Features of modern sealant guns

Many repair compounds are produced in tubes made of plastic or cardboard. It is for such containers that the sealant gun is intended; with its help, the composition can be applied to the surface evenly and accurately.

The tube itself is a large syringe equipped with a piston, but without a rod.

The role of the last element is performed by a special device, the operating principle of which is as follows:

- A part like a trigger presses on the rod.

- The rod, under pressure, pushes the piston inside the tube.

- The piston forces the contents of the tube out.

This tool is used to apply:

- Silicone;

- Acrylic;

- Chemical anchor;

- Liquid nails, etc.

In this case, the compositions can be packaged in appropriate tubes, or they can be completely unpackaged.

Instructions for use

This tool is characterized by ease of use.

Beginners should read the step-by-step instructions before using this mechanism.

First of all, you need to take care of protective measures. You need to wear gloves and cover objects and surfaces near the work area with film or cloth. This will protect them from getting sealant. In the future, you need to prepare everything in order to apply the composition. In this situation, you must be guided by what is written on the back of the cartridge. The only thing is that you first need to remove the previous coating from the surface, and this can be done with a sharp knife

To remove crumbs, you can use a brush or vacuum cleaner, but the surface must be degreased. It is then important to remove the limiters. Then you need to remove the rod from the device. To do this, you need to press the lever and remove the part.

You need to install the cartridge in the free space and apply a few small pressures on the hook. This will allow the container to fit tightly into the gun. It is important to note that these instructions are provided for a skeletal view. Other ways of using this device differ only in the method of inserting the cartridge. Then you need to make a small hole in the container through which a straight line of sealant will come out. To do this, you need to make an incision into the existing cone.

The method of using a tube-type gun should be separately considered.

Initially, you need to create a hole in the pipe with sealant. If you choose a material that is packaged in bags, then one corner must be cut off as carefully as possible. Otherwise, the mixture will probably leak out. You need to squeeze the sealant into the tool itself, but before that you will need to remove the rod in the same way as described in the previous version. Typically, such pistols come with several different attachments, which are characterized by the presence of tips of different types. You should choose the appropriate option for the job and tighten the cylinder with it. If there is no hole on the tip, you can make it yourself. To do this, take a sharp knife and make a cut at an angle of 45 degrees.

Please note that it is necessary to predict the size of the future hole. This is necessary so that the resulting seam has the required diameter.

This will make it easier to apply the mixture.

Packing of sealant guns

There are different types of guns designed for different types of formulations. The differences between such devices depend on the sealant container and are as follows:

- Packaged products are packaged in hard tubes made of plastic or foil material.

- Unpackaged - most often supplied for sale in buckets, therefore, in order to apply the composition, you must additionally purchase, in addition to the gun, special plungers and a valve cover.

Types of instruments

Pistols are produced in different types, which varies the complexity of their use. To understand which option will be best for the job, you need to understand the differences between each type.

Pistols are produced in different types, which varies the complexity of their use.

Mechanical (manual)

A mechanical pistol is a simple modification of this device. Its operation is simple; if it is made of good metal or aluminum, then the device will serve for a long time and reliably. The process of how to insert the caulk into the gun is very easy. At the tip of the frame there is a special slot for sealant, thanks to which the product is well fixed.

Guns are suitable for tubes measuring 350-500 ml. They are often chosen in everyday life because of:

- Balanced, weighs little;

- The volume of material extruded is well regulated;

- Can be used several times.

A mechanical pistol is a simple modification of this device.

Pneumatic

The pneumatic type controls the release of sealant using air pressure. Therefore, the master does not have to constantly monitor the pressing of the lever. When the lever is pressed, the composition comes out constantly; professionals value the product for its ease of use. Large seam areas can be covered without much effort.

The work is carried out by a compressor, which makes movement difficult.

The pneumatic type controls the release of sealant using air pressure.

Electric

The electric type makes it possible to distribute the sealant quickly and efficiently, the layer will be even, and the technician will not have to make a lot of effort. The limitation during operation is the connection to the cable. Working in small rooms, such as bathrooms, will not be difficult, but in larger rooms you will have to use extension cords. Plus, you can work for many hours without needing to charge the device.

The electric type makes it possible to distribute the sealant quickly and efficiently.

Characteristics

The device for applying compositions contains the following elements:

- The housing in which the tube is placed;

- Rod with tip. The rod can be smooth, hexagonal or serrated. It serves to push the piston inside the tube;

- Handle with trigger. Pressing the trigger extrudes the composition in a certain amount;

- Safety system. It keeps the rod from returning and fixes it at the proper level.

The tool can also be equipped with additional attachments.

Design and principle of operation

The design of this useful device is extremely simple and consists of the following elements:

- Frame. Designed to hold a plastic tube or bag of sealant and comes in different types: skeletal, semi-closed, closed.

- Stock. Used directly to squeeze sealant out of packaging. Having a wide round plate at the end that rests against the bottom of the tube, the rod moves forward with each press on the gun, pushing the sealant through the spout (narrow nozzle).

- Lever mechanism. It is extremely simple. When you press the lever, the system pushes the rod to the allotted distance.

- Latch. This device blocks the stroke of the rod, and in improved models of guns it also relieves pressure from it, which prevents the sealant from spontaneously squeezing out of the tube. To pull the rod back, you must first press the lock with your fingers.

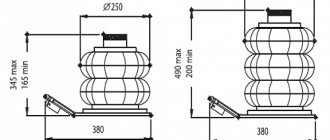

Dimensions and weight of the sealant gun

Most devices are made to standard sizes. For tubes with a volume of 310 ml, the length of the instrument is about 22 cm, if the volume is 600 ml - 44 cm.

In essence, the dimensions of the device do not play a big role; more often, the parameters of the cartridges with which you have to work are important.

The average weight of the tool is 250g.

Dimensions and weight

Most sealant guns are manufactured to fit the current sizes of standardized tubes, containing 220 and 440 ml.

- The length of one of the simplest pistols is approximately 22 and 44 cm.

- In general, the dimensions of the pistol are not so important and differ according to the standards of the cartridges for which they are produced.

- The average weight of a pistol is 250 g.

Additional functions of caulk guns

For the most comfortable work, the tool can be supplemented with some accessories:

- Illumination of the area where the composition is applied;

- Fixation of the trigger, which makes it possible to work for a long period of time;

- Adjusting the speed of application of the composition, which ensures more accurate performance of work;

- Leak protection.

The following are often purchased as related materials:

- Nozzles of various shapes;

- Cleaning needles;

- Punch for removing frozen mass.

First Steps: Removing Unneeded Gun Parts

First, you need to extend the piston rod and, holding it in a vice, saw off 5-10 cm from the stop. An ordinary grinder with a cutting wheel can easily cope with such work.

The rod is then pulled out into the gun. At the same time, the presser foot and spring are removed, which will not be needed in the updated tool. It is possible that the spring will still be useful in other modifications if the master often deals with such things. As for the rod, you will have to cut it again. To do this, you need to clamp the rod in a vice and saw off, using the same angle grinder with a cutting disc, the part on which the pusher platform is fixed. In this case, the cut should pass 2-3 cm from the plate.

The part needed for work should look something like this PHOTO: youtube.com

Removing the handle and pedal of the push mechanism

Further work is done directly with the gun itself. Due to the fact that the piston of the sealant tube will be pushed out automatically, the handle and pedal on the tool will only get in the way, so they should be removed. Having clamped the gun in a vice, you need to carefully cut off the rivets that secure the pedal to the gun, after which it can be freely removed. There are absolutely no difficulties in cutting off the rivets; it’s a matter of two minutes.

When the rivets are cut, the pedal can be easily removed PHOTO: youtube.com

But, in addition to the pedal, the pistol also has a handle, which is also superfluous for today’s homemade products. Typically, the body of such pistols is made of duralumin, and this often becomes the main problem. Paradoxical as it may seem, it happens that an old disk, having cut the duralumin a little, begins to cut worse. This happens because the soft metal clogs the abrasive, smoothing it out. However, you still have to cut off the handle.

After the handle is sawed off, it is necessary to sand the edges a little so as not to injure yourself on the sharp chamfer during subsequent work.

The pistol handle also needs to be sawed off PHOTO: youtube.com

Thread for push rod stud

The last step in preparing the pistol body is the thread in its rear part, into which the pin will be screwed. A tap is used to cut it. It can be used both with a driver (tap holder) and installed in a screwdriver. At this stage, the softness of duralumin plays into the hands of the master.

The thread in the rear of the gun is made using an appropriate tap PHOTO: youtube.com

Types and costs of sealant guns

The pistol body can be of the following types:

Skeletal

Used for one-time or rare use. The case is made of steel 1.5mm thick. The rod most often has a hexagonal shape, but can be toothed and smooth, with a cross section of 6 mm.

- The smooth movement of the rod and the reliability of the position of the tube are ensured by plastic stiffeners.

- The cost of such a tool varies from 120 to 400 rubles.

Reinforced

It differs from the previous type of design in that in their production materials with greater strength are used, i.e. all elements are thick-walled, and the rod has a cross-section of more than 8 mm.

The price for them is 200 rubles and above.

Semi-open (semi-case)

This option is not suitable for long-term work, so it is the lowest in cost - 120-150 rubles. It is made of steel with a thickness of one millimeter. It has the shape of a half-cylinder, which is why it got its name.

The rod can be of any configuration. The disadvantages include:

- Lack of stiffeners;

- Frequent stem distortion.

Case cylindrical

It is considered a universal tool; it makes it possible to apply the composition in any container or without packaging at all. It is made of plastic or aluminum, equipped only with a smooth rod.

Their cost exceeds 500 rubles.

Tools and Supplies

To make a tool for processing tile and interpanel seams, filling up chips, cracks, defects, and sealing joints, you need to prepare the following list of accessories:

- PVC sewer pipe with a diameter of 5 cm;

- a piece of plywood 1 cm thick;

- furniture persistent nut M8;

- M8 pin;

- M6 washer;

- M6 bolt;

- 4 M8 nuts;

- 3 M6 nuts;

- small screws;

- a piece of rubber tube;

- plastic bottle with a volume of 5 liters;

- spout from a bottle, can of glue, ketchup;

- piece of steel sheet;

- hot melt glue or other reliable adhesive;

- compass and pencil;

- hacksaw (saw);

- screwdriver;

- sandpaper or grinding wheel;

- hammer.

Types of Sealant Supply

Pistols are also divided according to the method of supplying the composition:

Mechanical

The simplest tool, it is used professionally in rare cases. The composition is squeezed out of the tube by periodically pressing the trigger.

Rechargeable

This device will be useful when performing any work, even on construction sites in conditions with increased intensity.

Smooth adjustment of the speed of release of the composition makes it possible to achieve high-quality results.

The cost of such a tool is quite high:

- The cheapest - more than 4,000 rubles;

- Professional - from 20,000 rubles.

Pneumatic

Used when performing large volumes of work, with its help the composition can be applied quickly and evenly.

Advantages:

- Convenient to use;

- It is light in weight;

- With a rotary type body, it greatly simplifies operation;

- Models equipped with a counterweight evenly distribute the load on the hand.

The price for this device is about 3,500 rubles.

Varieties by drive type

Focusing on the source of the generated force for pushing out the sealant, guns are created of the following types:

- Mechanical, manual type. There are a large number of them and they are inexpensive. They are equipped with a lever; with rhythmic movements, the rod pushes the contents out of the tube. The advantage of such devices is their low cost, no dependence on electricity, light weight and silent operation. If it is necessary to do a large amount of work, pistols with mechanics cause severe fatigue in the hands, so such devices are not suitable for professional builders;

- Electric models. These guns are presented as pro-level tools; procedures with them make it possible to achieve the greatest productivity. The device can operate on electricity or battery. It has a heavy mass, but quickly pushes out the sealing agent. The feed speed can be adjusted, which mainly distinguishes an electric tool from a mechanical product;

- Pneumatic device. Connects to the compressor. This largely limits his field of activity, which is determined by the length of his hoses. The action of this gun is carried out with the noise of a compressor.

Nevertheless, such tools turn out to be useful in production for the leakage of sealants when creating aquariums, in the automotive industry, and in the formation of boats. Often guns of this type come with a pressure regulator, which makes it possible to set the feed power.

How to choose a sealant gun

You need to choose a pistol taking into account its purpose.

Household

For simple work that is performed periodically, a device with a mechanical feed mechanism is sufficient. A model for a 310mm tube with a reinforced body is desirable.

To perform a one-time job, you can purchase a semi-cased gun that can withstand three refills.

Professional

In such a situation, it is better to choose a model according to the following criteria:

- Comfortable switching of the tool to the operating mode with the composition in different containers;

- Reliability;

- Service life and warranty;

- Weight;

- Pressure endurance.

A few simple tips for working with sealant

The composition must be applied to a cleaned surface, monitoring the thickness of the layer to leave the required distance for its polymerization. The manufacturer writes recommendations on the packaging. They try to fill the seam in one go to maintain evenness.

If the surface is smooth, for example metal, then it is advisable to sand the base, then adhesion will be better. The drying time of the composition depends on the type of product. It is advisable for the master to wear gloves and a respirator.

The composition must be applied to a cleaned surface, monitoring the thickness of the layer to leave the required distance for its polymerization.

Working with sealant is greatly simplified by using a special gun. You need to choose the right device so that the repair is comfortable and the device lasts a long time. Also, if you follow the rules for assembling the gun, you can apply the composition without difficulty.

Caring for your pistol

Naturally, every instrument needs care. A pistol is no exception; moreover, it comes into contact with various objects and substances. Basic care consists of mandatory cleaning of various particles after each use.

In fact, this is not the most expensive tool, but it can come in handy at any time. Therefore, it is advisable to always have it “at hand”.

Andron17051993 › Blog › (Workshop) Repair of a construction gun

Hello everyone, we all know that now almost everything is Chinese and except for electronics everything is unreliable, and then my construction gun broke and I really needed it for liquid nails, I wanted to fix the corners on the window.

What should I do? It’s evening now and all the stores are closed, and I’ll buy the same disposable one again. They don’t carry good ones, only in Yaroslavl you can buy them. And then it was decided to fix the broken pistol and we needed: - a broken pistol - a wooden block - a knife - 2 self-tapping screws (very small) - a screwdriver or a screwdriver - pliers

The problem with such pistols is the trigger, it crumples closer to the beginning and there’s more horseradish than you can squeeze out of it, not silicone, not sealant, not what to throw away... I did it differently

In the evening I tested all this when I was making a window and what can I say, it works perfectly, no more wrinkles, you can even squeeze out the dried sealant that collects in the spout... In general, the simplest option and who doesn’t want a collective farm, the handle can be covered with heat shrink, for example, and heated, it will take shape trigger and you will have a regular black handle, you can do the same for the second one... In short, a note to you)

Thank you to everyone who is waiting for the video about the manipulator, we will have to wait for the showers and wind and cold, when the weather gets better I will start filming))

Photo of a sealant gun

Floating chain wine stand

Hi all! I tried to make a bottle holder from a chain.

I used 5mm long link galvanized chain. Ideally, it is better to make such things from ordinary chains without galvanization, but I could not find one in the city. The bottle is held with the neck down on purpose so that the cork does not dry out. In order for the base to be evenly round in shape, I made a template from a board. As a “neck” for welding, I used a regular shovel handle.

Essentially, this stand is a trinket that can be made in 10-40 minutes, but on the other hand, for all its simplicity, it is a good gift for someone who loves wine. I hope someone will learn something interesting and useful from the video. I will be happy to answer all questions and gratefully listen to fair criticism :)

Cutting board

Hello everyone, I made a couple more cutting boards.

One in the shape of a whale's tail and the other a cobra. material for whale furniture panel pine for cobra solid pine.

I cut it out with a jigsaw, deepened the whale's tail with a grinder with a sanding attachment, then I sanded everything for a long time, first 80, then 120, and then 220. I covered the whale's knee with a mocha cobra stain. Once dry, I sanded it again.

Covered with oil. My wife photographed everything beautifully.

Something like this, thank you for your attention, write your opinion.