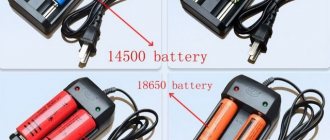

The charger for lithium batteries is very similar in structure and principle of operation to the charger for lead-acid batteries. Each lithium battery bank has a higher voltage value. In addition, they are more sensitive to overvoltage and overcharging.

Li-ion battery 18650

The jar is one life-giving element. It got its name from its resemblance to tin cans for drinks. For lithium cells, the most common option is 18650. This number is easy to decipher. The thickness is indicated in millimeters - 18 and height - 65.

If other types of batteries allow you to have a greater variation in the supplied voltage when charging, then for lithium batteries this indicator should be much more accurate. When the battery voltage reaches 4.2 volts, charging should stop; overvoltage is dangerous for them. A deviation from the norm of 0.05 volts is allowed.

The average charge time for lithium batteries is 3 hours. This is an average figure, yet each individual battery has its own value. Their service life depends on the charging quality of lithium batteries.

Long-term storage conditions

Advice. Lithium-ion batteries must be stored correctly. If the device will not be used for a long time, it is better to remove the battery from it.

If a fully charged battery cell is left in storage, it may permanently lose some of its capacity. If a discharged battery is left in storage, it may not recover. This means that even if you try to revive her, you can fail. Therefore, the optimal recommended charge for storing lithium cans is 30-50%.

Communities › DIY › Blog › Simple charger for lithium 18650.

When a lot of 18650 cans appeared, I charged them from various converted chargers from cameras, etc. Then, when I opened eBay, I saw these chargers for lithium cans. A dozen boards in 2014 cost 280 rubles.

This device is based on the well-known TP4056 chip. With one resistor you can set the charging current from tens of milliamps to 1 ampere. You can install a variable and regulate the current smoothly. Power supply from 4.8 to 7 volts. Moreover, the board already has a USB connector and charge indication. Red is charged, green is charged. According to my observations, this scarf quite consistently cuts off the battery from the charge when it reaches 4.16-4.19 volts. Quite what you need. Here is a table for “programming” the charge current. Everything is elementary.

And here is a typical diagram from the datasheet. It's also simple.

I assembled 2 blocks, for 2 and 4 cans. I made the box with springs myself. Made from single-sided foil PCB. I cut the parts and soldered them with a soldering iron. cut off the excess copper. Next, I glued the scarves themselves to the side. The power supply is connected in parallel. The charging outputs via GND were combined into one bus, and the “pluses” were distributed across each section. I configured the controllers for a current of 700mA. I took the springs from old Chinese broken toys. I tinned them with hydrazine and soldered them to copper foil. This is how the device turned out. You can insert batteries to charge without disconnecting the charger from the power supply.

A small addition: There are disposable electronic cigarettes in nature (they cost from 100 rubles like Pons, etc.), and this is a source of small (size 08570) lithium batteries with an approximate capacity of 280-300 mAh. They hit me with about 30-40 of these cigarettes and I tore out the batteries from them. The main thing is to charge them after tearing them out of the cigarette. They produce a decent amount of current, although they are not quite designed for that, but I even flew a small helicopter with them on RU. 2 batteries have been working in the tester for the 4th month. In general, do not rush to throw away these cigarettes or shoot them from friends, gut them for batteries. Just remember that these batteries do not have any protection, not even mechanical, they are quite soft. I deliberately pierced a couple of these charged batteries with a knife and they almost caught fire. carefully. This is what they look like. It is better to store charged ones

40% chilled. So they wait longer in the wings.

Source

Using original chargers

Battery charger

Some manufacturers indicate that using non-original chargers for li ion batteries may void the warranty on the device. The thing is that a bad charger can destroy the battery cell. Lithium batteries can deteriorate due to incorrect voltage or incorrect attenuation at the end of charging. Therefore, using an original charger is always the best choice.

Factory memory

Circuit 10 - on the LM3914 chip

A line of 10 LEDs informs the user about the level of battery discharge. The threshold voltages (minimum DIV_LO and maximum DIV_HI) are determined by the divider R3-R4-R5. To save energy, it is recommended to connect pin 9 to ground. As a result, not a line of LEDs will light, but one that corresponds to the current voltage. The power consumption of this circuit is about 2.5 mA and another 5 mA for each illuminated LED.

Read our previous article about why scooter batteries explode.

Danger of overcharging and complete discharge

Universal charger

Based on the design of lithium batteries, it is not recommended to allow them to be completely discharged or recharged.

For example, nickel-cadmium batteries have a memory effect. This means that incorrect charging mode leads to loss of capacity. The mode is considered incorrect when a battery is recharged that is not completely discharged. If you start charging it when it is not completely discharged, it may lose its capacity. Chargers for such batteries are manufactured with special operating modes that first discharge the battery to the required level, then begin to recharge it.

Lithium batteries do not require such troublesome maintenance. They do not have a memory effect, but they are afraid of complete discharge. Therefore, it is better to recharge them when the opportunity arises, without waiting for a complete discharge. But overcharging is also unacceptable for them. Therefore, it would be optimal not to allow the discharge to fall below 15% and the charge to exceed 90%. This can increase battery life.

This only applies to batteries without protection. If the batteries have protection implemented on a separate board, then it cuts off the charge beyond measure; if the discharge reaches a minimum level, it turns off the device. Usually these are indicators of more than 4.2 Volts and 2.7 Volts, respectively.

Scheme 1 - using a zener diode and a transistor

When the voltage is above 3.25 V, the zener diode is in breakdown, the transistor is in the off state, and the current flows entirely through the green LED. When the voltage drops to values in the range of 3+1.2 V, the transistor opens and the current is distributed between the LEDs. There is a smooth transition between colors. The brighter the red indicator is, the more discharged the element is. At 3 V there is no color transition - the red light is on.

When implementing this scheme, difficulties may arise in finding zener diodes that provide the required response threshold. Another disadvantage is its constant power consumption of about 1 mA.

Attitude to temperature changes

Charger for screwdriver

The operating temperature range for lithium batteries is small - from +5 to +25 degrees Celsius. Strong temperature changes are undesirable for their operation.

Homemade charger for lithium-ion batteries

When overcharging, the temperature of the battery may rise, which has a negative effect on its performance. Low temperature also has a negative effect. It has been noted that in cold weather the batteries lose their charge faster and run out, although in warm conditions the device shows a full charge.

DC/DC converters for solar panels

For most battery-powered mobile devices, the charger is designed as a stand-alone device for household AC power. That is, in any case, an AC/DC converter is required to generate a DC input voltage for the battery charging microcircuit. STMicroelectronics offers a wide range of such converters, as well as proven network adapter design technology. However, network chargers, although the most common, are not the only possible solution. Solar energy stored in solar panels can be used as an energy source. The STMicroelectronics product range includes DC/DC converter microcircuits for solar cells using the MPPT (Maximum Power Point Tracking) algorithm. Without going into specific details, we note that today MPPT technology is the most advanced and efficient technology for solar charge controllers. Calculating the maximum charging efficiency point from a solar module allows you to increase the efficiency of solar energy generation by up to 25...30% compared to other types of controllers [6]. STMicroelectronics currently produces two microcircuits - SPV1020 and SPV1040 . The first works with a chain of series-connected solar cells with an output voltage in the range of 6.5 ... 40 V. The second, as a rule, with a single battery with a voltage of up to 5.5 V. STMicroelectronics has also released a demo board STEVAL-ISV012V1, which includes MPPT DC/DC converter SPV1040 and charge chip L6924D . Figure 8 shows a demo board.

Rice. 8. Solar charger demo board STEVAL-ISV012V1

The material [7] indicates that the total efficiency of such a combination is approximately 85% (for SPV1040 - 94%, for L6924D - 90%).

Features of lithium batteries

Li-ion batteries are very unpretentious to use. If handled with care, they will last about 3-4 years. However, it is worth focusing on the fact that even if batteries are not used, they slowly die. Therefore, stocking up on batteries for the device for future use is not entirely reasonable. 2 years is the normal time from the date of production. If more has passed, then these may be already failed batteries.

Interesting. The most common 18650 can size has an average capacity of 3500 mAh. The normal price for such a battery is 3-4 dollars. Therefore, manufacturers who promise a 10,000 mAh Power bank for $3 are, to put it mildly, deceiving. It would be good if there was at least 3000 mAh.

How to charge a 18650 battery

When charging a 18650 battery, the following rules must be observed:

The optimal mode consists of two stages:

Some “charger” models are equipped with a battery recovery mode for deep discharge (less than 2.5 V). The battery is charged with low current (no more than 5-10% of capacity) until its voltage reaches 2.8 V. After this, the charger switches to direct current mode.

Source

How to make a charger for a lithium battery with your own hands

Homemade charging circuit for lithium batteries

Let's look at one of the simplest charger circuits for lithium-ion batteries. A homemade charging circuit is implemented on a microcircuit that acts as a zener diode and charge controller, and a transistor. The base of the transistor is connected to the control electrode of the microcircuit. Lithium batteries do not like overvoltage, so the output voltage must be set to the recommended voltage of 4.2 V. This can be achieved by adjusting the microcircuit with resistances R3 R4, which have values of 3 kOhm and 2.2 kOhm, respectively. They are connected to the first leg of the microcircuit. The adjustment is set once, and the voltage remains constant.

To be able to adjust the output voltage in place of the resistor R, install a potentiometer. The adjustment must be made without a load, that is, without the battery itself. With its help, you can precisely adjust the output voltage to 4.2 V. Then, instead of the potentiometer, you can install a resistor of the obtained value.

Resistor R4 is used to turn on the base of the transistor. The nominal value of this resistance is 0.22 kOhm. As the battery charges, its voltage will increase. This will cause the control electrode on the transistor to increase the emitter-collector resistance. This, in turn, will reduce the current going to the battery.

You also need to adjust the charging current. To do this, use resistance R1. Without this resistor, the LED will not light up; it is responsible for indicating the charging process. Depending on the required current, a resistor with a nominal value of 3 to 8 ohms is selected.

Charging cobalt-blended batteries

Classic lithium-ion battery designs are equipped with cathodes whose structure is made up of materials:

- cobalt,

- nickel,

- manganese,

- aluminum.

All of them are usually charged at a voltage of up to 4.20V/I. The permissible deviation is no more than +/- 50 mV/I. But there are also certain types of nickel-based lithium-ion batteries that allow a charge voltage of up to 4.10V/I.

Cobalt-blended lithium-ion batteries are equipped with internal protective circuits, but this rarely prevents the battery from exploding when overcharged.

There are also developments of lithium-ion batteries, where the percentage of lithium has been increased. For them, the charge voltage can reach 4.30V/I and higher.

Well, increasing the voltage increases the capacity, but if the voltage goes beyond the specification, it can lead to destruction of the battery structure.

Therefore, for the most part, lithium-ion batteries are equipped with protective circuits, the purpose of which is to maintain the established standard.

Full or partial charge

However, practice shows: most powerful lithium-ion batteries can accept a higher voltage level, provided that it is supplied for a short time.

With this option, the charging efficiency is about 99%, and the cell remains cool during the entire charging time. True, some lithium-ion batteries still heat up by 4-5C when they reach a full charge.

This may be due to protection or due to high internal resistance. For such batteries, the charge should be stopped when the temperature rises above 10ºC at a moderate charge rate.

Lithium-ion batteries in the charger are being charged. The indicator shows the batteries are fully charged. Further process threatens to damage the batteries

Full charging of cobalt-blended systems occurs at a threshold voltage. In this case, the current drops by up to 3-5% of the nominal value.

The battery will show a full charge even when it reaches a certain capacity level that remains unchanged for a long time. The reason for this may be increased self-discharge of the battery.

Increasing charge current and charge saturation

It should be noted that increasing the charge current does not speed up the achievement of a full charge state. Lithium will reach peak voltage faster, but charging until the capacity is completely saturated takes longer. However, charging the battery at high current quickly increases the battery capacity to approximately 70%.

Lithium-ion batteries do not require a full charge, as is the case with lead-acid devices. Moreover, this charging option is undesirable for Li-ion. In fact, it is better to not fully charge the battery, because high voltage “stresses” the battery.

Selecting a lower voltage threshold or completely removing the saturation charge helps extend the life of the lithium-ion battery. True, this approach is accompanied by a decrease in the battery energy release time.

It should be noted here: household chargers, as a rule, operate at maximum power and do not support adjustment of the charging current (voltage).

Manufacturers of consumer lithium-ion battery chargers consider long battery life to be less important than the cost of circuit complexity.

Li-ion battery chargers

Some cheap household chargers often work using a simplified method. Charge a lithium-ion battery in one hour or less, without going to saturation charge.

The ready indicator on such devices lights up when the battery reaches the voltage threshold in the first stage. The state of charge is about 85%, which often satisfies many users.

This domestically produced charger is offered to work with different batteries, including lithium-ion batteries. The device has a voltage and current regulation system, which is already good

Professional chargers (expensive) are distinguished by the fact that they set the charging voltage threshold lower, thereby extending the life of the lithium-ion battery.

The table shows the calculated power when charging with such devices at different voltage thresholds, with and without saturation charge:

| Charge voltage, V/per cell | Capacity at high voltage cut-off, % | Charging time, min | Capacity at full saturation, % |

| 3.80 | 60 | 120 | 65 |

| 3.90 | 70 | 135 | 75 |

| 4.00 | 75 | 150 | 80 |

| 4.10 | 80 | 165 | 90 |

| 4.20 | 85 | 180 | 100 |

As soon as the lithium-ion battery begins to charge, there is a rapid increase in voltage. This behavior is comparable to lifting a load with a rubber band when there is a lag effect.

Capacity will eventually be gained when the battery is fully charged. This charge characteristic is typical for all batteries.

The higher the charging current, the brighter the rubber band effect. Low temperature or the presence of a cell with high internal resistance only enhances the effect.

The structure of a lithium-ion battery in its simplest form: 1- negative busbar made of copper; 2 — positive tire made of aluminum; 3 - cobalt oxide anode; 4- graphite cathode; 5 - electrolyte

Assessing the state of charge by reading the voltage of a charged battery is impractical. Measuring the open circuit (idle) voltage after the battery has been sitting for several hours is the best evaluation indicator.

As with other batteries, temperature affects idle speed in the same way it affects the active material of a lithium-ion battery. , laptops and other devices is estimated by counting coulombs.

Lithium-ion battery: saturation threshold

A lithium-ion battery cannot absorb excess charge. Therefore, when the battery is completely saturated, the charging current must be removed immediately.

A constant current charge can lead to metallization of lithium elements, which violates the principle of ensuring the safe operation of such batteries.

To minimize the formation of defects, you should disconnect the lithium-ion battery as quickly as possible when it reaches peak charge.

This battery will no longer take exactly as much charge as it should. Due to improper charging, it lost its main properties as an energy storage device.

As soon as the charge stops, the voltage of the lithium-ion battery begins to drop. The effect of reducing physical stress appears.

For some time, the open circuit voltage will be distributed between unevenly charged cells with a voltage of 3.70 V and 3.90 V.

Here, the process also attracts attention when a lithium-ion battery, which has received a fully saturated charge, begins to charge the neighboring one (if one is included in the circuit), which has not received a saturation charge.

When lithium-ion batteries need to be constantly kept on the charger in order to ensure their readiness, you should rely on chargers that have a short-term compensation charge function.

The flash charger turns on when the open circuit voltage drops to 4.05 V/I and turns off when the voltage reaches 4.20 V/I.

Chargers designed for hot-ready or standby operation often allow the battery voltage to drop to 4.00V/I and will only charge Li-Ion batteries to 4.05V/I rather than reaching the full 4.20V/I level.

This technique reduces physical voltage, which is inherently associated with technical voltage, and helps extend battery life.

Charging cobalt-free batteries

Traditional batteries have a nominal cell voltage of 3.60 volts. However, for devices that do not contain cobalt, the rating is different.

Thus, lithium phosphate batteries have a nominal value of 3.20 volts (charging voltage 3.65V). And new lithium titanate batteries (made in Russia) have a nominal cell voltage of 2.40V (charger voltage 2.85).

Lithium phosphate batteries are energy storage devices that do not contain cobalt in their structure. This fact somewhat changes the charging conditions for such batteries.

Traditional chargers are not suitable for such batteries, as they overload the battery with the risk of explosion. Conversely, a charging system for cobalt-free batteries will not provide sufficient charge to a traditional 3.60V lithium-ion battery.

Exceeded charge of lithium-ion battery

The lithium-ion battery operates safely within specified operating voltages. However, battery performance becomes unstable if it is charged above operating limits.

Long-term charging of a lithium-ion battery with a voltage above 4.30V, designed for an operating rating of 4.20V, is fraught with lithium metalization of the anode.

The cathode material, in turn, acquires the properties of an oxidizing agent, loses its stability, and releases carbon dioxide.

The pressure of the battery cell increases and if charging continues, the internal protection device will operate at a pressure between 1000 kPa and 3180 kPa.

If the pressure rise continues after this, the protective membrane opens at a pressure level of 3.450 kPa. In this state, the lithium-ion battery cell is on the verge of exploding and eventually does just that.

Structure: 1 - top cover; 2 - upper insulator; 3 - steel can; 4 - lower insulator; 5 — anode tab; 6 - cathode; 7 - separator; 8 - anode; 9 — cathode tab; 10 - vent; 11 - PTC; 12 — gasket

Triggering of the protection inside a lithium-ion battery is associated with an increase in the temperature of the internal contents. A fully charged battery has a higher internal temperature than a partially charged one.

Therefore, lithium-ion batteries appear to be safer when charged at a low level. That is why the authorities of some countries require the use of Li-ion batteries in aircraft that are saturated with energy no more than 30% of their full capacity.

The internal battery temperature threshold at full load is:

- 130-150°C (for lithium-cobalt);

- 170-180°C (for nickel-manganese-cobalt);

- 230-250°C (for lithium manganese).

It should be noted: lithium phosphate batteries have better temperature stability than lithium manganese batteries. Lithium-ion batteries are not the only ones that pose a danger in energy overload conditions.

For example, lead-nickel batteries are also prone to melting with subsequent fire if energy saturation is carried out in violation of the passport regime.

Therefore, using chargers that are perfectly matched to the battery is of paramount importance for all lithium-ion batteries.

How to choose a battery

Special attention should be paid to battery manufacturers. There are reputable brands and some unknown analogues. Sometimes unscrupulous manufacturers can sell goods that are 3 times or more lower than the declared characteristics.

Note! Brands that have gained popularity include Panasonic, Sony, Sanyo, Samsung.

Purchasing lithium batteries should not be a big problem. You can buy them at local electronics stores, online stores, or order them directly from China. Don't go after cheap prices. A good battery cannot be very cheap. Some manufacturers supply high-quality banks, but poor boards responsible for power supply. This will inevitably lead to the death of the battery.

Useful tips for using 18650 batteries

To preserve battery capacity and extend their service life, you need to follow several tips:

When purchasing a battery, you need to pay attention to the release date. Batteries manufactured more than 3 years ago are considered expired and low-functional.

How does charging work?

How does the finished circuit of such a charger work? First, the battery is charged with a constant current, which is determined by the resistance of resistor R5; with a standard rating of 11 ohms, it will be approximately 100 mA. Further, when the rechargeable energy source has a voltage of 4.15-4.2 volts, charging with constant voltage will begin. When the charging current drops to small values, LED D1 will stop lighting.

As you know, the standard voltage for charging Li-ion is 4.2V; this figure must be set at the output of the circuit without load, using a voltmeter, so the battery will be fully charged. If you reduce the voltage a little, by about 0.05-0.10 Volts, then your battery will not be fully charged, but this way it will last longer. Author of the article Egor .

Discuss the article CHARGING LITHIUM BATTERIES

Source: radioskot.ru

What batteries is the device suitable for?

The circuit is designed to charge only one can of a lithium battery. You can charge standard 18 650 batteries and other batteries, you just need to set the appropriate voltage at the output of the charger. If suddenly for some reason the circuit does not work, then check the presence of voltage at the control pin of the microcircuit. It must be at least 2.5 Volts. This is the minimum operating voltage for the chip's external reference voltage. Although there are versions where the minimum operating voltage is 3 Volts. It is also advisable to build a small test bench for the specified chip to check its functionality before soldering. And after assembly, we carefully check the installation.

Another publication contains material about improving charging for screwdrivers.

Source: izobreteniya.net

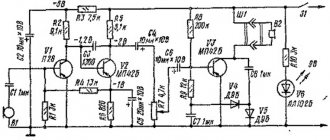

Description of charging operation

Voltage stabilization is based on the rather popular tl431 adjustable zener diode microcircuit. Transistor as an amplifying element. The charge current is set by resistor R1 and depends only on the parameters of the battery being charged. This resistor is advised with a power of 1 watt. And all other resistors are 0.25 or 0.125 watts.

As we know, the voltage of one can of a fully charged lithium-ion battery is about 4.2 Volts. Therefore, at the output of the charger we must set exactly this voltage, which is set by selecting resistors R2 and R3. There are many online programs for calculating the stabilization voltage of the tl431 microcircuit. For the most accurate adjustment of the output voltage, it is recommended to replace resistor R2 with a multi-turn resistance of about 10 kilo-ohms. By the way, such a solution is possible. We use an LED as a charge indicator; almost any LED, color to your taste, will do. The whole setup comes down to setting the output voltage to 4.2 volts. A few words about the tl431 zener diode. This is a very popular microcircuit, do not confuse it with transistors in a similar package. This microcircuit is found in almost any switching power supply, for example a computer, where the microcircuit is most often found in the harness. The power transistor is not critical; any reverse conduction transistor of medium or high power is suitable, for example, from the Soviet ones, KT819, KT805 are suitable. Of the less powerful KT815, KT817 and any other transistors with similar parameters.

The simplest scheme

Today we’ll look at options for a UDB charger for lithium batteries that anyone can replicate. The scheme is the simplest one you can think of.

This is a hybrid circuit where there is voltage stabilization and battery charging current limitation.

Purpose of the charging controller

The controller regulates the process of charging and discharging the battery. If the voltage drops below 3 V, the protection disconnects the can from the current consumer: the device turns off. The protective circuit also prevents short circuits. Some types of protective boards have a thermistor that protects battery elements from overheating.

All boards monitor:

- battery overdischarge;

- recharge;

- load current;

- temperature.

Having a protective board on hand, you can convert old screwdriver and drill batteries to lithium batteries, which have a long service life.