For a vast army of motorists who are accustomed to performing car repairs on their own, the appearance of new tools and devices in the arsenal of existing ones is a self-evident inevitability. Today we will talk about repairing the brake system, which very often requires replacing the brake pipes. These elements are more susceptible to external factors than others, which affects their condition. But they can only be replaced if you have a specialized tool that can be used to flare the tubes. If you don't have a tool, you won't be able to perform this operation. This means that you still have to go to the nearest car service center. Or go to a car store to become the owner of another very useful device.

Non-ferrous metal tubes in vehicle systems

We won’t touch the radiators for now, this is a separate topic. Let's take an interest in the pipes that are responsible for the operation of the car's brake and fuel systems. Rotten brake pipes are a problem not only of old Soviet cars, but also of newer foreign cars that have been driving on roads generously sprinkled with salt and all sorts of chemicals for several years. Tubes become unusable primarily due to the fact that they are affected by an aggressive chemical environment. In winter, we have plenty of this environment under our wheels. With human-made road surfaces, the salt comes off the roads along with the snow, but with our roads, it can remain there until next winter.

How to flare a copper tube at home

When installing copper piping systems, it is often necessary to expand the cut end of the pipe - for installing climate control systems or soldering heating and water supply pipelines.

I greet our dear reader and offer an article about what flaring of copper tubes is, in what situations it is used and how to do it yourself.

What is it and why is flaring necessary?

Flaring is a radial uniform expansion of the walls of a copper pipe. When flaring, a conical expansion of only the end of the pipe or expansion of a sufficiently long section can be carried out, in which a sleeve is formed - a section of a larger diameter.

The need for such deformation at home arises:

- When installing air conditioning systems.

- When repairing refrigerators, heat exchangers, cars, household appliances, heat pumps.

- When installing heating and water supply systems.

When installing using welding (soldering), the ends of copper pipes are flared in the form of a coupling, inserted into a pipe of the original diameter and welded. Flaring is used less frequently than soldering with fittings, as this method is slightly less reliable, but sometimes fittings may be in short supply or not available for repair work.

The need for flaring arises if the necessary fittings are not at hand, it is not possible to purchase a copper tube of the required diameter, or a very precise adjustment of the size of the tube along the internal section is required. In practice, flaring is used when installing climate control equipment, in cars, and during urgent repair work, when copper tubes available on the farm are used.

Flaring stages

To obtain a high-quality cone or expansion coupling at the end of a pipe, it is necessary to follow the correct work procedure.

Flaring as a process of deformation of the ends of copper pipes includes the following steps:

- Cut off the pipe blank. Copper is a very soft material, so it is necessary to use a quality pipe cutter designed for soft pipes made of non-ferrous metals.

- After cutting even with a high-quality pipe cutter, the copper pipe becomes jammed and its internal diameter decreases. Therefore, with the help of a special device - a rimmer - a chamfer is removed from the inside of the workpiece, and the shape is restored.

- Clean the end of the tube from burrs, remove copper shavings, dust, dirt, and grease.

- The workpiece is inserted into the flaring machine and rotated until a small socket is obtained with a wall angle of 45° to the pipe axis.

- Take out the product, try it on to see if it is the right size for further installation with a union nut. If the diameter of the socket is insufficient, then the flaring operation is repeated. An insufficient socket during installation creates an unreliable connection: water leakage is unpleasant, refrigerant leakage is dangerous, since it consists of toxic fluorocarbons.

- Then the pipe is used for its intended purpose.

All the details of flaring a copper tube can be seen in the video.

Tools and accessories for rolling

For high-quality expansion of pipe ends, a special tool is used - mechanical or electrically driven. The use of cones or templates and manual expansion are used only for manual rolling of single pipes. If you have to install a heating system or plumbing, it makes sense to purchase a mechanical flaring machine.

Expander

An expander is a simple rolling machine with several template attachments for processing pipes of different sizes.

It stretches the ends of the tubes quite quickly, the force is applied using a lever, and flaring does not require much physical effort.

The quality of flared products is not ideal - most likely, the deformation will be non-uniform, thinner sections of the walls will stretch, and the bell will have different thicknesses. Cracks and tears may occur.

Cone flaring machine

The cone tool is one of the simplest, providing an acceptable quality copper flare, but worse than other types of mechanical flaring tools.

The pipe is fixed in a vice, the cone is pressed into the workpiece several times, each time to a greater depth, then removed - and so on until a bell of the required size is obtained.

This device is used quite often because of its cheapness and simplicity.

Mechanical flaring machine

The best quality of rolling is ensured by a flaring machine in which the pipe is processed using several rollers made of alloyed tool steels. The tool is equipped with a set of rollers for several pipe diameters.

Causes of brake pipe failures

But this is not the only reason for the wear of sealed tubes. From salt they only rot, and from constant strong constrictions of fittings, improper fixation, breaks and bends, they receive severe mechanical damage that is incompatible with life. This is not the fault of the pipes, but of unfortunate craftsmen who do not know how to properly handle soft or brittle metal. One way or another, the time comes to replace the tubes, and if the required configuration is not found, which is almost impossible, then you have to make the tube yourself. Cut off the required piece, put on fittings and flare. And you need to be able to do this. Flaring brake pipes with your own hands is not a difficult task, quick, and inexpensive.

The use of tubes in the design of vehicles

Modern machines use several hydraulic systems with different main lines. One of them is the braking system. The working fluid moving through it must be isolated from the external environment due to tightness.

You need to know that thanks to good connections at the joints of the pipes, it is possible to achieve a high degree of tightness for the vehicle’s vehicle.

The success of reliable connections depends on the quality of the flaring. This operation uniformly increases the diameter of one tube tip. At the counter tube, the diameter of the tip is reduced to ensure rolling (entering a small diameter into a larger one and holding the pair in this position for a long time).

If the tubes in any of the sections receive mechanical damage, then due to depressurization of the system, part of the main wiring must be replaced. At a car factory, flaring is done using special equipment that contains hydraulic, electrical and mechanical drives. In garage conditions, a device for flaring brake pipes is most often mechanically driven by the muscular strength of the performer.

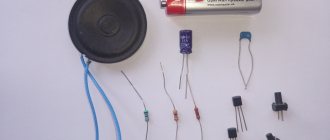

Brake pipe flaring kit

You cannot prepare copper tubing for use with your bare hands. To do this you need to have at least minimal equipment. Although the metal is soft, the end of the tube must exactly correspond to the landing cone, otherwise we will not achieve a sealed system. Ideally, for flaring tubes, they use a machine that needs to be purchased, but if we have the opportunity, we can use a homemade kit, which, once done, we will use for many years. And it will come in handy more than once, believe me. Here is his drawing.

It is not anything complicated. This is a frame made of two corners 5mm thick and a shelf 32mm. The length of each corner is 100 mm. The drawing shows that the set is suitable for tubes with a diameter of 9 and 12 mm. The bed itself is completed in ten minutes with a sharpening machine, drilling machine and grinder. Both corners are fastened with two M8 bolts; holes and chamfers are drilled in them when assembled. You will either have to order the mandrels from a turner, which is not at all problematic, or grind them yourself. But with the help of such a kit, any tube turns into a perfectly prepared part. The flaring process occurs in exactly the same way as using a machine, which we will discuss later.

Performing work on a homemade machine

A self-made machine can be used for a long time in the future. It will be useful for car owners whose cars have high mileage.

The tools you will need are a sharpening machine, a grinder and a drill. The materials will be custom-made mandrels, angles (100x32x5 mm, 2 pcs.) and a pair of M8 bolts. The corners are bolted to each other, and holes are drilled in the base of the frame. Don't forget about the chamfer for the edges of the holes.

The process of working on a homemade machine will be similar to working on factory equipment. The algorithm consists of the following points:

- We fix the workpiece so that the outer edge protrudes 5–6 mm beyond the jaws of the vice;

- select a cone of the required diameter;

- the fittings must be multi-directional;

- slowly screw in the cone, flaring the edges of the tube until it fits in to the extreme mark;

- lift the cone and remove the formed burrs.

Brake Tube Flaring Machine

the simplest tube flaring machine will cost you 600-700 rubles. But this will not be the highest quality product. We would recommend not going below 1800, otherwise there is a chance of wasting your money. We showed several sets and machines in the photo. One of them is more expensive, the second is cheaper, but they have the same essence.

The machine consists of a bar that holds the cutting. Actually, our homemade set also has the same structure, only the branded sets are required to include:

- the bar itself for fixing the tubes;

- machine with a flaring angle of 45 degrees;

- a set of replaceable dies made of durable hardened steel;

- tube cutter.

More expensive models have even more equipment, but we will consider only the most minimal configurations.

Flaring can be of three types, but the first two are of little interest to us, because they are used mainly in refrigerators and air conditioners. Flaring occurs as follows:

- We clamp the tube in the holder so that it protrudes beyond its edge by 5-6 mm.

- Instead of a cone, we install a stamp that matches the diameter of the tube.

- We screw in the stamp and flatten the very end of the copper tube.

- Do not forget to put on the fittings, and the threads should be directed away from each other towards the ends of the tube.

- Remove the stamp and change it to a cone.

- Screw in the cone carefully and gradually.

- We take out the tube, carry out a careful inspection, and clean it if necessary.

Thus, we get a neat flared brake pipe, which can be used to safely replace the old one that has failed. We can't say that every garage should have a tube flaring machine, but as a rule, the most valuable items are those that are not always at hand. Monitor the condition of the brake system, and good luck on the roads!

Execution Features

Flaring of copper tubes may be necessary if:

- the cut end of the tube must be given the required configuration;

- the end of the product must be prepared for its connection using a coupling (in this case, using flaring, the geometric parameters of the tube are adjusted, such as the internal diameter, bending angle, etc.);

- it is necessary to prepare the ends of the copper tubes for their connection by soldering.

Pipes are cut to length using a special tool - a pipe cutter for copper or aluminum pipes

To qualitatively flare a copper tube using special tools and devices, you must perform the following steps.

- The end of the tube whose connection needs to be made is carefully cleaned.

- A special coupling is put on the stripped end.

- Using a special tool or device, the end of the tube is flared until its expansion angle is 45°.

- After the procedure is completed, the end of the product is removed from the device. You can then immediately begin making the connection.

Reamer - devices for stripping the ends of copper tubes

If copper is needed in order to connect it by soldering, then the sequence of actions for carrying out such a procedure will look like this.

- The surface of the end of the tube that needs to be flared is carefully cleaned (for this it is best to use a special brush).

- Using a special device, the end of the copper tube is expanded to such an extent that the end of another tube can be inserted into it and at the same time maintaining a gap of 0.124 mm between the connected elements. Naturally, for this you need to use a measuring tool.

- The flux necessary to ensure the formation of a reliable and tight connection is applied in an even layer to the inner surface of the pipe section that has already been flared.

- The end of the second connection element is inserted into the flared part to a depth equal to the diameter of the pipe.

- Using a gas torch, electric soldering iron or blowtorch, the future joint is heated until the solder begins to melt.

- Melted solder fills all the gaps between the edges of the copper pipes being connected, resulting in a reliable and tight connection.

Flaring machine

Of course, if the pipes are faulty, you can take the car to a service station and entrust the repair to specialists. But why spend money on something you can do yourself? To do this, you need to purchase a flaring tool in specialized stores or order it online. It is available for inch or metric threads. The set includes a pipe cutter, a device, pliers, a clamp, and dies for different diameters of tubes for flaring with a fungus.

Pipe flaring

Increasing the diameter of the product is necessary when performing a fittingless connection of pipeline elements, for example, capillary soldering of copper pipes. The resulting expansion allows you to insert one pipe into another.

The simplest flaring tool is a regular cone that is screwed into a fixed pipe, expanding its edge.

The improved model is equipped with a ratchet that allows you to adjust the force,

Thanks to this, the walls are protected from rupture. Pipe flaring is also carried out with an expander; its working body has several segments, which, when the handles are compressed, begin to diverge, stretching the pipe.

Flaring with the tools described above is the simplest method, but the quality of the resulting sleeve is far from perfect.

The highest quality flaring is obtained when using a tool whose working body is an eccentric cone. When you turn the handle, which is also equipped with a safety mechanism, the cone begins to roll along the inner wall of the pipe, reducing its thickness and bending the edge. The resulting extension is of high quality.

Such devices are mainly used for pipes made of soft metals. Steel pipes can also be flared, but this process requires considerable effort when cold. Therefore, it is advisable to preheat such pipes; after this, flaring with hand tools will become much easier.

Homemade device for repairing brake pipes

An even cheaper method is to make a homemade device. If you have the desire and minimal skills to work with your hands, there is nothing difficult about it. First you need to make a base (frame) for attaching the tubes. You can assemble it from two steel corners. Cut the corners to the required length with a grinding machine, drill two holes in them for fastening with bolts. This is done in 15 minutes.

Having assembled the frame, you need to make holes for the tube and chamfer it using a drill press or drill. The most difficult thing is the production of punches (mandrels). You can order them from a familiar turner.

Recommendations for flaring

Independent beading of copper tubes is an easy task only if you have practical experience. At the same time, the tightness and reliability of the connections made depend on the quality of flaring.

Therefore, before installing a copper pipeline, installing or repairing heat-generating devices, it is better to practice on pipes of different diameters.

A specialist professionally involved in the repair of pipelines or equipment will need a set of professional tools, which, in addition to a flaring tool, includes a pipe edger, a pipe bender and a pipe cutter. For rare repair work, an inexpensive flaring tool with a minimum set of attachments will suffice.

Recommendations to help you perform flaring correctly:

Before starting work, carefully check the pipe: there should be no burrs or debris on it, the edge and walls should be smooth and free of bends, only pipes with a round cross-section are allowed for flaring. During flaring, it is important to ensure that the expanding tip does not skew relative to the pipe. Otherwise, the socket will be asymmetrical and will not be able to provide a reliable connection. When expanding a pipe manually, the taper blank should be screwed in rather than pressed into the hole

This will help distribute the force and avoid damaging the pipe. It is better to carry out beading of a pipe with an expander in two or three stages. First, widen the edge a little, and then turn the expander and stretch the pipe to the desired diameter. When installing a pipe into the die of a rolling machine, you should select the hole that exactly matches the diameter of the pipe. Before flaring, the outer surface of the tube is treated with an abrasive sponge to remove dust and debris and ensure reliable fixation in the holder. If this is not done, the tube will slip in the die, interfering with the flaring process.

The process of flaring brake pipes with your own hands

First you need to determine the extent of the tube failure and the possibility of repair. To do this, unscrew it from the caliper or brake cylinder. If it is possible to remove the damaged area while maintaining the desired length, cut this piece with a pipe cutter. After this, we treat the remaining part with gasoline, clamp it with pliers and remove the internal chamfer with a drill. If it is impossible to carry out repairs, we buy the handset in the store.

DIY tube repair instructions:

- We install the tube in the device (base). It is necessary that the end protrudes 5 mm beyond the edge;

- We change the cone with a stamp required for the diameter of the tube;

- Screw the stamp;

- Screw in the stamp and slightly flatten the end of the copper tube;

- We put on the fittings. Be sure not to forget, otherwise you will have to redo everything;

- Remove the stamp and replace it with a cone-shaped tool;

- Carefully, slowly, twist;

- We take out the tube and clean it if necessary.

At the exit we have a new brake pipe under the cone. You can also flare the tube in another way, called a “fungus”. Typically, European-made cars use “fungus” flaring, while Japanese and other Asian models use “cone” flaring. To flare it under the “fungus” you just need not remove the required stamp.

Tube flaring technology

Tube flaring technology

The technology for flaring pipes can be illustrated by the operation of a hand-held flaring tool, which consists of a base with countersunk holes for the main pipe sizes and a corresponding set of nozzles.

Before starting work, the tube must be cut evenly, so that the cut is strictly perpendicular to the central axis. It is recommended to use pipe cutters specially adapted for this purpose. After this, we process the cut edge of the pipe with a file or cut off a chamfer using a rimmer and thereby remove all burrs from the inner and outer parts of the end.

Next, a tube is inserted into the hole of the base strictly along the diameter and clamped with a strong metal frame so that the edge of the tube protrudes slightly above the plane of the base level.

We take a nozzle corresponding to the hole, which is a steel cylindrical object on one side with a cone-shaped surface and a device for a pressure screw on the other side. Depending on the type of future connection, the flaring nozzle may have a different shape, so we select the surface of the required configuration.

Having installed the nozzle we need, we begin to gradually tighten the screw of the centering rod, pressing the surface of the nozzle onto the tube, gradually pressing it to the edges of the hole in the base. Upon completion of the operation, the rod screw is unscrewed, the base is disassembled and the flared tube is freely removed from the device.

The most important thing is not to forget to put the fitting nut on the tube in advance, otherwise you will have to repeat all the operations in the same sequence one more time.

Pros and cons of do-it-yourself flaring

Of the minuses, it is worth noting that brake pipes do not fail very often and your tool may only be needed once. An exception is if you buy used cars with high mileage that have been kept in poor, unfavorable conditions or have been in accidents and replace them quite often.

Whether to do the repairs yourself according to the instructions or entrust them to specialists is up to each person to decide individually, but it is always necessary to monitor the condition of the brake system and pipes, among other things! » alt=»»>

Frequently asked questions

In general, there should be no problems with the selection of tubes, tools and other things that will be required during rolling. However, many interesting things can be learned from manuals for car mechanics and auto mechanics. Let's answer popular questions regarding brake pipes, using instructions and advice from these guides:

- How to coat brake pipes? Answer : The original tubes are usually coated with a polymer material. The average car enthusiast can use an anti-corrosion spray;

- Is it possible to solder a brake pipe? Answer : this is an extremely unreliable solution that experts do not resort to. Leaking tubes are replaced. Only in some cases is soldering using hard solder allowed - with proper rolling, the solder will not reduce the diameter of the entire tube;

- Is it possible to bend brake pipes? Answer : it is possible, but the bend angles should not be large. It is especially not recommended to bend steel tubes at a large angle. For such work, it is best to use a pipe bender. Unbending the tubes is prohibited;

- Do I need to clean my brake lines? Answer : Yes, but it's really about cleaning the entire system. It is enough to monitor the brake fluid level and its condition. Periodically, the brake system should be flushed with fresh brake fluid.

It should also be noted that some car enthusiasts carefully clean the brake pipes and paint them in the color they like. This procedure is not mandatory, but it is quite possible to paint the brake pipes without harm to the brake system.

Do-it-yourself flaring of brake pipes, pros and cons

Flaring brake pipes is a process that may be needed at any time by someone who has a personal car. Of course, the implementation of this and any other procedure associated with technological service and vehicle repair can always be entrusted to competent service station professionals, however, many drivers take a different path and strive to do everything with their own hands. Any owner has the right to decide who to trust with the maintenance of their vehicle, and many of the problems can be completely resolved on their own.

How to change front tubes?

To operate you will need a special key. It is a tool with a bolt for tightening. The key resembles a spanner, but there is no need to purchase a cheap product in stores. Such keys are made of soft alloys that cannot withstand heavy loads. The nut on the tube is made of steel - the key easily fails, and the edges on the nut get licked off. Then unscrewing and tightening such a part can be a big problem. The nuts are tightened tightly enough that you can water them with WD-40, but you shouldn’t heat them. When heated, the brake fluid boils; due to the high pressure in the system, the hoses can rupture, especially if they are old.

Purpose of brake pipes

brake pipes are needed for and what function they perform , you do not need to regard them as an independent component, you should get acquainted with the entire system of the car. The car braking system functions in this way: if it is necessary to reduce speed or during sudden braking, the driver unscrews the corresponding lever, and the piston, which is in the main cylinder under great pressure, begins to drive away the liquid along special paths.

Braking itself or the absolute stop of the car occurs at the moment of restructuring the fluid pressure forces on the wheel cylinders in opposition to the brake pads. So, the paths along which the piston drives fluid to the wheels consist of tubes and hoses. Taking a part out of operation results in a malfunction of the entire braking system, and your car becomes unusable for use.

What to do to prevent brake pipes from souring in the future

There is no universal recipe here, it all depends on the time. But the use of penetrating anti-corrosion compounds for hidden body cavities, which envelop parts, prevent the development of corrosion due to the inhibitors contained in the composition, and do not allow water and oxygen to pass through to the threads, helps a lot.

The connection of the tube, nut and mating part is generously moistened with one of these compounds. After drying, they remain in a fairly elastic state.

This is interesting: What to do if the battery terminals oxidize

On top of this treatment, you can apply a layer of protection with more durable characteristics. These can be compositions such as anti-gravel or other body sealants. If necessary, they are easily removed.

Before screwing, the thread itself is coated with a special lubricant containing finely dispersed copper. Such auto chemical goods have recently been widely used during repair installations, significantly facilitating subsequent unscrewing.

Tube faults

If there is poor transmission of fluid through the pipes, the car brakes with delay, and the braking distance almost doubles. In addition, during the operation of the system, most often when the brake pedal is pressed, extraneous sounds and some impulse movements occur.

The cause of pipe damage is loss of fluid in the brake system. This loss will cause the brake drums to overheat and cause uneven pad wear. Another indicator may be the unusual behavior of the car when the lever is pressed, namely: the car moves a little to the side. Of course, this is not a direct cause, however, as professionals say, it may indicate a broken tube.

Each motorist should be a little familiar with the design of his own car in order to be able to repair the breakdown with his own hands in the event of repair work, if possible. This especially applies to the autobraking system. Often, when it malfunctions, it is necessary to flare the pipes through which the liquid passes, when the lever is pressed, from the cylinder to the pads.

When is flaring required?

If there is poor transmission of fluid through the pipes, the car brakes late, and the braking distance almost doubles. Also during the operation of the system, especially noticeable when the brake pedal is pressed, extraneous sounds appear, as well as some pulsating movements. The movement of the pedal, while pressing it, will seem a little free to you, this is very typical when the brake system, namely the brake pipes and hoses, is not functioning correctly. Also, one of the reasons for the malfunction of the pipes is the visible leakage of fluid and the brake system. This leak will cause the brake drums to overheat and cause the brake pads to wear unevenly. Another sign may be unusual behavior of the car when you press the pedal, namely, the car moves a little to the side. Of course, this is an indirect reason, but, according to experts, it may indicate a malfunction of the tubes.

It is important to know that the main problems due to which tubes break quite often are:

- destruction of the hexagonal head structure;

- the ingress of debris and dirt into the threaded connections or the ingress and coking of liquid in these places.

The above mentioned troubles cause great harm not only to the elements, but to the entire system. If the owner wants to protect the car from this kind of trouble, he should remember that it is necessary to test the car’s brake system at least once a year. If we equate the elements and the system itself with mileage, then diagnostics must be carried out every 50,000 kilometers, and parts, in particular rubber tubes, are changed after 125 thousand kilometers, regardless of their technical condition.

Flaring machine

When purchasing a flaring device, you need to focus on the manufacturer and cost. It is better not to purchase the cheapest kits, since their quality is not conducive to long-term use. This method of repair work will cost less than in a car repair shop.

Utility services are considered to be the culprit for unscheduled wear of pipes. Various chemical reagents and salts, generously scattered to combat, for example, ice, stimulate the rusting of the alloy several times and reduce the operating time of numerous elements allowed by the manufacturer. And another factor that forces us to often work on the braking system is the notorious domestic roads. When loaded, the tubes become deformed and burst. All together leads to the fact that the components quickly fail.

Tools and accessories

In order to flare tubes made of copper with your own hands, use special devices. Such devices can be either manual or electric driven. They are used for installation of air conditioning, water supply and heating systems. Tools equipped with an electric drive often combine several functions: with their help, you can not only flare a copper tube, but also bend it at the required angle.

Any device used to flare tubes made of copper operates on the principle of plastic deformation, so it is very important that it handles this process as carefully as possible, without disturbing the homogeneity of the structure of the material, maintaining the uniform thickness of the walls of the products, as well as the smoothness of their internal surfaces

Scheme of correct flaring and examples of an incorrectly performed operation

Sample

This is a cone-shaped blank made of a harder metal alloy than copper. The advantages of such a device are low price and ease of use. Meanwhile, its use may be accompanied by ruptures in the walls of the copper product, which results in low quality flaring.

With this simple device you can flare one tube, but you can’t talk about any quality of work

Mechanical flaring machine

The main working element of this device is a hard alloy roller, which, rolling along the edge of the copper tube, gives the latter the required configuration. The use of a mechanical flaring machine makes it possible to uniformly deform the treated section of the tube and form walls of the same thickness at its end with a high quality of their inner surface.

Hand tools are capable of providing high quality flaring and good work speed

Electric flaring machine

Such a device with a whole set of replaceable attachments, having all the advantages of a mechanical tool, allows you to flare copper tubes with higher productivity and less labor costs. Perhaps the only drawback of an electric flaring machine is its fairly high price.

The battery of this flaring machine lasts for approximately 100 operations.

Expander

This manual device, operating on the principle of a lever mechanism, allows you to flare the end of the tube in one movement. Despite its simplicity of design, such a device also has a number of significant disadvantages, the most significant of which is the inability to control the wall thickness of the workpiece. Thus, the use of an expander, which is most often chosen by those who do flaring with their own hands, does not guarantee a high-quality result.

Self-flaring

A cheaper way is to make a homemade machine rather than purchase a brake pipe flaring kit. With the desire and minimal ability to work with your hands, there is nothing difficult about this. First you need to make a base (frame) for attaching the parts. You can make it up from two metal corners. Cut the corners to the required length with a grinding machine, drill 2 holes in them for fastening with bolts. This is completed in 15 minutes.

Having assembled the frame, you need to make holes for the tube and remove the chamfers on a drill press or drill. The most difficult is the production of punches (mandrels). You can order them to a turner.

If you decide to purchase a pipe flaring kit, don't go with the cheapest alternatives on the market. Yes, you can buy devices for 800 rubles, but they will probably be disposable parts. It has been determined that a more or less high-quality tube flaring kit cannot cost less than 2,000 rubles, or even more.

Often the body of the tube remains intact, but the structure of its head is destroyed. There may be other types of breakdowns:

- coking of the thread as a result of liquid entering it;

- contamination of connections, etc.

In such situations, if the length allows, you can simply cut off the defective part with a special tool. You can replace the entire tube if you carry out the following repairs.

Work order

- The required piece of tube is cut with a pipe cutter.

- It is pressed with a holder so that the edge protrudes beyond it by 5-6 mm.

- Instead of the cone, a stamp corresponding to the cross-section of the tube is installed.

- The inner edge of the pipe is cleaned with something sharp; an ordinary knife will do just fine.

- The end is slightly filed with a file.

- The fitting is put on. The threads of the nut should be oriented toward the end of the tube, not toward the body.

- The seal is screwed in with the end of the tube flattened. The main thing here is not to overdo it and not to flatten too deeply.

- The stamp is knocked down and a cone is installed in its place. It must be screwed in carefully and without distortion.

- The result should be a tube ringed with a nut with a holder at the end.

- The finished tube is installed in place of the broken part, brake fluid is poured into the system, and then passed through it.

- The vehicle and system are tested for problems.

Having figured out how to flare the pipes yourself, provide yourself with a minimum amount of similar work in the future. To do this, install a copper tube in a special place. We assure you that you will need to remember about flaring much less often. Even with very active use of the machine, you will not need it in less than 3 years.

Pros and cons of do-it-yourself flaring

One of the advantages of do-it-yourself flaring is that you don’t need to pay someone for the work.

The downside is that your mechanism may only be needed once. An exception is if you purchase used cars with high mileage, which were in bad, negative circumstances or were in accidents, and change them quite often.

Whether to carry out repairs according to the instructions yourself or to entrust them to professionals is a personal decision, but it is necessary to constantly monitor the condition of the entire brake system and pipes.

So, to summarize, it can be noted that the work of flaring pipes is not very labor-intensive and complicated. You need to understand that most of the repair work on a steel friend can be easily done on your own. And this is very significant, because by fixing the problem yourself, you can not only save money, but also do the job better than any car mechanic. The main thing is to follow the instructions.

Tools

You can increase the diameter of a soft and elastic copper pipe manually by simply pulling it onto a conical blank of a suitable size.

However, it is very difficult to obtain a bell with the correct geometry using this artisanal method. The walls may have uneven thickness, causing thinner ones to stretch too much and thick ones not to stretch at all. The force applied by a person is also uneven, so it is possible that the pipe will bend during operation and the blank will be skewed, as a result of which the socket will turn out to be asymmetrical and skewed.

To make the beading carefully and form a socket of the desired shape from the edge of the pipe, which can subsequently ensure a reliable connection of structural elements, various tools are used.

Expander

This is a manual mechanism in which flaring is carried out simply by applying force, just like when using a conical blank. The expander consists of two handles and an expander - a sliding conical element that is inserted into the pipe. When the levers are acted upon, parts of the expander diverge in different directions, stretching the pipe.

The expander is inexpensive and allows you to get the job done quickly and without much labor. However, it is difficult to obtain high-quality results using this tool. The walls stretch unevenly, and thinner sections may rupture.

Cone flaring machine

This is a small set of two tools: a matrix and the flaring machine itself.

The matrix is a vice with several cylindrical holes, widened at the top to 45⁰. The hole sizes correspond to standard pipe diameters.

The flaring machine consists of:

- housings with guides,

- conical expander,

- control mechanism,

- power screw.

When the power screw that activates the control mechanism rotates, the expander is gradually screwed into the edge of the pipe, expanding it. The guides ensure that the relative position of the pipe and the expander remains constant, so that there are no distortions and a smooth and neat socket is obtained.

Mechanical flaring machine

This tool is similar to the previous one, but its working body is not a cone, but a set of rollers. The rollers do not stretch, but roll out the walls of the pipe, expanding it evenly and gradually, due to which the metal has the same thickness over the entire flared surface, and the socket is neat and symmetrical.

Electric flaring machine

Such a rolling apparatus, in addition to a mechanical flaring machine, has an electric drive, due to which pipe expansion work is completed faster and with less labor.

How to flare brake pipes yourself

The main condition for successful pipe end flaring has always been and will be the use of high-quality, or better yet professional, tools. For our cars, Europe-Asia, buy metric flaring kits. The Americans look more than decent, sparkling with chrome, but they can slip an inch system. The old Soviet standard for a copper brake pipe was 8 mm, more recent Soviet and Russian versions used 6 mm steel.

In terms of choice, the most affordable is the Force 656B, 906T2 brake pipe flaring kit; you can use the more elegant JonnesWay kits, or the common Biltema or Licota.

The flaring tool kit includes:

- a screw rolling press and a clamp, which is used to tighten the vise bars and deform the metal of the brake tube;

- two split clamp bars with six to seven holes with cones into which tubes for flaring are clamped;

- cutting device that allows you to cut off the end in a strictly perpendicular direction;

- a set of mandrels and cones of various diameters for the formation of fungi.

When choosing a flaring kit, pay attention to the following points. First, the screw pairs of the screw-nut of the press and the clamps should be matte black. This indicates heat treatment and hardening of the screw surface. A cheaper option uses chrome plating.

Secondly, the accuracy of the calibrated holes in the vise bars. Typically, the inner surface of the cones is coated with a protective phosphate-based oxide film. This coating facilitates the sliding of the deformed metal along the inner surface of the matrix.

Third, all calibrated holes have numerical markings of sizes, indicating units of measurement - millimeters or inches, punched by embossing to a depth of up to 0.1 mm, without additional chrome plating or painting. Alternatively, the entire structure can have an oxidized coating. Non-working parts can be painted with plain light paint.

Procedure for flaring brake pipes using a fungus with your own hands:

- select from the set a device for precise perpendicular cutting of the end of the brake pipe, insert it into a hole of the appropriate diameter, tighten the screw and turn the cutter a couple of times until it stops;

- there is also a sharp semicircular saw for removing internal chamfers and burrs;

- after filing the end of the brake pipe with a file, place a fitting nut on the pipe and secure the end in a vice with a clamp, observing the amount of release of the end of the pipe above the plane of the vice;

- add a couple of drops of brake fluid to the end of the tube, insert a mandrel of the appropriate size and press down on the edges of the tube, obtaining a fungus.

If, according to the flaring conditions, it is necessary to obtain the American version of the fitting, a cone is inserted into the clamp, and the edges of the upper part of the fungus are pressed under the cone of the matrix. Sometimes a ratchet is built into the design of the clamp, which allows you to limit the force applied to the surface of the fitting.

If flaring needs to be done quickly and at a large number of points, in the case of copper pipes, a simpler tool is used - pliers and a rotary roller.

The plasticity and pliability of copper does not require much effort to deform the metal, so it is faster and easier to flare the end with the force of your hand. Due to the compactness of the device, the pliers can be used for flaring brake pipes directly on the car, in conditions where it is difficult to carry out work with a standard set.

Copper pipe flaring tools

Types of flaring for most copper pipes are performed using special, manual and powered flaring devices. The former, due to their compactness and low weight, are used more often.

The operation of the tool is based on the principle of transverse distribution of a limited section of pipe. The following conditions must be taken into account:

- The flaring coefficient k = d/D (d is the internal diameter of the undeformed part of the copper tube, D is the maximum diameter of the lower cone after the end of flaring) should not be 0.75...0.85;

- The flaring angle should not exceed 300; in practice, this condition is often not met, as a result of which wavy folds and even cracks are possible at the end of the cone (in some cases, microcracks are visible even on the inner surface of the tube). Such products are defective and cannot be allowed for installation;

- The end of the tube to be flared must be cut evenly from the coil and carefully sanded. For cutting, it is recommended to use not an ordinary hacksaw, but a device for circular cutting, which ensures a clean cut. The device includes a cutting blade, a guide wheel and a tightening handle. As the tool rotates around the workpiece, the blade gradually penetrates the material, leaving a clean edge;

- After flaring, a thinning of the tube wall is observed, which can be determined by the formula s1 = sk0.5 (s is the initial thickness of the tube wall, s1 is the wall thickness after flaring, in the lower part of the cone).

When heating the copper tube, the limit value of the flaring coefficient can be reduced by 15-20%.

Let us briefly consider the most common types of flaring equipment.

Mechanical flaring machine

The key part of such a device is a roller (less often a ball), which is made of carbide or high-speed hardened steel. The roller is pressed against the prepared edge of the workpiece and rolled over it with pressure.

The flaring intensity is set visually, taking into account the above restrictions. The roller is moved along the deformable surface manually. When choosing the standard size of the device, you should correlate the geometric characteristics of the roller - radius of curvature, diameter - with the required size of the deformable end of the product.

Cone flaring machine

It represents the most successful instrument design. The main element is a conical punch. Moving in a screw guide, it produces a uniform distribution of the side walls of the tube. In appearance it resembles a manual screw press that can be mounted on a desktop or workbench.

The movement of the punch is controlled visually when the required degree of deformation is achieved. To reduce friction, the inner surface of the workpiece can be lubricated. When working with a cone flarer, the operating force will continuously increase.

Electric flaring machine

Manufacturers of such tools usually equip them with sets of various attachments, differing in the angle of the cone, the radius of curvature of the working part and its length. The price of the tool increases, but its operational capabilities increase. Flaring of copper tubes using powered flaring machines is advisable when the volume of operations performed is significant. The drive is powered by a battery.

Eccentric flaring machine

It works on the principle of rolling a pressing device over the surface of the workpiece. The processing force in this case is minimal, but a significant drawback is the uneven characteristics of the deformed part of the tube. In addition, the flaring process itself takes a longer time.

Lever flaring machine

The simplest type of equipment that can be made by hand. Another name is expander. It is a system of 2…4 levers, which are evenly located around the deformable workpiece, overcoming the resistance of the return springs during operation.

Flaring occurs by sequential and simultaneous movement of levers in the direction of deformation. The three-lever circuit is used less frequently because it requires two people to work. Another disadvantage of the device is the impossibility of ongoing quality control.

Features of flaring brake pipes

Steel brake pipes, unlike copper ones, have practically no reserve of ductility, so fungus and funnel can result in the formation of a large number of microcracks. In this sense, the rolled edge of the fungus remains less sensitive to the presence of microcracks, unless, of course, they are located only in the area of the hole. If cracks have formed on the periphery, in the widest part of the fitting, this option is definitely subject to rejection.

For American double funnels, it is often possible to use only copper brake pipe. In extreme cases, if there is an urgent need to flare a steel tube according to the American standard, the procedure is performed in two or three stages. At the first stage, after cutting and filing the end of the tube, it is flared to fit the fungus. Next, the resulting version is subjected to short-term annealing by heating with a burner, which makes it possible to relieve a significant part of the stress in the metal. The third stage will be flaring at an intermediate angle of 25-30°, instead of the required 45°, and repeated annealing. The last thing to do is final flaring to the desired funnel size.

If possible, before flaring the tube, it is worth practicing making a steel American funnel on an unnecessary piece of pipe made of a similar material.

The video shows the process of flaring brake pipes:

More about materials

Today, brake lines are made from several types of materials, but in passenger vehicles only copper and steel are used. It is impossible to mention here several types of rolling. The “mushroom” type rolling is most common in European cars, while the conical type is most common in Asian cars. Both types of rolling have their own characteristics. For example, when flaring copper tubes, deformation is often observed in the “fungus” area - a direct consequence of the high ductility of copper. But if the rolling is conical, then the connection, on the contrary, becomes more airtight. Here's what's important for ordinary car enthusiasts to know:

- Copper tubes are easier to install, they are more flexible and pliable and better withstand the effects of an aggressive environment (it’s not for nothing that we mentioned the salt used to cover roads in winter). Copper tubing is considered particularly preferable if the system uses conical rolling;

- Steel tubes are rigid and hold their shape well. They are recommended for use in automotive clutch systems, where the tube is rigidly fixed. The clutch tubes are quite short, so the high strength and low tendency of steel to deform comes in handy.

Experts note, however, that with the transition from conventional brake fluids of butyl alcohol and castor oil to DOT 3 and higher fluids, copper brake lines began to show serious shortcomings. First, DOT are quite hygroscopic and form several galvanic couples in the braking system. Damage may occur at contact points. Secondly, copper has a different coefficient of thermal expansion than steel. In some cars, the brake line can be about 4 meters or more in length, and it is this line that will noticeably lengthen when the brake fluid heats up. Experienced car enthusiasts note that in ordinary cars you can safely use copper tubes, but in SUVs that are used in particularly harsh conditions, it is better to use tubes made of high-quality stainless steel.