Purpose of automobile gas analyzers

The general purpose of gas analyzers is to measure and analyze gas mixtures to determine their quantitative and qualitative (volume and percentage) composition. In particular, a gas analyzer for a car is used to measure the amount of harmful emissions in the exhaust gases of internal combustion engines running on gasoline, diesel and gaseous fuels: carbon monoxide (CO), carbon dioxide (CO2), hydrocarbons and other compounds. Engine diagnostics, adjustment and repair of carburetors , gas equipment, setting up fuel injection systems - this is not a complete list of work, the implementation of which is almost impossible without the use of automobile gas analyzers. Fuel consumption adjustment is a service that is especially in demand these days, when the cost of fuel is rising day by day.

Depending on the design, automotive gas analyzers can measure one or more components of exhaust gases (single-component and multi-component). One- or two-component gas analyzers can measure the amount of harmful impurities in the exhaust gases of cars (CO, nitrogen oxides) that are not equipped with catalysts. Some time ago, the most common were single-component gas analyzers for determining the content of carbon monoxide CO. The introduction of emission standards according to EURO environmental standards not only of CO, but also of other components of exhaust gases stimulated the production and use of multicomponent gas analyzers to assess their composition. Using conventional automotive gas analyzers, you can diagnose and adjust either gasoline or diesel engines. Universal gas analyzers allow you to diagnose and adjust both gasoline and diesel internal combustion engines.

EURO environmental standards

European standards are introduced by the UN EEC (European Environmental Commission) and regulate the content of carbon monoxide (CO), nitrogen oxides (NO), hydrocarbons (CH), and other harmful substances. Starting with the EURO1 environmental standard, introduced in 1992, the standards are gradually becoming more stringent, while exhaust gas aftertreatment systems must comply with a certain environmental class (environmental standards of the car) depending on its service life. There are 6 classes in total, from 0 to 6. Car engines equipped with catalysts and fully meeting EURO environmental standards that regulate the content of harmful impurities in the exhaust gases of cars and special equipment require the use of multicomponent gas analyzers, which are more accurate and expensive. The measurement methods for single- and multi-component gas analyzers of automobile exhausts are somewhat different from each other.

Exhaust gas composition

The exhaust gases removed from the combustion chamber during the exhaust stroke contain toxic and non-toxic components (about 200 in total), which can be combined into several groups depending on the chemical composition, properties and nature of the impact on the environment and the human body: – Non-toxic components. These are natural components of atmospheric air (for example, water vapor H2O). – Carbon monoxide (carbon monoxide CO). Released during incomplete combustion of fuel, it has a pronounced toxic effect. The degree of poisoning depends on its concentration and duration of exposure to humans. At doses above 1%, loss of consciousness and death are possible. – Nitrogen oxides NO and nitrogen dioxides NO2. Considered more dangerous than carbon monoxide. When nitrogen oxide is oxidized by atmospheric oxygen, nitrogen dioxide is formed - a gas heavier than air, which collects in niches and recesses and is very dangerous when servicing cars. Affects the mucous membrane and lung tissue; with prolonged exposure, bronchitis and disruption of the cardiovascular system are possible. – Aromatic hydrocarbons (compounds of the CxHy type). They are also formed during incomplete combustion of fuel. Incorrect engine adjustment, delayed ignition and low temperature in the combustion chamber lead to smoke. Hydrocarbon compounds are toxic, affect the cardiovascular system and are strong carcinogens.

Design and principles of operation of automobile gas analyzers

A simple automotive single-component gas analyzer is designed to measure the content of only carbon monoxide CO in exhaust gases, mainly using the method of afterburning incompletely burned components in the exhaust gases. Afterburning of CO is carried out in the measuring chamber of the device using a special heated filament, and the change in the temperature of the filament characterizes the CO content in the gases. The accuracy of the readings of such a gas analyzer is low and depends largely on the content of another component - CH hydrocarbon.

Determination of the content of harmful substances in exhaust gases by modern multi-component gas analyzers for cars is carried out without the use of chemical reagents, mainly by thermal (infrared) measurement method. The method is based on the principle of measuring the absorption of thermal radiation by various components of exhaust gases. Gas analyzers have built-in infrared emitters and radiation receivers. Between them there are measuring elements into which the analyzed mixture is supplied. By the magnitude of the decrease in the intensity of infrared rays passing through the gas and arriving at the receiver, it is possible to determine the concentration of any component in the gas mixture.

In addition to the measuring ones, the gas analyzer contains tubes with a reference gas mixture. They serve for continuous comparison of the degree of absorption of thermal radiation in the reference mixture and in the analyzed gas. The value of this difference is converted into digital or analog form and transmitted to a indicating or recording device. Before starting measurements, in order to avoid additional errors, the gas analyzer must be warmed up. Gas is sampled using a gas sampling tube (probe). To clean the exhaust gases supplied for analysis from soot, solid particles and water droplets, the tube is equipped with replaceable filters and water separators. A built-in pump is used to force the test gases through the measuring tubes. The calibration of the scales of automobile gas analyzers for O2, CO and CO2 is usually carried out in percentages, for CH - in parts per million (ppm), i.e. 1000 ppm = 0.1%. Thus, an experienced technician, using a gas analyzer of automobile exhausts, based on the complete information received about the process of fuel combustion in the engine, will be able to draw correct conclusions about the possible causes of its violation.

GAZ 24 Red Special › Logbook › Lambda probe and alphameter on 24d

It's no secret that the end of the school year is a difficult time for students and teachers, and I am a student who manages to teach in two schools, therefore, between frantic preparations for exams and filling out magazines, there is little time left for poking around the Volga. Today I received a sad email from Drive2: “How is the GAZ 24 Red Special doing? We noticed that you have not updated the logbook of the GAZ 24 Red Special for a long time. 315 people have subscribed to your car and are waiting for news about it.”

And I decided to tell the public what I’m working on now...

Actually, I decided to introduce a lambda when I was building the exhaust. I was inspired by Mortis's article “How to build a racing Volga”. Quote from the article: “ Carburetors are a very broad topic, but the fundamental desire of the organizers to strangle the engine with standard models does not leave much freedom for creativity. The first thing you need to worry about in this field is installing an oxygen sensor and a display meter that will visualize its signal. This way you can monitor the composition of the mixture in real time and save yourself a LOT of time when setting up the carb and diagnosing faults. Any four-wire zirconium lambda will do (cheapest from VAZ cars), display meters are very rare in our stores and are expensive, so the best option is to order on Aliexpress (search for the phrase “Air Fuel Ratio Gauge”). The connection diagram for this goodness is usually included in the kit.

«

So, a four-wire zirconium VAZ lambda was purchased, and the alphameter had been waiting for this moment for a long time (Brake force regulator and Chinese collective farm (Alphameter, tachometer)).

At first I thought that the lambda would fit at the junction of the exhaust pipes, but at the ceremonial moment of installation it turned out that the sensor did not fit there in height and then I was once again happy about my exhaust system with flange connections. I unscrewed the corrugation and installed the sensor.

The alphameter, in fact, like the tachometer, are in my cabin where the fuses are. It's hard to see, but these devices only play a tuning role, and it's likely that in the end they won't exist at all.

The selection of jets is still underway, but the direction has become much clearer. It corresponds exactly the opposite to my previous one. After the session I’ll finish and tell you what jets I used for the 55 shaft. Comparing the obtained readings from the lambda probe and carbon deposits on the spark plugs, I at least realized that my beautiful new spark plugs were too “hot” for my configuration.

There is a video where the alphameter still shows something incomprehensible.

In general, this is how things are going for the GAZ 24 Red Special.

Thank you for your attention. Solomon2302.

Source

Types and applications of automotive gas analyzers

Modern combined automotive gas analyzers, in addition to determining the composition of exhaust gases, are capable of diagnosing and providing additional information about the technical parameters of the engine (oil temperature, engine speed, start of injection pump operation, ignition timing, excess air ratio, etc.). Gas analyzers can be additionally equipped with a printing device, an interface for transferring data to a computer or a synchronized printer.

Depending on the conditions of use, automobile gas analyzers are divided into: – stationary – designed for operation in stationary premises; – transportable – used in mobile laboratories; – portable – for outdoor work; – block-modular – systems that are moved on special trolleys and are not tied to a specific location.

Gas analyzer

A gas analyzer is an electro-optical device for measuring the volume fraction of components in engine exhaust gases.

Gas analyzers come in 1,2,3,4,5-component types. Measured exhaust gas components: CO, CH, CO2, O2, NOx. We know that all modern gasoline cars (except for cars with direct fuel injection into the cylinders and stratified mixture distribution) at steady state (except for full load) must operate at a stoichiometric air / fuel ratio (Lambda equal to 1). Moreover, the accuracy of maintaining this ratio is quite high (Lambda = 0.97-1.03). Lambda is an integral parameter that allows you to evaluate the quality of the working mixture. And the quality of combustion of the mixture can be assessed by the composition of the exhaust gases. For diagnostic tasks, it would be correct to use 4 and 5-component gas analyzers, and those that are capable of calculating the Lambda coefficient.

For autodiagnostics, a 4-component gas analyzer is indispensable. It helps to look inside the combustion chambers of a running engine and determine how the combustion process of the fuel-air mixture proceeds. This mixture should, if possible, burn completely in the engine so that the maximum possible engine power can be achieved with low fuel consumption and the resulting harmful substances can be kept as insignificant as possible from the very beginning. Absolutely perfect combustion is impossible even with an ideal air-fuel mixture, since the time available for this is too short, even with the best design and optimal adjustment of all components important for combustion. From a theoretical point of view, combustion would be perfect with a fuel to air weight ratio of 1:14.7 or, representing in volume, 1 liter of fuel mixed with 10,000 liters of air. This ratio is denoted lambda.

The analyzed gas enters the analyzed cuvette, where the components being determined, interacting with the radiation, cause its absorption in the corresponding spectral ranges. Radiation fluxes of characteristic regions of the spectrum are separated by interference filters and converted into electrical signals proportional to the concentration of the analyzed components. When interacting with oxygen, the electrochemical sensor produces a signal proportional to the oxygen concentration. The l value is calculated automatically by the gas analyzer based on the measured CO, CH, CO2 and O2.

Modern high-class gas analyzers, in addition to reliability and ease of use, have many additional functions. They can measure engine crankshaft speed, oil temperature, and also store intermediate measurement protocols and transfer the results to a personal computer or print them on a built-in printer.

A very important quality of a gas analyzer from the operator’s point of view is its reliability. Since, by design, a gas analyzer is a complex electronic device, it is usually impossible to repair it on your own and you have to contact a company service center, which is extremely inconvenient. Therefore, when choosing a gas analyzer model, you should pay attention to its protection from external influences and the presence of a preliminary preparation unit gases

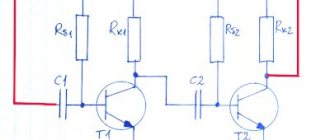

DIY alphometer

This device does not claim any calibrated measurement accuracy and belongs to the class of indicators, or, as people say, “display meters”. However, its modest capabilities are quite enough for fairly precise adjustment of the mixture composition. The device is very simple and is implemented on an Atmel microcontroller (AVR series) with built-in comparators and allows you to measure and display the signal from the sensor (range 0...1 volt) and its dynamics. The device is practically inertia-free and allows, in addition to the level, to evaluate the switching speed (signal edges). The resolution of the indicator is approximately 0.1V; to simplify reading, one LED is always on.

The capacitor connected to pins 13 and 14 of the microcontroller is the master capacitor for the comparator, so it is desirable to be more precise and stable (in my case, K71-7 2710pF one percent). A DS1811 or similar power monitoring chip/Watch Dog Timer can be used to reset/start up the microcontroller. Quartz 4 MHz. I provide files for flashing the microcontroller in two versions - in hexadecimal (tes tlambda.hex) and binary (testlambda.bin) formats...

Connection on the car: (+12) in the diagram – battery plus, (GND) – battery minus/ground, input (IN) – to the signal wire of the oxygen sensor (Lambda probe). And this is what the finished device looks like, assembled on a breadboard

The oxygen sensor begins to work when the temperature of the sensing element reaches 350 degrees Celsius. Therefore, immediately after turning it on, you need to wait a few minutes for it to completely warm up. If a single-wire (not heated) probe was installed in the car, you must wait until it is warmed up to operating temperature by exhaust gases. We have never repeated this design, so we cannot give any comments on it. But, most likely, this is a simple narrow-range voltmeter. That is, to put it simply, this is not quite an alphometer, since the characteristics of the DC are not taken into account and it is not alpha that is displayed, but the voltage removed from the DC, which in an “adult” alphometer is converted into alpha. But its readings can be easily calibrated using a standard gas analyzer.

Source