the thickness of the pallet (about 10 cm). Fasten the slats to the bars with nails so that you get a structure similar to a ladder. Pallets will be installed on these slats as shelves. The distance between the shelves should be about 40 cm.

- Place the pallets on the slats. You can secure them with nails or put them on wood glue.

Varieties

Racks are divided into stationary, mobile, and collapsible.

Stationary racks are attached to the wall or ceiling. This adds strength and durability to the entire structure. Suitable for large apartments, where a bulky rack will not disturb the residents. After the plants are “moved” into the garden, it is used to place household utensils, flowers, and toys.

The reliable design of the stationary rack will support a large number of seedlings and last for several seasons

Mobile racks are equipped with wheels; the racks can be moved around the room and rotated. There is no need to unload the contents of the shelves if you need to place the seedlings in another part of the room.

The use of wheels allows access to seedlings from all sides due to the rotation of the structure

Collapsible racks are easy to use. They can be disassembled and stored until the new season.

The design of perforated corners allows you to change the height of the shelves and completely disassemble the rack

The size of the rack is selected depending on the area of the room allocated for seedlings. Often the gardener has only window sills at his disposal. The height and width of the rack in this case is limited by the size of the window opening. If it is possible to allocate part of the room to prepare for the gardening season, then you can equip a rack with a large usable area.

The frame of the rack is made of metal or wood. The original option is a frame made of plumbing pipes. Wood, plastic, glass or metal are used to make shelves. If the purchased rack is not equipped with lighting, then purchase lamps and install lighting.

Selecting a lighting fixture and installing backlighting

If you plan to place the rack in a fairly well-lit place, then you do not need to install additional lamps, otherwise they will still need to be installed to guarantee the seedlings the necessary daylight hours.

The lamps must provide bright light, but at the same time emit a minimum of heat, otherwise the seedlings can get seriously burned. In this regard, any lighting fixtures except incandescent lamps can be used for lighting. Here are the best options:

- High pressure sodium lamps . These lamps emit an orange-yellow glow that promotes seedling growth. In addition, it does not irritate human eyes, so such lamps can be used in residential areas. Their disadvantage is their high cost and the need to use a power regulator when installing them.

- Phytolamps . Although the spectrum of such lamps is good for plants, it is dangerous for human eyes. When installing, they need to be adjusted so that the light hits the seedlings from above and from the sides. The distance from the lamp to the tops of the plants should be at least 10 cm.

- Fluorescent lamps . Such lamps produce cold light, which lacks the red component of the spectrum. They need to be installed at a distance of 30-60 cm from the seedlings. In addition, to ensure uniform heating of the plant, the lamps should protrude 5 cm from the edge of the shelves.

- LED bulbs . Plants that are illuminated by such lamps produce a larger harvest, so they are used more often than other options. In addition, such lamps consume little electricity and also combine the spectra most needed for plants - blue and red.

Since LED lamps are in greatest demand, let’s look at installing the backlight using them as an example. In an electrical goods store, you need to purchase lamps whose length corresponds to the size of the rack (or rather, the length of the shelves).

At the same time, it is extremely important to follow safety precautions - do not leave exposed electrical wires in the public domain, and even turn off the electricity during preparatory work.

Required materials and tools:

- red and blue diodes on the tape;

- glue “Moment” (transparent);

- plastic base or plinth with cable channel;

- screwdriver and screws;

- switch;

- plug and electrical cord;

- insulating tape;

- reflectors.

Instructions for installing the backlight are as follows:

- Attach a chain of LEDs to a plastic base.

- Connect the tape to the switch, and from it stretch a wire with a plug to the socket. If you plan to pass electrical wiring through metal corners, then you need to drill holes in them. Of course, you can take a simpler route - carefully distribute the wire along each metal element.

- Secure the base with tape to the bottom of the shelf. To do this, you can use transparent Moment glue.

- Attach mirrors or sheets of foil to the sides of the rack to reflect light.

If the shelves are made of plexiglass, then through them the light will fall unhindered on the seedlings, which is an additional advantage of this design.

In the following video you can clearly see how LED strip lighting is installed in a finished plant rack:

To grow healthy and strong seedlings, it is imperative to provide the seedlings with sufficient heat and light. A favorable microclimate for them can be created using racks for seedlings, which will also help solve the problem of lack of free space. You can make similar designs yourself using the above ideas, diagrams and instructions.

0

0

Copy link

Lighting organization

If there is not enough lighting for flowers during the day, it can, and even needs to be created artificially.

To do this, you can use ice lamps, fluorescent lamps and other devices. Flowers need additional lighting mainly in the autumn-winter period, when daylight hours are reduced.

This is especially true for violets, since lack of lighting affects their development almost immediately. But sources of artificial light have a beneficial effect on them, since Saintpaulias have no intolerance.

If the flowers have wilted leaves or peduncles have stretched out, artificial additional lighting will also be very useful.

How to choose the right lamps?

Ideally, plants should be illuminated with lamps and fluorescent lights. The lighting should be white or slightly yellowish. Also, instead of conventional lamps, you can use lighting units that are recharged from the mains and last much longer.

The problem of lack of lighting for saintpaulias on glass shelves can be easily solved by attaching an LED strip to the bottom of the shelf.

Calculation of required lighting

The lighting required for violets is calculated based on the length of daylight hours. Usually it is direct sunlight from the morning until 10.00, as well as from 16.00 until sunset. The rest of the time, diffused light is recommended for violets.

When it is difficult to comply with natural lighting conditions, artificial light sources are used.

Examples of location and mounting of lamps

Lamps for additional lighting are best mounted in twos, maximum three on one shelf. Metal structures are most suitable for mounting such lamps.

In this case, the distance between the shelves should be at least 20-22 centimeters so that the heat from artificial lighting does not harm the plants.

Lamps placed too close can burn the violets.

LED strips are also often used to illuminate violets that are on glass shelves. Such a device not only provides the necessary lighting to flowers, but is also an interesting decorative solution for any room.